The global laser marking machine market is experiencing robust growth, driven by increasing demand for permanent, high-precision marking across industries such as automotive, electronics, medical devices, and consumer goods. According to a report by Mordor Intelligence, the market is projected to grow at a CAGR of over 7.5% from 2023 to 2028, with Asia-Pacific emerging as the fastest-growing region due to expanding manufacturing capabilities and rising automation adoption. Similarly, Grand View Research valued the global laser marking and engraving market at USD 3.6 billion in 2022 and forecasts a CAGR of 7.3% from 2023 to 2030, citing advancements in fiber laser technology and the shift toward eco-friendly, non-contact marking solutions. As cost-efficiency becomes a critical factor for SMEs and contract manufacturers, demand for affordable yet reliable laser marking systems has surged. This growing need has fueled the rise of manufacturers offering high-performance, low-cost alternatives without compromising essential features. In this context, we highlight the top 10 low-cost laser marking machine manufacturers that are delivering value-driven solutions to meet the evolving needs of modern production environments.

Top 10 Low Cost Laser Marking Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 Industrial Laser Markers

Website: telesis.com

Key Highlights: Fiber laser markers are versatile machines that are easy to use and require minimal maintenance. They are mostly used for engraving metal and plastic….

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

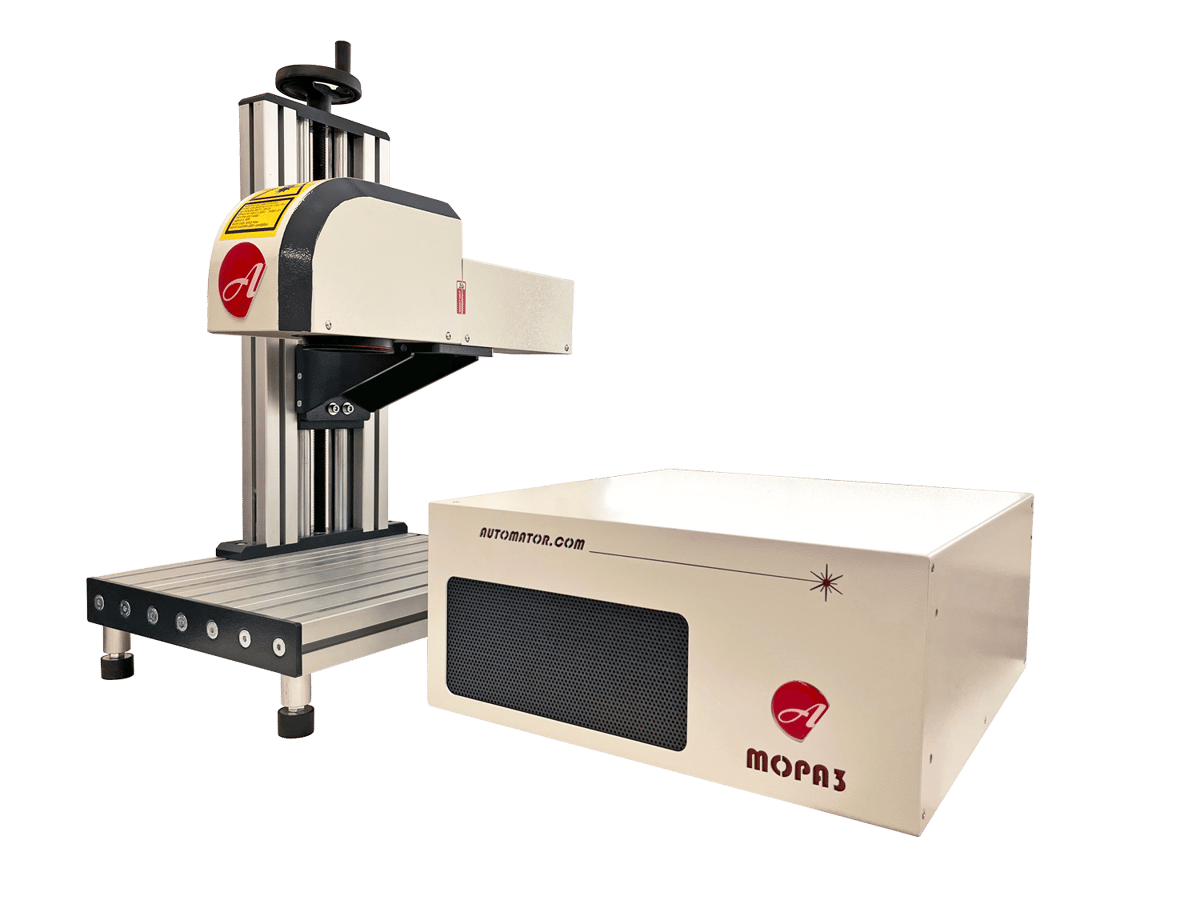

#4 Automator Marking Systems

Founded: 1940

Website: automator.com

Key Highlights: Since 1940, Automator Marking Systems has been a world leader in industrial marking solutions, with an unwavering commitment to customer-centric innovation….

#5 Full Spectrum Laser

#6 CO2 Laser Cutters and Engravers, Fiber Lasers, and More

Website: omtech.com

Key Highlights: Free deliveryFrom CO2 laser engravers and cutters to the best fiber laser engravers for metal marking, find your laser machine here at OMTech Laser….

#7 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#8 MECCO

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#9 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Aurora Lite, the most cost-effective fiber laser marking machine in the Aurora series. Priced lower than the Aurora 8, with higher power and speeds up to 7000mm ……

#10 Laser engravers & laser cutters

Website: gravotech.com

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

Expert Sourcing Insights for Low Cost Laser Marking Machine

H2: 2026 Market Trends for Low-Cost Laser Marking Machines

The global market for low-cost laser marking machines is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and rising demand across emerging economies. As industries seek cost-effective, efficient, and eco-friendly marking solutions, affordable laser systems are becoming increasingly accessible and versatile. Below are key trends expected to shape the low-cost laser marking machine market in 2026:

-

Increased Adoption in SMEs and Emerging Markets

Small and medium-sized enterprises (SMEs) in Asia-Pacific, Latin America, and Africa are increasingly adopting low-cost laser marking systems due to declining prices of core components like fiber laser sources and improved system integration. Governments promoting “Make in Asia” or “Digital Manufacturing” initiatives are further accelerating adoption in countries such as India, Vietnam, and Mexico. -

Technological Democratization and Standardization

Advances in modular design and mass production of laser diodes and controllers have significantly reduced manufacturing costs. Standardized software interfaces (e.g., user-friendly GUIs and compatibility with CAD/CAM platforms) enable non-specialists to operate machines efficiently, broadening market reach beyond high-tech industries. -

Growth in Consumer Electronics and Medical Device Manufacturing

The consumer electronics sector—especially in smartphone, wearable, and IoT device production—requires precise, permanent, and non-contact marking on small components. Similarly, the medical device industry demands compliant, sterile marking solutions. Low-cost fiber and UV laser markers now meet these needs at a fraction of traditional system prices. -

Rise of Hybrid and Compact Systems

Manufacturers are launching compact, desktop-sized laser markers with hybrid capabilities (e.g., combining marking, engraving, and etching). These systems appeal to prototyping labs, educational institutions, and startups, contributing to market expansion beyond industrial use. -

Sustainability and Regulatory Compliance

As environmental regulations tighten globally, businesses are shifting from ink-based marking to laser solutions, which produce no chemical waste. Low-cost laser markers offer a greener alternative while ensuring compliance with traceability standards such as UDI (Unique Device Identification) in healthcare and QR/serial code requirements in automotive and aerospace. -

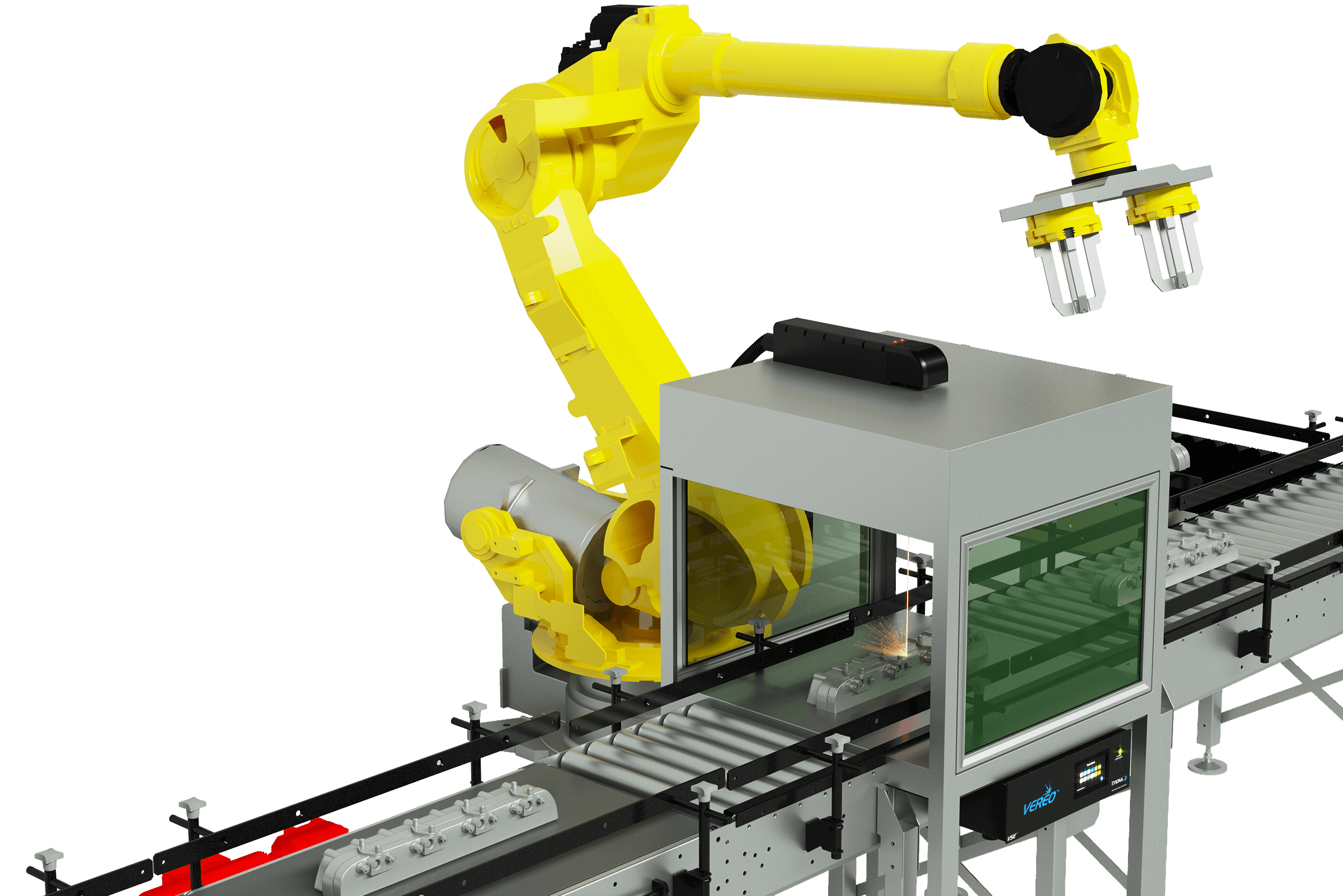

Integration with Industry 4.0 and Smart Manufacturing

By 2026, many low-cost laser marking machines will feature IoT connectivity, enabling remote monitoring, predictive maintenance, and integration with MES (Manufacturing Execution Systems). Plug-and-play compatibility with industrial robots and conveyor systems enhances automation scalability for budget-conscious factories. -

Competitive Pricing and Market Fragmentation

Chinese and Indian manufacturers are intensifying competition by offering sub-$3,000 fiber laser systems with reliable performance. This price pressure is pushing established brands to innovate or offer budget lines, resulting in a fragmented but dynamic market landscape. -

Expansion of After-Sales and Digital Support Services

To overcome perceived reliability concerns, vendors are investing in online training, cloud-based diagnostics, and AI-powered troubleshooting. This digital support ecosystem boosts customer confidence and reduces operational downtime.

In conclusion, the 2026 market for low-cost laser marking machines will be characterized by broader accessibility, smarter integration, and deeper penetration into diverse sectors. As innovation continues to drive down costs while improving performance, these machines are set to become indispensable tools in modern, agile manufacturing environments.

Common Pitfalls When Sourcing Low-Cost Laser Marking Machines (Quality & IP)

Sourcing a low-cost laser marking machine can be appealing for budget-conscious businesses, but it often comes with significant risks related to quality and intellectual property (IP). Being aware of these pitfalls can help avoid costly mistakes.

Poor Build Quality and Component Selection

Many inexpensive laser machines use substandard materials and low-grade components to cut costs. This includes inferior optical lenses, unstable galvanometer scanners, and weak structural frames. As a result, machines may suffer from inconsistent marking, frequent breakdowns, and shorter lifespans, ultimately increasing total cost of ownership due to downtime and repairs.

Inaccurate or Inconsistent Marking Performance

Low-cost systems often lack precision calibration and quality control during manufacturing. This leads to issues such as uneven engraving depth, blurry markings, or positioning errors. These inconsistencies can compromise product branding, traceability, and compliance—especially in regulated industries like medical devices or aerospace.

Lack of Safety Features and Regulatory Compliance

Budget machines may not meet international safety standards (such as CE, FDA, or IEC). Missing or inadequate safety interlocks, improper laser shielding, or insufficient ventilation systems pose risks to operators and can result in non-compliance with workplace safety regulations.

Weak or Non-Existent Intellectual Property Protection

Many low-cost laser markers, especially from regions with lax IP enforcement, incorporate cloned or reverse-engineered software and control systems. Using such machines may expose your business to legal risks, including IP infringement claims, especially if the machine uses pirated software or patented technologies without authorization.

Limited Technical Support and Spare Parts Availability

Suppliers of low-cost machines often lack robust customer support infrastructure. You may face long delays in getting technical assistance or replacement parts. In some cases, the supplier may disappear entirely, leaving you with an unsupported machine and costly downtime.

Hidden Costs and Integration Challenges

While the initial purchase price is low, integrating a cheap laser marker into an automated production line may require additional investments in custom fixtures, software modifications, or third-party controllers. These hidden costs can quickly erode the perceived savings.

No Warranty or Limited After-Sales Service

Many budget suppliers offer little or no warranty, or provide only short-term coverage with restrictive terms. Even when warranties exist, service may be limited to the country of origin, making repairs time-consuming and expensive.

Risk of Counterfeit or Misrepresented Specifications

Some manufacturers exaggerate laser power, marking speed, or software capabilities. A machine advertised as a 30W fiber laser might actually perform like a 20W unit due to under-spec components or poor thermal management. This misrepresentation can lead to performance shortfalls in real-world applications.

Conclusion

While the upfront cost savings of a low-priced laser marking machine may be tempting, businesses must carefully evaluate the long-term implications on quality, reliability, compliance, and legal risk. Conducting thorough due diligence—such as requesting live demos, checking certifications, verifying IP legitimacy, and reviewing service terms—can help avoid these common pitfalls.

Logistics & Compliance Guide for Low Cost Laser Marking Machine

Product Classification & Documentation

Ensure accurate product classification using the Harmonized System (HS) Code. For low cost laser marking machines, a typical classification is 8456.11 or 8456.12 (Laser Micromachining Machines). Obtain a detailed commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Confirm whether the machine includes any controlled components (e.g., high-power lasers) that may require additional export documentation.

Export Controls & Regulatory Compliance

Verify compliance with export control regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation, especially if the laser exceeds certain power thresholds. Most low cost laser marking machines fall under lower power classifications and are not strictly controlled, but confirm jurisdiction with your local authority. A laser product report or FDA registration (in the U.S.) may be required under 21 CFR 1040.10 if applicable.

Safety & Technical Standards

Ensure the machine complies with IEC 60825-1 (Safety of Laser Equipment) and IEC 61010-1 (Safety Requirements for Electrical Equipment). CE marking is mandatory for sale in the European Union, confirming conformity with health, safety, and environmental protection standards. For markets like the U.S., adherence to FDA/CDRH laser safety regulations and optional UL certification is recommended. Include required safety labels, interlocks, and user manuals in the local language.

Packaging & Shipping Requirements

Package the laser marking machine securely using shock-absorbing materials and a sturdy wooden or metal crate if shipping internationally. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include all compliance markings (CE, laser class, etc.). Protect optical components with protective caps and secure moving parts to prevent damage during transit.

Import Regulations & Duties

Research import duties, taxes, and local regulations in the destination country. Some countries may require additional certifications such as CCC (China), KC (Korea), or RCM (Australia). Engage a licensed customs broker to facilitate clearance and avoid delays. Provide technical specifications and proof of compliance upon request.

End-User Documentation & Training

Supply users with a comprehensive operation manual, safety guidelines, and maintenance instructions. Include laser safety training recommendations and emergency procedures. Maintain records of compliance documentation and user training for audit purposes.

Environmental & Disposal Compliance

Inform users of proper disposal procedures for electronic waste in compliance with WEEE (EU) or local e-waste regulations. Recommend recycling programs for obsolete units and provide take-back options if available.

Ongoing Compliance Monitoring

Stay updated on changes in international trade regulations, laser safety standards, and environmental laws. Regularly review product specifications and certifications to ensure continued compliance across all target markets.

In conclusion, sourcing a low-cost laser marking machine requires a careful balance between price, quality, and long-term value. While budget-friendly options can significantly reduce initial investment, it is essential to evaluate factors such as laser type (fiber, CO2, or UV), power output, build quality, software compatibility, after-sales support, and warranty coverage. Sourcing from reputable manufacturers—particularly in regions known for competitive pricing like China—can offer substantial savings, especially when engaging directly through B2B platforms or trade shows. However, due diligence is critical to avoid hidden costs related to maintenance, replacement parts, or inadequate technical support.

Ultimately, the most cost-effective solution is not always the cheapest upfront but the one that delivers reliability, precision, and durability over time. By conducting thorough market research, requesting live demonstrations, and verifying supplier credentials, businesses can secure an affordable laser marking machine that meets their production needs without compromising on performance or longevity.