The global trailer manufacturing market is witnessing robust growth, driven by expanding logistics networks, rising e-commerce activity, and increasing demand for heavy-duty transportation solutions. According to a report by Mordor Intelligence, the global truck trailer market was valued at USD 58.3 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A significant contributor to this growth is the rising demand for specialized trailers, including low bed models, used extensively in construction, oil & gas, and heavy equipment transport. Low bed trailers, known for their low deck height and high load capacity, are increasingly preferred for transporting oversized and heavy machinery safely and efficiently. With infrastructure development accelerating across emerging economies and developed nations alike, manufacturers are innovating in design and materials to improve payload efficiency and compliance with safety regulations. This growing demand underscores the importance of identifying leading players in the low bed truck trailer segment—companies that combine engineering excellence, scalable production, and global reach. Based on market presence, innovation, and customer reviews, here are the top 10 low bed truck trailer manufacturers shaping the future of heavy haul transportation.

Top 10 Low Bed Truck Trailer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Trail King Industries

Domain Est. 1996

Website: trailking.com

Key Highlights: Trail King Industries, Inc., headquartered in Mitchell, SD, is the leading manufacturer of a complete line of hauling trailers in North America….

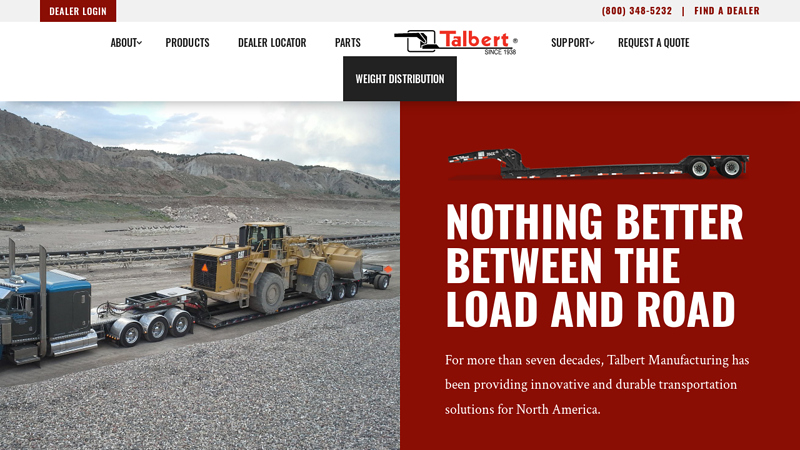

#2 Talbert Manufacturing

Domain Est. 1997 | Founded: 1938

Website: talbertmfg.com

Key Highlights: Talbert Manufacturing, Inc. is a world-class trailer manufacturer. Since 1938, Talbert has been trusted by a wide variety of commercial, military, government, ……

#3 TowHaul: Mining Lowboy Trailer

Domain Est. 1997 | Founded: 1977

Website: towhaul.com

Key Highlights: Since 1977, TowHaul has been designing and manufacturing the most reliable and adaptable off-road hauling equipment in the mineral extraction industry….

#4 WITZCO

Domain Est. 1998

Website: witzco.com

Key Highlights: WITZCO is top brand trailer manufacturer in USA featuring full range of heavy duty trailers like Lowboy, Highboy, Step Deck, Drop Deck, Flatbed, ……

#5 Pitts Trailers

Domain Est. 1998

Website: pittstrailers.com

Key Highlights: As the world’s largest and only complete line forestry trailer manufacturer, Pitts offers a widevariety of truck trailers including log trailers, open and ……

#6 XL Specialized Trailers

Domain Est. 2001

Website: xlspecializedtrailer.com

Key Highlights: XL Specialized Trailers is a leading designer and manufacturer of highly engineered and customized heavy haul trailers in the USA….

#7 Utility Trailer

Domain Est. 1996

Website: utilitytrailer.com

Key Highlights: Proven on a real-world test track, we have a flatbed that will give you unparalleled performance and value. Every Utility flatbed can be custom built with a ……

#8 Big Tex Trailers

Domain Est. 1997

Website: bigtextrailers.com

Key Highlights: Explore the Big Tex trailer lineup built for relentless professionals. Find a quality trailer for reliability, strength, and performance. Shop now!…

#9 Lowbed trailers for the transport of higher loads

Domain Est. 1998

Website: faymonville.com

Key Highlights: With their low loading height, lowbed trailers are suited for the transport of higher loads. The versatile double drop range makes various uses possible….

#10 Custom U.S. Made Heavy Haul Equipment Trailers by Globe Trailers

Domain Est. 1998

Website: globetrailers.com

Key Highlights: Crafting Stronger, Safer, and More Reliable Custom Lowboy, RGN, Demolition Dump, Tag-Along, Hydraulic Tail and Sliding Axle Trailers!…

Expert Sourcing Insights for Low Bed Truck Trailer

2026 Market Trends for Low Bed Truck Trailers

The global low bed truck trailer market is poised for significant transformation by 2026, driven by infrastructure development, technological advancements, and evolving transportation needs. These trailers—also known as lowboy trailers—are essential for transporting heavy and oversized equipment such as construction machinery, industrial components, and military vehicles. As industries recover from supply chain disruptions and governments increase investments in infrastructure, the demand for low bed trailers is expected to rise substantially. This analysis explores the key market trends shaping the low bed truck trailer industry in 2026.

Rising Infrastructure and Construction Activities

One of the primary drivers of the low bed trailer market in 2026 is the global surge in infrastructure and construction projects. Governments in North America, Europe, and Asia-Pacific are investing heavily in transportation networks, renewable energy installations, and urban development. These initiatives require the transport of heavy machinery like excavators, cranes, and generators—equipment best carried on low bed trailers due to their low deck height and high load capacity. For example, the U.S. Infrastructure Investment and Jobs Act continues to stimulate demand for heavy haulage solutions through 2026, positively impacting trailer manufacturers and rental fleets.

Adoption of Lightweight and Durable Materials

Manufacturers are increasingly integrating advanced materials such as high-strength steel and aluminum alloys into low bed trailer designs. The shift aims to reduce overall trailer weight without compromising load-bearing capabilities, thereby improving fuel efficiency and complying with stricter emissions regulations. In 2026, trailers made with composite materials are expected to gain market share, particularly in regions with high fuel costs and sustainability mandates. These innovations also extend the service life of trailers, reducing long-term operational costs for transport companies.

Electrification and Smart Trailer Technologies

The trend toward electrification in the transportation sector is extending to trailers. While full electric low bed trailers remain in early development, hybrid systems and electric auxiliary systems (e.g., for landing gear and braking) are becoming more common. Additionally, smart technologies such as telematics, real-time load monitoring, and predictive maintenance are being integrated into new models. By 2026, digitally connected trailers will allow fleet operators to optimize routing, ensure cargo safety, and reduce downtime—enhancing operational efficiency and meeting customer expectations for transparency.

Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing market for low bed trailers in 2026, fueled by industrialization in India, China, and Southeast Asia. China’s Belt and Road Initiative and India’s National Infrastructure Pipeline are key catalysts. Meanwhile, North America maintains a strong demand due to aging infrastructure renewal and energy sector expansions, particularly in oil & gas and wind energy. Europe’s market growth is more moderate but steady, supported by green logistics policies and cross-border freight movement.

Expansion of Rental and Shared Fleet Models

As capital costs for heavy equipment transportation rise, many companies are turning to trailer rental and shared logistics platforms. In 2026, the rental segment of the low bed trailer market is expected to grow faster than ownership models, especially among small and medium-sized enterprises (SMEs). Digital platforms that connect transporters with available trailers are streamlining access and improving asset utilization, reducing idle time and increasing profitability across the supply chain.

Regulatory and Safety Standards

Safety and compliance are becoming more stringent worldwide. In 2026, low bed trailer manufacturers must adhere to updated regulations regarding load security, braking systems, and emissions. The European Union’s General Safety Regulation and similar frameworks in North America are pushing for advanced safety features such as automatic emergency braking (AEB) and lane departure warnings on trailers. These requirements are increasing production costs but also improving road safety and market standardization.

Sustainability and Circular Economy Initiatives

Environmental concerns are influencing trailer design and end-of-life management. By 2026, manufacturers are focusing on recyclable materials, modular designs for easier repairs, and remanufacturing programs. Some companies are offering take-back schemes to refurbish and resell used trailers, aligning with circular economy principles. This trend is particularly strong in Europe and is gradually gaining traction in other regions.

Conclusion

The low bed truck trailer market in 2026 will be shaped by technological innovation, regulatory changes, and robust demand from infrastructure and industrial sectors. Companies that embrace lightweight materials, digital integration, and sustainable practices will gain a competitive edge. As global trade and construction activity continue to expand, low bed trailers will remain a critical component of heavy haul logistics, with market growth supported by both economic and technological tailwinds.

Common Pitfalls When Sourcing Low Bed Truck Trailers (Quality and Intellectual Property)

Sourcing low bed truck trailers, especially from international or unfamiliar suppliers, can present several challenges related to both quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps in making informed procurement decisions and minimizing risks.

Quality-Related Pitfalls

Inadequate Manufacturing Standards

One of the most frequent issues is sourcing trailers that do not comply with regional safety and engineering standards (e.g., ISO, DOT, ADR, or local transport regulations). Suppliers may cut corners by using substandard materials or improper welding techniques, compromising structural integrity and safety.

Poor Material Selection

Low-cost suppliers might use inferior-grade steel or insufficient thickness in critical components like the deck, gooseneck, and axles. This leads to reduced load capacity, premature fatigue, and increased risk of failure under stress.

Lack of Third-Party Certification

Many suppliers fail to provide independent certification or test reports (e.g., load testing, non-destructive testing). Without verified documentation, buyers cannot confirm the trailer’s performance and durability claims.

Inconsistent Build Quality

Inconsistencies in assembly—such as misaligned components, poor fitment, or improper painting/coating—can signal lax quality control processes, which may affect long-term reliability and maintenance costs.

Insufficient After-Sales Support

Some suppliers offer limited technical support, spare parts availability, or service networks. This becomes a major issue when repairs or modifications are needed, especially in remote or international locations.

Intellectual Property (IP) Risks

Design and Brand Infringement

Low bed trailers often incorporate patented designs (e.g., hydraulic systems, suspension setups, or coupling mechanisms). Sourcing from unverified suppliers increases the risk of inadvertently purchasing counterfeit or IP-infringing products, which can lead to legal liability.

Unauthorized Use of Trademarks

Some suppliers replicate well-known brand logos or model names without authorization. Purchasing such products—even unknowingly—can result in customs seizures, legal disputes, or reputational damage.

Lack of IP Due Diligence

Buyers often fail to verify whether the supplier owns or has rights to the designs and technologies used. Without proper contracts or IP assignment clauses, there’s a risk of future disputes, especially if customization or large-volume production is involved.

Reverse Engineering Concerns

In some manufacturing regions, designs can be copied and resold without consent. If your specifications are shared without proper non-disclosure agreements (NDAs), there is a risk of them being used to produce competing products.

Mitigation Strategies

- Conduct thorough supplier audits, including factory visits and quality management system reviews (e.g., ISO 9001).

- Require material certifications, weld inspection reports, and load test documentation.

- Work with legal counsel to include IP ownership and warranty clauses in contracts.

- Use NDAs when sharing technical drawings or custom design requirements.

- Source from reputable manufacturers with verifiable track records and compliance certifications.

Avoiding these common pitfalls ensures that low bed truck trailers meet safety, durability, and legal standards, protecting both operational integrity and intellectual assets.

Logistics & Compliance Guide for Low Bed Truck Trailers

Low bed truck trailers are essential for transporting heavy, oversized, or tall machinery and equipment that cannot be hauled on standard flatbed trailers. Ensuring efficient logistics and full regulatory compliance is critical for safety, legal operation, and cost-effectiveness. This guide outlines key considerations for operating low bed trailers in compliance with industry standards and legal requirements.

Understanding Low Bed Trailer Types

Low bed trailers come in various configurations, including extendable, hydraulic, and modular designs. Common types include:

- Fixed Gooseneck Low Loaders: Ideal for consistent heavy loads with permanent low deck height.

- Hydraulic Modular Trailers: Adjustable axle lines and height, suitable for extremely heavy or irregularly shaped cargo.

- Extendable Low Boys: Deck can be extended to accommodate longer equipment.

Choosing the right trailer type depends on load dimensions, weight, route restrictions, and destination accessibility.

Weight and Load Capacity Compliance

Adherence to weight regulations is crucial to avoid fines and ensure road safety.

- Gross Vehicle Weight Rating (GVWR): Never exceed the combined GVWR of the tractor, trailer, and cargo.

- Axle Load Limits: Distribute weight evenly across axles to comply with federal and state axle weight limits (typically 20,000 lbs per single axle, 34,000 lbs per tandem axle).

- Bridge Formula Compliance: For vehicles over certain weights, the Federal Bridge Formula (23 U.S.C. 127) restricts weight distribution based on axle spacing to protect road infrastructure.

Use certified scales before departure to verify load weights.

Oversize and Overweight Permits

Low bed trailers often carry loads that exceed standard size and weight limits, requiring special permits.

- Permit Requirements: Vary by state and depend on load dimensions (width, height, length) and weight. Loads exceeding:

- 8.5 feet in width

- 13.5 to 14 feet in height (varies by state)

- 53 to 60 feet in length (varies)

-

Legal weight limits (80,000 lbs federal gross limit)

-

Permit Types:

- Single-Trip Permits: For one-time moves.

- Annual or Recurring Permits: For frequent oversized moves.

- Escorted vs. Non-Escorted: Wider or taller loads may require pilot cars.

Apply well in advance through state DOT portals or third-party permit services.

Route Planning and Restrictions

Careful route planning is essential for oversized loads.

- Low Clearance Areas: Avoid bridges, tunnels, and overpasses with insufficient vertical clearance. Use GPS systems designed for commercial vehicles (e.g., CoPilot, PC*Miler).

- Road Conditions: Ensure roads can support heavy loads—avoid weak bridges, narrow roads, or unpaved surfaces.

- Prohibited Routes: Some highways or urban areas ban oversized vehicles.

- Temporary Closures: Check for construction zones or detours.

Coordinate with local authorities if route includes restricted zones.

Safety and Securement Standards

Proper load securement prevents accidents and ensures compliance with DOT regulations.

- FMCSA Cargo Securement Rules (49 CFR Part 393, Subpart I):

- Use appropriate tie-downs (chains, binders, straps) rated for the load.

- Minimum number of tie-downs: One for every 10 feet of cargo (minimum two per load).

- Working Load Limit (WLL) of each tie-down must be sufficient.

- Chock wheels and block equipment to prevent shifting.

Inspect all securement points before and during transit.

Escort and Signage Requirements

Visibility and warning are critical for public safety.

- Warning Signs:

- “OVERSIZE LOAD” signs (front and rear).

- Strobe lights and reflective markings.

- Escort Vehicles:

- Required for loads exceeding certain dimensions (e.g., over 12’6″ wide or 125′ long).

- Pilot cars provide advance warning and traffic control.

- Must have two-way communication with the driver.

Follow state-specific rules for escort placement and equipment.

Documentation and Recordkeeping

Maintain complete and accessible documentation:

- Valid oversize/overweight permits

- Bill of lading and shipping manifest

- Vehicle registration and insurance

- Driver’s license and medical certificate

- Equipment inspection reports

- Securement checklist

Carry originals or digital copies accessible during inspections.

State and Federal Regulations

Understand jurisdictional requirements:

- Federal Motor Carrier Safety Administration (FMCSA): Governs safety standards, hours of service (HOS), and vehicle maintenance.

- Department of Transportation (DOT): Enforces weight, size, and permitting rules.

- International Registration Plan (IRP) and International Fuel Tax Agreement (IFTA): Required for interstate operations.

Stay updated on regulation changes through FMCSA and state DOT websites.

Maintenance and Inspection

Regular maintenance ensures safety and compliance.

- Pre-Trip Inspections: Check tires, lights, brakes, suspension, and hydraulic systems.

- Periodic Maintenance: Follow manufacturer schedules for axle servicing, hydraulic fluid changes, and structural inspections.

- DVIR (Driver Vehicle Inspection Report): Required daily; document and address any defects.

Training and Driver Qualifications

Operators must be properly trained and licensed.

- Commercial Driver’s License (CDL): Class A with appropriate endorsements (e.g., doubles/triples, tank vehicles if applicable).

- Specialized Training: On handling heavy loads, permit procedures, and emergency response.

- Hours of Service (HOS): Comply with FMCSA rules for driving and rest periods.

Emergency and Contingency Planning

Prepare for unexpected events:

- Breakdown Procedures: Have roadside assistance and recovery plans.

- Accident Response: Know reporting procedures and coordinate with authorities.

- Weather Delays: Monitor forecasts; avoid travel during high winds or storms with tall loads.

Having a contingency route and contacts improves response time.

By adhering to this logistics and compliance guide, operators of low bed truck trailers can ensure safe, legal, and efficient transport of oversized and heavy cargo across jurisdictions.

In conclusion, sourcing a low bed truck trailer requires careful consideration of several key factors, including payload capacity, trailer dimensions, axle configuration, material quality, and compliance with regional regulations. It is essential to evaluate suppliers based on their reputation, manufacturing standards, after-sales support, and ability to customize trailers to meet specific operational needs. Conducting thorough market research, comparing quotes, and performing due diligence on potential vendors will ensure a cost-effective and reliable investment. Ultimately, selecting the right low bed trailer not only enhances transport efficiency and safety but also contributes to long-term operational success in heavy equipment and oversized cargo transportation.