The global loudspeaker connector market is experiencing steady growth, driven by rising demand in audio equipment, consumer electronics, and automotive sound systems. According to Grand View Research, the global audio speaker market size was valued at USD 10.7 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 7.2% from 2024 to 2030, fueled by advancements in audio technology and increasing adoption of high-fidelity sound systems. This growth trajectory directly impacts the demand for reliable, high-performance loudspeaker spade connectors, which are essential for secure and efficient signal transmission. As audio systems become more sophisticated, manufacturers are prioritizing connectors with superior conductivity, durability, and ease of installation. In this competitive landscape, a select group of suppliers have emerged as industry leaders, consistently delivering quality and innovation. Below is a data-driven overview of the top 9 loudspeaker spade connector manufacturers shaping the market today.

Top 9 Loudspeaker Spade Connectors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

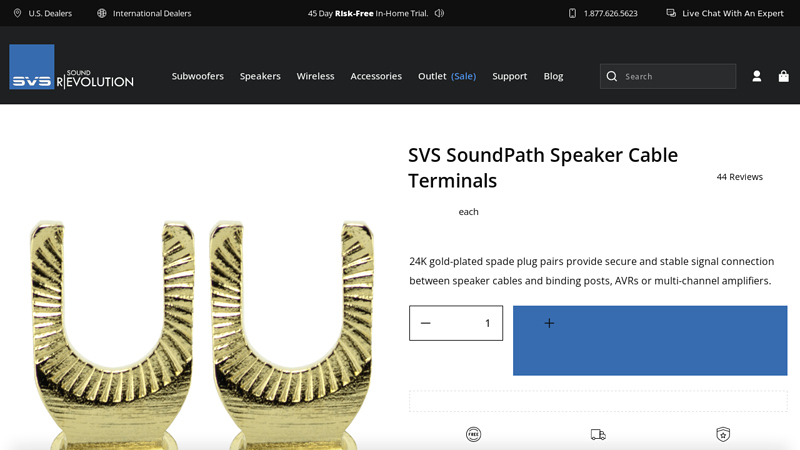

#1 SVS SoundPath Speaker Cable Terminals

Domain Est. 2005

Website: svsound.com

Key Highlights: In stock Rating 4.8 (44) 24K gold-plated spade plug pairs provide secure and stable signal connection between speaker cables and binding posts, AVRs or multi-channel amplifiers.M…

#2 Spades

Domain Est. 1996

Website: cardas.com

Key Highlights: Cardas spades are machined or stamped from pure copper, and plated with silver and rhodium. Spades are the best way to connect a cable to an amp & speaker….

#3 WBT

Domain Est. 1996

Website: wbtusa.com

Key Highlights: The product line has expanded from the first RCA type plug to include male and female RCA type connectors, binding posts, banana plugs and spade lugs with ……

#4 Universal Spade Connectors for soldering

Domain Est. 1996

Website: transparentcable.com

Key Highlights: This high quality gold-plated universal spade connector has been specifically designed to provide a good fit on Transparent DIY Speaker Cables….

#5 Spade Connectors

Domain Est. 1998

Website: silversonic.com

Key Highlights: For 14-16 AWG wire; Fits binding posts up to 8.3 mm (5/16 inch). Overall width: 13.4 mm. BSP. A mini-spade for the screw terminals on vintage amps and speakers….

#6 Furutech

Domain Est. 1998

Website: furutech.com

Key Highlights: RCA Connectors · XLR Connectors · Spade Connectors · Banana Connectors · BNC Connectors · Phono Connectors · Headphone Connectors · RCA Sockets · XLR sockets ……

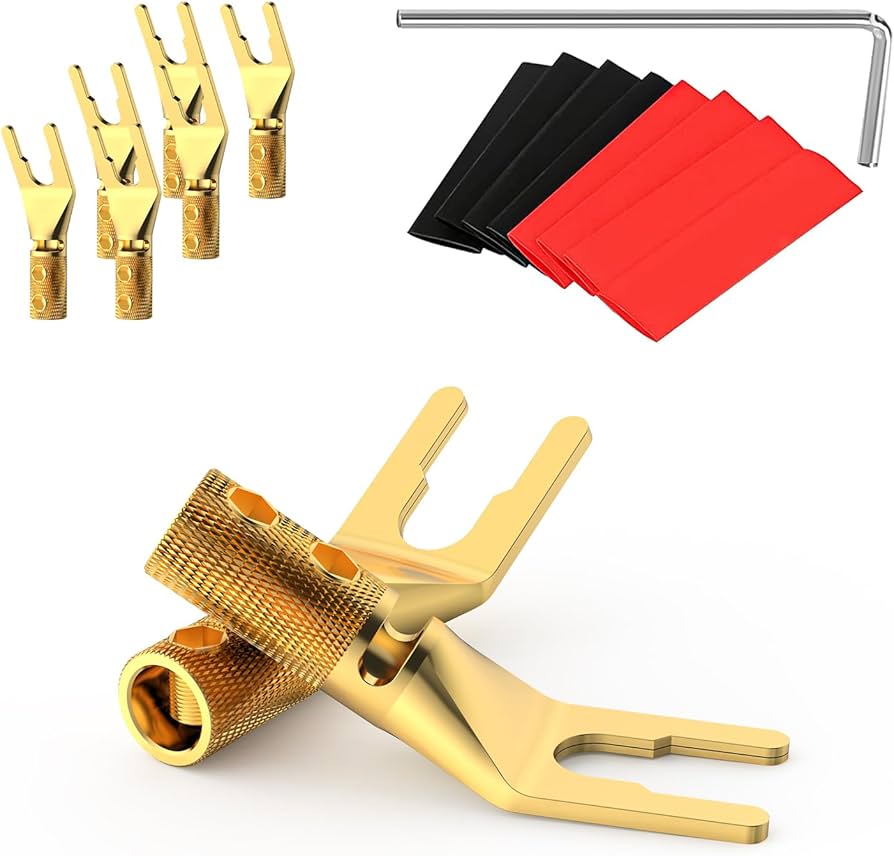

#7 Parts & Components

Domain Est. 2001

#8 Speaker Cable Connectors and Binding Posts

Domain Est. 2002

Website: vhaudio.com

Key Highlights: Free delivery over $100 60-day returnsThe new Link Spade connector from ETI Research is made from one Rod of Tellurium Copper with the Gold Plated directly to the Copper without an…

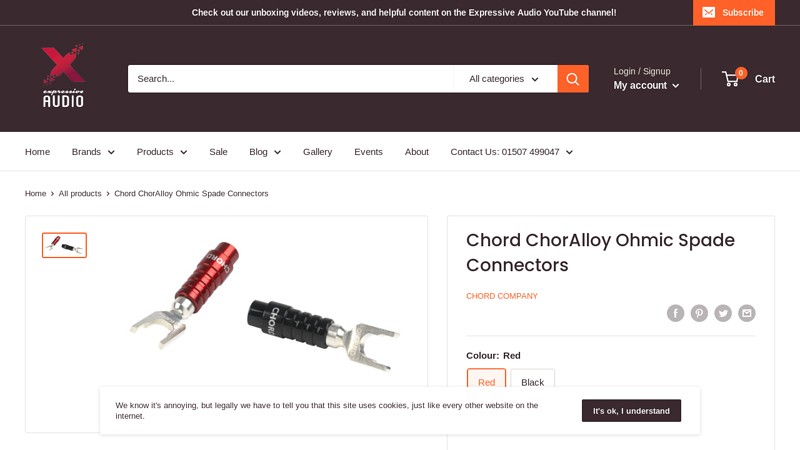

#9 Chord ChorAlloy Ohmic Spade Connectors

Domain Est. 2017

Website: expressiveaudio.com

Key Highlights: In stock 30-day returnsChordOhmic ChorAlloy™ plated spade loudspeaker connectors are designed to bring electrical and sonic benefits to speaker cables everywhere….

Expert Sourcing Insights for Loudspeaker Spade Connectors

H2: Projected Market Trends for Loudspeaker Spade Connectors in 2026

The global market for loudspeaker spade connectors is expected to undergo significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications in both consumer and professional audio sectors. As a critical component in audio signal transmission, spade connectors continue to play a vital role in ensuring reliable and high-fidelity connections between amplifiers and loudspeakers. The following analysis outlines key trends shaping the loudspeaker spade connector market in 2026 under the H2 framework.

-

Rising Demand in High-End Audio Systems

The growing popularity of premium home theater setups, audiophile-grade sound systems, and immersive entertainment experiences is fueling demand for high-performance spade connectors. In 2026, consumers are increasingly prioritizing audio clarity and system durability, leading to a preference for gold-plated, oxygen-free copper (OFC) spade connectors that minimize signal loss and resist corrosion. This trend is particularly pronounced in North America and Western Europe, where disposable income supports investment in high-end audio equipment. -

Expansion in Commercial and Professional Audio Applications

The professional audio sector—including live sound, studio recording, and commercial installations—is expected to be a major growth driver. Spade connectors are widely used in fixed installations such as conference halls, theaters, and houses of worship due to their secure fit and ease of maintenance. As venues upgrade their audio infrastructure to support higher power and better sound distribution, the need for robust, high-current spade connectors will rise. -

Influence of Smart Audio and IoT Integration

While spade connectors remain analog components, their integration into hybrid smart audio systems is increasing. By 2026, many smart amplifiers and networked audio systems still rely on traditional binding posts, where spade connectors provide a stable interface. The trend toward system modularity and backward compatibility ensures that spade connectors retain relevance even as digital signal processing and wireless technologies advance. -

Material Innovation and Sustainability

Environmental regulations and consumer demand for sustainable electronics are pushing manufacturers to adopt recyclable materials and lead-free manufacturing processes. In 2026, expect to see more spade connectors made from eco-friendly metals and insulating materials, with an emphasis on durability and reduced environmental impact throughout the product lifecycle. -

Competitive Landscape and Regional Growth

Asia-Pacific is anticipated to emerge as a key market and manufacturing hub, driven by strong electronics production in China, Japan, and South Korea. Local brands are improving quality to compete with established Western manufacturers, leading to price competition and greater product availability. Meanwhile, North America and Europe maintain high standards for audio fidelity, supporting a steady market for premium spade connector variants. -

E-Commerce and Distribution Channels

Online retail platforms are becoming primary sales channels for audio components, including spade connectors. By 2026, consumers increasingly rely on detailed product specifications, customer reviews, and compatibility guides available online, enabling informed purchasing decisions. This shift benefits niche brands and promotes product diversification.

In conclusion, the 2026 market for loudspeaker spade connectors will be characterized by sustained demand in high-performance audio systems, technological adaptation to modern audio architectures, and a focus on quality and sustainability. While facing competition from alternative connector types like banana plugs and pin connectors, spade connectors will maintain a strong foothold due to their reliability, compatibility, and suitability for high-power applications.

Common Pitfalls When Sourcing Loudspeaker Spade Connectors (Quality, IP)

Sourcing loudspeaker spade connectors may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to performance issues, reliability problems, and legal risks. Here are common pitfalls to avoid:

Poor Material Quality and Conductivity

Low-cost spade connectors often use substandard materials such as brass with low copper content or inadequate plating (e.g., thin nickel or poor-quality tin). This results in higher electrical resistance, increased signal loss, and susceptibility to corrosion—especially in humid or outdoor environments. Inferior conductivity compromises audio fidelity and may cause overheating under high-power conditions.

Inadequate Mechanical Fit and Durability

Cheap connectors may feature imprecise tolerances, leading to loose fits on speaker terminals or binding posts. This causes intermittent connections, arcing, and potential damage to equipment. Additionally, brittle or weak metal alloys can fracture during installation or repeated use, reducing longevity and reliability.

Lack of Environmental Protection (IP Rating Misinterpretation)

While spade connectors are rarely fully sealed, sourcing connectors marketed for outdoor or harsh environments without verifying actual ingress protection (IP) ratings is risky. Many suppliers falsely claim “weather-resistant” properties without compliance to IP standards (e.g., IP54 or IP65 for dust and moisture resistance). Without proper sealing or corrosion-resistant materials, connectors degrade quickly when exposed to moisture or dust.

Counterfeit or IP-Infringing Products

Reputable connector designs (e.g., specific geometries or patented plating technologies) may be protected by intellectual property rights. Sourcing from unauthorized manufacturers can result in counterfeit products that mimic well-known brands, violating trademarks or patents. This exposes buyers to legal liability, supply chain disruptions, and inconsistent quality.

Inconsistent Quality Control and Certification

Suppliers, especially from unverified sources, may lack robust quality assurance processes. Absence of certifications such as RoHS, REACH, or ISO 9001 increases the risk of receiving non-compliant or defective batches. Without traceability and testing documentation, ensuring long-term reliability becomes difficult.

Overlooking Plating and Corrosion Resistance

Copper or brass connectors without proper plating (e.g., gold, silver, or high-quality tin) oxidize over time, increasing resistance and degrading signal transmission. Inadequate or uneven plating—common in budget connectors—accelerates corrosion, particularly in high-humidity environments, leading to premature failure.

Avoiding these pitfalls requires due diligence: sourcing from reputable suppliers, verifying material specifications, requesting IP and safety certifications, and ensuring compliance with IP laws. Prioritizing quality over initial cost helps maintain audio performance and system integrity.

Logistics & Compliance Guide for Loudspeaker Spade Connectors

Overview

Loudspeaker spade connectors are electrical terminals used to securely connect speaker wires to amplifiers, receivers, or loudspeakers. Ensuring proper logistics handling and regulatory compliance is critical for product safety, performance, and market access. This guide outlines key considerations for transporting, storing, and complying with relevant standards and regulations.

Packaging and Storage

- Protective Packaging: Spade connectors should be packaged in anti-static, moisture-resistant materials to prevent corrosion and electrostatic damage. Small connectors are typically sealed in resealable bags or blister packs.

- Labeling: Each package must include clear labeling with product specifications (e.g., size, material, wire gauge compatibility), manufacturer details, and lot numbers for traceability.

- Storage Conditions: Store in a dry, temperature-controlled environment (10°C to 30°C) away from direct sunlight and corrosive chemicals to prevent oxidation or degradation of plating (e.g., nickel, tin, or gold).

- Inventory Rotation: Follow FIFO (First In, First Out) inventory practices to minimize the risk of aging or obsolescence.

Transportation and Handling

- Domestic and International Shipping: Use sturdy outer packaging to prevent crushing during transit. For international shipments, ensure packaging complies with ISTA or ASTM standards for drop and vibration resistance.

- Hazard Classification: Spade connectors are generally non-hazardous and not subject to dangerous goods regulations (e.g., IATA, IMDG). However, confirm with material declarations if plating involves restricted substances.

- Customs Documentation: Include commercial invoices, packing lists, and certificates of origin. Harmonized System (HS) Code for spade connectors typically falls under 8536.90 (other electrical connectors). Verify with local customs authorities as classifications may vary by region.

Regulatory Compliance

- RoHS (EU): Ensure connectors comply with the Restriction of Hazardous Substances Directive (2011/65/EU), limiting lead, cadmium, mercury, and other harmful substances. Provide RoHS compliance certificates upon request.

- REACH (EU): Confirm that no Substances of Very High Concern (SVHC) are present above threshold levels. Maintain a detailed substance declaration.

- UL/CSA (North America): While spade connectors may not require individual UL certification, they must be used in UL-listed systems. Ensure materials meet flammability and dielectric strength requirements (e.g., UL 486A-B for wire connectors).

- Proposition 65 (California): If connectors contain listed chemicals (e.g., lead in brass alloys), provide appropriate warnings on packaging or documentation.

- China RoHS: Label products with environmental protection markings if sold in China, and provide compliance documentation for restricted substances.

Quality and Testing Standards

- Electrical Performance: Test for current-carrying capacity, contact resistance, and temperature rise per IEC 60352-3 or UL 486A-B.

- Mechanical Durability: Verify retention force, tensile strength, and resistance to vibration and thermal cycling.

- Material Certification: Provide mill test reports for base materials (e.g., copper alloy C11000) and plating thickness (e.g., 2–5µm tin plating).

- Traceability: Maintain batch records and test reports for a minimum of 5 years to support quality audits and recalls.

Sustainability and End-of-Life

- Recyclability: Design connectors using recyclable materials (e.g., brass, copper). Clearly mark materials for proper sorting.

- WEEE Compliance (EU): Register with national WEEE authorities if selling finished audio equipment incorporating these connectors.

- Conflict Minerals: Comply with U.S. SEC Rule 13p-1 by conducting due diligence on tin, tungsten, tantalum, and gold (3TG) sourcing. Submit annual CMRT (Conflict Minerals Reporting Template) if applicable.

Conclusion

Effective logistics and compliance practices ensure loudspeaker spade connectors meet performance expectations and regulatory requirements across global markets. Partner with certified suppliers, maintain thorough documentation, and stay updated on evolving regulations to minimize risk and support sustainable operations.

In conclusion, sourcing loudspeaker spade connectors requires careful consideration of several key factors including conductivity, durability, size compatibility, and ease of installation. High-quality materials such as oxygen-free copper and gold plating enhance signal transmission and resist corrosion, ensuring long-term audio performance. It is essential to match the connector size to the speaker terminals and wire gauge to achieve a secure and reliable connection. Whether sourcing for professional audio systems or consumer applications, selecting reliable suppliers and reputable brands ensures consistency and product integrity. Ultimately, investing in premium spade connectors contributes to optimal sound quality and system reliability, making it a critical component in any high-fidelity audio setup.