The global demand for precision metal components has fueled significant growth in advanced manufacturing techniques, with the lost wax casting market standing out as a key enabler across aerospace, automotive, medical, and industrial sectors. According to Grand View Research, the global investment casting (lost wax casting) market was valued at USD 13.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is driven by increasing demand for complex, high-tolerance components and the aerospace industry’s shift toward lightweight, high-performance alloys. Additionally, rising adoption in dental and medical device manufacturing further solidifies the relevance of this age-old technique in modern production. As competition intensifies and technological capabilities evolve, identifying the top lost wax casting manufacturers becomes critical for businesses seeking quality, scalability, and innovation. Leveraging capacity, material expertise, certifications, and global reach, the following ten manufacturers represent the leaders shaping the future of precision metal casting.

Top 10 Lost Wax Casting Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lost Wax Casting & Investment Casting OEM Manufacturer

Domain Est. 1998

Website: cscasting.com

Key Highlights: C&S Metal Products Co., Ltd. works with honesty and creativity to develop high quality lost wax casting supplier, and finished parts for all industrial ……

#2 LOST WAX CASTING

Website: castem.co.jp

Key Highlights: We have more than 30,000 experiences with lost wax casting, which is the largest number among lost wax manufacturers. We are good at simple to complex 3D shapes ……

#3 Aristo

Domain Est. 2000

Website: aristo-cast.com

Key Highlights: Our original additive manufacturing methods for lost-wax casting includes 3D scanning and in-house tooling for the fastest delivery and highest quality….

#4 Investment Casting, Lost Wax Casting Manufacturer

Domain Est. 2007 | Founded: 1994

Website: kfrcast.com

Key Highlights: A professional investment casting manufacturer, established in 1994 in Taiwan,Asia. Our company has specialized technologies and expertise in automobile parts….

#5 Tamboli Castings Limited

Domain Est. 2020

Website: tambolicastingslimited.com

Key Highlights: Investment casting manufacturers produces lost wax parts in aluminium, stainless steel, and other non-ferrous alloys in India….

#6 Lost Wax Casting Factory from Taiwan

Domain Est. 2021

Website: jinholly.com

Key Highlights: Our lost wax casting services are mainly used to produce stainless steel, carbon and alloy steel, low-alloy steel, aluminum alloy steel, and tool steel….

#7 EAGLE PRECISION SERVICES

Domain Est. 2007

Website: eagleprecisioncastparts.com

Key Highlights: Eagle Precision Cast Parts offers high-quality lost wax casting services, producing ferrous and non-ferrous investment castings with tight tolerances and ……

#8 Lost Wax Casting

Domain Est. 2013

Website: pmcsupplies.com

Key Highlights: 30-day returnsShop lost wax casting supplies for jewelry making. Wax, flasks, burnout furnaces, and casting equipment for detailed, professional results….

#9 Lost wax investment casting

Domain Est. 2014

Website: cirexfoundry.com

Key Highlights: CIREX is a supplier of precision castings which are cast by using the lost wax technique. These castings are characterized by low surface roughness values and ……

#10 Investment Castings

Domain Est. 2015

Website: investment-castings.net

Key Highlights: Lost wax casting is a casting process that uses a wax pattern to create a ceramic mold for creating a part or product design. It has been known over the years ……

Expert Sourcing Insights for Lost Wax Casting

H2: Market Trends in Lost Wax Casting for 2026

As the global manufacturing and industrial sectors evolve, the lost wax casting (also known as investment casting) market is poised for significant transformation by 2026. Driven by advancements in technology, rising demand from high-performance industries, and a growing focus on precision and sustainability, several key trends are shaping the future of this traditional yet innovative metal casting process.

1. Increased Adoption in Aerospace and Defense

The aerospace and defense sectors are expected to remain the primary drivers of the lost wax casting market in 2026. The need for lightweight, complex, and high-strength components—especially in jet engines, turbine blades, and airframes—is fueling demand for investment-cast parts. With major aerospace OEMs ramping up production of next-generation aircraft and expanding defense programs globally, the precision and reliability offered by lost wax casting make it indispensable. Titanium and nickel-based superalloys are seeing higher usage, further boosting market growth.

2. Technological Integration and Automation

By 2026, digitalization and automation are transforming traditional lost wax casting facilities. The integration of technologies such as 3D printing (additive manufacturing) for wax pattern creation, AI-driven quality control, and IoT-enabled production monitoring is improving efficiency, reducing lead times, and minimizing human error. Foundries are increasingly adopting digital twins and simulation software to optimize mold design and predict casting defects before production, significantly enhancing yield rates.

3. Growth in Medical and Dental Applications

The medical and dental sectors are emerging as high-growth areas for lost wax casting. Custom prosthetics, surgical instruments, and dental crowns/bridges require the high precision and biocompatibility that investment casting provides. As personalized medicine and minimally invasive procedures gain traction, demand for small, complex, and corrosion-resistant components made from cobalt-chrome and titanium alloys is expected to rise steadily through 2026.

4. Sustainability and Green Manufacturing Initiatives

Environmental concerns are pushing foundries to adopt more sustainable practices. By 2026, there will be greater emphasis on recycling ceramic shells, reclaiming wax, and reducing energy consumption during the dewaxing and sintering stages. Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals are encouraging investment in cleaner technologies and closed-loop systems, aligning the lost wax casting process with global sustainability targets.

5. Regional Market Shifts and Supply Chain Resilience

Asia-Pacific, particularly China and India, will continue to dominate production due to lower operational costs and expanding industrial bases. However, reshoring trends in North America and Europe—driven by supply chain disruptions and geopolitical factors—are leading to renewed investments in local foundries. By 2026, a more balanced global supply chain is expected, with regional hubs enhancing resilience and responsiveness to customer demands.

6. Material Innovation and Alloy Development

Ongoing R&D into new alloys and composite materials is expanding the capabilities of lost wax casting. High-entropy alloys (HEAs), advanced stainless steels, and refractory metals are being explored for extreme environment applications. These innovations are opening new markets in energy (e.g., nuclear and renewable), automotive (especially electric vehicle components), and space exploration.

In conclusion, the lost wax casting market in 2026 will be characterized by technological sophistication, sector diversification, and a strong push toward sustainability. Companies that embrace digital transformation, invest in R&D, and adapt to evolving regulatory and market demands will be best positioned to capitalize on these emerging opportunities.

Common Pitfalls in Sourcing Lost Wax Casting: Quality and Intellectual Property Risks

Sourcing lost wax casting, especially from overseas suppliers, offers cost advantages but introduces significant risks related to both product quality and intellectual property (IP) protection. Being aware of these common pitfalls is crucial for mitigating potential problems.

Quality-Related Pitfalls

Inconsistent Material Composition and Certification

Suppliers may use substandard alloys or fail to provide verifiable material certifications (e.g., mill test reports). This can lead to castings that do not meet required mechanical properties, corrosion resistance, or industry standards (e.g., ASTM, AMS), resulting in premature component failure.

Poor Surface Finish and Dimensional Accuracy

Inadequate control over wax patterns, mold-making, or the casting process itself often results in rough surfaces, excessive porosity, or dimensional deviations. These defects necessitate costly post-casting machining, increase scrap rates, or render parts unusable.

Inadequate Process Control and Lack of Traceability

Many foundries lack standardized quality management systems (e.g., ISO 9001) and fail to document process parameters. Without traceability, identifying the root cause of defects or replicating successful batches becomes nearly impossible.

Insufficient Inspection and Testing

Relying solely on visual inspection or skipping critical non-destructive testing (NDT) methods—such as radiographic (X-ray), ultrasonic, or dye penetrant testing—can allow internal defects like shrinkage voids or inclusions to go undetected until final use.

Inexperienced Pattern Making and Design Limitations

The precision of the final casting depends heavily on the wax pattern. Suppliers with limited CAD/CAM or rapid prototyping capabilities may introduce inaccuracies or be unable to produce complex geometries, leading to design compromises or repeated iterations.

Intellectual Property-Related Pitfalls

Unprotected Design Files and Digital Theft

Sharing detailed CAD models, tooling designs, or process specifications without proper legal safeguards exposes proprietary data to theft or unauthorized duplication. Digital files can be easily copied and shared with competitors.

Weak or Unenforceable Contracts

Many sourcing agreements lack robust IP clauses specifying ownership of designs, molds, and improvements. Contracts may also omit non-compete or non-disclosure terms, leaving companies vulnerable to imitation by the supplier or its affiliates.

Lack of Control Over Tooling and Molds

Suppliers often retain physical possession of wax injection molds and ceramic shell tooling. Without clear agreements, they may reuse or replicate these tools for other customers, leading to knock-offs or market saturation of your product.

Reverse Engineering and Market Competition

Finished castings can be reverse-engineered, especially if the supplier has access to the full product assembly. In regions with lax IP enforcement, this enables competitors to produce and sell identical or similar products, undermining market exclusivity.

Inadequate Jurisdiction for Dispute Resolution

Sourcing from countries with underdeveloped IP legal frameworks complicates enforcement. Even with a strong contract, pursuing legal action against IP infringement abroad can be prohibitively expensive and ineffective.

Mitigating these risks requires thorough due diligence, strong contractual protections, controlled data sharing, and ongoing quality monitoring throughout the supply chain.

Logistics & Compliance Guide for Lost Wax Casting

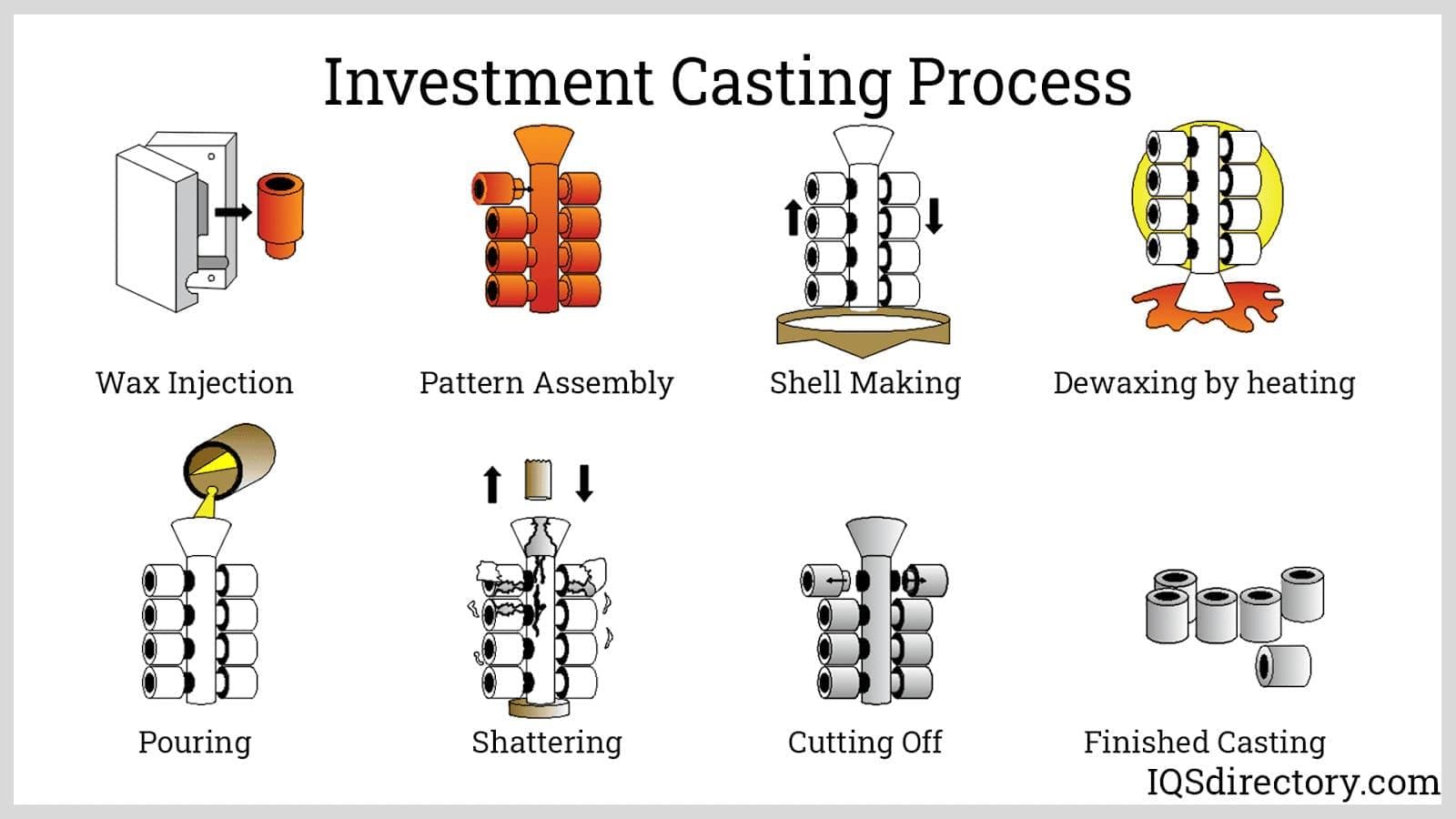

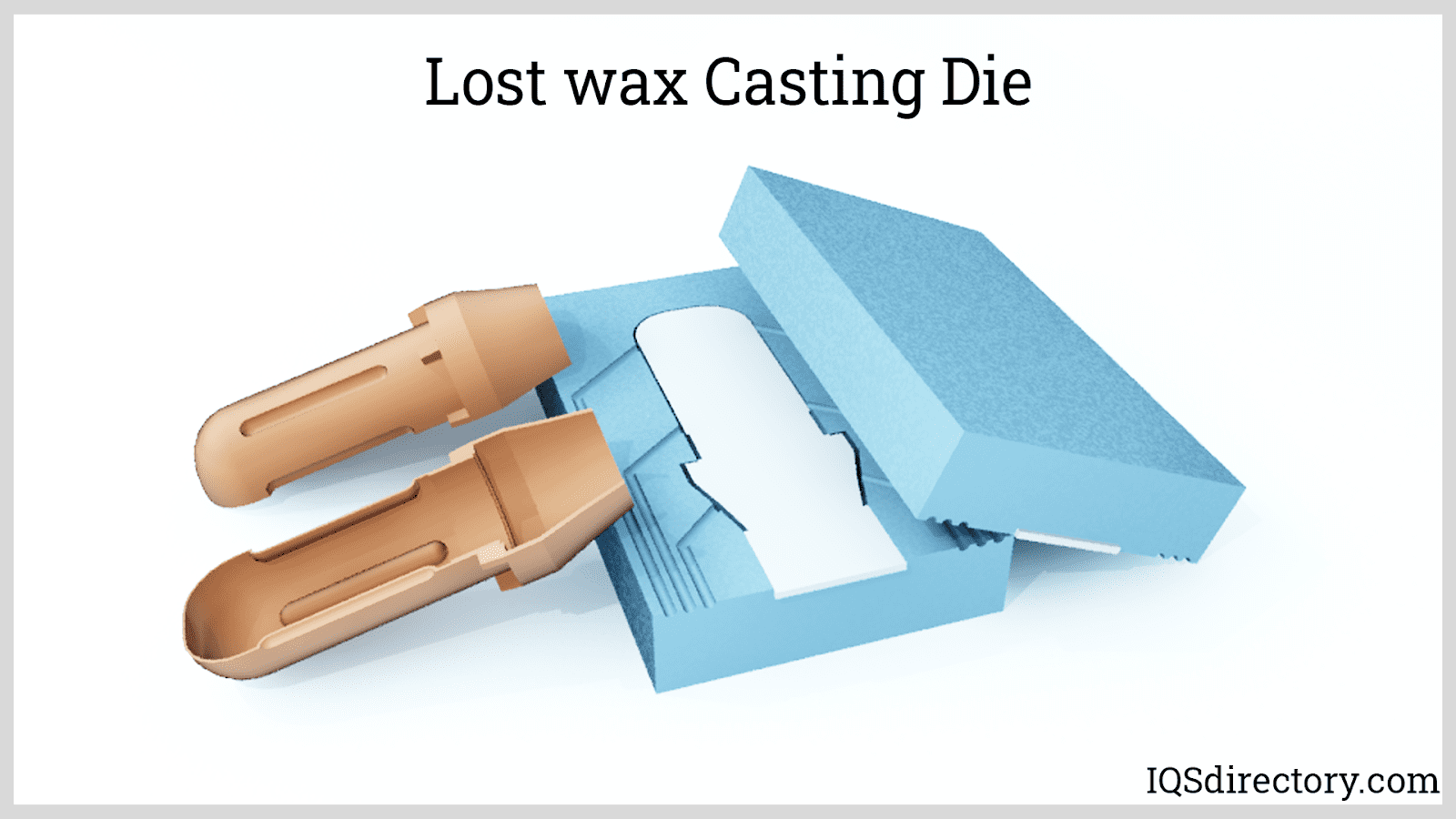

Overview of Lost Wax Casting Process

Lost wax casting, also known as investment casting, is a manufacturing process used to produce complex metal parts with high precision and excellent surface finishes. The process involves creating a wax pattern of the desired part, coating it with a ceramic shell, melting out the wax, and then pouring molten metal into the cavity. Due to its intricate nature and use of specialized materials and high-temperature equipment, proper logistics and regulatory compliance are essential.

Regulatory Compliance

Environmental Regulations

Lost wax casting operations must comply with environmental regulations related to air emissions, hazardous waste disposal, and water discharge. Key considerations include:

- Air Quality Standards: Emissions from burnout furnaces (which remove wax) and metal melting operations may release volatile organic compounds (VOCs) and particulate matter. Facilities must comply with local, state, and federal air quality regulations (e.g., U.S. EPA’s NESHAP standards).

- Hazardous Waste Management: Spent ceramic shells, spent mold materials, and cleaning solvents may be classified as hazardous waste. Proper storage, labeling, and disposal through licensed waste handlers are required.

- Wastewater Discharge: If water is used in cooling or cleaning processes, discharge must comply with Clean Water Act regulations (in the U.S.) or equivalent local standards.

Occupational Health & Safety (OHS)

Worker safety is paramount due to high temperatures, molten metal, and chemical exposure. Compliance with OHS standards includes:

- OSHA Standards (U.S.) or Equivalent: Adherence to standards for personal protective equipment (PPE), machine guarding, heat stress prevention, and hazard communication (e.g., SDS for chemicals).

- Ventilation Systems: Proper fume extraction and ventilation in wax removal, melting, and casting areas.

- Training: Regular training on emergency procedures, handling molten metal, and use of equipment.

Material Handling & Chemical Compliance

- Globally Harmonized System (GHS): All chemical containers (e.g., binders, solvents, release agents) must be properly labeled with GHS-compliant hazard pictograms and safety data sheets (SDS) available.

- REACH & RoHS (EU): If exporting to the European Union, ensure that final castings and process materials comply with REACH (chemicals regulation) and RoHS (restriction of hazardous substances in electrical/electronic equipment, where applicable).

Logistics Management

Raw Material Sourcing & Inventory

- Wax Supply: Ensure a reliable supply chain for investment casting wax, stored in a controlled environment to prevent deformation.

- Refractory Materials: Ceramic slurries and stucco materials should be stored according to manufacturer specifications (e.g., temperature, humidity).

- Alloys & Metals: Maintain inventory of required metal alloys (e.g., stainless steel, aluminum, titanium), considering shelf life and oxidation risks.

Production Workflow Planning

- Pattern Making & Assembly: Coordinate wax pattern injection, assembly into sprue trees, and quality inspection before shell building.

- Shell Building: Track slurry dwell times, drying conditions (controlled humidity and temperature), and number of coatings to ensure consistency.

- De-waxing & Firing: Schedule furnace capacity for burnout cycles; monitor temperature profiles to prevent shell cracking.

- Casting & Cooling: Plan metal melting schedules, ladle availability, and cooling time to maintain throughput.

- Finishing & Inspection: Allocate space and resources for cut-off, grinding, heat treatment, and non-destructive testing (NDT).

Shipping & Packaging

- Finished Part Handling: Use protective packaging (foam, crates, desiccants) to prevent damage during transit, especially for fragile or precision components.

- Export Documentation: For international shipments, ensure proper documentation including commercial invoices, packing lists, certificates of origin, and material compliance statements.

- Customs Compliance: Classify products under the appropriate HS code (e.g., 8109.30 for titanium castings) and adhere to import/export regulations of destination countries.

Quality & Traceability

Process Documentation

- Maintain detailed records of each casting batch, including wax lot numbers, shell build parameters, furnace logs, and melt chemistry.

- Implement a traceability system (e.g., barcodes or serial numbers) linking finished parts to raw materials and process steps.

Certifications & Audits

- ISO 9001: Quality management system certification ensures consistent process control.

- AS9100 (Aerospace): Required for aerospace casting suppliers; includes additional traceability and inspection requirements.

- NDT Certification: Personnel performing radiographic, ultrasonic, or penetrant testing must be certified (e.g., to NAS410 or equivalent).

Sustainability & Best Practices

- Wax Recovery: Install wax reclamation systems to filter and reuse spent wax, reducing material costs and waste.

- Energy Efficiency: Optimize furnace cycles and insulation to minimize energy consumption.

- Recycling: Recycle metal sprues, gates, and scrap through certified foundries.

Conclusion

Effective logistics and compliance in lost wax casting require coordination across environmental, safety, quality, and supply chain functions. By integrating regulatory adherence with streamlined operational planning, manufacturers can ensure product integrity, worker safety, and market access—especially in highly regulated industries such as aerospace, medical, and automotive.

In conclusion, sourcing reliable lost wax casting suppliers requires a strategic approach that balances quality, cost, lead times, and communication. It is essential to conduct thorough due diligence by evaluating suppliers’ technical capabilities, certifications, production facilities, and past client reviews. Engaging with suppliers who demonstrate expertise in your specific material and component requirements—such as aerospace-grade alloys or intricate artistic designs—ensures better outcomes. Additionally, clear communication, sample testing, and site visits (where feasible) help build trust and alignment. Ultimately, establishing long-term partnerships with flexible, responsive, and quality-focused lost wax casting suppliers can significantly enhance product integrity, reduce production risks, and support sustainable growth in competitive markets.