The global demand for lorry diesel tanks is on a steady upward trajectory, closely aligned with growth in commercial vehicle production and freight transportation activities. According to Mordor Intelligence, the commercial vehicle market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, driven by expanding e-commerce logistics, infrastructure development, and rising fuel transportation needs—factors directly influencing the demand for high-quality diesel fuel tanks. Additionally, Grand View Research reports that the global fuel tank market size was valued at USD 14.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% through 2030, fueled by stricter emission regulations and the need for fuel-efficient, durable storage solutions in heavy-duty applications. As fleet operators prioritize fuel safety, regulatory compliance, and operational efficiency, the role of reliable lorry diesel tank manufacturers has become increasingly critical. In this context, the following list highlights the top 10 manufacturers leading innovation, scalability, and market presence in the lorry diesel tank sector.

Top 10 Lorry Diesel Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 IFH Group: Trust in Every Tank

Domain Est. 1998

Website: ifhgroup.com

Key Highlights: We’re proud to be one of the country’s largest manufacturers of fuel tanks, hydraulic oil tanks, and built to print custom OEM tanks for off-road and specialty ……

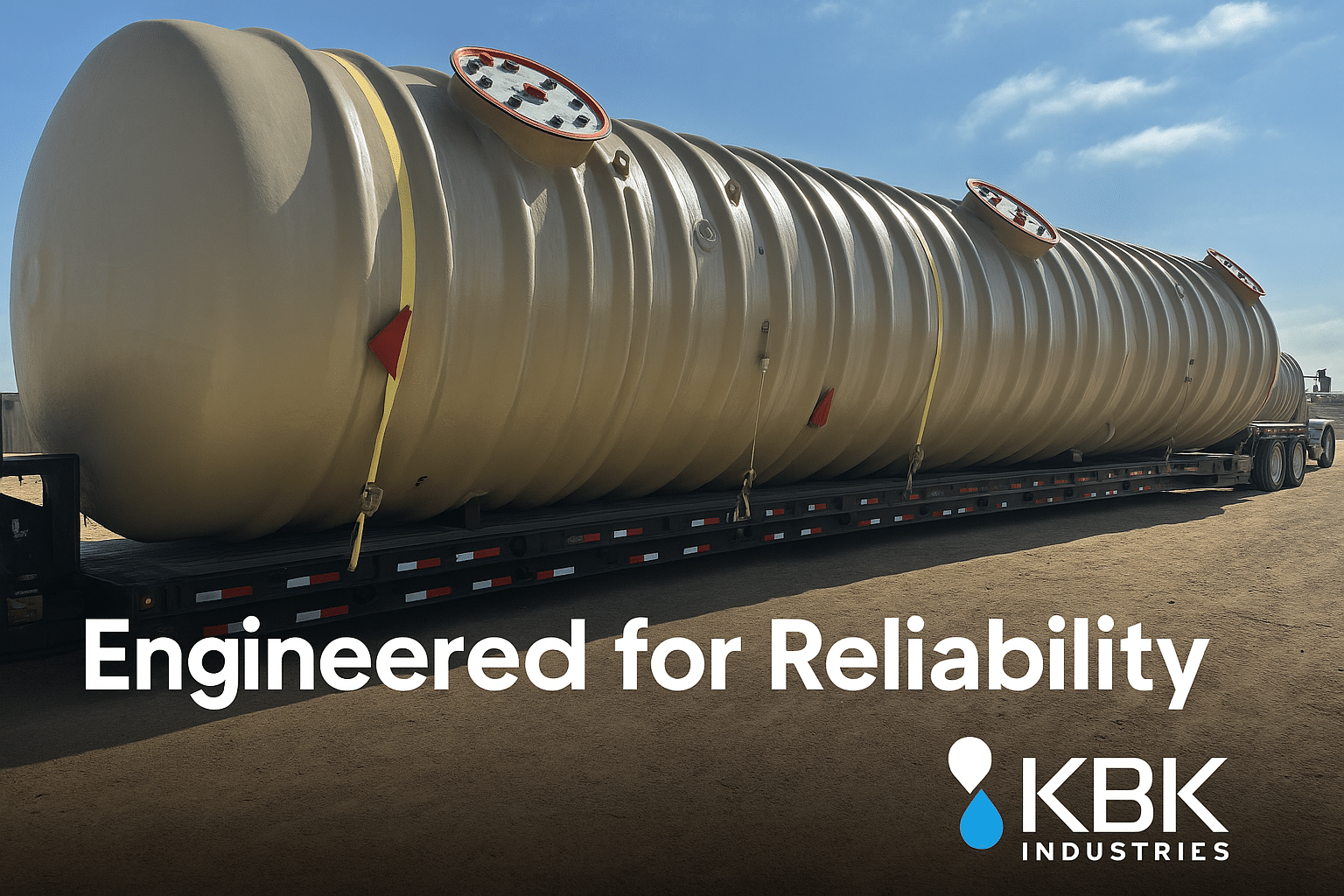

#2 KBK Industries

Domain Est. 2011

Website: kbkindustries.com

Key Highlights: KBK Industries is a leading storage tank manufacturer of carbon steel, stainless steel, and fiberglass tanks used in agriculture, municipal, and industrial …Missing: lorry diese…

#3 Highland Tank

Domain Est. 1996

Website: highlandtank.com

Key Highlights: Manufacturing high-quality steel storage tank products accommodating commercial and industrial customers. Proven manufacturing and exceptional quality….

#4 Tremcar

Domain Est. 1997

Website: tremcar.com

Key Highlights: Tremcar is a manufacturer of tank trailers and tank trucks for the North American market. Its production output includes stainless steel and aluminum tanks….

#5 Transfer Flow, Inc.

Domain Est. 1997

Website: transferflow.com

Key Highlights: Transfer Flow offers a range of fuel tanks manufactured in the USA, using durable American-made steel….

#6 Polar Tank Trailer

Domain Est. 1997

Website: polartank.com

Key Highlights: Polar Tank Trailer has established itself as a trusted manufacturer, meeting the demands of diverse industries such as chemical, food-grade materials, ……

#7 TANKS Inc. gas tanks for street rods, muscle cars, custom cars and …

Domain Est. 1999

Website: tanksinc.com

Key Highlights: Tanks, Inc. manufactures fuel system components and polyethylene, steel and stainless steel gas tanks for street rods and special interest vehicles.Missing: lorry diesel…

#8 Amthor International

Domain Est. 2001

Website: amthorinternational.com

Key Highlights: America’s premier custom tanker truck manufacturer. From aluminum, stainless steel, & steel, our tanks boast of unparalleled craftsmanship….

#9 AlumiTank, The Fuel Tank Specialists

Domain Est. 1999

Website: alumitank.com

Key Highlights: Discover custom aluminum fuel tanks for trucks, diesel caps, and tank straps. Alumitank builds durable, DOT-compliant fuel solutions made in the USA….

#10 TITAN Fuel Tanks

Domain Est. 2004 | Founded: 2003

Website: titanfueltanks.com

Key Highlights: Founded in 2003, Titan Fuel Tanks is world renowned for our cutting-edge designs made from cross-linked high-density polyethylene (XLHDPE)….

Expert Sourcing Insights for Lorry Diesel Tank

H2: 2026 Market Trends for Lorry Diesel Tanks

The global market for lorry diesel tanks is poised for significant transformation by 2026, driven by regulatory changes, technological advancements, and evolving transportation demands. This analysis examines key trends shaping the industry under the broader context of sustainability, efficiency, and supply chain resilience.

1. Regulatory Pressure and Emission Standards

By 2026, stringent emission regulations—particularly in the European Union, North America, and parts of Asia—are expected to reshape the design and material specifications of diesel tanks. The Euro 7 standards in Europe and updated EPA regulations in the U.S. will demand reduced evaporative emissions and improved fuel containment. This will accelerate the adoption of advanced polymer composites and multi-layer tank designs that minimize hydrocarbon leakage and enhance durability.

2. Shift Toward Lightweight and Durable Materials

To improve fuel efficiency and reduce CO₂ emissions, manufacturers are increasingly shifting from traditional steel tanks to high-density polyethylene (HDPE) and reinforced thermoplastic composites. These materials offer superior corrosion resistance, lighter weight, and longer service life. By 2026, HDPE is projected to dominate the market, particularly in medium- and heavy-duty lorries where weight savings directly impact payload capacity and operational costs.

3. Integration with Fuel Efficiency and Telematics Systems

Diesel tanks are becoming more than passive fuel reservoirs—they are integrating with vehicle telematics and fuel monitoring systems. By 2026, smart fuel tanks equipped with sensors for real-time fuel level, temperature, and leak detection will gain traction. These systems enable fleet operators to optimize routing, reduce fuel theft, and ensure compliance with environmental reporting requirements.

4. Regional Demand Variations

While diesel-powered lorries are expected to decline in Western Europe due to electrification policies, strong demand will persist in emerging markets such as India, Southeast Asia, and Africa, where diesel remains the dominant fuel for freight transport. In these regions, affordability, fuel infrastructure, and long-haul logistics needs will sustain demand for reliable diesel tank solutions through 2026.

5. Sustainability and Circular Economy Initiatives

Environmental concerns are pushing manufacturers toward recyclable tank materials and end-of-life recovery programs. By 2026, leading suppliers are expected to offer take-back schemes and design tanks for easier disassembly and recycling. This trend aligns with broader circular economy goals within the automotive sector.

6. Impact of Alternative Fuels and Electrification

Although full electrification of long-haul trucking remains limited by battery technology and charging infrastructure, hybrid and dual-fuel systems may influence diesel tank design. Some manufacturers are exploring modular tank systems that can accommodate biodiesel blends or hydrogen-diesel hybrids. However, pure diesel tanks will remain prevalent for non-electrified fleets.

Conclusion

By 2026, the lorry diesel tank market will be characterized by innovation in materials, increased digitization, and responsiveness to regional regulatory landscapes. While the long-term outlook includes a gradual decline due to electrification, diesel tanks will remain critical for global freight logistics in the near term, evolving to meet higher performance and sustainability benchmarks.

Common Pitfalls When Sourcing Lorry Diesel Tanks (Quality & IP)

Sourcing lorry diesel tanks involves more than just finding a supplier with the lowest price. Overlooking critical quality and intellectual property (IP) aspects can lead to safety hazards, regulatory non-compliance, costly downtime, and legal risks. Below are key pitfalls to avoid:

1. Compromising on Material Quality and Construction Standards

One of the most frequent pitfalls is selecting diesel tanks made from substandard materials or poor manufacturing processes. Low-quality steel or improper welding can lead to corrosion, leaks, or structural failure, especially under harsh operating conditions.

- Risk: Fuel contamination, environmental spills, fire hazards, and premature tank failure.

- Best Practice: Specify tanks made from high-grade, corrosion-resistant materials (e.g., aluminized steel or marine-grade aluminum) and ensure compliance with relevant standards such as ISO 12106 or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road).

2. Ignoring Regulatory and Safety Compliance

Different regions have strict regulations governing fuel tank design, installation, and emissions. Sourcing non-compliant tanks can result in failed inspections, fines, or vehicle impoundment.

- Risk: Legal penalties, vehicle downtime, and safety hazards.

- Best Practice: Verify that the tank meets local and international safety standards (e.g., EPA, CE marking, UKCA, or DOT regulations). Ensure features like rollover protection, overfill prevention, and proper venting are included.

3. Overlooking Intellectual Property (IP) Infringement

Using or sourcing diesel tanks that replicate patented designs, branding, or proprietary technology can expose your business to IP litigation.

- Risk: Legal disputes, product recalls, financial damages, and reputational harm.

- Best Practice: Conduct due diligence on suppliers to confirm they own or are licensed to produce the tank design. Avoid suppliers offering “compatible” or “OEM-style” tanks without verified IP rights. Request documentation such as design patents or licensing agreements.

4. Choosing Suppliers Without Proper Certification or Traceability

Working with uncertified or unverified manufacturers increases the risk of receiving counterfeit or subpar products.

- Risk: Inconsistent quality, lack of after-sales support, and difficulty in traceability during recalls.

- Best Practice: Source from suppliers with recognized quality certifications (e.g., ISO 9001). Demand full traceability, including batch numbers, material certifications, and test reports.

5. Failing to Assess Long-Term Durability and Warranty Support

Some suppliers offer attractive upfront pricing but provide limited or voidable warranties, especially if installation is not performed by an authorized technician.

- Risk: Unexpected maintenance costs and operational disruptions.

- Best Practice: Evaluate warranty terms carefully—ensure coverage includes corrosion, weld failure, and manufacturer defects. Confirm post-sales service and technical support availability.

6. Neglecting Compatibility with Vehicle Systems

A diesel tank must integrate seamlessly with the vehicle’s fuel delivery, monitoring, and emission systems (e.g., SCR or AdBlue integration).

- Risk: Poor fuel efficiency, error codes, or damage to engine components.

- Best Practice: Verify tank dimensions, mounting points, fuel pickup location, and sensor compatibility with the specific lorry model before purchase.

By proactively addressing these pitfalls, fleet operators and procurement managers can ensure they source lorry diesel tanks that are safe, compliant, durable, and free from intellectual property risks.

Logistics & Compliance Guide for Lorry Diesel Tanks

Transporting diesel fuel using lorry-mounted tanks is subject to strict regulations to ensure safety, environmental protection, and legal compliance. This guide outlines key logistics considerations and regulatory requirements applicable in most jurisdictions, with emphasis on best practices and compliance standards.

Regulatory Framework and Licensing

Diesel transportation is governed by national and international regulations, particularly when carried in bulk. In many regions, including the European Union and the United States, the movement of diesel falls under dangerous goods (hazard class 3 – flammable liquids) regulations.

- ADR Regulations (Europe): The European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) applies to diesel transport. Even though diesel has a higher flash point than gasoline, it is still classified as a flammable liquid (UN 1202) and subject to ADR when carried above certain thresholds (typically >1,000 liters).

- Hazard Classification: Diesel is classified as UN 1202, Class 3, PG III (low danger, but still regulated).

- Operator Licensing: Transport companies must hold valid dangerous goods operator licenses. Drivers require specific training and certification (e.g., ADR driver training, valid every 5 years).

- Vehicle Certification: Lorry diesel tanks must be certified for dangerous goods transport, bearing appropriate tank approval codes (e.g., TANK CODE: LGBF under ADR) and inspection plates.

Vehicle and Tank Specifications

The lorry and its diesel tank must meet construction, safety, and maintenance standards.

- Tank Design: Must comply with ADR Chapter 6.8 or equivalent standards. Tanks should be made of corrosion-resistant materials, equipped with overfill prevention, pressure/vacuum relief valves, and emergency cut-off systems.

- Marking and Labeling: Vehicles must display:

- Orange hazard panels at front and rear with correct UN number (1202) and hazard class (3).

- Hazard diamond (Class 3 flammable liquid) on both sides and rear.

- Proper identification of the substance and emergency contact information.

- Compartmentalization: Tanks may be divided to prevent surge; baffles or surge plates are often required.

- Grounding and Bonding: Anti-static grounding cables must be used during loading and unloading to prevent ignition risks.

Driver Training and Responsibilities

Drivers play a crucial role in compliance and incident prevention.

- Mandatory ADR Training: Includes handling procedures, hazard awareness, emergency response, and use of personal protective equipment (PPE).

- Documentation: Drivers must carry:

- Transport document (waybill) specifying UN number, class, quantity, and proper shipping name.

- Written instructions for emergencies (ADR Form 7.5.11).

- Certificate of tank inspection and vehicle fitness.

- Pre-Trip Inspections: Drivers must inspect the tank, valves, hoses, and safety equipment before each journey.

Loading, Transport, and Unloading Procedures

Safe handling practices minimize spill and fire risks.

- Loading:

- Conduct at approved facilities with spill containment.

- Use vapor recovery systems if required.

- Avoid overfilling — maximum fill level typically 95% to allow for thermal expansion.

- Ensure grounding during fuel transfer.

- In Transit:

- Follow designated dangerous goods routes where applicable.

- Avoid unnecessary stops in populated or sensitive areas.

- Monitor temperature and pressure in tank (if equipped).

- Unloading:

- Conduct in well-ventilated areas away from ignition sources.

- Use closed transfer systems when possible.

- Verify recipient’s credentials and environmental permits.

Environmental and Safety Compliance

Environmental protection is a key component of diesel logistics.

- Spill Prevention: Vehicles must have secondary containment (e.g., bunded tanks), drip trays, and spill kits onboard.

- Accident Reporting: Any spill, leak, or accident involving diesel must be reported to relevant authorities (e.g., environment agency, transport department) under mandatory reporting laws.

- Waste Management: Residual diesel or contaminated materials must be disposed of as hazardous waste through licensed contractors.

Maintenance and Inspection

Regular upkeep ensures safety and regulatory compliance.

- Tank Inspections: Periodic inspections (e.g., every 2.5 or 5 years depending on tank type) by accredited bodies as per ADR 6.8.2.

- Valve and Hose Checks: Inspect for wear, leaks, or damage at least monthly.

- Record Keeping: Maintain logs of maintenance, inspections, driver training, and incidents for minimum of 5 years.

Insurance and Liability

Carriers must have appropriate insurance coverage.

- Minimum Liability Coverage: Required by law for dangerous goods transport (e.g., EUR 1 million+ under EU directives).

- Pollution Liability: Additional coverage for environmental damage due to spills.

- Cargo Insurance: Protects against loss or damage to the diesel being transported.

International and Cross-Border Considerations

For cross-border transport:

- Verify ADR compliance in all transit countries.

- Ensure driver holds valid ADR certificate in required languages.

- Check for national restrictions (e.g., tunnel codes, weekend bans).

- Carry bilingual transport documents if required.

Conclusion

Operating a lorry diesel tank safely and legally requires adherence to comprehensive logistics and compliance standards. From proper vehicle specification and driver training to environmental safeguards and documentation, each element is critical. Regular audits, employee training, and engagement with regulatory bodies help maintain continuous compliance and operational safety.

Conclusion for Sourcing Lorry Diesel Tanks

In conclusion, sourcing lorry diesel tanks requires a strategic approach that balances quality, cost, compliance, and long-term operational efficiency. It is essential to partner with reputable suppliers who adhere to industry standards such as ISO, ADR, or local regulatory requirements to ensure the safety and durability of the tanks. Factors such as tank capacity, material (steel or polyethylene), compatibility with vehicle specifications, and resistance to environmental conditions must be carefully evaluated.

Additionally, considering the total cost of ownership—beyond the initial purchase price—to include maintenance, fuel efficiency, and potential downtime—is crucial in making a cost-effective decision. Supplier reliability, lead times, after-sales support, and warranty offerings also play a significant role in minimizing operational disruptions.

Ultimately, a well-sourced diesel tank enhances vehicle performance, ensures regulatory compliance, and contributes to safer, more efficient fleet operations. By conducting thorough market research and due diligence, organizations can secure a reliable supply of diesel tanks that meet both current needs and future scalability requirements.