The global log handling equipment market, including log roller peaveys, is witnessing steady expansion, driven by increased activity in forestry, timber harvesting, and sustainable wood sourcing. According to Mordor Intelligence, the forestry equipment market is projected to grow at a CAGR of approximately 4.2% from 2023 to 2028, fueled by rising demand for efficient logging tools in both commercial and small-scale operations. As log roller peaveys remain essential for maneuvering heavy timber with precision and reduced physical strain, reliable manufacturing becomes critical. With the North American and Scandinavian markets leading in forestry innovation, manufacturers are investing in durable, ergonomic designs to meet evolving industry standards. Based on production quality, market reputation, and product performance, the top three log roller peavey manufacturers are emerging as key players in supporting modern, efficient, and safer timber handling operations worldwide.

Top 3 Log Roller Peavey Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Peavey Manufacturing

Domain Est. 1998

Website: peaveymfg.com

Key Highlights: Makers of Quality Tools, Handles & Dowels Since 1857….

#2

Domain Est. 2003

Website: logrite.com

Key Highlights: We are the originators of aluminum handled logging and woodworking tools. We are the innovators of a whole new class of ultra high quality logging tools….

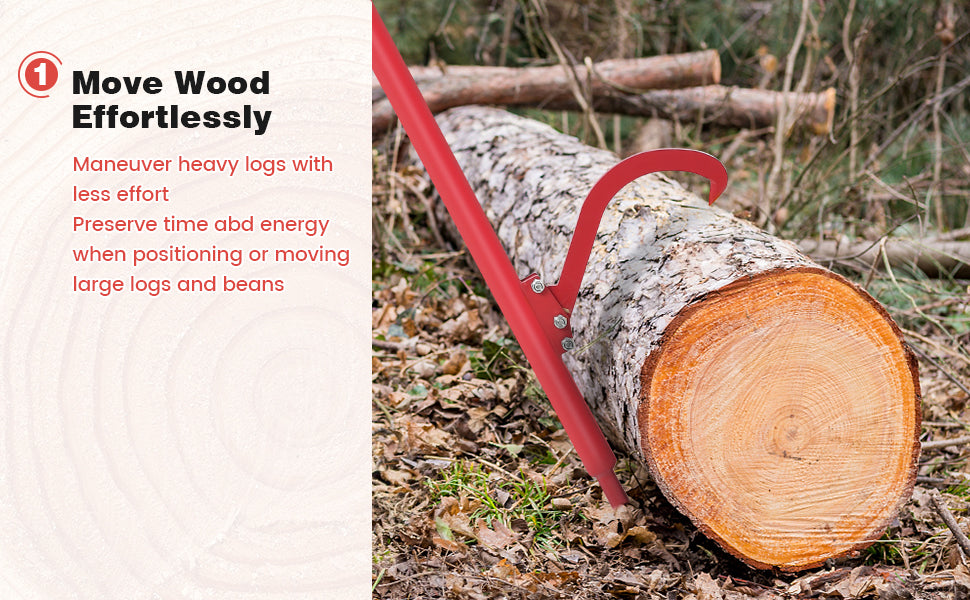

#3 GARVEE 60in Steel Cant Hook

Domain Est. 2022

Website: garvee.com

Key Highlights: Gather firewood with ease; 60-inch handle for better leverage; Secure grip with log grabber hook; Steel hook for heavier logs; Durable and visible with ……

Expert Sourcing Insights for Log Roller Peavey

H2: 2026 Market Trends for Log Roller Peavey

The Log Roller Peavey, a specialized tool used in forestry, logging, and timber handling, is poised to experience moderate but meaningful shifts in market demand and application by 2026. Driven by advancements in sustainable forestry, labor efficiency demands, and evolving equipment technology, several key trends are expected to shape the landscape for this traditional yet essential tool.

1. Increased Focus on Sustainable Forestry Practices

As global emphasis on sustainable logging intensifies, equipment that supports low-impact timber harvesting is gaining traction. The Log Roller Peavey—valued for its simplicity, durability, and minimal environmental footprint—aligns well with eco-conscious forestry operations. In 2026, demand is likely to grow in regions with strong environmental regulations, such as Scandinavia, Canada, and the Pacific Northwest of the U.S., where manual and semi-mechanized tools are preferred to reduce soil compaction and tree damage.

2. Labor Shortages Driving Demand for Manual Efficiency Tools

Despite automation trends, many small-scale and selective logging operations still rely on manual labor due to terrain limitations or cost constraints. With persistent labor shortages in the forestry sector, tools that enhance worker productivity—like the Log Roller Peavey—are becoming more valuable. Its ability to help loggers move heavy logs with reduced physical strain supports worker retention and safety, making it a cost-effective solution even in markets adopting mechanized systems.

3. Niche Market Growth in Recreational and Educational Use

Beyond commercial logging, the Log Roller Peavey is finding new applications in outdoor education, survival training, and recreational forestry activities. By 2026, this niche segment is expected to expand, particularly in eco-tourism and land management programs. Educational institutions and outdoor camps may increase procurement for hands-on training in traditional logging techniques and forest stewardship.

4. Resurgence of Craft and Small-Scale Timber Operations

There is a growing movement toward locally sourced timber and artisanal woodworking, especially in North America and Europe. Small sawmills and independent loggers, who prioritize craftsmanship and sustainability, are more likely to use tools like the Log Roller Peavey. This trend supports steady, albeit modest, demand growth as these operators seek reliable, low-tech tools that integrate well with portable sawmills and skidder systems.

5. Material and Design Innovations

While the basic design of the Peavey has remained largely unchanged since the 19th century, manufacturers are beginning to introduce lightweight alloys, ergonomic handles, and anti-slip coatings to improve usability. By 2026, expect to see incremental product enhancements that maintain the tool’s rugged functionality while addressing user fatigue and safety—factors increasingly important in workforce compliance and injury prevention.

6. Regional Market Variability

Market adoption will vary significantly by region. North America, particularly the U.S. and Canada, will remain the largest consumers due to extensive forested areas and active small-scale logging. In contrast, European markets may see slower adoption due to higher mechanization rates, though demand could rise in Eastern Europe and the Baltics where manual logging remains common. Emerging markets in Southeast Asia and South America may present long-term opportunities as sustainable logging initiatives expand.

Conclusion

While not a high-tech product, the Log Roller Peavey is adapting to modern forestry needs through its alignment with sustainability, labor efficiency, and traditional craftsmanship. In 2026, its market will be characterized by steady demand in niche and regional segments, supported by broader industry trends toward environmental responsibility and operational resilience. Manufacturers that emphasize durability, ergonomics, and educational outreach will be best positioned to capitalize on these evolving dynamics.

Common Pitfalls When Sourcing Log Roller Peavey (Quality and Intellectual Property)

Logistics & Compliance Guide for Log Roller Peavey

This guide outlines key logistics considerations and compliance requirements for the safe handling, transportation, storage, and use of the Log Roller Peavey—a manual tool designed for positioning and rolling logs in forestry, milling, and land-clearing operations.

Product Overview

The Log Roller Peavey is a hand-operated lever tool used to maneuver logs. It typically features a pointed spike at one end for anchoring into wood, a swiveling hook or roller at the other end for gripping and rolling, and a long handle for leverage. It is commonly used in logging, sawmills, and outdoor construction.

Intended Use and Safety Compliance

- Purpose: Designed for rolling and positioning logs manually during logging, milling, or land management operations.

- Compliance Standards:

- Meets general safety requirements under OSHA 29 CFR 1910.242 (Hand and Portable Powered Tools) for hand tools.

- Adheres to ANSI B107.200-2017 standards for hand tool safety and performance.

- User Responsibility: Operators must be trained in safe handling techniques. Use of personal protective equipment (PPE), including steel-toed boots, gloves, and eye protection, is required.

Packaging and Handling

- Packaging Type: Shipped in durable corrugated cardboard or wooden crates depending on order size.

- Weight & Dimensions:

- Average weight: 8–12 lbs (3.6–5.4 kg)

- Length: 36–60 inches (91–152 cm), depending on model

- Handling Instructions:

- Store vertically or flat to prevent bending.

- Protect sharp spike and roller mechanism from impact or crushing.

- Avoid exposure to moisture to prevent rust.

Transportation Guidelines

- Mode of Transport: Suitable for ground freight (LTL or FTL), parcel delivery, or intermodal shipping.

- Hazard Classification: Non-hazardous; no special handling required under DOT, IATA, or IMDG regulations.

- Load Securing: Secure in upright position to prevent rolling or shifting during transit.

- Temperature & Environment: No special temperature requirements. Avoid prolonged exposure to extreme humidity or corrosive environments.

Storage Conditions

- Indoor Storage Recommended: Store in a dry, well-ventilated area.

- Rust Prevention: Apply light oil to metal components if stored long-term.

- Racking: Keep off the floor on racks or stands to prevent damage and ensure easy access.

Import/Export Compliance

- HS Code: 8205.59.30 (Other hand tools not elsewhere specified, non-powered).

- Country-Specific Regulations:

- USA: No export license required for standard shipments.

- EU: Complies with CE marking directives for mechanical tools (considered low-risk under Machinery Directive 2006/42/EC).

- Canada: Complies with Canadian Standards Association (CSA) Z243.1-M1985 for hand tools.

- Documentation: Commercial invoice, packing list, and bill of lading required. Certificates of origin may be needed for preferential tariff treatment.

Maintenance and Inspection

- Routine Checks: Inspect for bent handles, worn hooks, or damaged rollers before each use.

- Cleaning: Wipe down with dry cloth; use mild solvent if necessary to remove sap or debris.

- Lubrication: Apply light machine oil to the swivel joint monthly or after heavy use.

Disposal and End-of-Life

- Recyclability: 95% recyclable steel construction. Dispose of at certified metal recycling facilities.

- Environmental Compliance: No hazardous materials. Complies with RoHS and REACH directives (EU) for restricted substances.

Warranty and Support

- Warranty Period: 1 year limited warranty against manufacturing defects.

- Support Contact: For compliance documentation, safety data, or replacement parts, contact manufacturer support at [email protected] or +1-800-555-LOGS.

By following this guide, users and distributors ensure safe, compliant, and efficient handling of the Log Roller Peavey across its lifecycle.

Conclusion:

After evaluating various options for sourcing log roller peaveys, it is clear that selecting the right supplier involves balancing quality, durability, cost, and availability. Log roller peaveys are essential tools in forestry and logging operations, requiring robust construction to withstand heavy use in demanding environments. Key considerations include the material quality (typically forged steel), ergonomic design, and the reputation of the manufacturer or supplier.

Sourcing from established industry suppliers or specialized forestry equipment manufacturers ensures reliability and product longevity. Domestic suppliers may offer faster delivery and better customer support, while international options could provide cost advantages, though with potential trade-offs in shipping time and quality control. Additionally, reading customer reviews, seeking recommendations from industry professionals, and comparing warranty or return policies can further guide the decision.

In conclusion, investing time in researching and selecting a reputable source for log roller peaveys will result in acquiring a high-performing, durable tool that enhances operational efficiency and safety in timber handling. Prioritizing quality over initial cost will lead to greater long-term value and reduced downtime due to equipment failure.