The global Lockout Tagout (LOTO) equipment market is experiencing steady growth, driven by increasing regulatory emphasis on workplace safety and rising industrial automation. According to Mordor Intelligence, the LOTO market was valued at USD 1.24 billion in 2023 and is projected to grow at a CAGR of 4.8% from 2024 to 2029. This expansion is fueled by stringent OSHA and EU safety regulations, heightened awareness of industrial accident prevention, and expanding operations in high-risk sectors such as manufacturing, oil & gas, and energy. As organizations prioritize compliance and employee safety, demand for reliable, standardized lockout tagout kits has surged—making the choice of manufacturer a critical factor in safety program effectiveness. In this evolving landscape, nine key suppliers have emerged as leaders, combining innovation, compliance assurance, and scalable solutions to meet global safety standards.

Top 9 Log Out Tag Out Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BOZZYS

Domain Est. 2004

Website: bozzys.com

Key Highlights: A professional manufacturer, specializing in all kinds of lockout tagout & safety products to help avoiding industrial accidents….

#2 E

Domain Est. 2003

Website: safetylock.net

Key Highlights: Lockout Tagout : E-Square is the leading lockout tagout manufacturer, supplier of LOTO products/devices. Avail best LOTO devices and services now….

#3 Lockout Tagout Kits & Stations

Domain Est. 1994

Website: panduit.com

Key Highlights: Lockout Tagout Kits & Stations. Filter By: This Product Category has products … Lockout Tagout Lock, Electrical Safety Locks,… Lockout Tagout Hasps….

#4 Lockout/Tagout Locks & Solutions

Domain Est. 1995

Website: masterlock.com

Key Highlights: Discover lockout/tagout locks and solutions to achieve workplace safety. Get compliant and protect teams with Master Lock. Call us today….

#5 Lockout Tagout Devices

Domain Est. 1998

Website: bradyid.com

Key Highlights: Lockout Tagout Devices. Expert LOTO devices, solutions, services, software, kits and safety padlocks built by Brady for your safety – your work is our work….

#6 Reece Safety

Domain Est. 2002

Website: reecesafety.com

Key Highlights: Reece Safety has been manufacturing and supplying Lockout/Tagout for 20 years in the UK and we pride ourselves on providing expert advice and great service….

#7 Lockout Tagout Devices

Domain Est. 2002

Website: accuform.com

Key Highlights: 4.9 43 Lockout Tagout devices and tags from AccuformNMC provide the reliable performance businesses need to keep workers safe. Easy ordering….

#8 Lockout Tagout Kits – Lockout LOTO KIT

Domain Est. 2010

#9 Lockout Tagout Kits and Supplies

Domain Est. 2019

Website: trdsf.com

Key Highlights: Lockout tagout supplies from a reliable safety partner. Buy premium grade LOTO padlocks, stations, do not operate lockout tagout tags, kits, and lockout ……

Expert Sourcing Insights for Log Out Tag Out Kit

H2: 2026 Market Trends for Lock Out Tag Out (LOTO) Kits

The global Lock Out Tag Out (LOTO) kits market is projected to experience significant growth and transformation by 2026, driven by increasing industrial safety regulations, rising awareness of workplace hazards, and technological advancements. Below is an analysis of key market trends expected to shape the LOTO kits industry in 2026:

-

Stringent Regulatory Compliance Driving Demand

Governments and regulatory bodies worldwide, including OSHA in the U.S. and similar agencies in Europe and Asia-Pacific, are tightening safety standards in industrial environments. By 2026, compliance with these regulations will remain a primary driver for the adoption of standardized LOTO kits across manufacturing, oil & gas, chemical, and energy sectors. Companies will increasingly invest in certified LOTO solutions to avoid penalties and ensure worker safety. -

Growth in Industrial Automation and Smart Manufacturing

As industries embrace Industry 4.0, there is a rising integration of digital tools into safety protocols. By 2026, smart LOTO kits equipped with RFID tags, QR codes, and IoT-enabled tracking systems are expected to gain traction. These advanced kits allow real-time monitoring of lockout procedures, audit trails, and integration with enterprise safety management systems, improving accountability and reducing human error. -

Expansion in Emerging Markets

Emerging economies in Asia-Pacific (particularly India, China, and Southeast Asia), Latin America, and Africa are witnessing rapid industrialization. This growth is fueling demand for industrial safety equipment, including LOTO kits. Local manufacturers are expected to enter the market with cost-effective solutions, increasing accessibility and adoption rates in small and medium-sized enterprises (SMEs). -

Customization and Modular Kit Designs

By 2026, there will be a strong trend toward customizable and modular LOTO kits tailored to specific machinery and operational environments. Businesses are moving away from one-size-fits-all solutions in favor of kits that include application-specific locks, tags, hasps, and storage cases. This customization enhances efficiency and ensures better adherence to lockout procedures. -

Focus on Training and Safety Culture

Organizations are increasingly recognizing that effective LOTO implementation requires more than just equipment—it requires proper training and a strong safety culture. In 2026, the market will see bundled offerings that combine LOTO kits with digital training modules, augmented reality (AR) simulations, and certification programs, reinforcing proper usage and compliance. -

Sustainability and Durable Materials

Environmental concerns are influencing product design. Manufacturers are expected to use recyclable and durable materials in LOTO kits to reduce waste and improve longevity. This shift supports corporate sustainability goals and reduces long-term costs for end-users. -

Consolidation and Competitive Landscape

The LOTO kits market is likely to see further consolidation, with major safety equipment providers acquiring niche players to expand their product portfolios. Competition will intensify, leading to innovation in product design, pricing models, and after-sales services such as inventory management and refill programs.

In summary, the 2026 market for Lock Out Tag Out kits will be characterized by regulatory enforcement, technological integration, geographic expansion, and a greater emphasis on training and customization. Companies that adapt to these trends by offering intelligent, compliant, and user-centric solutions will be well-positioned to capture market share in this evolving safety landscape.

Common Pitfalls When Sourcing Lock Out Tag Out (LOTO) Kits: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Lock Out Tag Out (LOTO) Kits

Purpose and Scope

This guide outlines the logistics and compliance requirements for the management, distribution, storage, and use of Lock Out Tag Out (LOTO) kits. These kits are critical to ensuring employee safety during maintenance, servicing, or repair of machinery and equipment by preventing unexpected energization or startup.

Regulatory Compliance Overview

LOTO kits must comply with relevant occupational health and safety regulations, including but not limited to:

– OSHA 29 CFR 1910.147 – The Control of Hazardous Energy (Lockout/Tagout Standard)

– ANSI Z244.1 – Procedures for the Management of Lockout/Tagout

– Applicable local, state, and international safety standards (e.g., CSA Z460 in Canada)

All LOTO kits must meet or exceed these regulatory requirements to ensure legal compliance and worker protection.

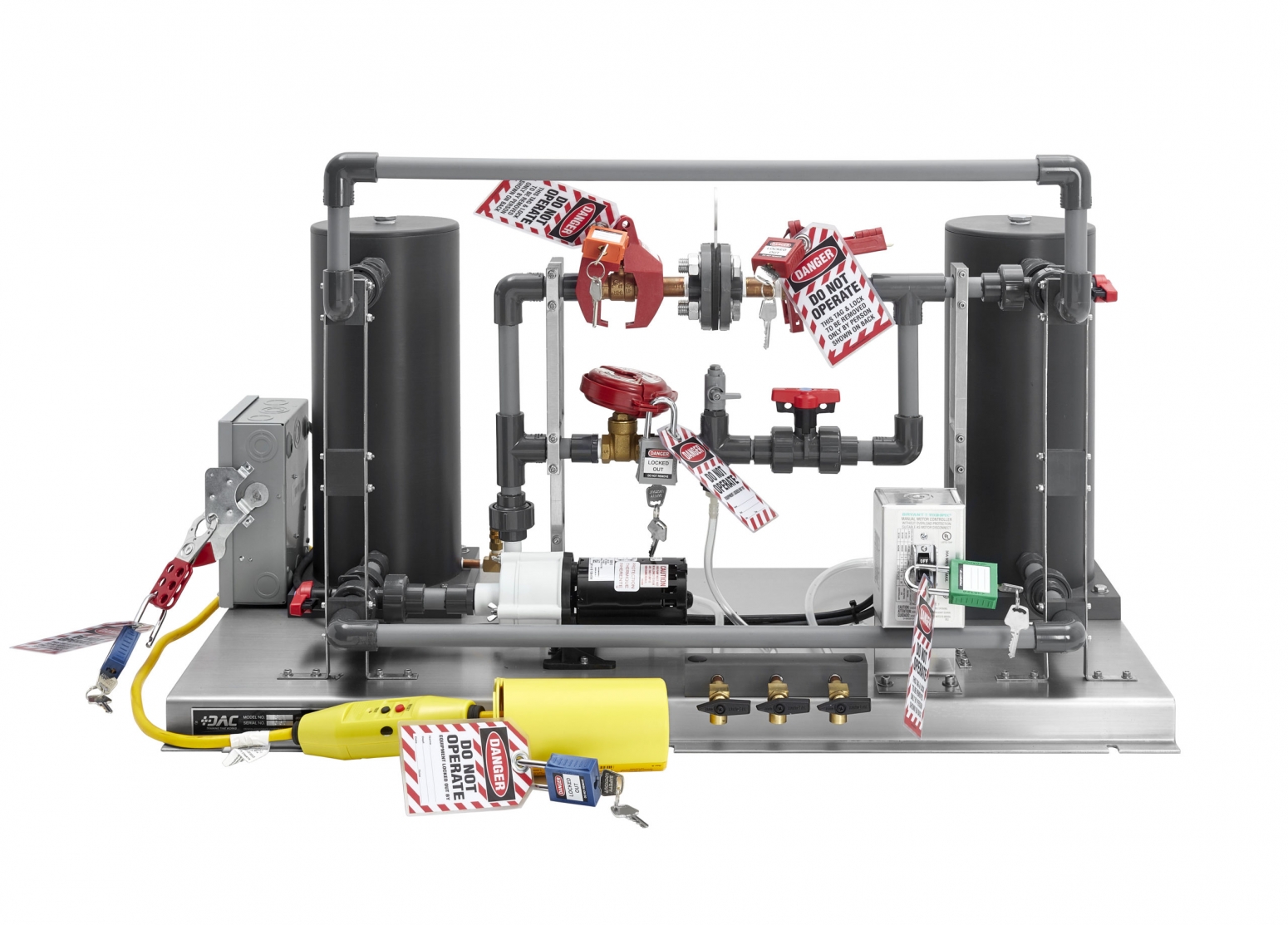

Kit Contents and Specifications

Each LOTO kit must include standardized components, such as:

– Lockout hasps and lockout devices (breaker locks, valve locks, etc.)

– Safety padlocks (keyed-alike or keyed-different per site policy)

– Warning tags (bilingual if required)

– Tie-wraps, cable lockouts, and plug lockouts

– Instruction cards or checklists

– Personal protective equipment (PPE) tags (optional but recommended)

Components must be durable, legible, and resistant to environmental conditions (e.g., moisture, heat, chemicals).

Inventory Management and Distribution

- Maintain a central inventory log of all LOTO kits, including serial numbers, issue dates, and assigned custodians.

- Kits should be stored in accessible, designated locations (e.g., maintenance rooms, near high-risk equipment).

- Deploy kits based on departmental needs, equipment type, and risk assessment.

- Conduct quarterly audits to verify kit completeness and condition.

Training and Authorization

- Only authorized employees, as defined by OSHA standards, may use LOTO kits.

- Required training includes:

- Procedures for energy isolation

- Proper use of LOTO devices and tags

- Employee and authorized employee roles

- Retraining every 12 months or after procedural changes

- Documentation of training must be retained in personnel files.

Usage and Application Procedures

- Before maintenance, authorized personnel must:

- Notify affected employees

- Shut down equipment following established procedures

- Isolate all energy sources (electrical, pneumatic, hydraulic, thermal, etc.)

- Apply lockout devices and personal locks

- Attach tagout tags with employee name, date, and reason

- Verify zero energy state (test before touching)

- Each employee working on the equipment must apply their own lock (group lockout procedures apply for multiple workers).

Maintenance and Inspection

- Inspect LOTO kits monthly for missing, damaged, or worn components.

- Replace damaged or illegible tags and defective locks immediately.

- Store kits in dry, secure containers to prevent contamination or loss.

- Retire and destroy used or expired kits according to organizational waste protocols.

Recordkeeping and Audits

- Maintain records of:

- LOTO procedures for each piece of equipment

- Training completion

- Periodic inspections (annually, per OSHA)

- Incident reports involving LOTO failures

- Conduct annual audits to ensure compliance with internal policies and regulatory standards.

Non-Compliance and Corrective Actions

Failure to adhere to LOTO procedures may result in:

– Disciplinary action

– Increased risk of injury or fatality

– Regulatory citations and fines

Corrective actions must be documented and include retraining, procedural updates, or engineering controls as needed.

Conclusion

Proper logistics and compliance with LOTO kit protocols are essential for workplace safety and regulatory adherence. By following this guide, organizations can minimize the risk of hazardous energy releases and protect employees during equipment servicing.

Conclusion for Sourcing Lockout/Tagout (LOTO) Kits:

Sourcing high-quality Lockout/Tagout (LOTO) kits is a critical step in ensuring workplace safety, regulatory compliance, and the prevention of accidental energy release during equipment maintenance. After evaluating various suppliers, product features, durability, and compliance with OSHA and other safety standards, it is evident that investing in comprehensive, well-organized, and standardized LOTO kits significantly enhances operational safety and efficiency. Kits that are customizable, clearly labeled, and made from durable materials offer long-term value and reliability across diverse industrial environments. Furthermore, proper employee training and consistent implementation must accompany the deployment of these kits to maximize their effectiveness. In conclusion, selecting the right LOTO kits from reputable suppliers not only supports regulatory adherence but also fosters a strong safety culture, minimizing downtime, reducing injury risks, and protecting both personnel and equipment.