The global zipper market is experiencing steady growth, driven by rising demand from the apparel, luggage, and outdoor equipment sectors. According to Grand View Research, the global zippers market size was valued at USD 14.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A key segment within this market is locking zipper pulls—engineered components that prevent accidental opening and enhance functional security in high-performance products. With increasing consumer preference for durable and reliable fastening solutions, the demand for high-quality locking zipper pulls has surged, particularly in technical outerwear, military gear, and travel accessories. As supply chains evolve and sourcing priorities shift toward precision manufacturing and compliance, identifying leading manufacturers in this niche becomes critical for brands seeking reliability and scalability. Based on production capacity, innovation, global reach, and compliance standards, we profile the top 10 locking zipper pull manufacturers shaping the future of functional fastening systems.

Top 10 Locking Zipper Pull Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

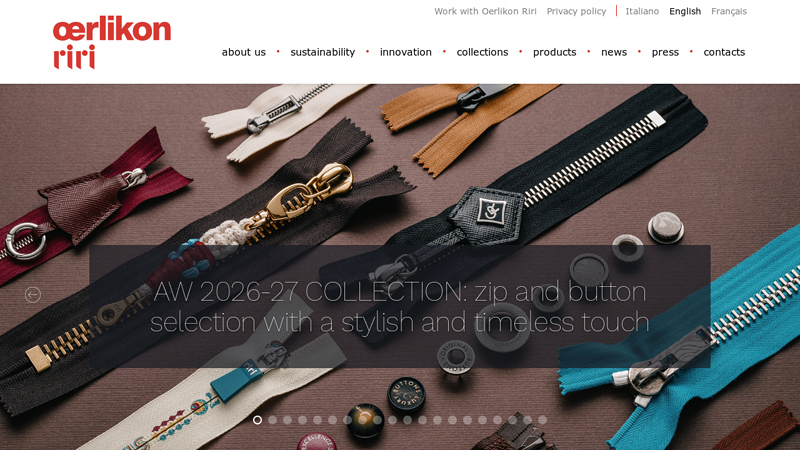

#1 RIRI excellence in details

Domain Est. 1995

Website: riri.com

Key Highlights: The group is one of the most authoritative producers of high-end accessories, which include zippers, buttons, metal components and fashion jewels….

#2 ZIPPERS

Domain Est. 2006

Website: taloninternational.com

Key Highlights: Talon International provides fully customized products and solutions for clients, ranging from zippers and packaging to trims and tags….

#3 Auto lock Zipper Slider Manufacturer Supplier Gold Black 5# Custom …

Domain Est. 2015

Website: zippermachine.com

Key Highlights: Zipper Slider Manufacturer Supplier offers high-quality Gold and Black 5# custom zipper pullers and heads. Perfect for luggage, handbags, and hardware ……

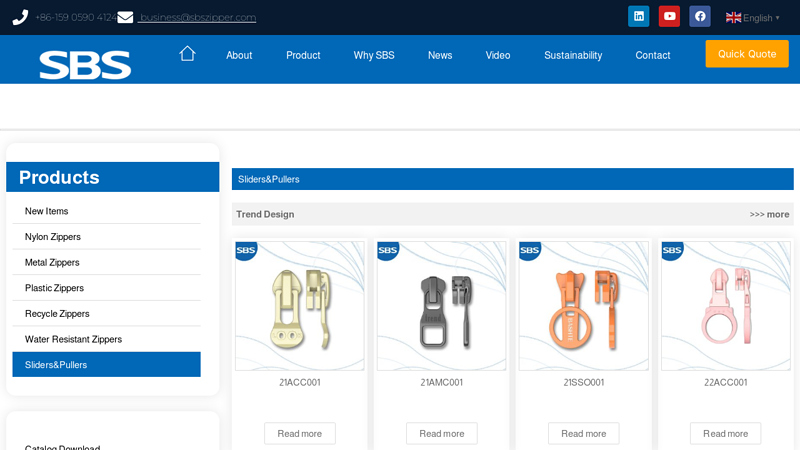

#4 Sliders&Pullers

Domain Est. 2016

Website: sbs-zipper.com

Key Highlights: +86-159 0590 4124; [email protected]. Linkedin Youtube Facebook. sbs logo · About · Who We are · Company Culture · Organization · FAQ · Contact Us….

#5 Zippers

Domain Est. 1999

Website: idealfastener.com

Key Highlights: The winner of the zipper popularity contest, the Coil Zip is crafted using polyester or nylon and plastic spiral coils. Popular because of its versatility, the ……

#6 Zipper Chain & Sliders

Domain Est. 1999

Website: johnhowardcompany.com

Key Highlights: Locking sliders are manufactured with a small pin between the teeth on the zipper chain. This locking pin prevents the slider from moving down ……

#7 YKK FASTENING PRODUCTS GROUP / The finest zipper company …

Domain Est. 2001

Website: ykkfastening.com

Key Highlights: The YKK Fastening Products Group is trusted world-wide for their impeccable production standards and thorough quality control processes for zippers, ……

#8 Zipper Pulls And Sliders

Domain Est. 2012

#9 SEARCH ITEM

Domain Est. 2021

Website: ykkdigitalshowroom.com

Key Highlights: NATULON Plus® Coil Zipper with Puckering Resistant Lightweight Tape. Organic Cotton Tape Zipper. VISLON® with Magnetic Closure and Rubber Ring Puller….

#10 Posi

Domain Est. 2021

Expert Sourcing Insights for Locking Zipper Pull

H2: 2026 Market Trends for Locking Zipper Pull

The global market for locking zipper pulls is poised for significant transformation by 2026, driven by rising demand for enhanced security, durability, and design innovation across consumer goods, travel, and outdoor industries. These small but critical components are increasingly being integrated into high-value products such as luggage, backpacks, protective gear, and security bags, where tamper resistance and ease of use are paramount.

One of the dominant trends shaping the 2026 landscape is the growing emphasis on anti-theft functionality. As personal safety and product security become top consumer priorities—especially in urban and travel environments—locking zipper pulls are evolving beyond basic zippers. Manufacturers are incorporating advanced locking mechanisms, including combination locks, key-based systems, and even smart-lock integrations with Bluetooth or RFID technology. This shift is particularly evident in the premium luggage and outdoor gear markets, where brands like Samsonite and The North Face are leading innovation.

Another key trend is material and sustainability advancement. By 2026, there is a rising demand for eco-friendly locking zipper pulls made from recycled metals, bioplastics, or bio-based polymers. Regulatory pressures and consumer preferences for sustainable products are pushing manufacturers to adopt greener production processes without compromising strength or security. Companies that align with circular economy principles—such as modular designs that allow for easy repair or recycling—are expected to gain competitive advantage.

In terms of regional dynamics, the Asia-Pacific region is anticipated to dominate production and consumption by 2026, fueled by robust manufacturing capabilities in China and Vietnam and increasing domestic demand from a growing middle class. Meanwhile, North America and Europe are expected to lead in innovation and adoption of high-tech locking solutions, particularly in sectors like law enforcement, military, and luxury fashion.

Additionally, customization and branding are becoming more prominent. Brands are using locking zipper pulls not just for function but as signature design elements—featuring logos, unique color schemes, or ergonomic shapes that enhance user experience and brand loyalty.

In summary, the 2026 market for locking zipper pulls will be defined by convergence: security meets smart technology, sustainability meets durability, and function meets fashion. Companies that invest in R&D, embrace sustainable practices, and respond to evolving consumer needs will be best positioned to thrive in this dynamic and expanding market.

Common Pitfalls When Sourcing Locking Zipper Pulls: Quality and Intellectual Property Risks

Logistics & Compliance Guide for Locking Zipper Pull

Product Overview

The Locking Zipper Pull is a secure fastening accessory designed to enhance the tamper-resistance of zippers on luggage, backpacks, travel bags, and other personal or commercial goods. It features a locking mechanism that prevents unauthorized access and provides an added layer of security during transport.

Regulatory Compliance

Ensure all Locking Zipper Pull units meet relevant international and regional regulations:

– REACH (EU): Compliant with Registration, Evaluation, Authorisation and Restriction of Chemicals. No restricted substances (e.g., phthalates, heavy metals) above permissible limits.

– RoHS (EU): If electronic components are included, ensure compliance with Restriction of Hazardous Substances.

– CPSIA (USA): Compliant with Consumer Product Safety Improvement Act, especially regarding lead and phthalate content for consumer goods.

– UKCA (UK): Conformity marking required for sale in Great Britain.

– Proposition 65 (California, USA): Provide appropriate warnings if components contain listed chemicals.

Packaging Requirements

- Use recyclable, minimal packaging to reduce environmental impact.

- Clearly label each package with product name, model number, country of origin, and safety warnings.

- Include multilingual instruction inserts if shipping internationally.

- Avoid excessive plastic; use biodegradable or FSC-certified materials where possible.

Shipping & Handling

- Dimensions & Weight: Standard unit dimensions: 2.5 x 1.5 x 0.8 cm; Weight: ~5g per unit. Packed in inner boxes of 100 units and master cartons of 1,000 units.

- Labeling: Include UPC/EAN codes, batch/lot numbers, and handling symbols (e.g., “Fragile,” “Do Not Stack”).

- Export Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin as needed.

- Incoterms: Clearly define responsibilities (e.g., FOB, DDP) in sales contracts.

Import/Export Regulations

- Verify tariff classification (HS Code: 9607.20 for zipper sliders/pulls).

- Confirm import duties and taxes in destination countries.

- Comply with customs requirements for metal components (e.g., steel, zinc alloy) in certain regions.

- For air freight: Ensure product contains no restricted materials under IATA Dangerous Goods Regulations.

Quality Assurance & Testing

- Conduct routine batch testing for mechanical strength, corrosion resistance, and lock functionality.

- Third-party lab certification (e.g., SGS, Intertek) recommended for global market access.

- Maintain traceability via batch numbering and quality control logs.

Storage Conditions

- Store in dry, temperature-controlled environments (15–30°C; 30–60% humidity).

- Keep away from direct sunlight and corrosive chemicals to prevent material degradation.

- Use palletized stacking with a maximum of 8 cartons high to prevent crushing.

Sustainability & Disposal

- Design for disassembly and recyclability.

- Provide end-of-life guidance: Metal components can be recycled through standard metal recovery channels.

- Align with corporate sustainability goals and ESG reporting requirements.

Customer Support & Recalls

- Establish a product registration system for traceability.

- Maintain a recall protocol compliant with local consumer safety authorities.

- Provide clear contact channels for compliance or defect reporting.

Summary

Adherence to this logistics and compliance guide ensures the safe, legal, and efficient distribution of Locking Zipper Pulls worldwide. Regular audits and updates to regulatory changes are essential for continued compliance.

Conclusion:

After thorough evaluation of various suppliers, material options, and manufacturing processes for sourcing locking zipper pulls, it is evident that selecting the right partner requires a balanced consideration of quality, cost, durability, and reliability. Locking zipper pulls are critical components in applications requiring security and ease of use—such as luggage, outdoor gear, and technical apparel—making performance and consistency key priorities.

Based on supplier assessments, domestic suppliers offer quicker turnaround and better communication, while overseas manufacturers—particularly in Asia—provide cost advantages at scale. However, quality control and lead times must be closely monitored. Materials such as zinc alloy, aluminum, and reinforced plastics each present trade-offs between strength, weight, and cost, with zinc alloy emerging as the preferred option for high-durability applications.

In conclusion, we recommend partnering with a pre-qualified supplier that demonstrates consistent quality control, compliance with industry standards, and the capability for customization and scalability. Implementing sample testing, periodic audits, and clear specifications will ensure long-term reliability. Strategic sourcing of locking zipper pulls not only supports product performance but also contributes to overall supply chain efficiency and customer satisfaction.