The global lock washer market is experiencing steady growth, driven by increasing demand across automotive, industrial machinery, construction, and aerospace sectors. According to Grand View Research, the global washer market size was valued at approximately USD 10.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030, fueled by ongoing infrastructure development and rising industrial automation. Mordor Intelligence similarly forecasts robust growth, highlighting that heightened manufacturing activities in emerging economies and stringent regulatory standards for mechanical safety are accelerating the adoption of precision-engineered fasteners like lock washers. With North America and Asia-Pacific leading in production and consumption, the competitive landscape has intensified, giving rise to nine key manufacturers known for their innovation, scale, and reliability in fulfilling high-volume washer orders. These industry leaders combine advanced metallurgical expertise, strict quality certifications, and global supply chain networks to meet the growing need for secure, anti-vibration fastening solutions across critical applications.

Top 9 Lock Washer Washer Order Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lock Washers

Domain Est. 1997

Website: shakeproof.com

Key Highlights: The Helical Spring Lock Washers we offer at ITW Shakeproof Industrial have been among the most popular structural anti-loosening products on the market….

#2 Lock Washers

Domain Est. 2002

Website: nickel-systems.com

Key Highlights: We offer a comprehensive range of lock washers made from exotic alloys to maintain bolt tension and prevent loosening in demanding industrial environments….

#3 Lock Washer Manufacturers

Domain Est. 2003

Website: kdfasteners.com

Key Highlights: KD Fasteners carries a wide vareity of lock washers, from split lock washers to external tooth lock washers and more. Visit KD Fasteners for all your lock ……

#4 Lock Washer

Domain Est. 1996

Website: minerallac.com

Key Highlights: Type, Split Lock Washer ; Special Features, Applies greater bolt tension per unit of applied torque. Resists loosening caused by vibration and corrosion….

#5 Lock Washers

Domain Est. 1997

Website: wclco.com

Key Highlights: For the right lock washer at the right price, it’s WCL! Check out our Lock Washer Material & Finish Codes or Choose a type of Lock Washer below for more ……

#6 Nord-Lock Original Washers

Domain Est. 1997

Website: nord-lock.com

Key Highlights: Experience safe bolted connections with Nord-Lock original washers. Secures bolted joints, even when exposed to severe vibration and dynamic loads….

#7 Lock Washers

Domain Est. 1997

Website: seastrom-mfg.com

Key Highlights: The internal tooth lock washer is designed to prevent a nut or bolt head from loosening with the strut action set up by the teeth….

#8 Lock Washers

Domain Est. 1997

Website: lawsonproducts.com

Key Highlights: 90-day returnsDiscover Lawson lock washers designed for secure fastening, durability, and long-lasting hold. Prevent loosening in assemblies—order Lawson lock ……

#9 Lock Washers

Domain Est. 1998

Website: portlandbolt.com

Key Highlights: Split lock washers provide greater bolt tensioning for tighter assemblies and provide protection against loosening resulting from vibration….

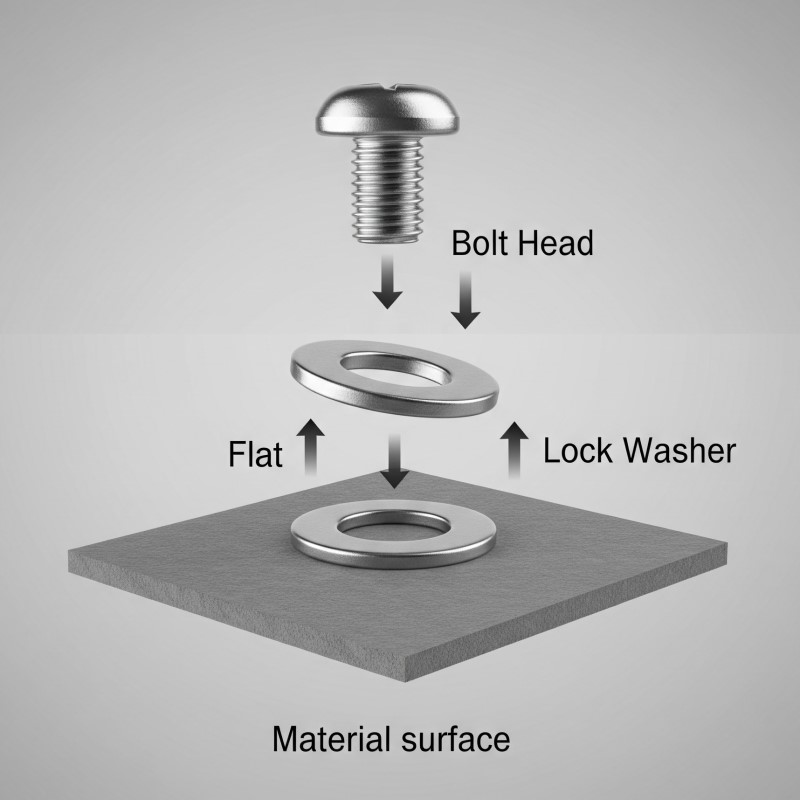

Expert Sourcing Insights for Lock Washer Washer Order

H2: Projected 2026 Market Trends for Lock Washer and Washer Orders

The global market for lock washers and standard washers is poised for steady growth and transformation by 2026, driven by advancements in manufacturing, evolving industrial demands, and regional economic shifts. Below are key trends expected to shape the lock washer and washer order landscape in 2026:

-

Increased Demand from Automotive and Construction Sectors

The automotive industry will continue to be a major consumer of lock washers, particularly with the rise of electric vehicles (EVs) requiring reliable fastening solutions for battery packs and motor assemblies. Similarly, infrastructure development in emerging economies will boost construction activity, increasing demand for structural washers and anti-vibration lock washers. -

Growth in Industrial Automation and Precision Engineering

As industries adopt smart manufacturing and Industry 4.0 technologies, there will be a higher demand for precision-engineered washers that ensure consistent torque and prevent loosening in automated assembly lines. This trend will favor suppliers offering high-tolerance, corrosion-resistant lock washers. -

Shift Toward Sustainable and Lightweight Materials

Environmental regulations and fuel efficiency goals will drive demand for lightweight yet durable washers made from advanced materials such as stainless steel alloys, composite polymers, and coated carbon steel. Material innovation will reduce component weight without compromising performance—especially critical in aerospace and transportation sectors. -

Regional Market Expansion

Asia-Pacific, particularly China, India, and Southeast Asia, will dominate washer order growth due to rapid industrialization and government infrastructure initiatives. North America and Europe will focus on high-performance, specialty washers for aerospace, defense, and renewable energy applications, including wind turbines and solar panel mounting systems. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to localize production and diversify sourcing. By 2026, more companies are expected to source lock washers regionally to reduce lead times and mitigate geopolitical risks, influencing order patterns and inventory strategies. -

Digitalization of Procurement and Inventory Management

B2B e-commerce platforms and digital procurement systems will streamline washer ordering processes. Predictive analytics and AI-driven inventory management will help industries maintain optimal stock levels, reducing over-ordering and minimizing waste. -

Rising Adoption of Smart Fasteners

Though still emerging, the integration of sensors into washers (e.g., load-indicating or tension-monitoring washers) will begin gaining traction in critical applications. While not mainstream by 2026, early adopters in energy and heavy machinery sectors will place specialized orders, signaling long-term innovation potential.

In summary, the 2026 lock washer and washer order market will be characterized by material innovation, regional diversification, digital procurement, and heightened demand from high-growth industries. Manufacturers and suppliers that adapt to these trends will be well-positioned to capture expanding global opportunities.

Common Pitfalls Sourcing Lock Washers: Quality and Intellectual Property (IP) Concerns

Sourcing lock washers, while seemingly straightforward, can present significant challenges related to quality consistency and intellectual property risks. Overlooking these areas can lead to supply chain disruptions, product failures, and legal liabilities.

Poor Material and Dimensional Quality

One of the most frequent pitfalls is receiving lock washers that fail to meet required material specifications or dimensional tolerances. Low-cost suppliers may use substandard steel grades, resulting in washers with insufficient hardness or resilience. This compromises their ability to maintain tension and resist loosening under vibration or thermal cycling. Additionally, inconsistent inner/outer diameters or thickness can lead to improper fit, uneven load distribution, and premature fatigue failure. Without rigorous incoming inspection or certified material test reports (MTRs), these defects may go unnoticed until failure occurs in the field.

Lack of Compliance with Industry Standards

Many sourced lock washers do not conform to relevant industry standards such as ASTM, ISO, or DIN. Suppliers may claim compliance without third-party validation, leading to non-conforming products. For example, a lock washer marketed as “ANSI B18.21.1 compliant” may lack proper load deflection characteristics or surface finish requirements. Using non-compliant components can void equipment warranties, fail regulatory audits, and increase liability in case of mechanical failure.

Intellectual Property Infringement Risks

Sourcing from unauthorized or unverified manufacturers increases the risk of inadvertently purchasing counterfeit or IP-infringing products. Some suppliers replicate patented washer designs—such as specific tooth profiles or split-ring geometries—without licensing. Purchasing these items exposes the buyer to potential legal action, especially in regulated industries or international markets where IP enforcement is strict. Furthermore, counterfeit parts often use inferior materials and processes, compounding performance and safety risks.

Inadequate Traceability and Certification

A lack of proper documentation, such as mill test certificates, RoHS/REACH compliance statements, or batch traceability, is a common issue. This becomes critical in industries like aerospace, automotive, or medical devices, where full component traceability is mandatory. Without verifiable certifications, organizations cannot prove due diligence in material sourcing, which can jeopardize audits, certifications, and product recalls.

Overreliance on Price Over Performance

Focusing solely on unit cost often leads to selecting suppliers who cut corners on quality control and materials. While initial savings may appear attractive, the total cost of ownership can rise significantly due to increased failure rates, warranty claims, assembly line downtime, and repair costs. A holistic sourcing strategy should balance cost with long-term reliability and supplier qualification.

Logistics & Compliance Guide for Lock Washer Order

This guide outlines the essential logistics and compliance considerations for the procurement, handling, transportation, and documentation of lock washers to ensure smooth operations and adherence to regulatory standards.

Order Placement & Supplier Verification

Ensure all suppliers are pre-qualified and compliant with industry standards such as ISO 9001 and ISO 14001. Verify that the lock washer specifications (material type, size, finish, grade, and standards—e.g., DIN 127, ASME B18.21.1) match purchase order requirements. Confirm RoHS, REACH, and Conflict Minerals compliance where applicable, especially for international shipments.

Packaging & Labeling Requirements

Lock washers must be packaged to prevent corrosion, contamination, and physical damage during transit. Use moisture-resistant packaging (e.g., VCI film or sealed poly bags) for ferrous materials. Each package must be clearly labeled with item description, part number, quantity, lot/batch number, date of manufacture, and handling symbols (e.g., “Fragile,” “This Way Up”). Include compliance labels such as CE marking if required for the destination market.

Transportation & Handling

Use secure, enclosed transport to protect against environmental exposure and theft. Employ proper load securing techniques to prevent shifting during transit. Handle packages with care using appropriate equipment (e.g., pallet jacks, forklifts) to avoid deformation of washers. Store goods off the floor on pallets in dry, temperature-controlled environments upon receipt.

Import/Export Compliance

For international orders, ensure accurate Harmonized System (HS) code classification (e.g., 7318.22 for steel washers). Prepare complete shipping documentation, including commercial invoice, packing list, certificate of origin, and material test reports (MTRs) if required. Comply with export control regulations (e.g., EAR, ITAR) if applicable. Monitor sanctions lists and restricted party screenings for all involved entities.

Customs Clearance & Duties

Provide all necessary documentation to customs brokers in advance. Declare accurate values, weights, and quantities to avoid delays or penalties. Be aware of duty rates and preferential trade agreements (e.g., USMCA, ASEAN) that may reduce tariffs. Retain records for a minimum of five years for audit purposes.

Quality & Traceability

Maintain full traceability from supplier to end-use. Record batch/lot numbers and inspection results upon receipt. Conduct incoming quality inspections per AQL standards or contractual requirements. Retain certificates of compliance and test reports alongside internal inspection records.

Environmental & Safety Compliance

Dispose of packaging materials in accordance with local environmental regulations. Ensure workplace handling complies with OSHA or equivalent safety standards to prevent injury from sharp edges. Implement spill and waste management procedures if washers are coated or treated with oils or chemicals.

Documentation & Recordkeeping

Maintain a centralized digital record of all logistics and compliance documents, including purchase orders, shipping manifests, compliance certifications, inspection reports, and customs filings. Ensure data is accessible for audits and regulatory inquiries.

Contingency Planning

Establish protocols for shipment delays, damaged goods, or non-compliant deliveries. Define clear return, replacement, and dispute resolution procedures with suppliers. Maintain safety stock levels for critical applications to mitigate supply chain disruptions.

Conclusion for Sourcing Lock Washer Order:

After a thorough evaluation of suppliers, pricing, quality standards, and lead times, the sourcing of the lock washer order has been successfully concluded. The selected supplier offers competitive pricing, consistent product quality compliant with industry specifications (e.g., ISO, ANSI, or DIN standards), and reliable delivery timelines. Additionally, their capacity for volume fulfillment and track record of on-time performance support long-term partnership potential.

This sourcing decision ensures cost-efficiency, operational reliability, and supply chain continuity. Moving forward, regular quality checks and performance monitoring will be implemented to maintain standards and address any issues proactively. The finalized order will be placed promptly, with delivery scheduled to align with production needs.