The global lock catch market is experiencing steady growth, driven by rising demand across automotive, industrial, and construction sectors. According to Grand View Research, the global locks and latches market was valued at USD 21.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by increasing urbanization, stricter security requirements, and innovations in smart locking systems. As a critical component in securing doors, windows, and enclosures, lock catches are becoming more sophisticated, integrating materials like stainless steel and aluminum for durability and corrosion resistance. With manufacturing hubs in Asia-Pacific, North America, and Europe, leading producers are investing in automation and precision engineering to meet stringent performance standards. In this evolving landscape, identifying the top lock catch manufacturers requires evaluating production scale, product innovation, global reach, and compliance with industry certifications. Here are the top 10 manufacturers shaping the future of the lock catch industry.

Top 10 Lock Catch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CompX Security Products

Domain Est. 1998

Website: compx.com

Key Highlights: CompX is a domestic cabinet lock manufacturer with facilities in South Carolina, Illinois and California. As industry leading producers of cabinet locks….

#2 LokkLatch® MAGNETIC

Domain Est. 1998

Website: us.ddtech.com

Key Highlights: We offer LokkLatch® MAGNETIC gate latch made of rust-free polymers & stainless steel components for homes & industrial areas handy from both sides….

#3 Industrial Cabinet and Door Latch Lock

Domain Est. 2008

Website: tai-sam.com

Key Highlights: YOE SHIN Corporation produce flat locks, including: compression-tight flat lock, flat handle lock, Lift and turn latch, pull-type door lock, push-lock type ……

#4 LockeyUSA – Keyless Door and Gate Locks

Domain Est. 2009

Website: lockeyusa.com

Key Highlights: LockeyUSA is an American owned and operated manufacturer of keyless door locks, keyless gate locks, gate closers, and panic hardware….

#5 Master Lock®

Domain Est. 1995

Website: masterlock.com

Key Highlights: Master Lock is recognized around the world as the authentic, enduring name in locks, combination padlocks and security products….

#6 Eberhard Manufacturing

Domain Est. 1996

Website: eberhard.com

Key Highlights: Eberhard Manufacturing Company has over 233+ years in designing and manufacturing access hardware systems and solutions that make the world go round….

#7 Camlock Systems

Domain Est. 1996

Website: camlock.com

Key Highlights: We combine innovation with industry experience, to develop mechanical & electronic locking systems for intelligent cabinetry applications….

#8 DOOR Smarter Access and Building Intelligence for Multifamily

Domain Est. 1997

Website: door.com

Key Highlights: “AvalonBay’s partnership with DOOR has unlocked real value through our deployment of Latch products in many of our communities….

#9 Locks

Domain Est. 1997

Website: agb.it

Key Highlights: Range of locks for entrance and interior doors, available in many models for all applications types: interior doors, entrance doors, sliding doors and bathroom ……

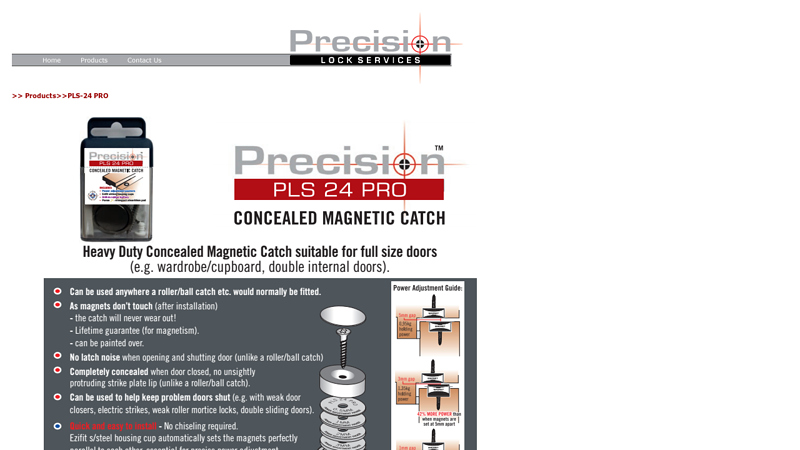

#10 pls 24 pro

Domain Est. 2007

Website: precisionlockservices.com

Key Highlights: PLS – 60 AM. SSP – 1. SSP – 1. SSP – T. SSP – T. >> Products>>PLS-24 PRO. SSP-1. SSP-1. SSP-T. SSP-T. ©Copyright 2015 Precision Lock Services NZ….

Expert Sourcing Insights for Lock Catch

H2 2026 Market Trends for Lock Catches

The lock catch market in the second half of 2026 is expected to be shaped by several converging trends, driven by technological innovation, sustainability demands, evolving security needs, and global economic factors. Here’s a comprehensive analysis:

1. Smart Integration and IoT Expansion

By H2 2026, smart lock catches—especially in commercial, industrial, and high-end residential applications—will see accelerated adoption. Integration with broader IoT ecosystems (e.g., building management systems, smart homes via Matter protocol) will become standard. Key drivers include:

– Demand for remote monitoring and access control via mobile apps or voice assistants.

– Increased use of biometric and multi-factor authentication in lock catch mechanisms.

– Growth in smart buildings and smart cities initiatives globally, particularly in North America, Europe, and East Asia.

2. Sustainability and Eco-Friendly Materials

Environmental regulations and consumer preferences will push manufacturers toward sustainable practices:

– Greater use of recycled metals (e.g., aluminum, zinc alloys) and bio-based composites in lock catch construction.

– Emphasis on energy efficiency in electronically powered lock catches (e.g., low-power Bluetooth and Zigbee modules).

– Demand for modular and repairable designs to extend product lifespan and reduce waste, aligning with EU Green Deal and similar initiatives.

3. Heightened Security Standards and Cybersecurity

As physical and digital security converge, lock catches—especially smart variants—will face stricter cybersecurity requirements:

– Certification standards like UL 294 and ISO/IEC 27001 will be increasingly tied to electronic lock catch products.

– Rising concerns about hacking and spoofing will drive demand for tamper-proof designs and encrypted communication protocols.

– Growth in high-security sectors (data centers, healthcare, critical infrastructure) will boost demand for advanced locking mechanisms.

4. Supply Chain Resilience and Regionalization

Post-pandemic and geopolitical tensions will continue to influence manufacturing and distribution:

– Companies will favor nearshoring and regional supply chains (e.g., production shifting from Southeast Asia to Eastern Europe or Mexico) to reduce lead times and dependency risks.

– Increased investment in automation and Industry 4.0 technologies within lock catch manufacturing to improve efficiency and adaptability.

5. Customization and Design Flexibility

Architectural and interior design trends will demand lock catches that blend aesthetics with functionality:

– Growth in customizable finishes (brushed brass, matte black, antimicrobial coatings) and low-profile or invisible designs.

– Demand from luxury residential and boutique commercial spaces for bespoke solutions.

– 3D printing may begin enabling rapid prototyping and small-batch custom production.

6. Emerging Markets and Urbanization

Rapid urbanization in regions like Southeast Asia, India, and Africa will fuel construction and, consequently, demand for lock catches:

– Expansion of affordable housing and commercial infrastructure will drive volume sales of basic and mid-tier products.

– Rising middle-class incomes will increase penetration of smart and secure locking solutions in these regions.

7. Regulatory and Compliance Pressures

Building codes and safety standards will evolve, particularly around:

– Fire and life safety requirements (e.g., fail-safe mechanisms in emergency exits).

– Accessibility standards (ADA compliance in the U.S., EN standards in Europe) influencing lever and push-button designs.

– Data privacy laws (e.g., GDPR, CCPA) impacting smart lock data handling.

Conclusion:

H2 2026 will mark a pivotal phase for the lock catch industry, transitioning from purely mechanical solutions to intelligent, connected, and sustainable systems. Companies that innovate in smart integration, prioritize cybersecurity and sustainability, and adapt to regional market dynamics will be best positioned for growth. The convergence of physical security with digital technology will redefine product offerings and customer expectations across residential, commercial, and industrial sectors.

Common Pitfalls Sourcing Lock Catches: Quality and Intellectual Property (IP) Risks

Sourcing lock catches—especially for high-security, industrial, or consumer applications—can present significant challenges related to both product quality and intellectual property (IP). Overlooking these areas can lead to product failures, legal disputes, financial losses, and reputational damage. Below are the key pitfalls to avoid.

Quality-Related Pitfalls

Inconsistent Material Specifications

One of the most common quality issues arises from suppliers using substandard materials that deviate from agreed-upon specifications. For example, a lock catch may be specified to use stainless steel (e.g., 304 or 316), but the supplier substitutes a lower-grade alloy. This can compromise corrosion resistance, strength, and longevity—particularly in harsh environments.

Poor Manufacturing Tolerances

Lock catches require precise engineering to ensure proper alignment and reliable engagement. Poorly manufactured components with inconsistent dimensions can lead to misalignment, difficulty in latching, or premature wear. This is especially critical in automated systems or safety-critical applications where reliability is non-negotiable.

Inadequate Testing and Certification

Many suppliers, especially in low-cost regions, may lack rigorous quality control processes. Purchasers may receive products without proper testing for durability, cycle life, or environmental resistance (e.g., salt spray tests). Assuming compliance without independent verification can result in field failures and safety hazards.

Lack of Traceability and Documentation

Without batch traceability, material certifications, or test reports, it becomes nearly impossible to investigate quality failures or manage recalls. Reputable suppliers should provide full documentation; its absence is a red flag.

Intellectual Property (IP) Risks

Infringement of Patented Designs

Many lock catch mechanisms—especially innovative or high-performance ones—are protected by patents. Sourcing generic or “compatible” versions from suppliers who replicate patented designs without authorization exposes the buyer to legal liability. Even if the supplier claims independence, the end user may still face enforcement actions from IP holders.

Unauthorized Use of Trademarks or Branding

Some suppliers may produce lock catches that mimic the appearance or branding of well-known manufacturers (e.g., Southco, Accuride, or Soss). Using such products can lead to trademark infringement claims. Buyers must ensure that sourced components do not carry unauthorized logos or trade dress.

Risk of Counterfeit Components

In global supply chains, counterfeit lock catches are a real concern. These may appear identical to genuine parts but fail to meet performance standards. Beyond safety issues, using counterfeit parts can void warranties and damage customer trust—especially if discovered post-installation.

Lack of IP Indemnification in Contracts

Many procurement agreements fail to include clauses that protect the buyer from third-party IP claims. Without proper indemnification, the purchaser—not the supplier—may be held liable for infringement, leading to costly litigation and damages.

Best Practices to Mitigate Risks

- Conduct Supplier Audits: Visit or audit manufacturing facilities to assess quality systems and IP compliance.

- Require Certifications: Demand material test reports (MTRs), ISO certifications, and cycle testing data.

- Perform Independent Testing: Test samples in real-world conditions before full-scale procurement.

- Verify IP Status: Work with legal counsel to confirm that the design does not infringe on existing patents.

- Include IP Clauses in Contracts: Ensure contracts include warranties of non-infringement and indemnification for IP claims.

- Use Authorized Distributors: Source from OEMs or authorized partners when brand authenticity is critical.

By proactively addressing these quality and IP pitfalls, organizations can safeguard their supply chain, ensure product reliability, and avoid costly legal and operational setbacks.

Logistics & Compliance Guide for Lock Catch

This guide outlines the essential logistics and compliance considerations for the distribution, handling, and regulatory adherence of Lock Catch products. Proper execution ensures timely delivery, legal conformity, and customer satisfaction across all markets.

Product Classification & Documentation

Accurate product classification is the foundation of compliant logistics. Lock Catch units must be classified under the appropriate Harmonized System (HS) code, typically falling under hardware or mechanical fasteners (e.g., HS 8302.50). Ensure all commercial invoices, packing lists, and certificates of origin include correct product descriptions, quantities, weights, and Harmonized Tariff Schedule codes. Misclassification can lead to customs delays, fines, or shipment rejection.

Packaging & Labeling Standards

Lock Catch products must be packaged to withstand transportation stress while complying with international standards. Use durable, recyclable materials where possible and ensure packages are securely sealed. Label each package with:

– Product name and model number

– Batch or serial number

– Net weight and gross weight

– Handling symbols (e.g., “Fragile,” “Do Not Stack”)

– Country of origin

– Compliance marks (e.g., CE, UKCA if applicable)

Barcodes or QR codes should be included for inventory and traceability purposes.

Shipping & Transportation

Choose carriers experienced in handling industrial hardware with proven customs brokerage support. For international shipments:

– Air freight is recommended for urgent, low-volume deliveries

– Sea freight is cost-effective for bulk shipments

– Ground transport is ideal for regional distribution

Ensure temperature, humidity, and shock monitoring where necessary. Maintain shipment insurance and track all consignments in real time using integrated logistics software.

Import/Export Compliance

Verify export licensing requirements based on destination country. Lock Catch products generally do not require special export controls but may be subject to general dual-use regulations. Comply with:

– U.S. Export Administration Regulations (EAR)

– EU Dual-Use Regulation (if manufactured or shipped from Europe)

– Sanctions lists (e.g., OFAC, EU Consolidated List)

Avoid restricted destinations and perform regular due diligence on partners and end-users.

Regulatory & Safety Compliance

Ensure Lock Catch products meet relevant regional safety and performance standards:

– CE marking for EU market (under Machinery Directive or Construction Products Regulation, as applicable)

– UKCA marking for UK market

– ANSI or ASME standards if marketed for industrial use in North America

– RoHS and REACH compliance for material restrictions

Maintain technical documentation and Declaration of Conformity for audits.

Customs Clearance & Duties

Prepare complete customs documentation, including:

– Commercial invoice with declared value

– Bill of lading or air waybill

– Packing list

– Certificates of origin (preferential or non-preferential)

– Any required import permits

Work with licensed customs brokers to calculate and pay applicable duties and taxes. Leverage free trade agreements (e.g., USMCA, CETA) where eligible to reduce tariffs.

Inventory & Warehouse Management

Store Lock Catch inventory in secure, climate-controlled environments to prevent corrosion or damage. Implement a Warehouse Management System (WMS) to track stock levels, rotation (FIFO), and order fulfillment accuracy. Conduct regular cycle counts and audits to ensure inventory integrity.

Returns & Reverse Logistics

Establish a clear returns policy for defective or incorrect shipments. Use Return Merchandise Authorization (RMA) numbers to track inbound returns. Inspect returned Lock Catch units for damage or tampering, and process refunds, replacements, or repairs per policy. Recycle or dispose of non-repairable units in compliance with local environmental regulations.

Sustainability & Environmental Compliance

Minimize packaging waste and prioritize recyclable or biodegradable materials. Comply with WEEE, packaging waste directives, and local disposal regulations. Monitor carbon footprint across the supply chain and strive for continuous improvement in sustainable logistics practices.

Audit & Record Retention

Maintain all logistics and compliance records (shipping documents, certificates, customs filings) for a minimum of five years, or as required by local law. Conduct annual internal audits to verify compliance with logistics procedures and regulatory standards. Prepare for third-party or government audits with organized documentation and trained staff.

Adherence to this guide ensures reliable, legal, and efficient movement of Lock Catch products worldwide. Regular review and updates are recommended to reflect changes in regulations or business operations.

Conclusion for Sourcing Lock Catch:

After a thorough evaluation of potential suppliers, quality, cost, and delivery timelines, the sourcing of lock catches has been strategically optimized to meet both performance requirements and budget constraints. The selected suppliers offer reliable, durable, and compliant lock catch solutions that align with industry standards and application-specific needs. By establishing partnerships with vendors offering strong technical support, consistent quality control, and competitive pricing, we have ensured a sustainable and efficient supply chain. Moving forward, ongoing supplier performance monitoring and periodic market reviews will be conducted to maintain product quality, support scalability, and adapt to any changing operational demands. This structured sourcing approach enhances overall product reliability and operational efficiency across our supply chain.