The load cell manufacturing industry in India is witnessing robust growth, driven by increasing automation across sectors such as automotive, industrial manufacturing, logistics, and food & beverage. According to a report by Mordor Intelligence, the India industrial automation market is projected to grow at a CAGR of over 9.5% during the forecast period of 2023–2028, with load cells serving as critical components in precision weighing systems. Additionally, Grand View Research estimates that the global load cell market size was valued at USD 1.8 billion in 2022 and is expected to expand at a CAGR of 6.4% from 2023 to 2030, fueled by rising demand for high-accuracy measurement solutions. As India strengthens its position as a manufacturing hub under initiatives like “Make in India,” domestic load cell manufacturers are scaling innovation and production to meet both local and international standards. This growing ecosystem has given rise to a competitive landscape of reliable and technologically advanced Indian suppliers catering to diverse industrial needs.

Top 10 Load Cell In India Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Load Cells Manufacturer,Precision Load Cells Supplier …

Domain Est. 2010

Website: hariom-loadcell.com

Key Highlights: HARIOM ELECTRONICS is a ZED Silver Certified and IIM Alumni-led manufacturer of LOADPIN® brand precision load cells, force sensors, and torque transducers….

#2 HBM: Test & Measurement

Domain Est. 1998

Website: hbm.com

Key Highlights: As a technology and market leader worldwide, HBM offers products for test and measurement including load cells, transducers, and strain gauges….

#3 Load Cells

Domain Est. 1999

Website: ipaindia.com

Key Highlights: We are a leading manufacturer of loadcells. We have our own in-house machining center and have total quality control on the process….

#4 Load Cell, S Type Load Cell, Shear Beam Load Cell Manufacturer …

Domain Est. 2007

Website: rudrra.com

Key Highlights: Rudrra Sensor is one of the leading manufacturers and suppliers of Load Cells, S Type Load Cells, Shear Beam Load Cell, Weighing Controller, and other force ……

#5 Sharp Electronics, Pune

Domain Est. 2011

Website: sharpweighingscale.com

Key Highlights: We are leading Load Cell Manufacturers of Load Cell and Weighing Scale Manufacturers in Pune, India. We are leading Manufacturers, Suppliers of Load Cell, ……

#6 Load Cell Manufacturers in India

Domain Est. 2014

Website: sensomaticloadcell.net

Key Highlights: We are manufactures and suppliers of high precision custom-built load cells for a wide range of applications; For the best load cell manufacture in India….

#7 Flintec

Domain Est. 2001

Website: flintec.com

Key Highlights: Flintec designs and manufactures high-quality load cells and force measurement technologies. View our standard products or discuss a custom solution with ……

#8 Sushma Industries

Domain Est. 2002

Website: sushmaindustries.com

Key Highlights: We design, develop & manufacture reliable & accurate Strain-gauge based Force,Torque, Pressure sensors with over 80 models & capacities….

#9 Epoch Load Cell

Domain Est. 2011

Website: epochloadcell.com

Key Highlights: Epoch Load Cell has a team of expert manufactures in Bangalore for load cells, weight transducer and aircraft weighing. Our load cell dealers are active ……

#10 Sensomatic

Domain Est. 2024

Website: sensomatic.co

Key Highlights: We are India’s leading manufacturer and supplier of Universal Load Cell, Double Ended Shear Beam Load Cells, S Type Load Cells, Button Type Load ……

Expert Sourcing Insights for Load Cell In India

2026 Market Trends for Load Cells in India

The load cell market in India is poised for significant growth by 2026, driven by increasing industrial automation, advancements in smart manufacturing, and rising demand across key sectors such as automotive, aerospace, logistics, and process industries. This analysis explores the key trends shaping the Indian load cell market in 2026.

Rising Industrial Automation and Smart Manufacturing

One of the primary drivers of the load cell market in India is the nationwide push toward industrial automation and the adoption of Industry 4.0 principles. As Indian manufacturers upgrade their production facilities to improve efficiency and reduce human error, the demand for precision measurement devices like load cells is surging. Load cells are essential in automated weighing systems, robotic assembly lines, and quality control mechanisms.

By 2026, the integration of load cells with IoT-enabled platforms and real-time data analytics is expected to become standard in smart factories. This trend is supported by government initiatives such as “Make in India” and “Digital India,” which promote technological modernization across manufacturing sectors.

Expansion in the Logistics and E-Commerce Sectors

India’s booming e-commerce industry is fueling demand for high-accuracy weighing solutions in logistics and warehousing operations. With the rise in online shopping and same-day delivery expectations, logistics companies are investing in automated sorting systems, conveyor belt scales, and dynamic weighing platforms — all of which rely heavily on load cells.

By 2026, the need for rugged, high-capacity, and corrosion-resistant load cells is expected to grow, especially in regional distribution centers and automated fulfillment hubs. The trend is further amplified by the expansion of cold chain logistics and pharmaceutical supply chains, where precise weight monitoring is critical.

Growth in the Automotive and Aerospace Industries

The automotive sector in India continues to adopt advanced manufacturing technologies, including automated testing and quality assurance systems. Load cells are integral to vehicle testing rigs, engine calibration, and torque measurement during production. As electric vehicle (EV) manufacturing gains momentum, specialized load cells for battery testing and EV component validation are in rising demand.

Similarly, the aerospace and defense sector is seeing increased investments in indigenous production and R&D. Load cells are used in structural testing, thrust measurement, and load simulation. By 2026, India’s growing aerospace ambitions, supported by public-private partnerships, are expected to generate strong demand for high-precision and high-reliability load cells.

Advancements in Load Cell Technology

Technological innovations are enhancing the performance and versatility of load cells. By 2026, Indian industries are expected to increasingly adopt digital load cells with built-in signal conditioning, wireless connectivity, and self-diagnostic features. These advancements reduce maintenance costs and improve system uptime.

Miniaturization and improved materials (e.g., stainless steel, aluminum alloys) are enabling load cells to operate in harsh environments, including high temperatures, humidity, and corrosive conditions. Additionally, the integration of AI algorithms for predictive maintenance and anomaly detection is emerging as a competitive advantage for load cell manufacturers.

Regulatory and Standardization Developments

As India strengthens its metrology and quality control frameworks, adherence to international standards (such as OIML, NIST, and ISO) is becoming mandatory in many industries. This regulatory shift is encouraging end-users to upgrade to certified, high-accuracy load cells.

By 2026, the Bureau of Indian Standards (BIS) is expected to enforce stricter compliance for weighing instruments used in trade, healthcare, and safety-critical applications. This will drive demand for calibrated and traceable load cells, especially in the pharmaceutical, food & beverage, and retail sectors.

Competitive Landscape and Localization

The Indian load cell market is witnessing increased competition between global players and domestic manufacturers. While international brands dominate the high-precision segment, local companies are gaining ground by offering cost-effective, application-specific solutions.

By 2026, localization of production — supported by the Production Linked Incentive (PLI) scheme — is expected to reduce import dependency and lower costs. Indian manufacturers are also investing in R&D to develop smart load cells tailored for local industrial conditions.

Conclusion

The load cell market in India is on a robust growth trajectory, with a CAGR projected above 8% leading up to 2026. Key growth drivers include industrial automation, e-commerce expansion, technological innovation, and supportive government policies. As industries demand higher accuracy, reliability, and connectivity, load cell manufacturers — both domestic and international — will need to adapt through innovation and localization to capture emerging opportunities in India’s evolving industrial landscape.

Common Pitfalls Sourcing Load Cells in India (Quality, IP)

Sourcing load cells in India offers cost advantages and access to a growing manufacturing base, but buyers often encounter significant challenges related to quality consistency and intellectual property (IP) protection. Being aware of these pitfalls is crucial for ensuring reliable performance and safeguarding business interests.

Inconsistent Quality Standards and Certification Gaps

One of the most prevalent issues when sourcing load cells in India is the variability in product quality across suppliers. While some Indian manufacturers adhere strictly to international standards like OIML, NTEP, or ISO, many others produce load cells with inconsistent accuracy, durability, and temperature stability. Buyers may receive units that drift over time, fail under load, or lack proper calibration traceability. A frequent pitfall is the absence of third-party certification or the use of fabricated test reports, making it difficult to verify performance claims. Additionally, inconsistent manufacturing processes—such as poor strain gauge bonding, substandard sealing, or inadequate protection against moisture and corrosion—can compromise long-term reliability, especially in industrial environments.

Risk of Intellectual Property Infringement and Reverse Engineering

India’s manufacturing ecosystem, while innovative, sometimes lacks stringent enforcement of intellectual property rights, especially in the sensor and instrumentation sector. A major concern when sourcing load cells is the risk of IP infringement, where suppliers may replicate patented designs, circuitry, or calibration methodologies from established global brands without authorization. Buyers, particularly those integrating load cells into proprietary systems, may inadvertently expose themselves to legal risks or reputational damage. Moreover, some suppliers engage in reverse engineering of high-end load cells and market them as generic alternatives, which may not meet the original specifications. This not only undermines innovation but also increases the likelihood of performance failures in critical applications.

Lack of Transparency in Material Sourcing and Traceability

Many Indian load cell manufacturers do not provide full transparency about the origin and quality of core components such as strain gauges, cables, and weld materials. Low-cost suppliers may use imported substandard strain gauges or domestically produced materials that lack long-term reliability. The absence of material traceability makes it difficult to conduct root cause analysis in case of failure. This opacity also extends to production processes—some units may be assembled in non-controlled environments, increasing susceptibility to defects.

Inadequate Technical Support and Calibration Documentation

Post-purchase support is another common shortcoming. Some suppliers offer limited technical assistance, lack detailed product documentation, or fail to provide proper calibration certificates with serial-number traceability. This becomes a critical issue in regulated industries such as pharmaceuticals, food processing, or legal-for-trade weighing, where audit trails and compliance are mandatory. Buyers may find themselves without recourse when load cells malfunction or fail calibration checks in the field.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence—verifying certifications, auditing manufacturing facilities, requesting sample testing, and including IP protection clauses in contracts. Partnering with reputable, transparent suppliers and investing in quality assurance upfront can prevent costly failures and legal complications down the line.

Logistics & Compliance Guide for Load Cells in India

Overview of Load Cells and Their Regulatory Framework

Load cells, which are transducers that convert force into an electrical signal, are widely used in industrial weighing systems, manufacturing, logistics, and testing applications. When importing, transporting, or using load cells in India, businesses must comply with a range of regulatory and logistical requirements to ensure safety, accuracy, and legal operation.

Import Regulations and Customs Compliance

Load cells imported into India are typically classified under HSN Code 8423 81 00 (parts of weighing machinery). Importers must adhere to the following:

- Customs Duties: As of 2024, the basic customs duty (BCD) for load cells under this code is generally 7.5%, but preferential rates may apply under trade agreements.

- IGST: Integrated Goods and Services Tax (IGST) at 18% is levied on imports.

- Import Policy: Load cells fall under the “Free” import category, meaning no license is required for importation.

- Bill of Entry & Documentation: Required documents include commercial invoice, packing list, bill of lading/airway bill, import license (if applicable), and technical specifications.

- BIS Certification (if applicable): While not mandatory for all load cells, if the load cell is part of a weighing instrument used for trade, it may fall under BIS certification requirements.

Legal Metrology Act and Weighing Instruments

Under the Legal Metrology (Packaged Commodities) Rules, 2011, and the Legal Metrology Act, 2009, any weighing instrument used for trade, commerce, or certification must be approved:

- Approval of Weighing Instruments: If the load cell is used in a system that determines price by weight (e.g., in retail, transport, or manufacturing), the entire weighing instrument must be verified and stamped by the State Legal Metrology Department.

- Indian Type Approval (ITA): Weighing systems incorporating load cells must obtain ITA from the Department of Legal Metrology before sale or use in commercial applications.

- Annual Verification: Commercial weighing instruments must undergo annual verification and stamping by authorized inspectors.

Bureau of Indian Standards (BIS) Compliance

While standalone load cells are not currently under mandatory BIS certification, if they are part of a system covered under BIS schemes, compliance becomes essential:

- Relevant Standards: IS 1248 (specifications for load cells) and IS 11654 (for electronic weighing instruments) provide technical guidelines.

- Voluntary Certification: Manufacturers may opt for BIS certification to improve market credibility and ensure compliance with Indian quality standards.

Transportation and Logistics Considerations

Proper handling during transportation is critical to maintain the accuracy and integrity of load cells:

- Packaging: Use anti-static, shock-resistant packaging with appropriate cushioning to avoid mechanical damage or electrical interference.

- Environmental Protection: Shield load cells from moisture, extreme temperatures, and electromagnetic fields during transit.

- Labeling: Clearly mark packages with “Fragile,” “This Side Up,” and ESD (Electrostatic Discharge) warnings.

- Domestic Transport: For movement within India, use reliable logistics partners experienced in handling precision instruments. Air freight is recommended for urgent or high-value shipments.

Installation, Calibration, and Maintenance

- Calibration: Load cells used in commercial applications must be calibrated regularly using traceable standards. Calibration should follow IS 1248 or OIML R60 standards.

- Certified Service Providers: Only authorized agencies recognized by the Legal Metrology Department should perform calibration and verification.

- Maintenance Records: Maintain logs of installation, calibration, repairs, and verification for audit and compliance purposes.

Penalties for Non-Compliance

Failure to comply with legal metrology or customs regulations can result in:

- Fines ranging from ₹5,000 to ₹50,000 under the Legal Metrology Act.

- Seizure of non-compliant instruments.

- Suspension of business operations involving trade-related weighing.

- Customs penalties for incorrect classification or undervaluation.

Conclusion

Successfully managing the logistics and compliance of load cells in India requires understanding customs procedures, legal metrology requirements, and proper handling practices. Businesses should ensure all commercial weighing systems are approved, calibrated, and documented in accordance with Indian regulations to avoid penalties and ensure operational integrity.

Conclusion: Sourcing Load Cell Manufacturers in India

Sourcing load cell manufacturers in India presents a strategic advantage for businesses seeking cost-effective, reliable, and technologically sound measurement solutions. With a growing industrial base, a skilled workforce, and increasing adherence to international quality standards such as ISO, CE, and OIML, Indian manufacturers have established themselves as competitive players in the global market.

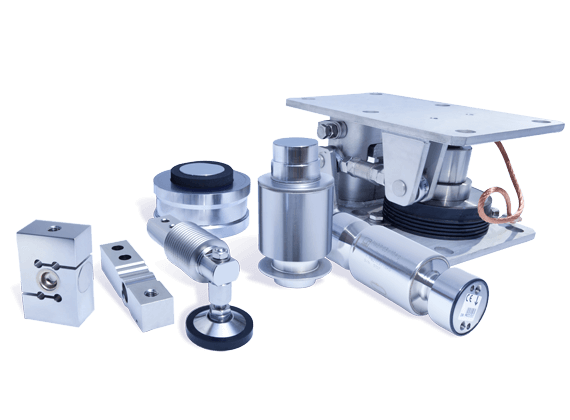

The diversity of load cell types—ranging from compression and tension to shear beam and single-point designs—ensures that suppliers can cater to a wide array of applications, including manufacturing, automotive, aerospace, logistics, and process control. Additionally, many Indian companies offer customization, prompt technical support, and scalable production capabilities, making them suitable partners for both domestic and international clients.

Key factors to consider when selecting a manufacturer include product quality certifications, R&D capabilities, production capacity, and after-sales service. Conducting due diligence through site visits, sample testing, and client references can further ensure long-term reliability and performance.

In conclusion, India offers a robust ecosystem of load cell manufacturers capable of meeting global standards. With the right selection criteria and partnership approach, sourcing from India can deliver high-quality, innovative, and cost-efficient solutions, supporting operational excellence across industries.