The global printing plates market is experiencing steady growth, driven by rising demand for high-quality, efficient, and sustainable printing solutions across commercial, packaging, and publication sectors. According to a report by Grand View Research, the global printing plates market size was valued at USD 4.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. This growth is fueled by technological advancements in digital platemaking, increased adoption of computer-to-plate (CTP) systems, and the expanding packaging industry, particularly in emerging economies. Lithographic plates, especially aluminum-based offset plates, continue to dominate due to their precision, durability, and compatibility with high-speed presses. As demand for automation and reduced turnaround times rises, manufacturers are investing heavily in environmentally friendly, process-free plates that minimize chemical usage and waste. In this evolving landscape, a select group of leading litho plate manufacturers are shaping the industry through innovation, global supply chain reach, and commitment to sustainability—setting the benchmark for performance and reliability.

Top 9 Litho Plate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1996

Website: lithopress.com

Key Highlights: Litho Press is a large format, offset, and digital printing company specializing in retail packaging, litho labels, and top sheets….

#2 Bell Litho, Inc.

Domain Est. 1997

Website: bell-litho.com

Key Highlights: Bell Litho Inc. was founded by Herman Bellagamba, trade lithographer, in 1965 in Chicago’s Printers’ Row. We devote ourselves fiercely to each client’s success….

#3 Valley Litho Supply

Domain Est. 1998

Website: valleylitho.com

Key Highlights: Valley Litho Supply provides quality printer supplies and reliable service to help professional printers maintain top performance and consistent output.Missing: plate manufacturer…

#4 El Paso Litho Plate Company, Inc.

Domain Est. 2004

Website: eplitho.com

Key Highlights: El Paso Litho Plate is the southwest’s only highly trained, third party field service organization specializing in quality, on-site service and installations….

#5 Plates

Domain Est. 2017

#6 Plates – Conventional

Domain Est. 1995

Website: fujifilm.com

Key Highlights: Fujiflm presensitized offset plates lead the world in quality and batch-to-batch consistency, winning numerous technical achievement awards….

#7 Presstek Page

Domain Est. 1997

Website: presstek.com

Key Highlights: Presstek offers new and Certified Pre-Owned DI presses, DI plates, consumables, CTP systems, CTP plates, parts and service for Commercial and Newspaper ……

#8 The ALC Group

Domain Est. 2012

Website: thealcgroup.com

Key Highlights: A creative graphics company. Creative solutions from concept to print. Learn more. Kansas City (Creative, Art Production, Digital Assembly, Proofing, Plate ……

#9 Offset Litho Products

Domain Est. 2024

Website: offsetlithoproducts.com

Key Highlights: From offset litho plates and chemistry to ink, proofing, and blankets — we help offset printers stay press-ready with dealer-backed, long-term supply solutions….

Expert Sourcing Insights for Litho Plate

H2: 2026 Market Trends for Lithographic Printing Plates

The global lithographic (litho) plate market is undergoing a significant transformation as it approaches 2026, shaped by technological advancements, sustainability demands, and shifting print industry dynamics. While digital media continues to grow, litho plates remain essential in commercial, packaging, and high-volume print applications. Below is an analysis of key market trends expected to influence the litho plate industry in 2026:

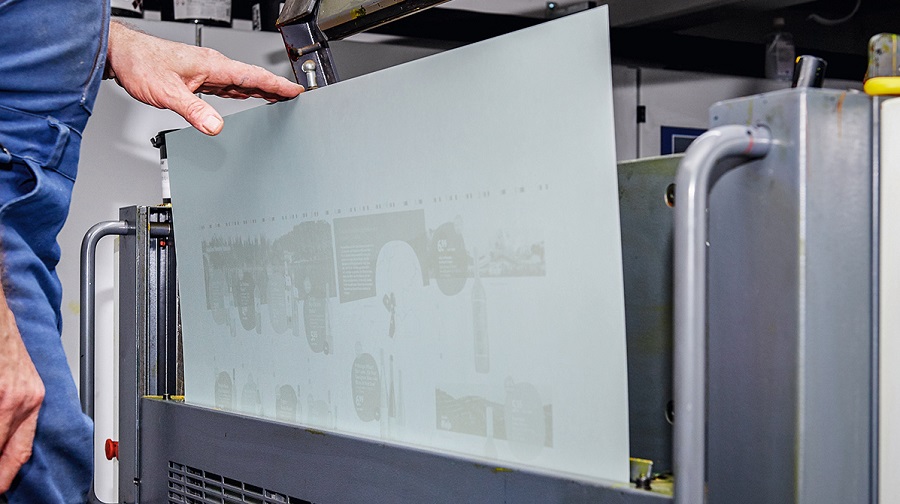

1. Continued Shift Toward Digital Integration and Automation

By 2026, the integration of digital workflows with offset printing is accelerating the demand for computer-to-plate (CTP) technologies. Printers are increasingly adopting automated CTP systems to reduce turnaround times, minimize waste, and enhance print precision. This trend favors high-performance thermal and violet laser plates compatible with digital prepress systems, driving innovation among plate manufacturers.

2. Growth Driven by Packaging and Label Printing

The packaging sector—especially flexible packaging, beverage labels, and luxury goods—remains a strong growth driver for litho plates. Rising consumer demand for attractive, high-quality packaging in e-commerce and retail is boosting offset printing volumes. In 2026, litho plates optimized for UV inks and specialty substrates will see increased adoption in label and folding carton printing.

3. Sustainability and the Rise of Eco-Friendly Plates

Environmental regulations and corporate sustainability goals are pushing the market toward greener solutions. In 2026, process-free and low-chemical plates that require no developer or reduced processing are gaining traction. Major suppliers are expanding their portfolios of eco-friendly plates, aligning with ISO 16759 standards for sustainable print production. Waterless lithography and recyclable plate materials are also emerging as niche but growing segments.

4. Regional Market Diversification

Asia-Pacific, particularly China and India, remains the largest consumer of litho plates due to robust packaging and publishing industries. However, by 2026, growth is expected to accelerate in Southeast Asia and parts of Africa, where print infrastructure is modernizing. In contrast, North America and Western Europe show slower growth but higher adoption rates of advanced plate technologies and automation.

5. Price Pressures and Raw Material Volatility

The cost of aluminum—the primary base material for litho plates—remains a key challenge. Fluctuations in raw material prices and energy costs are pressuring margins, prompting manufacturers to innovate with thinner plates and alternative substrates. Consolidation among suppliers is likely to continue as companies seek economies of scale.

6. Competition from Digital Printing (But Not Displacement)

While digital printing is expanding in short-run and personalized print, offset lithography still dominates high-volume, high-quality applications. Litho plates are not expected to be replaced but rather complement digital in hybrid print environments. In 2026, the focus is on improving plate durability, reusability, and compatibility with hybrid workflows.

Conclusion

By 2026, the litho plate market will be characterized by innovation, sustainability, and resilience. While facing competition and structural changes, the market remains vital—especially in packaging and commercial print. Success will depend on manufacturers’ ability to deliver high-performance, environmentally responsible solutions integrated into modern digital print ecosystems.

Common Pitfalls When Sourcing Litho Plates (Quality and Intellectual Property)

Sourcing lithographic printing plates is a critical step in the print production process. Poor decisions or oversight can lead to print defects, production delays, and even legal issues. Below are common pitfalls related to quality and intellectual property (IP) to watch for.

Quality-Related Pitfalls

Inconsistent Plate Coating Thickness

Variations in photosensitive coating thickness can lead to uneven exposure and development, resulting in inconsistent dot reproduction, poor image clarity, and shorter plate life. Sourcing from suppliers without strict quality control increases this risk.

Substandard Aluminum Substrate

The base aluminum must be precisely grained, anodized, and cleaned. Low-quality substrates may warp during printing, cause streaking, or fail to hold ink properly. Cheaper plates often use recycled or poorly processed aluminum, compromising durability and print performance.

Inadequate Shelf Life and Storage Sensitivity

Litho plates degrade over time, especially when exposed to heat, humidity, or light. Sourcing plates without clear expiration dates or proper storage instructions can result in premature deterioration and failed print runs.

Poor Compatibility with Press and Chemistry

Not all plates work optimally with every press, developer, or CTP (Computer-to-Plate) system. Using incompatible plates can lead to under- or over-development, plate scumming, or reduced run length. Always verify technical specifications and conduct compatibility tests.

Lack of Standardized Testing and Certification

Reputable suppliers provide data sheets, ISO certifications, and test results. Sourcing from vendors without documentation increases the risk of receiving off-spec plates that fail under production conditions.

Intellectual Property (IP) Pitfalls

Unauthorized or Counterfeit Plate Brands

Some suppliers offer “compatible” or “generic” plates that may infringe on patented technologies or trademarks. Using such plates can expose your print business to legal liability, especially if the OEM (Original Equipment Manufacturer) enforces IP rights.

Reverse-Engineered Plate Technologies

Certain third-party plates mimic the performance of branded plates (e.g., Kodak, Agfa, Fujifilm) by reverse-engineering proprietary coatings. This may violate patents or trade secrets, and using them could lead to cease-and-desist letters or lawsuits.

Unclear Licensing for Processless or Chemistry-Free Plates

Advanced plate technologies, such as processless thermal plates, often involve patented processes. Unauthorized use of these plates without proper licensing—especially when paired with specific CTP devices—can result in IP infringement claims.

Lack of Traceability and Documentation

When IP disputes arise, being able to prove the legitimate source and chain of supply is critical. Sourcing from opaque or unverified suppliers may leave you without legal defense if plates are found to be counterfeit or improperly licensed.

Best Practices to Avoid Pitfalls

- Verify supplier credentials and request quality certifications (e.g., ISO 9001).

- Request sample testing before bulk orders to evaluate print performance.

- Ensure technical compatibility with your existing equipment and workflows.

- Demand full traceability and documentation for all plate batches.

- Consult legal counsel when using third-party or compatible plates, especially for advanced technologies.

- Establish contracts that include quality guarantees and IP indemnification clauses.

By addressing these quality and IP-related pitfalls proactively, print service providers can ensure reliable production, protect their business, and maintain strong client relationships.

Logistics & Compliance Guide for Lithographic Plates

Lithographic plates (litho plates) are essential components in the commercial printing industry. Due to the materials used and their chemical sensitivity, proper logistics handling and regulatory compliance are critical for safety, environmental protection, and operational efficiency.

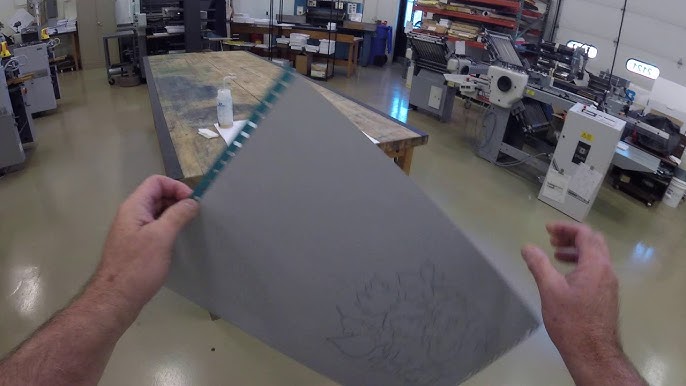

Handling and Storage Requirements

Litho plates must be handled with care to preserve image quality and ensure worker safety. Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, when handling plates. Store plates in a cool, dry environment away from direct sunlight, heat sources, and humidity to prevent premature chemical degradation or image distortion. Keep plates in their original packaging until ready for use to protect against scratches, dust, and contamination.

Packaging and Transportation

During transportation, litho plates must be securely packaged to prevent movement, bending, or damage. Use sturdy, moisture-resistant containers or cases designed for flat media. Plates should be stored vertically whenever possible to avoid warping. When shipping by air, road, or sea, ensure packages are labeled appropriately and comply with carrier requirements for flat, fragile items. Avoid stacking heavy items on top of litho plate shipments.

Regulatory Compliance

Litho plates may contain light-sensitive coatings, aluminum substrates, and chemical developers that are subject to environmental and safety regulations. Confirm compliance with local, national, and international regulations such as:

- REACH (EU) – Registration, Evaluation, Authorization, and Restriction of Chemicals

- RoHS (EU) – Restriction of Hazardous Substances in electrical and electronic equipment (if applicable)

- TSCA (USA) – Toxic Substances Control Act

- GHS/OSHA (USA) – Proper labeling and safety data sheet (SDS) availability for any hazardous components

Always maintain up-to-date Safety Data Sheets (SDS) for all litho plate products and ensure employees are trained in their use and handling.

Hazardous Materials Classification

Most litho plates are not classified as hazardous materials when shipped in their original, unprocessed form. However, plates containing certain chemical coatings or solvents may fall under hazardous classification (e.g., UN3268, Corrosive, Organic, N.O.S.). Always verify the UN number, hazard class, and packing group with the manufacturer before shipping. When in doubt, treat as non-hazardous but consult regulatory experts or shipping authorities.

Waste Disposal and Recycling

Used litho plates (especially aluminum-based) are often recyclable. Partner with certified metal recyclers who accept printing industry waste. Do not dispose of plates in regular trash if they have been processed with developer or fixer chemicals. Follow local environmental regulations for disposal of chemically treated plates, and ensure proper segregation of hazardous vs. non-hazardous waste streams.

Import and Export Considerations

When shipping litho plates internationally, verify customs requirements, import duties, and documentation needed (e.g., commercial invoice, packing list, certificate of origin). Some countries may impose restrictions on chemicals used in plate coatings. Ensure Harmonized System (HS) codes are correctly assigned—typically under 8443.99 (parts and accessories for printing machinery) or 7606 (aluminum plates, sheets, and foil).

Environmental and Sustainability Best Practices

Choose litho plates with reduced chemical processing requirements (e.g., processless or low-chemistry plates) to minimize environmental impact. Implement a sustainability program that includes recycling programs, energy-efficient plate processing equipment, and supplier engagement for eco-friendly packaging options.

Training and Documentation

Provide regular training for staff involved in receiving, handling, storing, and shipping litho plates. Maintain records of SDS access, training logs, waste disposal receipts, and compliance certifications. Conduct periodic audits to ensure ongoing adherence to logistics and regulatory standards.

Conclusion for Sourcing Litho Plates

In conclusion, sourcing lithographic plates requires a strategic approach that balances quality, cost, reliability, and technological compatibility. Selecting the right supplier is critical to ensuring consistent print quality, operational efficiency, and long-term cost savings. Factors such as plate resolution, durability, processing requirements, and environmental impact must be carefully evaluated based on specific printing needs and equipment specifications. Additionally, building strong relationships with reputable suppliers who offer technical support and sustainable solutions can significantly enhance print performance and reduce downtime. By conducting thorough market research, requesting samples, and considering total cost of ownership—rather than just upfront price—printers can make informed decisions that support high-quality output and sustainable business growth. Ultimately, effective sourcing of litho plates contributes directly to improved productivity and competitiveness in the dynamic printing industry.