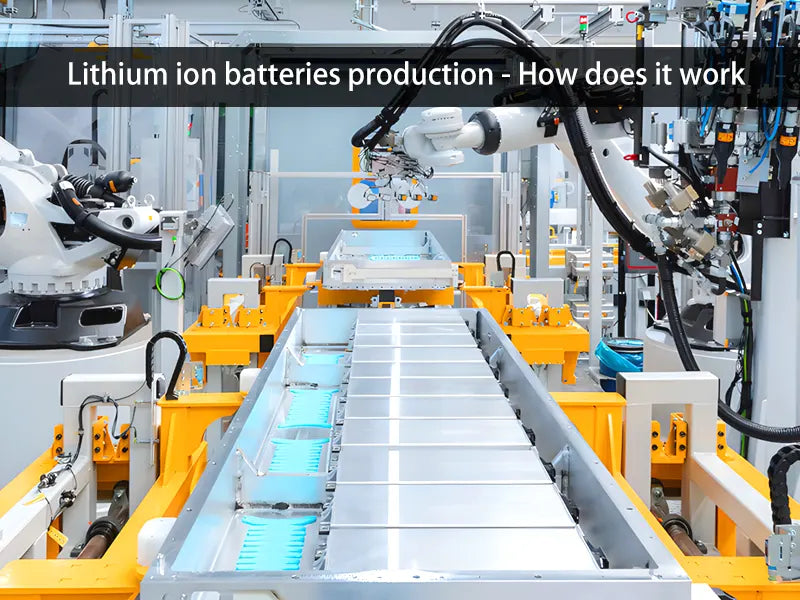

The global lithium-ion battery market is surging, driven by rapid advancements in electric vehicles (EVs), consumer electronics, and renewable energy storage systems. According to Grand View Research, the market was valued at USD 53.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 14.6% from 2023 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of over 13.5% during the period 2023–2028, underpinned by increasing EV adoption and supportive government policies aimed at reducing carbon emissions. As demand escalates, a select group of manufacturers are leading innovation, scale, and market share. Here are the top 10 lithium-ion battery manufacturers shaping the future of energy storage.

Top 10 Lithium Ion Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tadiran Batteries

Domain Est. 1996

Website: tadiranbat.com

Key Highlights: The world’s #1 manufacturer of ultra-long-life lithium batteries for industrial applications. Browse by Application. view our Products. EXTREME. LIFE. EXTREME….

#2 ProLogium Technology Co., Ltd

Domain Est. 2014 | Founded: 2006

Website: prologium.com

Key Highlights: Founded in 2006, ProLogium Technology is an energy innovation company focused on lithium ceramic battery research, development, and manufacturing….

#3 Lithium ion Batteries

Domain Est. 1990

Website: energy.panasonic.com

Key Highlights: Lithium ion Batteries offer high energy density, light weight, and a long cycle life, which makes them useful in a wide range of consumer devices….

#4 Pure Lithium

Domain Est. 2019

Website: purelithium.io

Key Highlights: At Pure Lithium’s lab Chicago, we produce a pure lithium metal anode from brine using our transformational Brine to Battery™ technology. We pair it with a ……

#5 American Battery Technology Company

Domain Est. 2020

Website: americanbatterytechnology.com

Key Highlights: ABTC is an advanced technology, first-mover lithium-ion battery recycling and primary battery metal extraction company that utilizes internally developed ……

#6 American Battery Factory

Domain Est. 2021

Website: americanbatteryfactory.com

Key Highlights: American Battery Factory (ABF) focuses exclusively on manufacturing and enhancing high-performance prismatic Lithium Iron Phosphate (LFP) batteries….

#7 Flux Power: Lithium

Domain Est. 2005

Website: fluxpower.com

Key Highlights: Flux Power lithium-ion batteries are cutting-edge energy solutions engineered to power electric ground support and material handling equipment….

#8 Battle Born Batteries

Domain Est. 2016

Website: battlebornbatteries.com

Key Highlights: Free delivery · 30-day returnsShop premium LiFePO4 lithium batteries from Battle Born for unmatched power, reliability, and a 10-year warranty. Get started today!…

#9 Lithion Battery

Domain Est. 2020

Website: lithionbattery.com

Key Highlights: Lithion keeps homes, businesses, and industries running with dependable lithium-ion batteries and energy storage systems for nearly every application….

#10 Ascend Elements

Domain Est. 2021

Website: ascendelements.com

Key Highlights: Ascend Elements manufactures advanced battery materials using valuable elements reclaimed from discarded lithium-ion batteries….

Expert Sourcing Insights for Lithium Ion

H2: Analysis of Lithium-Ion Battery Market Trends in 2026

As the global push toward electrification and renewable energy intensifies, the lithium-ion (Li-ion) battery market is projected to experience substantial growth and transformation by 2026. Driven primarily by the expansion of electric vehicles (EVs), energy storage systems (ESS), and portable electronics, the market is expected to evolve significantly in terms of technology, supply chain dynamics, regional production, and sustainability practices.

1. Market Growth and Demand Outlook

By 2026, the global lithium-ion battery market is forecasted to exceed $150 billion, growing at a compound annual growth rate (CAGR) of approximately 18–22% from 2022 to 2026. This surge is fueled by:

– EV Adoption: EV sales are expected to account for over 30% of new light-duty vehicle sales globally by 2026, particularly in regions like China, Europe, and North America. This will drive demand for high-energy-density Li-ion batteries.

– Stationary Energy Storage: Grid-scale and residential energy storage systems, especially in conjunction with solar and wind power, will contribute significantly. The global ESS market is projected to grow by over 30% annually, increasing the need for Li-ion batteries due to their declining costs and high efficiency.

– Consumer Electronics: Continued innovation in smartphones, laptops, wearables, and 5G-enabled devices will sustain baseline demand.

2. Technological Advancements

By 2026, several technological trends will shape the Li-ion landscape:

– Chemistry Evolution: While NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) remain dominant, there will be increased adoption of high-nickel chemistries (e.g., NMC 811, NCA) for EVs due to higher energy density. LFP batteries will gain traction in cost-sensitive and safety-critical applications, including entry-level EVs and energy storage.

– Solid-State Batteries: Although commercialization is still limited, significant R&D progress is expected by 2026. Pilot production lines from companies like Toyota, QuantumScape, and Solid Power could begin small-scale operations, setting the stage for a post-2026 market shift.

– Sodium-Ion Competition: Sodium-ion batteries may begin to challenge Li-ion in low-cost, short-range EVs and stationary storage, potentially affecting pricing and market segmentation.

3. Supply Chain and Raw Materials

- Lithium, Cobalt, and Nickel Supply: Demand for lithium is expected to triple by 2026 compared to 2022 levels. This will strain supply chains, prompting investment in mining and refining capacity, particularly in Australia, Chile, Argentina (the “Lithium Triangle”), and new entrants like Canada and the U.S.

- Cobalt Reduction: Ethical and supply concerns will accelerate the shift toward low-cobalt or cobalt-free chemistries. Recycling and urban mining will play a growing role.

- Geopolitical Influence: China will maintain dominance in refining and battery manufacturing (accounting for ~60% of global capacity), but the U.S. and EU will expand local production under policies like the Inflation Reduction Act (IRA) and the European Battery Regulation.

4. Manufacturing and Regional Shifts

- Gigafactory Expansion: Global battery manufacturing capacity is expected to surpass 3,500 GWh by 2026. Major expansions are underway in North America (e.g., Tesla, Ford-SK On, GM-LG Energy Solution) and Europe (e.g., Northvolt, ACC, CATL).

- Localization Trend: To meet regulatory requirements and reduce logistics risks, OEMs will increasingly localize battery supply chains. This includes vertical integration, from raw materials to cell production.

5. Sustainability and Regulation

- Recycling Infrastructure: Battery recycling will become a critical market segment. By 2026, regulatory mandates (e.g., EU’s 2030 recycling efficiency targets) will require manufacturers to use recycled content, spurring investment in hydrometallurgical and direct recycling technologies.

- Carbon Footprint Standards: Lifecycle emissions tracking and low-carbon battery certifications will influence procurement decisions, favoring manufacturers using renewable energy in production.

6. Price Trends

Average Li-ion battery pack prices are expected to reach $70–80/kWh by 2026 (down from ~$139/kWh in 2021), driven by economies of scale, improved manufacturing yields, and material innovations. However, short-term price volatility due to raw material supply constraints (especially lithium) may persist.

Conclusion

By 2026, the lithium-ion battery market will be characterized by robust demand, technological diversification, and heightened competition. While Li-ion will remain the dominant battery technology, the stage will be set for next-generation solutions. Success will depend on supply chain resilience, sustainable practices, and the ability to scale production efficiently amid evolving regulatory and environmental landscapes.

H2: Common Pitfalls in Sourcing Lithium-Ion Batteries – Quality and Intellectual Property (IP) Risks

Sourcing lithium-ion (Li-ion) batteries, whether for consumer electronics, electric vehicles (EVs), or energy storage systems, involves navigating complex supply chains and technical specifications. Two critical areas where companies often encounter pitfalls are product quality and intellectual property (IP) risks. Understanding and mitigating these risks is essential for ensuring product safety, performance, and legal compliance.

1. Quality-Related Pitfalls

a. Inconsistent Cell Performance and Reliability

Not all Li-ion cells are created equal. A common issue is receiving cells that do not meet stated specifications (e.g., capacity, cycle life, internal resistance). This often occurs when sourcing from low-cost or unverified suppliers who may rebrand or regrade used, recycled, or substandard cells.

- Risk: Premature battery degradation, reduced runtime, and safety hazards (e.g., overheating, swelling, or thermal runaway).

- Mitigation: Conduct rigorous third-party testing (e.g., cycle testing, capacity verification), demand detailed test reports, and audit supplier manufacturing processes. Prefer suppliers with certifications such as ISO 9001, IATF 16949 (for automotive), or UL standards.

b. Lack of Traceability and Batch Control

Poorly managed supply chains may lack proper traceability, making it difficult to identify the origin of cells or track defects back to specific production batches.

- Risk: Inability to conduct effective recalls or root cause analysis in case of failures.

- Mitigation: Require full batch traceability (including lot numbers, manufacturing dates, and material sourcing), and establish agreements that allow for on-site audits.

c. Counterfeit or “B-Grade” Cells Marketed as Premium

Some suppliers sell lower-tier (B-grade or salvaged) cells as A-grade, particularly in markets with weak regulatory oversight.

- Risk: Compromised product performance and safety; potential brand damage.

- Mitigation: Work with reputable, direct manufacturers or authorized distributors. Use independent lab testing to verify cell grade and authenticity.

2. Intellectual Property (IP) and Legal Pitfalls

a. Infringement of Patented Technologies

Li-ion battery technology is heavily patented, especially in areas like electrode materials (e.g., NMC, LFP), cell design, electrolyte formulations, and battery management systems (BMS).

- Risk: Importing or using batteries that incorporate patented technologies without license can lead to legal action, customs seizures, or injunctions (e.g., in the U.S. via ITC proceedings).

- Mitigation: Conduct freedom-to-operate (FTO) analyses, especially when sourcing for regulated markets. Verify that suppliers can provide IP indemnification and documentation of licensed technologies.

b. Use of Unlicensed or Cloned Battery Management Systems (BMS)

Many low-cost battery packs use reverse-engineered or unlicensed BMS firmware, which may infringe on software or circuit design patents.

- Risk: Software IP infringement, potential system malfunctions, and liability exposure.

- Mitigation: Audit BMS firmware and design; require suppliers to certify compliance with IP rights and provide source documentation.

c. Ambiguous Ownership of Custom Designs

When co-developing battery packs or cells with a supplier, unclear contracts may result in disputes over IP ownership.

- Risk: Loss of control over proprietary designs or inability to switch suppliers.

- Mitigation: Define IP ownership clearly in contracts. Ensure that custom designs, tooling, and processes developed for your product are assigned to your company.

Best Practices Summary

- Verify Supplier Credentials: Use only qualified manufacturers with proven track records and relevant certifications.

- Conduct Onsite Audits and Testing: Don’t rely solely on datasheets—validate performance and safety through independent labs.

- Secure IP Protections: Require IP warranties, indemnification clauses, and proof of licensed technologies in supply agreements.

- Ensure Supply Chain Transparency: Demand full documentation, including material origins, manufacturing locations, and compliance certifications.

By proactively addressing these quality and IP pitfalls, companies can reduce risk, ensure product integrity, and protect their long-term market position in the rapidly evolving Li-ion battery landscape.

H2: Logistics & Compliance Guide for Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries power a vast array of modern devices, from smartphones and laptops to electric vehicles and energy storage systems. However, their unique chemical properties pose significant safety risks during transport, primarily the potential for thermal runaway, which can lead to fire or explosion. Strict international and national regulations govern their safe handling, packaging, marking, documentation, and transport by air, sea, road, and rail.

H2: Key Regulatory Frameworks

The safe transport of lithium-ion batteries is governed by a complex web of international regulations, which are then adopted or adapted by national authorities:

- UN Recommendations on the Transport of Dangerous Goods (UN Model Regulations): The foundation for all other regulations. Li-ion batteries are classified under:

- UN 3480: Lithium-ion batteries (including lithium-ion polymer).

- UN 3481: Lithium-ion batteries contained in equipment or packed with equipment.

- Classification: Class 9 – Miscellaneous Dangerous Goods (specifically, “Lithium ion batteries, except when installed in equipment”).

- International Air Transport Association (IATA) Dangerous Goods Regulations (DGR): The mandatory standard for air transport worldwide. Based on UN models but often includes additional restrictions and requirements (e.g., State and Operator Variations). Air transport is the most restrictive.

- International Maritime Dangerous Goods (IMDG) Code: The mandatory standard for sea transport (SOLAS Convention). Also based on UN models, implemented through national maritime authorities.

- European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR): Mandatory for road transport within Europe.

- Regulations Concerning the International Carriage of Dangerous Goods by Rail (RID): Mandatory for rail transport within Europe.

- 49 CFR (Code of Federal Regulations) – US Department of Transportation (DOT): The primary regulations for domestic and international transport within, from, or to the United States (covering air, sea, rail, and road). Aligns closely with UN/IATA/IMDG but has specific US requirements.

- National Regulations: Countries may have additional requirements (e.g., specific permits, state/provincial variations within ADR/49 CFR, import/export controls).

H2: Classification, Identification & Classification

- Proper Shipping Name (PSN):

- UN 3480: “LITHIUM ION BATTERIES”

- UN 3481: “LITHIUM ION BATTERIES CONTAINED IN EQUIPMENT” or “LITHIUM ION BATTERIES PACKED WITH EQUIPMENT”

- UN Number: 3480 or 3481.

- Hazard Class: 9 (Miscellaneous Dangerous Goods).

- Packing Group: Not assigned (N/A) for Li-ion batteries under normal conditions, but the hazard is inherent.

- Subsidiary Risk: None typically assigned for Li-ion alone (unlike Lithium Metal).

H2: Packaging Requirements

Packaging is critical to prevent short circuits, physical damage, and containing potential incidents.

- General Principles:

- Robustness: Must withstand normal conditions of transport (stacking, vibration, temperature changes).

- Protection: Prevent short circuits (e.g., terminals protected from contact with conductive materials, other batteries, or the package walls). Terminals must be insulated (e.g., caps, tape, individual plastic bags).

- Containment: Must contain any leakage of electrolyte and prevent propagation if one battery fails.

- Separation: Batteries must be packed to prevent movement within the package. Use non-conductive, cushioning materials (bubble wrap, foam inserts).

- Specific Requirements by Type:

- UN 3480 (Batteries Alone): Must be packed in strong outer packaging. Individual cells/batteries require terminal protection. Often requires UN Performance Test certified packaging (e.g., boxes meeting 4G, 4GV standards).

- UN 3481 (In/Packed With Equipment):

- Contained In: The equipment provides inherent protection. Equipment must be packed to prevent damage and movement. Terminals of the equipment may need protection if exposed.

- Packed With: Batteries and equipment are in the same package but not installed. Batteries require full terminal protection and secure packing separately. The equipment must also be protected. Treat batteries as UN 3480 within the package.

- State of Charge (SoC): Crucial for Air Transport (IATA DGR):

- Li-ion batteries shipped alone (UN 3480) must not exceed 30% State of Charge of their rated capacity, unless specifically excepted (e.g., prototypes, damaged/defective batteries under special provisions). This significantly reduces the energy available in case of thermal runaway.

- Batteries in or packed with equipment (UN 3481) are generally shipped at the SoC necessary for the equipment’s function (often higher than 30%), but packaging must still protect against short circuits and damage.

- Sea/Road/Rail (IMDG/ADR/RID/49 CFR) generally do not have a 30% SoC limit for UN 3480, but best practice and some specific provisions may still recommend lower SoC for enhanced safety.

H2: Marking & Labeling

Proper identification is essential for handlers and emergency responders.

- Proper Shipping Name & UN Number: Clearly displayed on the outside of the package.

- Class 9 Hazard Label: A diamond-shaped label with “9” in the bottom corner, the “Class 9” text, and the “Miscellaneous Dangerous Goods” symbol (upward-pointing arrow over three horizontal lines). Must be visible on two opposite sides of the package. Mandatory for all modes.

- Orientation Arrows: Required on packages containing liquids (relevant for some battery chemistries or if electrolyte leaks) – “THIS SIDE UP” markings. Often required for Li-ion batteries.

- Additional Marks (Air Transport – IATA DGR):

- “LITHIUM BATTERY MARK” (Circular): Mandatory for packages containing UN 3480/3481. Features a flame symbol, “LITHIUM ION BATTERIES,” the UN number (3480 or 3481), and contact info for the shipper. Must be at least 120mm x 110mm.

- “CARGO AIRCRAFT ONLY” Label: Required if the package exceeds certain size/quantity limits (e.g., batteries alone exceeding 1.2kWh per cell or 20kWh per package; specific limits vary by regulation). Prohibits carriage on passenger aircraft.

- “Damaged/Defective” Batteries: Require special marking (e.g., “Damaged/Defective Lithium Ion Batteries, UN 3480, Class 9”) and are subject to even stricter packing and documentation requirements. Often require approval from the carrier/state authority.

H2: Documentation

Accurate and complete documentation is non-negotiable.

- Dangerous Goods Declaration (Shipper’s Declaration for Dangerous Goods – DGD): Mandatory for air (IATA) and sea (IMDG) transport. A legal document prepared by the shipper (or their agent) containing:

- Shipper/Consignee details.

- Proper Shipping Name, UN Number, Class.

- Packing Group (N/A).

- Quantity (net quantity of dangerous goods, e.g., number of batteries, total Wh/kWh).

- Packing Instructions used (e.g., IATA PI 965, PI 966, PI 967).

- Emergency contact number.

- Certification statement signed by a trained person.

- Note: For “Excepted” quantities or specific provisions allowing reduced documentation (e.g., small batteries in equipment under certain limits), a DGD is usually not required, but other documentation (like a commercial invoice noting “Lithium Batteries” per regulations) might be.

- Air Waybill (AWB) / Bill of Lading (BOL): The main transport contract. Must include the UN number and PSN in the “Nature and Quantity of Goods” section. The carrier will typically add “Dangerous Goods” notation.

- Commercial Invoice & Packing List: Must clearly describe the contents (e.g., “Lithium-ion Batteries, UN 3480, Class 9” or “Laptops containing Lithium-ion Batteries, UN 3481, Class 9”). Include total Wh/kWh if required by regulation or carrier.

- Training Certificate: Proof that personnel preparing the shipment (classifying, packing, marking, documenting) have received and passed appropriate dangerous goods training (IATA, IMDG, ADR, 49 CFR specific). Carriers often require this.

H2: Responsibilities

- Shipper (Offeror): Ultimate responsibility for correct classification, packaging, marking, labeling, documentation, and ensuring personnel are trained. Must provide accurate information to the carrier.

- Carrier: Responsible for accepting shipments only if properly prepared, ensuring correct stowage and segregation during transport (e.g., away from flammable materials, limited quantities of other Class 9 goods), providing emergency information to crew, and complying with operational restrictions (e.g., “Cargo Aircraft Only”).

- Freight Forwarder/Consolidator: Acts as an agent for the shipper. Shares responsibility for ensuring shipments meet regulations before tendering to the carrier. Often provides critical expertise.

- Packer: Responsible for packing batteries safely and according to the Packing Instructions. Must be trained.

- Loader: Responsible for ensuring packages are loaded correctly and securely, respecting orientation marks and segregation requirements.

H2: Key Challenges & Best Practices

- Complexity & Change: Regulations are complex and updated frequently (e.g., IATA DGR annually). Best Practice: Use a certified dangerous goods consultant or forwarder; subscribe to regulatory updates; maintain rigorous internal procedures.

- Liability: Non-compliance can lead to fines, shipment rejection, delays, accidents, and significant liability. Best Practice: Invest in comprehensive training for all involved staff.

- Counterfeit/Non-Compliant Batteries: Pose higher risks. Best Practice: Source from reputable suppliers; implement quality checks.

- Returns & Recycling: Transport of used, damaged, or defective batteries is highly regulated (Special Provisions like A154, A80). Best Practice: Use specialized hazardous waste/defective battery logistics providers; follow specific return protocols.

- E-commerce & Small Shipments: High volume, diverse shippers. Best Practice: Clear communication with customers/sellers on requirements; use pre-approved packaging solutions; automated compliance checks.

- State/Carrier Variations: Always check specific requirements of the origin/destination country and the chosen airline/carrier. Best Practice: Consult carrier-specific guidance documents.

H2: Training & Certification

- Mandatory: Personnel involved in preparing, offering, handling, or transporting dangerous goods must be trained and certified according to the relevant regulations (IATA, IMDG, ADR, 49 CFR).

- Frequency: Training must be refreshed every 2 years (IATA, 49 CFR) or as required by the regulation (e.g., ADR every 5 years, but refresher recommended).

- Content: Covers classification, packaging, marking, labeling, documentation, emergency procedures, and specific regulations.

Conclusion

Transporting lithium-ion batteries safely and legally requires strict adherence to a detailed framework of international and national regulations. Success hinges on accurate classification, robust packaging designed to prevent short circuits and damage, clear marking and labeling (especially the Class 9 label and IATA Lithium Battery Mark), complete and correct documentation (especially the DGD), and personnel who are properly trained and certified. Failure to comply poses significant safety risks and severe financial and legal consequences. Always consult the latest edition of the relevant regulations (IATA DGR, IMDG Code, ADR, 49 CFR) and consider engaging specialized dangerous goods logistics experts.

Conclusion on Sourcing Lithium-Ion Battery Suppliers

Sourcing reliable lithium-ion battery suppliers is a critical component in ensuring the quality, performance, and sustainability of products across industries such as electric vehicles, consumer electronics, and renewable energy storage. A successful sourcing strategy requires a comprehensive evaluation of suppliers based on key criteria including product quality, compliance with safety and environmental standards, manufacturing capacity, cost efficiency, technological innovation, and ethical sourcing practices.

After evaluating potential suppliers, it is evident that a balanced approach—combining established industry leaders with emerging, agile manufacturers—can offer both reliability and competitive advantage. Prioritizing suppliers with transparent supply chains, strong R&D capabilities, and certifications such as ISO 9001, IATF 16949, and UN38.3 is essential for mitigating risk and ensuring long-term partnership viability.

Additionally, geographic diversification of suppliers can help mitigate geopolitical and logistical risks, while fostering dual-sourcing or multi-sourcing strategies enhances supply chain resilience. Ongoing supplier performance monitoring, regular audits, and collaborative relationships are vital to adapt to evolving market demands and technological advancements.

In conclusion, effective sourcing of lithium-ion battery suppliers is not solely about cost reduction but involves strategic decision-making focused on quality, innovation, sustainability, and supply chain security. A well-structured supplier portfolio will position organizations to meet current needs while remaining agile and competitive in the rapidly evolving energy storage landscape.