The global lithium-ion battery market is experiencing robust growth, driven by rising demand for portable electronics, increasing laptop adoption, and advancements in energy density and charging technologies. According to Grand View Research, the global lithium-ion battery market size was valued at USD 74.4 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 14.7% from 2024 to 2030. This surge is underpinned by the proliferation of remote work, e-learning, and mobile computing, all of which rely heavily on high-performance laptop batteries. As consumers prioritize longer battery life, faster charging, and improved durability, manufacturers are intensifying R&D investments to meet evolving performance standards. In this competitive landscape, seven key players have emerged as leaders in producing lithium-ion batteries tailored specifically for laptop computers—combining innovation, scalability, and reliability to power the next generation of mobile productivity.

Top 7 Lithium Ion Battery For Laptop Computer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Amperex Technology Limited

Domain Est. 2000

Website: atlbattery.com

Key Highlights: ATL is the world’s leading producer and innovator of lithium-ion batteries. We are known worldwide for our high-tech, high-volume prowess….

#2 Lithium ion Batteries

Domain Est. 1990

Website: energy.panasonic.com

Key Highlights: Lithium ion Batteries offer high energy density, light weight, and a long cycle life, which makes them useful in a wide range of consumer devices….

#3 Highpower Technology

Domain Est. 2010

Website: highpowertech.com

Key Highlights: Highpower Technology (stock code: 001283) was found in 2002, and committed to the research, design, manufacturing and sales of Li-ion and Ni-MH batteries, ……

#4 Batteries

Domain Est. 1987

Website: apple.com

Key Highlights: Compared with older battery types, lithium-ion batteries weigh less, last longer, and charge more efficiently. Learn more about how your battery charges ……

#5 ASUS Battery Information Center

Domain Est. 1995

Website: asus.com

Key Highlights: Benefits of Li-ion batteries include high energy density, large power capacity, light weight, high cycle life, no memory effect, and fast ……

#6 Laptop Batteries Replacement Finder

Domain Est. 1996

Website: microcenter.com

Key Highlights: In need of a replacement laptop battery? Shop Micro Center for laptop batteries and schedule your laptop battery replacement service online!Missing: lithium ion…

#7 lithium

Domain Est. 2016

Website: gsl-energy.com

Key Highlights: They dominate the rechargeable battery market for today\’s laptops because they are much lighter than other types of laptop batteries and they ……

Expert Sourcing Insights for Lithium Ion Battery For Laptop Computer

H2: 2026 Market Trends for Lithium-Ion Batteries for Laptop Computers

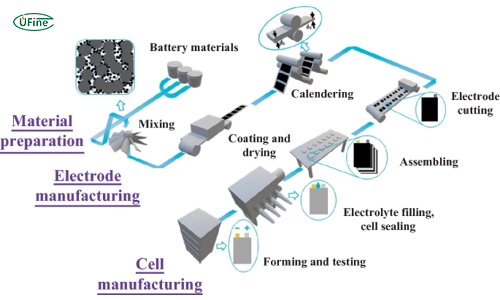

As the global demand for portable computing continues to rise, the lithium-ion (Li-ion) battery market for laptops is poised for significant transformation by 2026. Driven by advancements in technology, shifting consumer preferences, and sustainability mandates, several key trends are expected to shape the industry.

1. Increased Energy Density and Longer Lifespan

By 2026, manufacturers are anticipated to deliver Li-ion batteries with higher energy density, enabling thinner, lighter laptops with extended battery life. Innovations in cathode and anode materials—such as silicon anodes and nickel-rich cathodes—are expected to boost capacity by 20–30% compared to current benchmarks. This supports the growing need for all-day usability in ultraportable and hybrid work devices.

2. Fast-Charging Integration

Fast-charging technology will become standard across mid-to-high-end laptops. By 2026, more Li-ion batteries will support 80% charge in under 30 minutes, leveraging improved thermal management systems and advanced battery management software. This aligns with consumer demand for reduced downtime and seamless productivity.

3. Sustainability and Recycling Initiatives

Environmental regulations, particularly in the EU and North America, will push manufacturers to adopt greener battery solutions. Closed-loop recycling of cobalt, lithium, and nickel will gain traction, supported by policies like the EU Battery Regulation. By 2026, an estimated 40–50% of new laptop batteries are expected to contain recycled materials, reducing the carbon footprint and dependency on raw mineral extraction.

4. Shift Toward Solid-State Battery Development

While mainstream solid-state laptop batteries may not dominate by 2026, significant R&D investments will accelerate pilot production. Solid-state Li-ion alternatives promise enhanced safety, longer cycle life, and higher energy density. Major tech firms and battery producers are expected to announce commercial prototypes, setting the stage for market entry in the late 2020s.

5. OEM-Driven Vertical Integration

Leading laptop manufacturers, including Apple, Dell, and Lenovo, are increasingly investing in vertical integration of battery supply chains. By 2026, partnerships with battery innovators and in-house development will allow for optimized battery design tailored to specific device architectures, improving efficiency and performance.

6. Regional Market Dynamics

Asia-Pacific will remain the largest producer and consumer of laptop Li-ion batteries, driven by China’s manufacturing dominance and rising laptop adoption in India and Southeast Asia. Meanwhile, North America and Europe will focus on high-value, sustainable battery solutions, supported by local production incentives and green tech subsidies.

7. Price Stabilization Amid Raw Material Volatility

After fluctuations in lithium and cobalt prices earlier in the decade, supply chain diversification and alternative chemistries (e.g., lithium iron phosphate for entry-level models) are expected to stabilize battery costs by 2026. This will help maintain affordability while supporting innovation.

In summary, the 2026 landscape for lithium-ion batteries in laptops will be defined by performance optimization, sustainability, and strategic innovation. As environmental and efficiency demands intensify, the market will transition toward smarter, safer, and more responsible energy storage solutions.

Common Pitfalls Sourcing Lithium-Ion Batteries for Laptop Computers (Quality, IP)

Sourcing lithium-ion (Li-ion) batteries for laptop computers presents significant challenges, particularly concerning quality assurance and intellectual property (IP) protection. Falling into common pitfalls can lead to product failures, safety hazards, reputational damage, and legal liabilities. Below are key risks to avoid:

Poor Quality Control and Safety Risks

One of the most critical pitfalls is selecting suppliers based solely on price, resulting in substandard batteries. Low-quality Li-ion cells may lack proper safety mechanisms, use inferior materials, or fail to meet required specifications. This increases the risk of overheating, swelling, or even thermal runaway—potentially leading to fires or explosions. Additionally, inconsistent battery performance, shorter cycle life, and inaccurate charge reporting can severely impact user experience and brand trust.

Counterfeit or Non-OEM Components

The market is flooded with counterfeit or refurbished batteries falsely marketed as original equipment manufacturer (OEM) products. These batteries often mimic genuine branding but use recycled or low-grade cells. Sourcing such components not only compromises device reliability but also exposes companies to liability if safety incidents occur. Verifying authenticity through traceable supply chains and certified suppliers is essential to avoid this pitfall.

Lack of Compliance with Regulatory Standards

Li-ion batteries must comply with international safety and transportation regulations, such as UL, IEC 62133, UN 38.3, and RoHS. Sourcing from non-compliant manufacturers can result in shipment rejections, customs delays, or product recalls. Moreover, non-compliant batteries may not pass safety certifications required for market entry, jeopardizing product launch timelines.

Intellectual Property Infringement

Many OEM laptop batteries incorporate proprietary designs, firmware, and communication protocols protected by patents and copyrights. Sourcing aftermarket or third-party batteries that replicate these features without authorization can lead to IP infringement claims. This is especially critical when batteries include smart circuitry that mimics OEM authentication chips. Companies must ensure that their sourcing practices respect IP rights to avoid litigation and injunctions.

Inadequate Supplier Vetting and Traceability

Failing to conduct thorough due diligence on battery suppliers increases the risk of engaging with unreliable or unethical manufacturers. Lack of transparency in the supply chain—such as unclear cell origins or subcontracting practices—can hide quality and compliance issues. Establishing supplier audits, requesting material certifications, and requiring full traceability from cell manufacturer to final assembly are vital steps to mitigate these risks.

Insufficient Testing and Validation

Even with seemingly reputable suppliers, skipping rigorous in-house testing can be disastrous. Batteries should undergo performance, cycle life, environmental stress, and safety testing under real-world conditions. Without proper validation, defects may only emerge after mass deployment, leading to costly recalls and customer dissatisfaction.

Avoiding these pitfalls requires a strategic approach focused on quality, compliance, and legal diligence. Partnering with certified suppliers, enforcing strict procurement standards, and respecting intellectual property are essential to sourcing safe and reliable lithium-ion batteries for laptop computers.

Logistics & Compliance Guide for Lithium Ion Batteries for Laptop Computers

Overview

Lithium-ion (Li-ion) batteries are commonly used in laptop computers due to their high energy density and performance. However, because they pose potential fire and safety risks if damaged, improperly handled, or defective, they are strictly regulated during transportation by air, sea, ground, and rail. This guide outlines key logistics and compliance requirements for shipping lithium-ion batteries installed in or packed with laptop computers.

Regulatory Framework

Li-ion batteries are regulated under international and national transportation regulations, including:

– IATA Dangerous Goods Regulations (DGR) – for air transport

– IMDG Code – for sea transport

– ADR – for road transport in Europe

– 49 CFR – for transport in the United States (DOT/PHMSA)

These regulations classify lithium-ion batteries as Class 9 Miscellaneous Dangerous Goods.

Classification and Identification

- UN Number: UN 3480 (Lithium-ion batteries)

- Proper Shipping Name: “Lithium ion batteries”

- Class: 9 (Miscellaneous Dangerous Goods)

- Packing Group: Not assigned (PG II may be referenced in some contexts)

Note: Laptops with installed batteries are often eligible for exceptions under specific packing instructions.

Applicable Shipping Scenarios

1. Laptops with Installed Batteries (Equipment)

When lithium-ion batteries are installed in laptops (considered “equipment”), shipments may qualify for exceptions under certain conditions.

- IATA DGR Special Provision A123 and Packing Instruction 967, Section IB:

- Batteries must be securely installed in the equipment.

- No more than two spare batteries allowed per person if carried in carry-on baggage.

- For cargo shipments: Small consumer electronic devices like laptops are typically excepted from full dangerous goods requirements if the battery capacity does not exceed 100 watt-hours (Wh).

- Shipments must not contain defective or recalled batteries.

2. Spare (Loose) Lithium-Ion Batteries

Spare batteries not installed in equipment are subject to stricter rules:

– Must be packed to prevent short circuits (e.g., in original retail packaging or terminals protected with tape).

– Prohibited in checked baggage for passengers; must be carried in carry-on.

– In cargo: Limited to Packing Instruction 965, Section IB if under 100 Wh.

– Quantity limitations and state-of-charge restrictions apply (maximum 30% charge for air transport under some conditions).

Packaging Requirements

- For Laptops (with installed batteries):

- Use strong, rigid outer packaging.

- Prevent movement of equipment inside the box.

-

No special hazard labels required if qualifying for exceptions (e.g., IATA PI 967 Section IB).

-

For Spare Batteries:

- Each battery must be individually protected against short circuits (e.g., plastic bag, terminal covers).

- Packed in a way that prevents damage and accidental activation.

- Use packaging tested and certified if shipping under full dangerous goods regulations.

Labeling and Marking

When Full Dangerous Goods Regulations Apply:

- Class 9 Hazard Label

- Lithium Battery Handling Label (with UN number, proper shipping name, and contact info)

- Shipper/Consignee information

- UN3480 marking on package

When Exceptions Apply (e.g., PI 967 Section IB):

- No hazard labels required.

- Package must be marked:

“Lithium ion batteries in compliance with Section II of IATA DGR”

or equivalent (e.g., for IMDG: “Lithium ion batteries – permitted for transport in accordance with IMDG Code Special Provision 188”)

Documentation

- Dangerous Goods Declaration (DGD): Required only when shipping under full regulations (e.g., large quantities, defective batteries).

- For excepted shipments: No DGD is needed, but commercial invoice and packing list must clearly describe contents.

- Shipper’s Declaration for Dangerous Goods: Mandatory for air cargo shipments under full regulation.

State of Charge (SoC) Limitations

- For air transport, batteries should not exceed 30% state of charge when shipped as standalone (loose) batteries, unless approved by the operator.

- Installed batteries in equipment are typically not subject to SoC limits under exception provisions.

Air Transport Restrictions

- Airlines and airports may impose additional restrictions.

- Some carriers prohibit shipments of lithium batteries altogether unless compliant with strict packaging and documentation.

- Passenger baggage: Spare batteries must be in carry-on only.

Ground and Sea Transport

- IMDG Code (Sea): Applies to ocean freight; similar rules with Special Provision 188 allowing exceptions for small batteries in equipment.

- ADR (Road, Europe): Requires compliance with packaging, labeling, and documentation; small consignments may be exempt under limited quantities provisions.

- 49 CFR (USA): Allows exceptions for consumer electronics under specific conditions (e.g., §173.185).

Handling and Storage

- Store in cool, dry areas away from flammable materials.

- Avoid physical damage, punctures, or exposure to extreme temperatures.

- Segregate from other dangerous goods during storage and transport.

Training and Certification

- Personnel involved in packing, labeling, or shipping must be trained and certified in dangerous goods regulations (e.g., IATA DGR training for air shipments).

- Training must be refreshed every 12–24 months depending on mode and jurisdiction.

Non-Compliance Risks

- Fines and penalties from regulatory bodies (e.g., FAA, TSA, DOT, ECHA)

- Shipment rejection or confiscation

- Safety incidents (fires, explosions)

- Reputational and financial damage

Best Practices

- Verify battery specifications (watt-hour rating) before shipping.

- Use compliant packaging and protective measures.

- Apply correct markings and labels based on shipping scenario.

- Maintain records of training, shipments, and compliance checks.

- Stay updated on regulatory changes (e.g., annual IATA DGR updates).

Conclusion

Shipping lithium-ion batteries for laptop computers requires careful attention to regulatory exceptions and compliance standards. Most shipments of laptops with installed batteries qualify for simplified rules, but spare or defective batteries must be handled under full dangerous goods protocols. Partnering with trained logistics providers and maintaining strict internal procedures ensures safe, compliant, and efficient transportation.

In conclusion, sourcing lithium-ion batteries for laptop computers requires careful consideration of several key factors to ensure performance, safety, reliability, and cost-effectiveness. It is essential to identify reputable suppliers or manufacturers with proven quality standards, such as ISO certifications and compliance with safety regulations like UL, CE, or UN38.3. The battery’s specifications—such as voltage, capacity (mAh), energy density, cycle life, and compatibility with the laptop model—must align precisely with technical requirements.

Additionally, evaluating the total cost of ownership—beyond just the unit price—should include shipping, customs, warranty, and potential return policies. Sustainability and ethical sourcing practices, including responsible mining and recycling initiatives, are increasingly important for both regulatory compliance and corporate social responsibility.

Finally, maintaining strong relationships with suppliers, conducting regular quality audits, and staying informed about advancements in battery technology will help ensure a reliable and future-ready supply chain. By taking a strategic and due diligence-driven approach, organizations can source lithium-ion batteries that meet performance demands while minimizing risks and supporting long-term success.