The global lipstick molds market is experiencing steady growth, driven by rising demand in the cosmetics industry and the expansion of private-label beauty brands. According to Grand View Research, the global cosmetics packaging market—of which lipstick molds are a critical component—was valued at USD 49.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing consumer preference for premium and customizable cosmetic products, particularly in emerging markets across Asia-Pacific and Latin America. As brands prioritize design innovation and efficient production, the need for high-precision, durable lipstick molds has intensified. This demand has elevated the role of specialized manufacturers capable of delivering consistent quality, scalability, and advanced tooling technology. Based on production capacity, global reach, innovation in mold engineering, and customer reviews, here are the top six lipstick mold manufacturers shaping the future of cosmetic manufacturing.

Top 6 Lipstick Molds Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lipstick Mold (3 Cavity Plastic)

Domain Est. 1999

#2 Cosmopak

Domain Est. 2000

Website: cosmopak.com

Key Highlights: cosmopak offers a wide range of packaging options to suit your unique needs. From stock molds to custom tooling solutions, we have you covered for all beauty ……

#3 Lipstick Moulding Machines & Line Equipment

Domain Est. 2001

Website: marchesini.com

Key Highlights: We design and produce Lipstick Moulding Machines & Line Equipment. Technological innovation & experience: let’s work together on your project….

#4 How to Customize Lipstick Mold

Domain Est. 2008

Website: alovey.com

Key Highlights: At Alovey, we work with both silicone molds for creative, small-scale use and aluminum (alu) molds for large-scale professional manufacturing….

#5 Lipstick molding machines

Domain Est. 2011

Website: citus-kalix.fr

Key Highlights: Citus Kalix has a long history of developing high quality and innovative lipstick moulding machines. With over 160 machines worldwide, we are recognised as ……

#6 DIY Lipstick Mold,12.1 Aluminum Alloy Rose Gold Dual Uses Lip …

Domain Est. 2021

Expert Sourcing Insights for Lipstick Molds

H2: 2026 Market Trends for Lipstick Molds

The global lipstick molds market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and sustainability demands. As the cosmetics industry embraces personalization and eco-conscious production, lipstick mold manufacturers are adapting to meet new standards and opportunities.

-

Rise of Customization and Niche Brands

By 2026, the demand for customized lipstick molds is expected to surge, fueled by the growth of indie and direct-to-consumer (DTC) beauty brands. These brands prioritize unique product designs to differentiate themselves in a crowded market. As a result, mold manufacturers are increasingly offering low-volume, high-precision molds tailored to specific branding needs, including custom shapes, logos, and ergonomic designs. -

Sustainability and Eco-Friendly Materials

Environmental concerns are reshaping production practices. In response, mold producers are investing in recyclable and biodegradable mold materials, such as plant-based resins and aluminum alloys with lower carbon footprints. Additionally, reusable and long-life mold systems are gaining traction, reducing waste in manufacturing and aligning with circular economy principles. -

Advancements in 3D Printing and Rapid Prototyping

The integration of 3D printing technology is revolutionizing mold development. By 2026, more manufacturers will adopt additive manufacturing to produce prototype molds quickly and cost-effectively. This trend enables faster time-to-market for new lipstick designs and supports agile product development, particularly for seasonal or limited-edition releases. -

Growth in Asia-Pacific Manufacturing Hubs

China, India, and Southeast Asia will remain dominant in lipstick mold production due to cost efficiency and robust supply chains. However, increasing labor costs and environmental regulations may prompt some brands to explore nearshoring options in regions like Eastern Europe or Mexico. Still, the Asia-Pacific region is expected to maintain its leadership through innovation and economies of scale. -

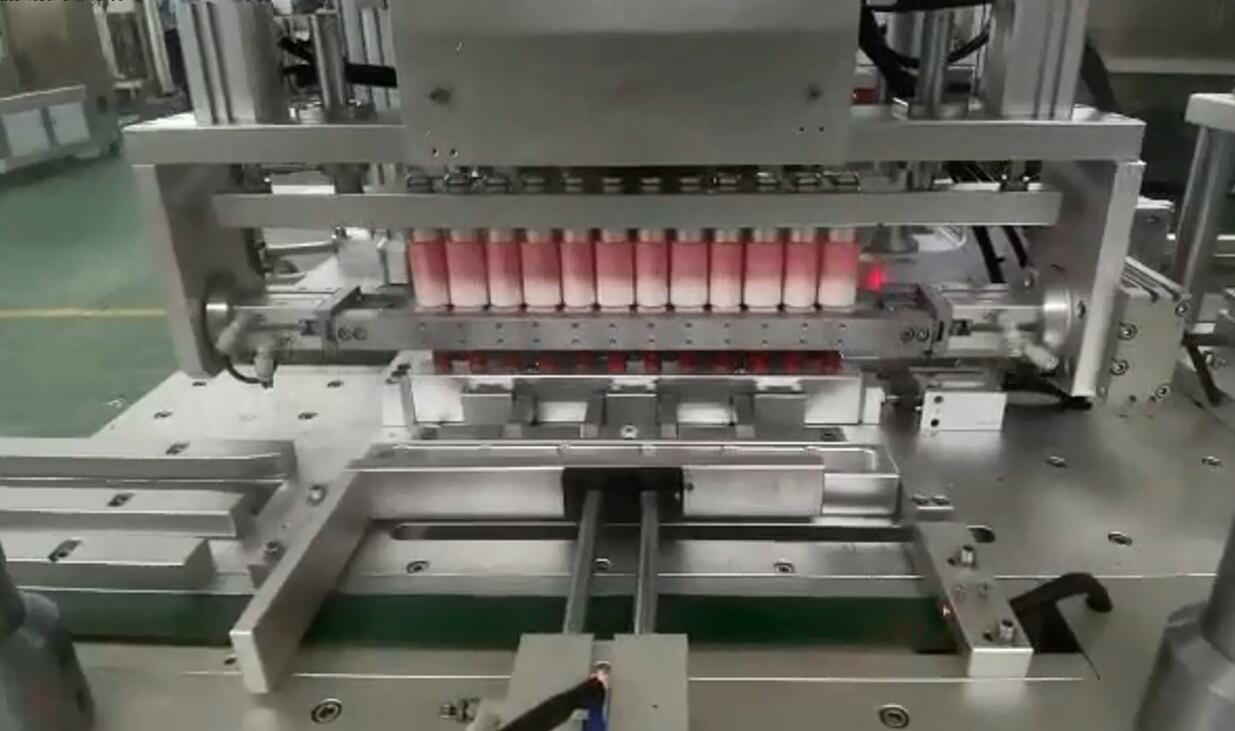

Smart Molds and Automation Integration

Automation in cosmetic manufacturing is driving demand for smart molds equipped with sensors and IoT connectivity. These advanced molds can monitor fill levels, temperature, and pressure in real-time, improving production accuracy and reducing defects. By 2026, integration with Industry 4.0 practices will become a key competitive advantage for mold suppliers. -

Regulatory Compliance and Material Safety

With tightening global regulations on cosmetic safety, lipstick mold manufacturers must ensure materials are non-toxic, hypoallergenic, and compliant with standards such as FDA, REACH, and ISO. This is particularly critical for molds used in organic and clean beauty formulations, where purity and safety are paramount.

In conclusion, the 2026 lipstick molds market will be shaped by innovation, sustainability, and responsiveness to niche market demands. Companies that invest in flexible manufacturing technologies, sustainable practices, and digital integration will be best positioned to lead in this dynamic landscape.

Common Pitfalls When Sourcing Lipstick Molds: Quality and Intellectual Property Risks

Sourcing lipstick molds, especially from overseas manufacturers, can be cost-effective but comes with significant risks if not managed carefully. Two major areas of concern are quality inconsistencies and intellectual property (IP) infringement. Being aware of these pitfalls helps mitigate potential setbacks in production, brand reputation, and legal exposure.

Quality Control Challenges

One of the most frequent issues when sourcing lipstick molds is inconsistent or subpar quality. Molds must meet precise specifications to ensure smooth demolding, consistent lipstick shape, and professional finish. Poorly made molds may lead to:

- Dimensional Inaccuracies: Slight deviations in cavity size or depth can result in lipstick misalignment, difficulty ejecting products, or inconsistent branding impressions.

- Surface Imperfections: Scratches, rough finishes, or uneven polishing on the mold surface transfer directly onto the lipstick, damaging product aesthetics.

- Material Defects: Low-grade steel or improper heat treatment can cause premature wear, warping, or corrosion, reducing mold lifespan and increasing long-term costs.

- Tolerance Issues: Inadequate attention to tolerances can lead to flashing (excess material at mold seams) or incomplete filling, resulting in wasted materials and rework.

To avoid these issues, it’s crucial to request detailed technical drawings, conduct factory audits, and require sample prototypes before mass production. Third-party inspection services can also verify quality standards are met.

Intellectual Property Risks

Another major pitfall in sourcing lipstick molds—particularly from regions with weaker IP enforcement—is the risk of design theft or unauthorized replication. Custom mold designs are often a brand’s proprietary asset, and unscrupulous suppliers may:

- Copy and Resell Designs: Use your unique mold design to produce and sell identical molds to competitors.

- Produce and Sell Counterfeit Products: Use your molds to manufacture and distribute knock-off lipsticks under different brands.

- Lack of Legal Recourse: Enforceable IP protection may be limited in certain countries, making it difficult to pursue legal action even if infringement is discovered.

To protect your IP:

– Work with suppliers who sign comprehensive Non-Disclosure Agreements (NDAs) and IP ownership clauses.

– Register design patents or trademarks in key markets.

– Limit design exposure by sharing only necessary details with suppliers.

– Consider using mold marking or serialization to trace unauthorized production.

Proactively addressing both quality and IP concerns ensures your lipstick molds meet high standards and safeguard your brand’s uniqueness and market position.

Logistics & Compliance Guide for Lipstick Molds

Product Classification and HS Code

Lipstick molds are typically classified under the broader category of cosmetic manufacturing equipment or molds for plastics. The most commonly applicable Harmonized System (HS) code is 8207.50 – “Parts and accessories, for tools of heading 8204 to 8207, for working in the cold, of base metal.” Alternatively, if the molds are made of plastic, 3923.90 (“Articles for the conveyance or packing of goods, of plastics”) may apply. For precision, consult local customs authorities or a trade compliance expert, as classification can vary by material and design.

Import/Export Regulations

Lipstick molds are generally not subject to stringent regulatory controls since they are manufacturing tools, not finished cosmetic products. However, importers must comply with general trade regulations, including accurate declarations of value, origin, and quantity. Countries may impose anti-dumping duties or trade restrictions on metal goods; verify if any such measures apply based on the country of manufacture (e.g., China, Germany, USA). Use Incoterms (e.g., FOB, CIF) clearly in contracts to define responsibilities.

Packaging and Shipping Requirements

Package molds securely in protective materials (e.g., foam inserts, corrugated boxes) to prevent damage during transit. Include desiccant packs if shipping metal molds to reduce moisture risk. Label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include a detailed packing list. For international shipping, use durable, export-grade packaging compliant with ISPM 15 standards if wooden crates are involved.

Customs Documentation

Essential documents include:

– Commercial Invoice (with full product description, HS code, value, and country of origin)

– Packing List

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (if claiming preferential tariff treatment under trade agreements)

– Import Declaration (completed by the importer or customs broker)

Ensure all documents are consistent and accurately reflect the shipment contents to avoid delays.

Material Compliance and Safety

Verify that mold materials comply with REACH (EU), RoHS (for electronic components, if applicable), and other regional chemical regulations. While lipstick molds do not contact end-users directly, manufacturers may require compliance with food-contact or medical-grade standards (e.g., FDA 21 CFR for indirect food contact) if molds are used in regulated production environments.

Intellectual Property Considerations

Ensure molds do not infringe on patented designs or trademarks. If molds are custom-designed, secure proper licensing or intellectual property rights documentation. Shipments may be detained if customs suspects IP violations.

Storage and Handling Post-Import

Store molds in a dry, temperature-controlled environment to prevent corrosion or deformation. Use appropriate handling equipment (e.g., gloves, lifting tools) to avoid surface damage. Maintain an inventory log for traceability, especially in regulated manufacturing settings.

Environmental and Disposal Regulations

At end-of-life, molds made of metal should be recycled in accordance with local waste management laws (e.g., WEEE in the EU). Avoid landfill disposal of metal components where recycling infrastructure is available.

In conclusion, sourcing lipstick molds requires careful consideration of material quality, precision in design, durability, and supplier reliability. High-grade materials such as food-safe silicone or aluminum are essential to ensure consistent production, ease of demolding, and product safety. It is important to evaluate suppliers based on their manufacturing capabilities, lead times, customization options, and compliance with industry standards. Additionally, balancing cost-effectiveness with long-term performance will contribute to efficient and sustainable lipstick production. By selecting the right molds from reputable sources, cosmetic brands can enhance product quality, maintain brand integrity, and support scalable growth in a competitive market.