The global textile market is undergoing a significant transformation, driven by rising consumer demand for high-performance, low-maintenance fabrics—particularly those that resist pilling and linting. According to a 2023 report by Grand View Research, the global technical textiles market size was valued at USD 237.5 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key contributor to this growth is the increasing preference for lint-free materials in industries ranging from healthcare and cleanroom manufacturing to sportswear and premium apparel. Mordor Intelligence further projects the specialty textiles market to expand steadily, fueled by advancements in fabric engineering and a shift toward sustainable, durable materials. In this evolving landscape, manufacturers specializing in lint-free fabrics are gaining strategic importance. These suppliers leverage advanced weaving techniques, premium fibers like microfiber, bamboo, and high-thread-count cotton, and proprietary finishes to deliver smooth, durable textiles with minimal shedding. As demand for cleaner, longer-lasting fabrics intensifies, identifying top-tier manufacturers capable of consistent quality and innovation has become critical for brands aiming to meet both performance and sustainability benchmarks.

Top 8 Lint Free Fabrics Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cleanroom Polyester Lint Free Cloth

Domain Est. 2014

Website: bsl-clean.com

Key Highlights: We are professional Cleanroom Polyester Lint Free Cloth,Lint Free Cloth manufacturer,can OEM/ODM customize according to personalized requests….

#2 Lint free cloth Manufacturers & Suppliers

Domain Est. 2021

Website: btpurify.com

Key Highlights: Lint free cloth Manufacturers, Factory, Suppliers From China, Please feel free to contact us at any time. We will reply you when we receive your inquiries….

#3 Lint Free Cloth

Domain Est. 1997

Website: berkshire.com

Key Highlights: Explore our extensive selection of Lint Free Cleaning Cloth for Cleanroom and Industrial cleaning applications today!…

#4 WypAll® Oil, Grease & Ink Cloths (33352), Brag Box, Lint

Domain Est. 2001

Website: kcprofessional.com

Key Highlights: These heavy duty towels made of meltblown technology are fast-absorbing, durable, and lint free. WypAll® Oil, Grease & Ink Cloths are a favorite replacement for ……

#5 Disposable Lint Free Essential Cloths/Wipes

Domain Est. 1995

Website: sisweb.com

Key Highlights: Description. Wipes are disposable, 100% cellulose, lint-free cloths designed for cleaning areas where non-contamination is essential….

#6 Lint Free Towels – Sanitary Towel

Domain Est. 1999

Website: nationalwiper.com

Key Highlights: An all-purpose, cloth-like wiper made from strong cellulose offering high bulk, stretch, softness and extremely absorbent….

#7 Hospitality Cleaning Cloths By Rifz Textiles

Domain Est. 2001

Website: rifz.com

Key Highlights: Free delivery over $99 30-day returnsThese lint-free cloths ensure a streak-free finish on glass, mirrors, and surfaces, making them ideal for high-standards housekeeping. Highly a…

#8 Lint free wiping cloth

Domain Est. 2014

Website: yessor.com

Key Highlights: Looking to buy lint-free cloth? Our lint-free wipes and lint-free cleaning wipes are designed for optimal performance in critical environments….

Expert Sourcing Insights for Lint Free Fabrics

H2: Market Trends in Lint-Free Fabrics for 2026

The global lint-free fabrics market is poised for significant transformation by 2026, driven by increasing demand across high-precision industries, technological advancements in textile manufacturing, and evolving regulatory standards. As industries such as healthcare, electronics, cleanroom manufacturing, and automotive continue to prioritize contamination control, lint-free fabrics are becoming essential components in operational workflows. Below is an analysis of the key market trends expected to shape the lint-free fabrics sector in 2026.

1. Rising Demand from the Healthcare and Life Sciences Sector

The healthcare industry remains a primary driver of growth for lint-free fabrics. With heightened awareness of infection control post-pandemic and the expansion of biotechnology and pharmaceutical research, the need for sterile, low-particulate wiping materials is intensifying. By 2026, hospitals, laboratories, and medical device manufacturers are expected to increase procurement of lint-free wipes and garments, particularly those made from spunlace nonwovens and microfiber blends that offer high absorbency and minimal fiber shedding.

2. Growth in Electronics and Semiconductor Manufacturing

The global semiconductor boom, fueled by AI, 5G, and IoT technologies, is creating robust demand for contamination-free environments. Lint-free fabrics used in cleanroom garments, wipes, and packaging are critical to maintaining yield and quality in microchip production. Countries investing heavily in semiconductor infrastructure—such as the U.S., South Korea, Taiwan, and China—are anticipated to lead market expansion, pushing manufacturers to innovate with anti-static and ultra-low particulate solutions.

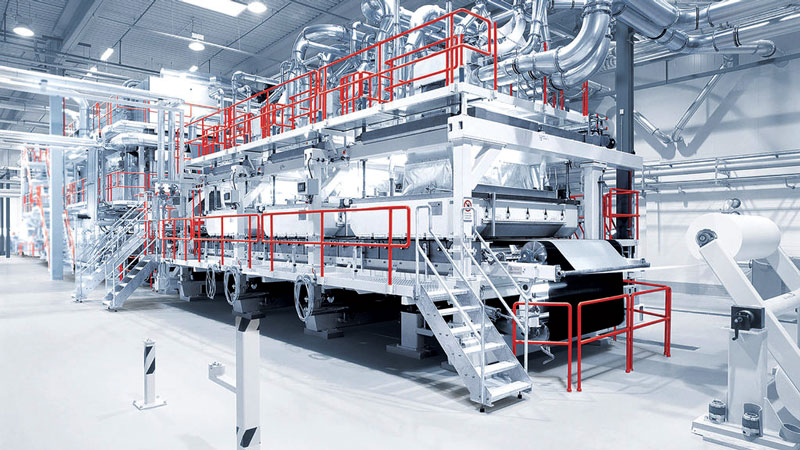

3. Technological Innovation in Material Science

By 2026, advancements in fiber engineering and nonwoven technologies are expected to enhance the performance of lint-free fabrics. Developments such as nanofiber integration, plasma-treated surfaces, and biodegradable synthetic blends will improve filtration efficiency, durability, and sustainability. These innovations will allow manufacturers to meet stringent ISO cleanroom standards (e.g., ISO Class 3–5) while reducing environmental impact.

4. Sustainability and Eco-Friendly Production

Environmental concerns are reshaping the lint-free fabric market. End-users and regulators are demanding greener alternatives to traditional petroleum-based synthetic fibers. In response, key players are investing in recyclable materials, waterless dyeing techniques, and compostable lint-free wipes. Biobased polymers like PLA (polylactic acid) and recycled polyester are expected to gain traction, particularly in Europe and North America where sustainability regulations are more stringent.

5. Regional Market Expansion and Localization

Asia-Pacific is projected to dominate the lint-free fabrics market by 2026, driven by rapid industrialization, growing electronics manufacturing hubs, and rising healthcare expenditures in countries like India, Vietnam, and Japan. At the same time, onshoring trends in the U.S. and EU due to supply chain resilience concerns will lead to localized production of lint-free textiles, reducing dependency on global suppliers and improving delivery timelines.

6. Consolidation and Strategic Partnerships

The competitive landscape is expected to see increased M&A activity and joint ventures as companies seek to expand product portfolios and geographic reach. Major nonwoven producers are likely to acquire niche innovators in cleanroom textiles, while collaborations between fabric suppliers and end-users (e.g., semiconductor firms) will accelerate customized product development.

7. Digital Integration and Smart Textiles

Emerging applications in smart lint-free garments—embedded with sensors for contamination monitoring or temperature regulation—are anticipated to gain pilot adoption by 2026. While still in early stages, digital integration could redefine performance metrics and open new revenue streams in high-value sectors.

Conclusion

By 2026, the lint-free fabrics market will be characterized by technological sophistication, sustainability imperatives, and sector-specific customization. Companies that invest in R&D, adopt circular economy models, and align with global cleanroom standards will be well-positioned to capture growth in this dynamic and essential segment of the technical textiles industry.

Common Pitfalls Sourcing Lint-Free Fabrics (Quality, IP)

Sourcing lint-free fabrics requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to production delays, compromised product performance, legal risks, and reputational damage. Below are common pitfalls to avoid:

Inadequate Fabric Quality Control

One of the most frequent issues when sourcing lint-free fabrics is failing to enforce rigorous quality standards. Lint generation can compromise sensitive applications in cleanrooms, electronics manufacturing, and medical environments. Buyers often assume “lint-free” is a universal standard, but definitions vary. Without clear specifications and third-party testing, suppliers may deliver fabrics that shed fibers under real-world conditions.

Misunderstanding Fabric Specifications

Not all lint-free fabrics are created equal. Pitfalls arise when buyers do not specify critical parameters such as fiber content (e.g., 100% polyester vs. blends), weave tightness, finishing treatments, and particle emission levels. Relying solely on supplier claims without requesting test data (e.g., IEST or ISO 14644 compliance) can result in unsuitable materials.

Overlooking Supply Chain Transparency

Many suppliers subcontract production, leading to inconsistent quality and obscured origins. Without traceability, it’s difficult to verify claims about fabric composition, cleanliness, and manufacturing processes. This lack of transparency increases the risk of receiving substandard or counterfeit materials.

Ignoring Intellectual Property Rights

When sourcing specialized lint-free fabrics—especially those with proprietary treatments or patented technologies—buyers may inadvertently violate IP rights. Using fabrics protected by patents without proper licensing exposes companies to legal action. Additionally, private-label or custom-developed fabrics may be resold by unethical suppliers to competitors, diluting competitive advantage.

Failing to Secure IP Agreements

A common oversight is not establishing clear contractual terms around IP ownership and usage rights. Without non-disclosure agreements (NDAs), work-for-hire clauses, or exclusivity provisions, suppliers may retain rights to replicate or distribute custom fabric formulations, leading to loss of competitive differentiation.

Prioritizing Cost Over Performance

Choosing the cheapest option can backfire when lint-free performance is compromised. Low-cost fabrics may use inferior fibers or processing methods that increase particle shedding. The resulting contamination issues often lead to higher long-term costs due to rework, equipment damage, or product recalls.

Neglecting Certification and Compliance

In regulated industries, using non-compliant lint-free fabrics can lead to audit failures or regulatory penalties. Buyers must ensure fabrics meet required standards (e.g., ISO 14698, EN 14683) and come with proper documentation. Assuming compliance without verification is a significant risk.

Conclusion

To avoid these pitfalls, buyers should define precise technical requirements, conduct supplier audits, require independent testing, and establish strong IP protections. Due diligence in both quality and legal aspects ensures reliable performance and safeguards innovation in lint-free fabric applications.

Logistics & Compliance Guide for Lint-Free Fabrics

Lint-free fabrics are critical in industries where cleanliness and contamination control are paramount, such as semiconductor manufacturing, pharmaceuticals, medical device production, and cleanroom environments. Proper logistics and regulatory compliance are essential to maintain fabric integrity, ensure safety, and meet industry standards. This guide outlines key considerations for handling, transporting, storing, and complying with regulations related to lint-free fabrics.

Understanding Lint-Free Fabric Specifications

Lint-free fabrics are engineered to minimize fiber shedding. They are typically made from synthetic materials like polyester, polypropylene, or blended fibers with tightly woven or non-woven constructions. Common types include:

- Cleanroom wipers (e.g., polyester knit, cellulose/polyester blends)

- Garments (e.g., lab coats, coveralls, gloves)

- Packaging materials (e.g., sealed pouches, sterile wraps)

Ensure specifications meet relevant standards such as ISO 14644 (cleanroom classification), IEST-G-CC003 (cleanroom garments), or ASTM F2252 (evaluating nonwoven fabrics).

Packaging and Contamination Control

Proper packaging is vital to preserve the lint-free properties of fabrics during transit and storage.

- Sealed, Low-Particulate Packaging: Use double-bagged or heat-sealed polyethylene or polypropylene pouches.

- Cleanroom Packaging: For high-sensitivity applications, pre-packaging within ISO Class 5 or better environments may be required.

- Labeling: Include product name, lot number, material composition, sterility status (if applicable), and expiration date.

- Avoid Contaminants: Packaging materials should be non-shedding, non-outgassing, and free from adhesives or inks that could compromise cleanliness.

Storage Requirements

Storage conditions directly affect the performance of lint-free fabrics.

- Environment: Store in a clean, dry, temperature-controlled environment (typically 15–25°C, 30–60% RH).

- Cleanroom Storage: High-grade fabrics should be stored in controlled cleanroom areas to prevent particulate accumulation.

- Shelving: Use non-shedding, easy-to-clean materials (e.g., stainless steel). Keep off the floor and away from walls.

- Rotation: Implement a first-in, first-out (FIFO) system to prevent aging and degradation, especially for sterile or treated fabrics.

Transportation and Handling

Minimizing exposure to contaminants during shipping is critical.

- Clean Transport Vehicles: Use vehicles dedicated to clean goods or thoroughly cleaned before loading.

- Protective Crating: Ship in sealed, rigid containers to prevent crushing, moisture, or dust ingress.

- Avoid Cross-Contamination: Do not transport lint-free fabrics with chemicals, food, or high-particulate materials.

- Handling Procedures: Personnel should wear gloves and cleanroom attire when handling unpackaged or high-grade fabrics. Avoid touching fabric surfaces directly.

Regulatory Compliance

Lint-free fabrics used in regulated industries must comply with relevant standards and certifications.

- ISO Standards:

- ISO 14644-1: Classification of air cleanliness in cleanrooms.

- ISO 13485: Quality management for medical devices (if used in medical settings).

- FDA Regulations (U.S.):

- 21 CFR Part 820 (Quality System Regulation) for medical devices.

- GMP (Good Manufacturing Practices) for pharmaceutical applications.

- EU MDR/IVDR: For medical devices and in-vitro diagnostics in Europe.

- REACH & RoHS: Ensure fabric materials comply with chemical restrictions in the EU.

- Sterility Claims: If fabrics are sold as sterile, validate sterilization methods (e.g., gamma irradiation, EO) and comply with ISO 11135 or ISO 11137.

Documentation and Traceability

Maintain complete records to support compliance and quality assurance.

- Certificates of Conformance (CoC): Provide with each shipment, including material specs, test results, and compliance statements.

- Lot Traceability: Track raw materials, production batches, and distribution for effective recalls if necessary.

- Validation Reports: For sterilization, cleanliness testing (e.g., particle count, non-viable sampling), and packaging integrity.

- SDS (Safety Data Sheets): Required if fabrics contain chemical treatments or are used with hazardous substances.

Quality Assurance and Testing

Regular testing ensures ongoing compliance and performance.

- Particle Emission Testing: Conduct per IEST-G-CC003.1 or ISO 14644-1 to verify low linting.

- Absorbency and Strength Tests: ASTM D5725 (surface wipability), ASTM D5035 (tensile strength).

- Microbial Testing: For sterile products, perform bioburden and sterility testing per USP <71> or ISO 11737.

- Supplier Audits: Evaluate fabric suppliers for cleanroom practices, quality systems, and compliance history.

Environmental and Disposal Considerations

Disposal methods depend on fabric use and contamination level.

- Non-Hazardous Waste: Unused, uncontaminated lint-free fabrics may be disposed of as general waste or recycled if material allows.

- Hazardous or Biohazardous Waste: Fabrics used with chemicals or biological agents must be disposed of following local regulations (e.g., EPA, OSHA, or EU directives).

- Sustainability: Consider recyclable or biodegradable options where performance permits.

Training and Personnel Protocols

Personnel involved in logistics must be trained in clean handling practices.

- Cleanroom Behavior: Training on gowning, movement, and minimizing particle generation.

- Handling Procedures: Use of gloves, avoiding unnecessary contact, and proper unpacking techniques.

- Compliance Awareness: Regular updates on regulatory requirements and internal SOPs.

Conclusion

Managing the logistics and compliance of lint-free fabrics requires a systematic approach focused on contamination control, regulatory adherence, and quality assurance. By following proper packaging, storage, transportation, and documentation practices—and ensuring alignment with international standards—organizations can maintain the integrity of lint-free materials and support critical operations in high-sensitivity environments.

In conclusion, sourcing lint-free fabrics requires a careful evaluation of material composition, manufacturing processes, end-use requirements, and supplier reliability. Fabrics such as polyester, microfiber, and tightly woven synthetics are preferred for their minimal shedding, making them ideal for sensitive environments like cleanrooms, healthcare, electronics manufacturing, and laboratories. Key factors to consider include fabric weight, weave density, certification standards (e.g., ISO Class ratings), and compliance with industry-specific regulations.

Establishing relationships with reputable suppliers who provide consistent quality, proper documentation, and testing data ensures reliability and traceability. Additionally, conducting sample testing under real-world conditions helps verify performance before large-scale procurement. By prioritizing these criteria, organizations can effectively source lint-free fabrics that maintain cleanliness, protect sensitive processes, and support operational efficiency.