The global line boring bar market is experiencing steady growth, driven by increasing demand for precision machining in the automotive, aerospace, and heavy equipment repair sectors. According to Grand View Research, the global metal cutting tools market—under which line boring bars fall—was valued at USD 28.9 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by the rising need for high-tolerance components and the expansion of manufacturing activities in emerging economies. Similarly, Mordor Intelligence forecasts sustained demand for advanced machining tools, citing automation and technological integration in CNC-based systems as key market drivers. As industries prioritize efficiency and accuracy in engine rebuilding, cylinder restoration, and custom machining applications, the role of high-performance line boring bars has become increasingly critical. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, durability, and precision to meet rigorous industrial standards.

Top 9 Line Boring Bar Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

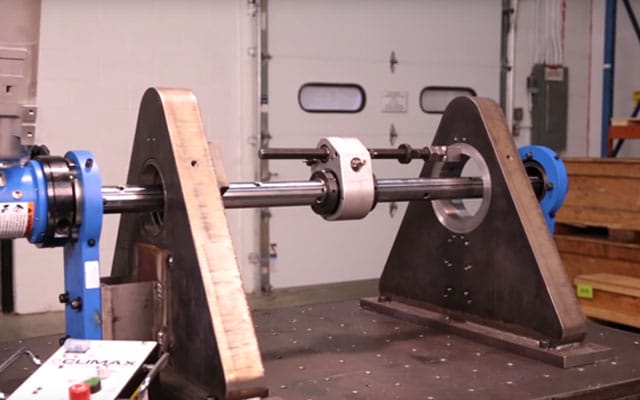

#1 Climax Portable

Domain Est. 2012

Website: climaxportable.com

Key Highlights: CLIMAX is the leading global manufacturer of portable machines, welding, valve testing equipment and repair tools, bringing the machine shop to the job ……

#2 Criterion Boring Tools Overview

Domain Est. 1996

Website: alliedmachine.com

Key Highlights: Browse the full Criterion boring product line including boring bars, boring heads, and other boring accessories….

#3 Boring & Sleeving Machinery

Domain Est. 1998

Website: rottlermfg.com

Key Highlights: We offer both dedicated CNC boring bars as well as multi purpose machining centers that are capable of boring and sleeving as well as many other functions….

#4 Line Boring Bars

Domain Est. 1999

Website: bdmfg.com

Key Highlights: Variety of different length and diameter Line Boring Bars to facilitate the adjustment of the radial feed of the cutters….

#5 Rigibore

Domain Est. 1999

Website: rigibore.com

Key Highlights: Rigibore manufactures special and standard boring bars and a wide range of standard products for boring that can be built into both standard and special tools….

#6 PINZBOHR BORING SYSTEM

Domain Est. 2001

Website: pinzbohr.com

Key Highlights: PINZBOHR is the robust boring system that provides accuracy, reliability and ease-of-use features that make setup and adjustment a snap….

#7 Line Boring Services & Equipment

Domain Est. 2008

Website: mactechonsite.com

Key Highlights: Our standard bars range from 1 ¾” to 10” diameters and lengths up to 24′. Visit our Line Boring Bar Page for more information on our tools. Want to see what ……

#8 Maucotools

Domain Est. 2020

Website: maucotools.com

Key Highlights: MAUCOTOOLS started specializing in only one product line: Multifunctional Portable line boring machine for on-site machining and bore welding….

#9 Line Boring Machines

Domain Est. 2020

Website: lineborer.com

Key Highlights: Need in situ boring solutions? Indi-Borer presents a range of line borer machines for sale. We also offer heavy equipment maintenance….

Expert Sourcing Insights for Line Boring Bar

H2: 2026 Market Trends for Line Boring Bars

The line boring bar market is poised for notable evolution by 2026, driven by advancements in manufacturing technologies, increasing demand for precision machining, and the expansion of key end-use industries. Below is an analysis of the primary trends expected to shape the line boring bar market in 2026:

-

Growing Demand from Heavy Industries

Sectors such as power generation, shipbuilding, oil & gas, and heavy equipment manufacturing will continue to rely on line boring bars for on-site repairs and maintenance of large machinery. The need for high-precision, in-situ machining operations—especially in legacy infrastructure—will bolster demand for robust and reliable line boring solutions. -

Adoption of Modular and Adjustable Systems

By 2026, manufacturers are expected to favor modular line boring bars that offer flexibility, faster setup times, and adaptability to various bore diameters and depths. This trend aligns with the broader industry push toward reducing downtime and increasing operational efficiency in maintenance and repair operations. -

Integration with CNC and Digital Machining Technologies

Line boring bars are increasingly being integrated with CNC-controlled systems and digital measurement tools. This enables enhanced accuracy, real-time monitoring, and data-driven adjustments during machining processes. The convergence with Industry 4.0 technologies will elevate the precision and repeatability of line boring applications. -

Material and Coating Innovations

Advances in cutting tool materials—such as carbide inserts with advanced PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings—will improve tool life, heat resistance, and performance in challenging materials like stainless steel and high-strength alloys. These innovations will be critical in maintaining efficiency in high-load applications. -

Expansion in Emerging Markets

Growth in industrial infrastructure in Asia-Pacific, Latin America, and parts of Africa will drive demand for line boring equipment. Localized manufacturing hubs and investments in energy and transportation sectors will increase the need for precision on-site machining tools, including line boring bars. -

Focus on Portability and Ease of Use

Equipment manufacturers are expected to emphasize compact, lightweight, and portable line boring systems that can be easily transported and set up in field environments. Ergonomic designs and quick-change tooling will be key selling points in competitive markets. -

Sustainability and Tool Reusability

With increasing emphasis on sustainable manufacturing, the industry will trend toward reusable and reconditionable line boring components. Refurbished tooling and insert recycling programs will gain traction, reducing waste and lifecycle costs for end users. -

Consolidation and Strategic Partnerships

The competitive landscape may see further consolidation among tooling manufacturers and strategic alliances with service providers offering integrated machining solutions. This will enable comprehensive service packages combining equipment, expertise, and digital support.

In summary, the 2026 line boring bar market will be shaped by technological innovation, industrial demand, and a shift toward smarter, more adaptable machining solutions. Companies that invest in R&D, digital integration, and global service networks are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Line Boring Bars (Quality, IP)

Sourcing Line Boring Bars—especially high-precision tools used in critical machining applications—can present several challenges related to quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps avoid costly errors, production delays, and legal complications.

Poor Quality Control and Inconsistent Tolerances

One of the most frequent issues is receiving Line Boring Bars that fail to meet required dimensional tolerances or material specifications. Low-cost suppliers—particularly those without robust quality management systems—may produce bars with inconsistent straightness, surface finish, or alignment, leading to subpar machining results, increased tool wear, or scrapped parts.

Use of Substandard Materials and Coatings

Inferior sourcing channels may use low-grade steel or inadequate heat treatment processes, compromising tool life and performance. Similarly, counterfeit or ineffective coatings (e.g., fake TiN or TiAlN) can mislead buyers into believing they are receiving high-performance tools, resulting in premature failure under load or high-temperature conditions.

Lack of Traceability and Certification

Reputable Line Boring Bars should come with material certifications (e.g., mill test reports), heat treatment records, and geometric inspection reports. Poor suppliers often lack traceability, making it difficult to verify compliance with industry standards (e.g., ISO, ANSI), which can be a major issue in regulated industries like aerospace or energy.

Intellectual Property (IP) Infringement Risks

Sourcing from unauthorized or unverified suppliers increases the risk of purchasing counterfeit or cloned tools that infringe on patented designs or proprietary technology. This exposes the buyer to potential legal liability, especially if the end product is involved in IP litigation or fails audit requirements.

Inadequate Documentation and Technical Support

Low-quality suppliers may provide limited or poor technical documentation, such as incorrect cutting parameters, installation guides, or compatibility information. This lack of support can lead to improper use, reduced tool life, and safety hazards.

Hidden Costs from Rework and Downtime

While a low initial purchase price may seem attractive, poor-quality Line Boring Bars often result in increased downtime, rework, and secondary machining operations. These hidden costs typically outweigh any upfront savings, affecting overall production efficiency and total cost of ownership.

Supply Chain Transparency and Counterfeit Risk

Global sourcing, especially from regions with weak IP enforcement, increases the risk of receiving counterfeit tools falsely branded as premium OEM products. Without supply chain transparency or direct relationships with manufacturers, verifying authenticity becomes difficult.

Conclusion

To mitigate these risks, buyers should prioritize suppliers with verifiable quality certifications (e.g., ISO 9001), clear IP compliance policies, and full technical support. Conducting supplier audits, requesting sample testing, and using trusted procurement channels are essential steps in ensuring reliable performance and legal safety when sourcing Line Boring Bars.

Logistics & Compliance Guide for Line Boring Bar

Product Classification & Documentation

Ensure the Line Boring Bar is correctly classified under the appropriate Harmonized System (HS) code, typically under HS 8466 (Parts and accessories of machine tools). Accurate classification is essential for customs clearance, duty calculation, and import/export compliance. Maintain detailed technical specifications, bills of materials, and commercial invoices to support classification and valuation.

Export Controls & Regulatory Compliance

Verify whether the Line Boring Bar is subject to export control regulations such as the Export Administration Regulations (EAR) in the U.S. or similar frameworks in other jurisdictions. Most standard boring bars may be classified as EAR99, meaning they are not specifically controlled, but confirm this based on technical capabilities (e.g., precision, materials, intended use). Avoid shipment to sanctioned countries or entities listed on restricted party screening lists (e.g., OFAC, BIS Denied Persons List).

Packaging & Handling Requirements

Package Line Boring Bars securely to prevent damage during transit. Use anti-corrosion protection (e.g., VCI paper or coating) and rigid containers to safeguard cutting edges and tool geometry. Clearly label packages with product details, handling instructions (e.g., “Fragile,” “This Side Up”), and barcodes for inventory tracking. Include protective caps on threads or precision surfaces where applicable.

Shipping & Transportation

Choose freight modes (air, sea, or ground) based on delivery timelines and cost. For international shipments, partner with freight forwarders experienced in industrial tooling logistics. Ensure proper Incoterms (e.g., FOB, DDP) are defined in sales contracts to clarify responsibilities for shipping, insurance, and customs. Provide accurate shipping documentation, including packing lists, commercial invoices, and certificates of origin.

Import Compliance & Duties

Confirm import requirements in the destination country, including local standards (e.g., CE marking in the EU, though not typically required for cutting tools). Pay applicable import duties and taxes based on the declared value and HS code. Retain all compliance documentation for audit purposes and ensure adherence to local product safety or labeling regulations if applicable.

End-Use & End-User Verification

Verify the end-use of the Line Boring Bar to ensure it is not intended for prohibited applications (e.g., military, nuclear). Conduct due diligence on end-users, especially in high-risk regions, to comply with anti-boycott and anti-terrorism regulations. Maintain records of end-user statements or certifications if required by law.

Recordkeeping & Audit Readiness

Retain all logistics and compliance documents for a minimum of five years, including export licenses (if applicable), shipping records, and compliance screenings. Establish internal procedures for regular audits of export and import activities to ensure ongoing adherence to international trade laws and regulations.

Environmental & Safety Compliance

Ensure disposal or recycling of packaging materials follows local environmental regulations. Comply with REACH (EU) and RoHS directives if applicable, particularly concerning heavy metals in tool coatings or substrates. Provide safety data sheets (SDS) if the product contains regulated substances, although this is rare for standard boring bars.

Conclusion for Sourcing Line Boring Bars

Sourcing the right line boring bar is a critical decision that directly impacts machining accuracy, productivity, and overall operational efficiency. After evaluating key factors such as rigidity, precision, material compatibility, tool life, and support services, it is evident that selecting a high-quality, application-specific line boring bar from a reputable supplier ensures consistent performance and long-term cost savings.

Investing in premium line boring bars not only enhances dimensional accuracy and surface finish in large-scale boring operations but also reduces downtime and maintenance requirements. Additionally, partnering with suppliers who offer technical expertise, customization options, and reliable after-sales support further strengthens operational reliability.

In conclusion, a strategic sourcing approach—balancing performance, durability, and total cost of ownership—will maximize return on investment and support sustained excellence in heavy-duty machining applications. Prioritizing quality and supplier reliability ensures that line boring operations remain efficient, precise, and adaptable to evolving production demands.