The global laser cleaning market is experiencing robust growth, driven by increasing demand for eco-friendly, precision-based surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to Grand View Research, the market was valued at USD 586.2 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 15.8% from 2023 to 2030. This surge is fueled by stringent environmental regulations, the push to eliminate chemical cleaning methods, and the superior efficiency of laser-based systems in rust, paint, and contaminant removal. As industries prioritize sustainability and operational efficiency, laser cleaning technology has emerged as a pivotal innovation. In this evolving landscape, a select group of manufacturers are leading the charge in technological advancement, product reliability, and global reach. Here, we present the top 10 limpeza a laser (laser cleaning) manufacturers shaping the future of industrial surface preparation and maintenance.

Top 10 Limpeza A Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine Manufacturers, Suppliers, Factory

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading intelligent laser equipment provider of laser cleaning machines. Email:[email protected]….

#2 China Laser Cleaning Suppliers, Manufacturers, Factory

Website: sdqy-laser.com

Key Highlights: QIANGYUAN is one of the most professional laser cleaning manufacturers and suppliers in China, specialized in providing high quality customized service….

#3 China Laser Cleaning Machine Manufacturers Suppliers Factory

Website: kingslaser.com

Key Highlights: We offer a range of laser cleaning machines tailored to the specific needs of different industries. Each machine has a unique set of features and performance….

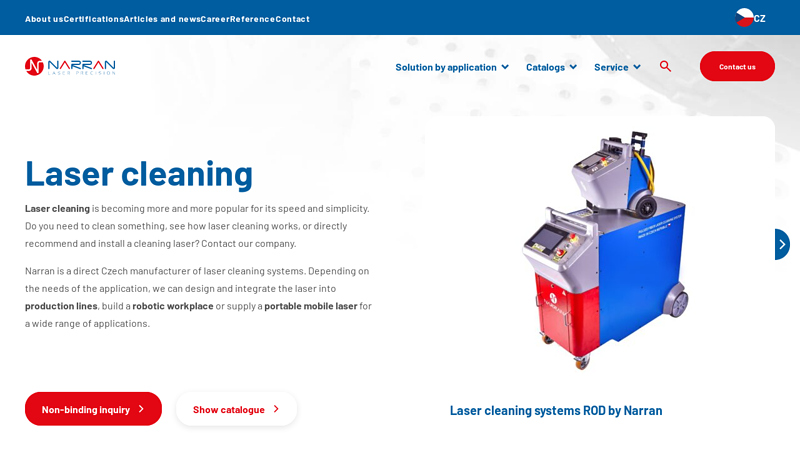

#4 Laser cleaning

Website: narran.cz

Key Highlights: We can design and integrate a laser cleaning system into production, build a robotic workstation or supply a mobile laser for a wide range of applications….

#5 Laser Cleaning

Website: keyence.com

Key Highlights: Elevate production quality with laser cleaning technology: remove dust, rust, and imperfections efficiently, reducing costs and improving precision….

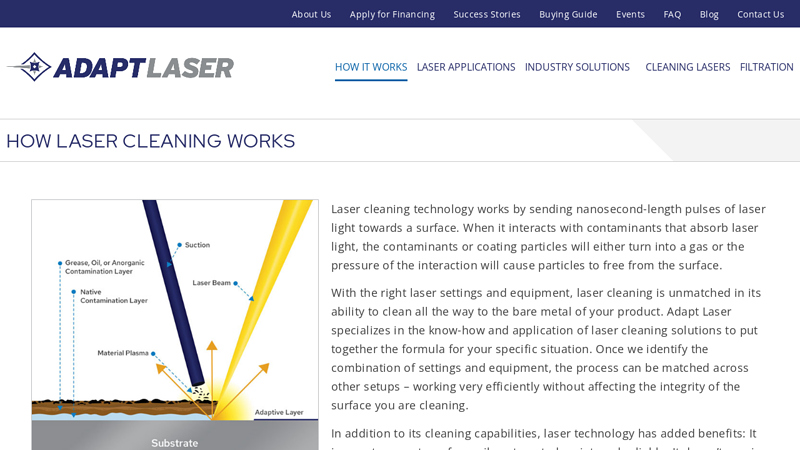

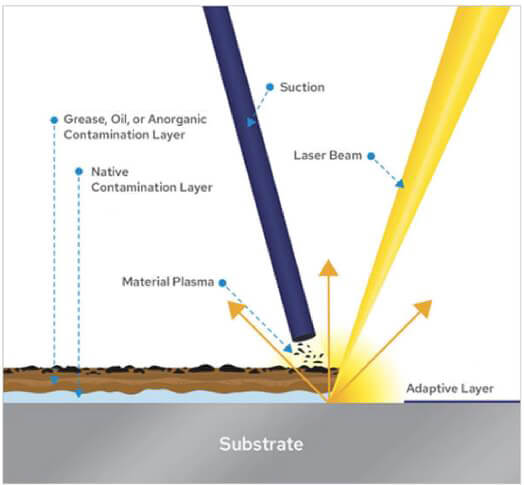

#6 How Laser Cleaning Works

Website: adapt-laser.com

Key Highlights: Laser cleaning technology works by sending nanosecond-length pulses of laser light towards a surface. When it interacts with contaminants that absorb laser ……

#7 Laser Cleaning

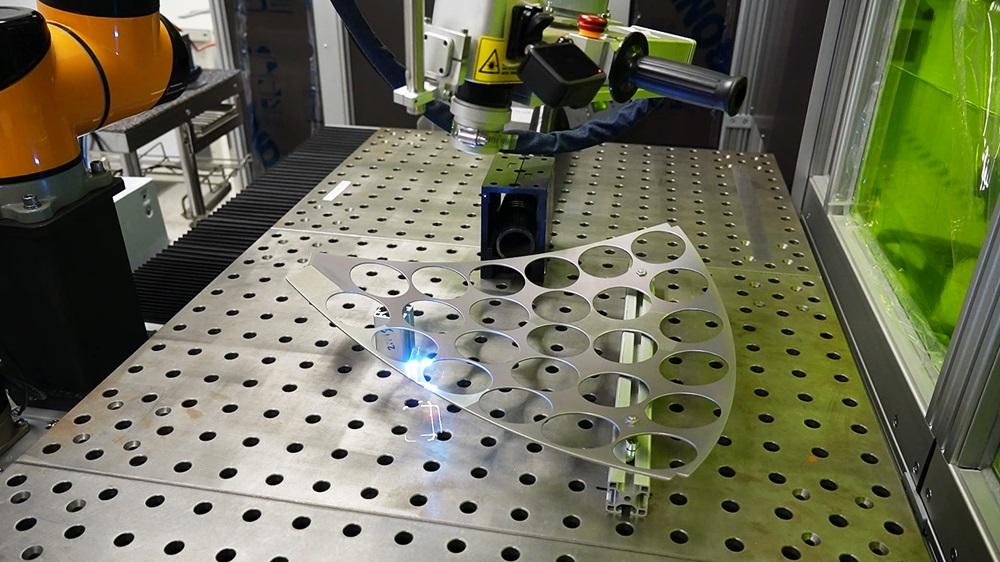

Website: ipgphotonics.com

Key Highlights: Laser cleaning, also known as laser material removal, is an advanced method of eliminating material from a surface achieved through the precise manipulation ……

#8 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#9 Manual & Automated Laser Cleaning Machines

Website: laserax.com

Key Highlights: Our laser cleaning machines range from manually loaded to fully automated solutions to meet the needs of various applications….

#10 Laser Cleaning

Website: greenstone-tech.com

Key Highlights: Limpeza a Laser. Provide customized overall solutions for laser cleaning according to customer needs to meet customers’ higher demands for advanced ……

Expert Sourcing Insights for Limpeza A Laser

H2: 2026 Market Trends for Limpeza a Laser (Laser Cleaning)

The market for Limpeza a Laser (Laser Cleaning) in 2026 is poised for significant growth, driven by increasing industrial automation, stringent environmental regulations, and a growing demand for precision, non-abrasive cleaning solutions. Here’s an analysis of key trends shaping the sector:

1. Accelerated Industrial Adoption Across Key Sectors:

By 2026, laser cleaning is expected to move beyond niche applications into mainstream industrial use. Key adopters will include:

– Automotive & Aerospace: For paint stripping, rust removal, and surface preparation before welding or coating, driven by quality and repeatability requirements.

– Manufacturing & Maintenance: Used for mold cleaning, tool restoration, and removal of oxides and residues without damaging substrates.

– Cultural Heritage & Restoration: Increasingly adopted by museums and conservationists for delicate cleaning of artworks, monuments, and historical artifacts due to its precision and non-contact nature.

– Energy Sector: Particularly in nuclear and wind industries, for decontamination and turbine blade cleaning, where safety and minimal waste are critical.

2. Environmental and Regulatory Drivers:

Stricter environmental regulations (e.g., VOC emissions, chemical waste disposal) across Europe, North America, and parts of Asia will push industries to abandon chemical and abrasive cleaning methods. Laser cleaning, being dry, chemical-free, and generating minimal secondary waste, will benefit significantly. This aligns with ESG (Environmental, Social, and Governance) goals, making it a preferred choice for sustainable operations.

3. Technological Advancements and Cost Reduction:

By 2026, expect:

– Lower Equipment Costs: Economies of scale and improved manufacturing will reduce the upfront cost of laser cleaning systems, improving ROI and accessibility for SMEs.

– Higher Efficiency & Portability: Advancements in fiber laser technology will lead to more compact, robust, and energy-efficient systems, enabling easier integration into production lines or field use.

– Automation & AI Integration: Increased use of robotics and AI-driven path planning will enhance precision, speed, and consistency, enabling 24/7 operation in smart factories.

4. Expansion of Service-Based Business Models:

A growing trend will be the shift from equipment sales to Cleaning-as-a-Service (CaaS). Companies like Limpeza a Laser may offer on-demand cleaning services using mobile units, reducing capital expenditure for clients and creating recurring revenue streams. This model is particularly attractive for sectors with sporadic cleaning needs.

5. Regional Growth Dynamics:

– Europe: A leader due to strict environmental policies (e.g., EU Green Deal) and high industrial maturity.

– Asia-Pacific: Fastest growth expected, especially in China, Japan, and South Korea, driven by manufacturing expansion and government support for green tech.

– North America: Steady growth fueled by aerospace, defense, and automotive industries adopting Industry 4.0 practices.

6. Competitive Landscape and Market Consolidation:

The market will see increased competition, with new entrants and existing players expanding their portfolios. Strategic partnerships between laser manufacturers, automation providers, and service companies will become common. Differentiation will come from specialized applications, software integration, and after-sales support.

Conclusion:

In 2026, Limpeza a Laser will operate in a dynamic and expanding market where sustainability, precision, and automation are paramount. Success will depend on technological innovation, strategic service offerings, and the ability to demonstrate clear environmental and economic advantages over traditional cleaning methods. Companies that adapt to these trends will capture significant market share in the growing green industrial economy.

Common Pitfalls When Sourcing Limpeza a Laser (Quality and IP)

Sourcing laser cleaning services or equipment—known as Limpeza a Laser in Portuguese—requires careful attention to both quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, legal risks, and compromised results. Below are the most common pitfalls to avoid.

Poor Quality Control and Inconsistent Results

One of the primary risks in sourcing Limpeza a Laser is encountering inconsistent cleaning performance due to inadequate quality standards. Not all laser cleaning providers use the same equipment, parameters, or technician expertise. Substandard services may result in incomplete surface cleaning, substrate damage, or rework requirements. Buyers often fail to define clear quality metrics (e.g., surface profile, cleanliness level per ISO 8501), leading to disputes over deliverables. Always request sample cleaning tests, detailed process documentation, and certifications to verify consistency and technical capability.

Lack of Equipment Calibration and Maintenance Records

Laser cleaning effectiveness heavily depends on properly calibrated and maintained equipment. Some suppliers may use outdated or poorly maintained systems, which compromise precision and safety. A common pitfall is not auditing the supplier’s maintenance logs or laser parameter validation procedures. Ensure that the provider follows regular calibration schedules and adheres to manufacturer specifications to guarantee repeatable, high-quality results.

Inadequate Operator Training and Certification

The skill level of the technician operating the laser system significantly impacts outcomes. Untrained operators may misuse settings, increasing the risk of surface ablation or incomplete contamination removal. When sourcing, verify that personnel are certified in laser safety (e.g., IEC 60825 compliance) and have documented training on the specific equipment used. Lack of proper training is a hidden quality risk that often surfaces only after project failures.

Intellectual Property Exposure During Process Development

When customizing laser cleaning parameters for proprietary components or materials, there’s a risk of exposing trade secrets. A major pitfall is failing to establish clear IP agreements before engaging a supplier. Without a robust Non-Disclosure Agreement (NDA) and IP ownership clauses, the service provider may retain rights to process innovations or reuse your data for competitive advantage. Always define upfront who owns the process parameters, settings, and any derived know-how.

Incomplete or Ambiguous Service Contracts

Many sourcing failures stem from vague contracts that omit critical technical and legal details. Contracts should explicitly define quality benchmarks, liability for damage, data usage rights, and IP ownership. A common oversight is neglecting to include provisions for audit rights or access to process logs, making it difficult to verify compliance or troubleshoot issues.

Overlooking Regulatory and Safety Compliance

Laser cleaning involves high-powered equipment subject to safety and environmental regulations. Sourcing from providers who do not comply with local or international standards (e.g., ANSI, CE, or NR-12 in Brazil) can expose your organization to liability. Ensure suppliers have proper safety protocols, emission controls, and operator certifications to mitigate health and legal risks.

Avoiding these pitfalls requires due diligence, clear contractual terms, and technical validation. Prioritize suppliers with proven quality management systems and transparent IP policies to ensure a secure and effective Limpeza a Laser partnership.

Logistics & Compliance Guide for Limpeza a Laser

This guide outlines the essential logistics and compliance considerations for operating a laser cleaning (Limpeza a Laser) business. Adhering to these standards ensures safety, legal conformity, operational efficiency, and customer satisfaction.

Regulatory Compliance

Laser cleaning operations are subject to strict national and international regulations. Non-compliance can result in fines, operational shutdowns, or liability.

Laser Safety Standards

Adopt and enforce standards such as IEC 60825-1 (Safety of Laser Products) and ANSI Z136.1 (Safe Use of Lasers). Ensure all laser systems are classified correctly (typically Class 4 for industrial cleaning), with appropriate engineering controls including interlocks, beam enclosures, and emergency stop mechanisms.

Workplace Health and Safety

Comply with local occupational health and safety regulations (e.g., OSHA in the U.S., NR-12 in Brazil). Implement a Laser Safety Officer (LSO) role to oversee protocols, conduct risk assessments, and manage training. Provide appropriate personal protective equipment (PPE), including laser safety goggles with the correct optical density for the laser wavelength used.

Environmental Regulations

Monitor and manage waste materials dislodged during laser cleaning (e.g., paint chips, rust, coatings). Classify debris according to local environmental laws and ensure proper disposal or recycling. Avoid operations that generate hazardous airborne particulates without adequate fume extraction and filtration systems (e.g., HEPA filters).

Permits and Certifications

Obtain necessary operational permits, especially for on-site services in industrial zones or public areas. Maintain certifications for laser equipment, operator training, and environmental compliance. Keep documentation up to date for audits and client requests.

Equipment Logistics

Efficient management of laser cleaning equipment is critical for service delivery and maintenance of performance standards.

Transportation and Handling

Use secure, shock-absorbent packaging when transporting laser units. Vehicles must be equipped with tie-downs and climate control if needed. Avoid exposing sensitive optics and electronics to extreme temperatures, moisture, or vibrations.

Maintenance and Calibration

Follow manufacturer-recommended maintenance schedules. Log all service activities, including lens cleaning, fiber inspections, and power calibration. Regular calibration ensures cleaning effectiveness and compliance with safety thresholds.

Spare Parts and Inventory

Maintain a strategic inventory of consumables (e.g., protective lenses, nozzles) and critical spare parts. Use inventory management software to track stock levels and prevent service delays.

Operational Logistics

Smooth operations depend on planning, scheduling, and on-site execution.

Service Scheduling and Dispatch

Use route optimization tools to plan on-site service visits efficiently. Coordinate with clients to minimize downtime, especially in industrial settings. Ensure technicians have all necessary tools and documentation before departure.

On-Site Setup and Safety Protocols

Establish controlled work zones using warning signs, barriers, and laser curtains. Conduct pre-job safety briefings with site personnel. Confirm that the work area is free of flammable materials and unauthorized personnel.

Waste Management and Cleanup

Collect debris in sealed, labeled containers. Segregate waste by material type (e.g., metallic, hazardous coatings). Provide clients with waste disposal certificates when required.

Documentation and Recordkeeping

Accurate records support compliance, quality assurance, and client trust.

Safety and Training Records

Maintain logs of employee training, safety drills, and PPE issuance. Store certifications and refresher training dates digitally with backups.

Service Reports

Generate detailed post-service reports including: equipment used, parameters (wavelength, pulse duration, power), area cleaned, waste collected, and any anomalies. Include before-and-after photos where applicable.

Compliance Audits

Conduct internal audits at least annually to verify adherence to safety, environmental, and quality standards. Prepare for external audits by regulatory bodies or client compliance teams.

Client and Contractual Compliance

Transparency and contractual clarity are essential for professional relationships.

Scope of Work (SOW)

Clearly define services, deliverables, safety responsibilities, and access requirements in contracts. Specify limitations, such as substrates or coating types that cannot be treated.

Liability and Insurance

Carry comprehensive liability insurance covering property damage, personal injury, and environmental incidents. Verify client site insurance requirements and provide certificates as needed.

Data Protection

Safeguard client data collected during service (e.g., site plans, process parameters). Comply with data privacy regulations such as GDPR or LGPD.

By implementing this logistics and compliance framework, Limpeza a Laser operations can ensure safe, efficient, and legally sound service delivery across diverse industrial and commercial environments.

Conclusion on Sourcing Laser Cleaning Services

Sourcing laser cleaning services presents a highly efficient, environmentally friendly, and cost-effective solution for industrial maintenance, surface preparation, and precision cleaning applications. The technology offers significant advantages over traditional methods—such as sandblasting or chemical cleaning—including minimal material wear, no secondary waste, and reduced downtime. When sourcing laser cleaning, it is essential to evaluate providers based on technical expertise, equipment capabilities, safety certifications, and industry experience.

Additionally, long-term cost benefits, compliance with environmental regulations, and the scalability of services should be considered. As industries increasingly adopt green and sustainable practices, laser cleaning emerges as a forward-looking investment. Therefore, strategic sourcing of qualified laser cleaning partners ensures operational excellence, enhanced safety, and alignment with innovation-driven maintenance strategies.