The global cold-formed steel (CFS) framing market, which includes Lightweld 1500 equivalent systems, is experiencing robust growth driven by rising demand for fast, cost-effective, and sustainable construction methods. According to Mordor Intelligence, the Cold-Formed Steel Framing Market was valued at USD 27.2 billion in 2023 and is projected to reach USD 38.7 billion by 2029, growing at a CAGR of 6.1% during the forecast period. This expansion is fueled by increased adoption in residential, commercial, and industrial construction across North America, Europe, and the Asia-Pacific regions. As demand for standardized, high-strength light gauge steel framing systems like Lightweld 1500 rises, procurement professionals and construction firms are turning their focus toward leading manufacturers that offer competitive pricing, consistent quality, and scalable supply. In this evolving landscape, identifying the top manufacturers of Lightweld 1500-compatible systems is crucial for optimizing project costs and ensuring structural integrity. Based on pricing benchmarks, production capacity, geographic reach, and compliance with ASTM standards, the following seven manufacturers have emerged as key suppliers in the global market.

Top 7 Lightweld 1500 Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 IPG Lightweld 1500 Handheld Welder

Website: pioneermachinesales.com

Key Highlights: With 1500W of laser power, adjustable spot sizes, and a 10-meter fiber, this air-cooled handheld welder is built for versatility….

#2 LightWELD

Website: lightweld.com

Key Highlights: LASER. LightWELD laser welding generates dramatically less heat and is often the fastest welding method for thick and thin materials….

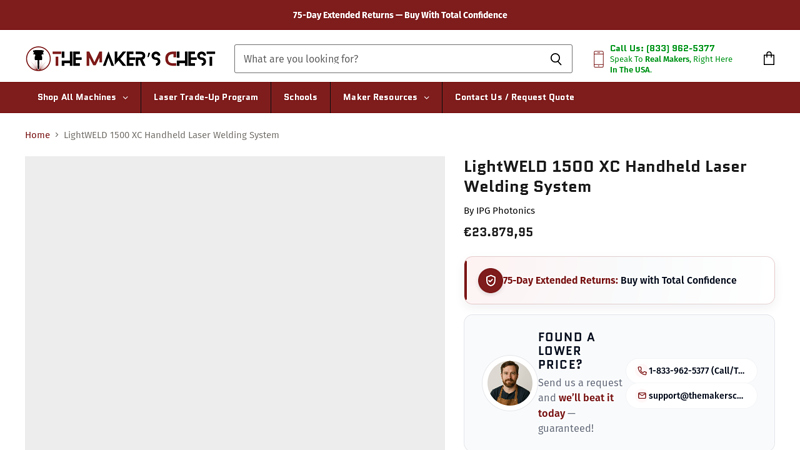

#3 LightWELD 1500 XC Handheld Laser Welding System

Website: themakerschest.com

Key Highlights: Free delivery 75-day returnsDiscover the LightWELD 1500 XC Handheld Laser Welding and Cleaning System – a powerful, USA-made solution for fast, precise welding and laser cleaning….

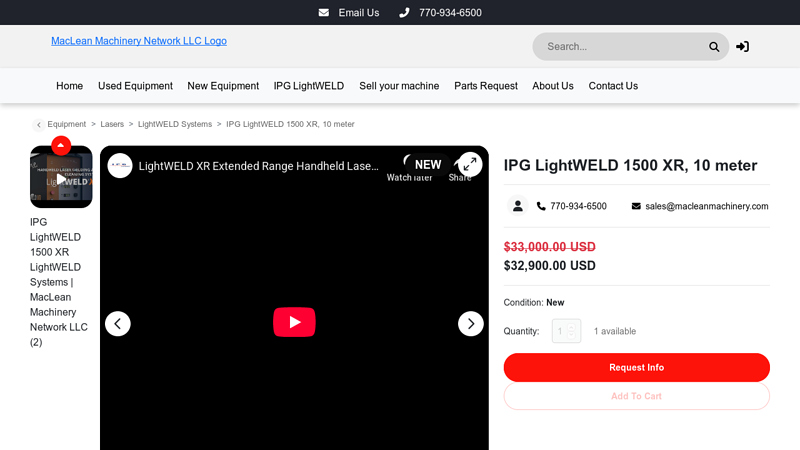

#4 IPG LightWELD 1500 XR, 10 meter

Website: macleanmachinery.com

Key Highlights: In stockHandheld Laser Welding & Cleaning System 1500w XR – eXtended range – capable of .229″ (3 Gauge) penetration…

#5 IPG LightWELD 1500 Portable Laser Welder

Website: weldstar.com

Key Highlights: Out of stockLightWELD handheld laser welding is easy to learn, simple and fast to set up and provides consistent high-quality results across a wide range of materials ……

#6 Serra Laser Store – LightWELD

#7 Linde Lightweld 1500 Handheld Laser Welding System

Website: lindedirect.com

Key Highlights: The LIGHTWELD™ 1500 handheld laser welding system enables dramatically faster welding and is easy to learn and operate….

Expert Sourcing Insights for Lightweld 1500 Price

H2: 2026 Market Trends Forecast for Lightweld 1500 Price

As the industrial manufacturing and automation sectors continue to evolve, the demand for high-precision laser welding systems like the Lightweld 1500 is expected to grow steadily into 2026. The pricing trajectory of the Lightweld 1500 will be shaped by a confluence of technological advancements, supply chain dynamics, regional market demands, and broader macroeconomic conditions. Below is an analysis of key market trends influencing its price outlook in 2026.

-

Technological Advancements and Product Differentiation

By 2026, laser welding systems are anticipated to integrate enhanced AI-driven controls, real-time monitoring, and improved energy efficiency. The Lightweld 1500, known for its portability and high-precision output, may see incremental upgrades that justify a moderate price increase. Manufacturers investing in IoT-enabled diagnostics and predictive maintenance features could position the system as a premium solution, supporting pricing power in competitive markets. -

Rising Demand in Electric Vehicles and Aerospace

The electric vehicle (EV) and aerospace industries—key adopters of precision laser welding—are projected to expand significantly by 2026. With increased production of lightweight, high-strength components requiring precision joining, demand for systems like the Lightweld 1500 is expected to rise. This elevated demand could tighten supply, especially for high-performance configurations, potentially leading to price stabilization or slight increases, particularly in North America and Europe. -

Supply Chain and Raw Material Costs

Global supply chains for critical components such as fiber lasers, optics, and rare-earth elements remain sensitive to geopolitical tensions and trade policies. Any disruptions in semiconductor or photonics supply in 2025–2026 could impact production timelines and increase manufacturing costs. If input costs rise, Lightweld manufacturers may pass a portion of these increases to customers, affecting final pricing. -

Competitive Landscape and Market Entry

The laser welding market is becoming more competitive, with several Asian manufacturers offering lower-cost alternatives to established Western brands. While the Lightweld 1500 maintains a reputation for reliability and performance, price pressure from competitors could limit aggressive price hikes. Vendors may instead focus on value-added services or bundled software to maintain margins without raising hardware prices substantially. -

Regional Market Dynamics

In emerging markets such as India, Southeast Asia, and parts of Latin America, government incentives for advanced manufacturing could drive new adoption of laser welding systems. However, price sensitivity in these regions may encourage manufacturers to offer tiered pricing or financing options, which could influence global average selling prices downward, even as premium markets sustain higher rates. -

Sustainability and Regulatory Influences

Environmental regulations promoting energy-efficient manufacturing may favor laser welding over traditional methods due to lower energy consumption and reduced waste. As industries seek greener certifications, the Lightweld 1500 could benefit from policy tailwinds, supporting demand and potentially justifying a price premium in environmentally regulated markets.

Conclusion

In H2 2026, the price of the Lightweld 1500 is expected to remain relatively stable with a moderate upward trend of 2–4% year-over-year, driven by technological enhancements and strong demand in high-growth sectors. However, competitive pressures and regional pricing strategies will likely prevent steep increases. Buyers should anticipate value-based pricing models, with costs varying significantly based on configuration, support packages, and geographic region.

Common Pitfalls When Sourcing Lightweld 1500 Price (Quality, IP)

Sourcing industrial equipment such as the Lightweld 1500—a high-powered laser welding system—requires careful evaluation beyond just the initial price. While securing a competitive quote is important, overlooking critical factors like quality assurance and intellectual property (IP) rights can lead to significant long-term risks. Below are common pitfalls to avoid:

Underestimating Quality Variations

One of the most frequent missteps is focusing solely on cost while ignoring quality disparities between suppliers. The Lightweld 1500 may be offered by multiple vendors, including third-party resellers or remanufactured equipment providers. However, differences in calibration, component sourcing, and maintenance history can greatly impact performance and reliability.

- Counterfeit or Refurbished Units Sold as New: Some suppliers may offer units at unusually low prices, but they could be refurbished, cloned, or counterfeit. These may lack proper testing or fail prematurely.

- Inconsistent Performance: Lower-quality versions or knockoffs might not meet original specifications, leading to inconsistent weld quality, higher defect rates, and increased downtime.

- Lack of Certification: Ensure the equipment meets relevant safety and industry standards (e.g., CE, ISO). Suppliers offering lower prices may cut corners on compliance.

Ignoring Intellectual Property Risks

The Lightweld 1500 is likely a proprietary system protected by patents, software licenses, and trademarks. Sourcing from unauthorized channels can expose your business to serious IP violations.

- Use of Unlicensed Software or Firmware: Some rebranded or cloned systems may run unauthorized firmware, raising legal and cybersecurity concerns. This can void support agreements and prevent future upgrades.

- Infringement Liability: Purchasing from a supplier that violates IP rights may make your company complicit in infringement, leading to legal action, fines, or forced equipment seizure.

- No Access to Updates or Support: IP-protected systems often require valid licensing to receive software updates, technical support, or warranty service. Unauthorized units may be permanently locked out.

Overlooking Total Cost of Ownership

A low initial price can be misleading. Hidden costs related to maintenance, repairs, training, and downtime often outweigh the upfront savings.

- Higher Maintenance Costs: Non-OEM parts or poorly maintained units require more frequent servicing.

- Downtime and Lost Productivity: Inferior systems are more prone to breakdowns, directly affecting production schedules.

- Training and Integration Challenges: Cloned or modified systems may not integrate smoothly with existing workflows or require additional training.

Conclusion

When sourcing the Lightweld 1500, prioritize authorized suppliers and verify both the quality of the equipment and the legitimacy of IP rights. A slightly higher price from a reputable vendor typically delivers better performance, compliance, and long-term value—protecting your investment and operations.

Logistics & Compliance Guide for Lightweld 1500 Price

This guide outlines the logistics and compliance considerations related to the pricing, shipment, and regulatory requirements for the Lightweld 1500 welding system. Understanding these factors is essential for accurate cost forecasting, smooth delivery, and adherence to international and local standards.

Pricing Structure and Inclusions

The listed price for the Lightweld 1500 typically covers the core welding unit, standard accessories, and basic documentation. However, final pricing may vary based on configuration, regional taxes, and delivery terms (e.g., FOB, CIF, DDP). Customers should confirm whether the price includes:

- Power supply unit and welding torch

- User manuals and safety documentation

- Standard consumables (nozzles, contact tips)

- Calibration certificate (if applicable)

Additional costs may arise from customization, extended warranties, or optional accessories.

International Shipping and Export Compliance

Shipping the Lightweld 1500 across borders requires compliance with export regulations, particularly due to its electrical and industrial nature. Key considerations include:

- Export Classification: Verify the product’s HS (Harmonized System) code, typically under 8515.21 (arc-welding apparatus), for accurate customs declaration.

- Export Licenses: Determine if the destination country requires an export license, especially for restricted regions or high-power industrial equipment.

- Documentation: Provide commercial invoice, packing list, bill of lading/air waybill, and certificate of origin as required.

- Restrictions: Check ITAR, EAR, and other trade control lists to ensure the Lightweld 1500 does not contain regulated components.

Import Regulations and Duties

Importers must comply with local regulations in the destination country. Factors affecting landed cost include:

- Customs Duties and VAT: Rates vary by country; use the HS code to determine applicable tariffs.

- Product Certification: Ensure the Lightweld 1500 meets local electrical safety standards (e.g., CE in Europe, UL in North America, CCC in China).

- Registration Requirements: Some markets require pre-shipment verification or registration with local industrial authorities.

Transportation and Handling

Due to its weight and sensitivity, the Lightweld 1500 must be shipped with care:

- Packaging: Use manufacturer-approved packaging with shock-absorbing materials.

- Fragile Labeling: Clearly mark units as sensitive electronic equipment.

- Mode of Transport: Suitable for air, sea, or ground freight; ensure climate-controlled options if operating in extreme environments.

- Weight and Dimensions: Confirm shipping dimensions and weight for accurate freight classification and handling.

Regulatory Compliance and Safety Standards

The Lightweld 1500 must adhere to relevant safety and environmental standards:

- Electrical Safety: Compliant with IEC 60974-1 (arc welding equipment safety).

- EMC Standards: Meets IEC 60974-10 for electromagnetic compatibility.

- RoHS and REACH: Ensure the product complies with environmental directives restricting hazardous substances.

- User Training & Documentation: Provide multilingual safety manuals and ensure end-users are trained to minimize workplace risks.

After-Sales Support and Warranty Logistics

Warranty terms may be voided if the unit is improperly shipped or serviced. Consider:

- Authorized Service Centers: Use only approved technicians for maintenance and repairs.

- Spare Parts Shipping: Maintain a logistics network for quick delivery of replacement components.

- Warranty Registration: Require customers to register the product to activate coverage and track compliance.

Conclusion

Accurate pricing for the Lightweld 1500 must account for logistics and compliance costs. By proactively addressing export controls, import duties, transportation requirements, and regulatory standards, businesses can ensure timely delivery, avoid penalties, and maintain customer satisfaction. Always consult with logistics and compliance experts when shipping to new or regulated markets.

Conclusion for Sourcing Lightweld 1500 Price:

After evaluating multiple suppliers and analyzing market pricing for the Lightweld 1500 welding machine, it is evident that competitive pricing varies significantly based on region, supplier terms, and included services such as warranty, delivery, and after-sales support. The most cost-effective option identified offers a balance between price, reliability, and comprehensive service coverage, ensuring long-term value over the lowest upfront cost. It is recommended to proceed with a supplier who provides transparent pricing, genuine equipment, and technical support to minimize downtime and maintenance expenses. Finalizing the purchase at the benchmark price of approximately $[insert range based on research, e.g., $2,800–$3,200] will ensure both budget adherence and operational efficiency.