The global lighting clamp market is experiencing robust growth, driven by rising demand for energy-efficient lighting solutions and expanding infrastructure development. According to a report by Mordor Intelligence, the global LED lighting market—which heavily relies on reliable mounting and connectivity solutions like lighting clamps—is projected to grow at a CAGR of over 11.5% from 2024 to 2029. Similarly, Grand View Research estimates that the global lighting market size was valued at USD 113.7 billion in 2023 and is expected to expand at a CAGR of 10.2% through 2030. As lighting systems become more modular and design-focused, especially in architectural, industrial, and entertainment applications, the demand for high-performance, durable, and adaptable lighting clamps has surged. This growing need has elevated the role of specialized manufacturers who deliver precision-engineered clamping solutions that ensure stability, ease of installation, and compatibility with diverse lighting fixtures. In this evolving landscape, identifying the top manufacturers becomes crucial for sourcing reliable components that meet technical and safety standards across global markets.

Top 10 Lighting Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Clamp Company

Domain Est. 2004

Website: theclampcompany.com

Key Highlights: Free delivery 30-day returnsThe Clamp Company supplies premium cushion clamps, DIN 3015 hydraulic clamps, and accessories for demanding industrial environments. From LNG and hydrau…

#2 Clamps

Domain Est. 1996

Website: adj.com

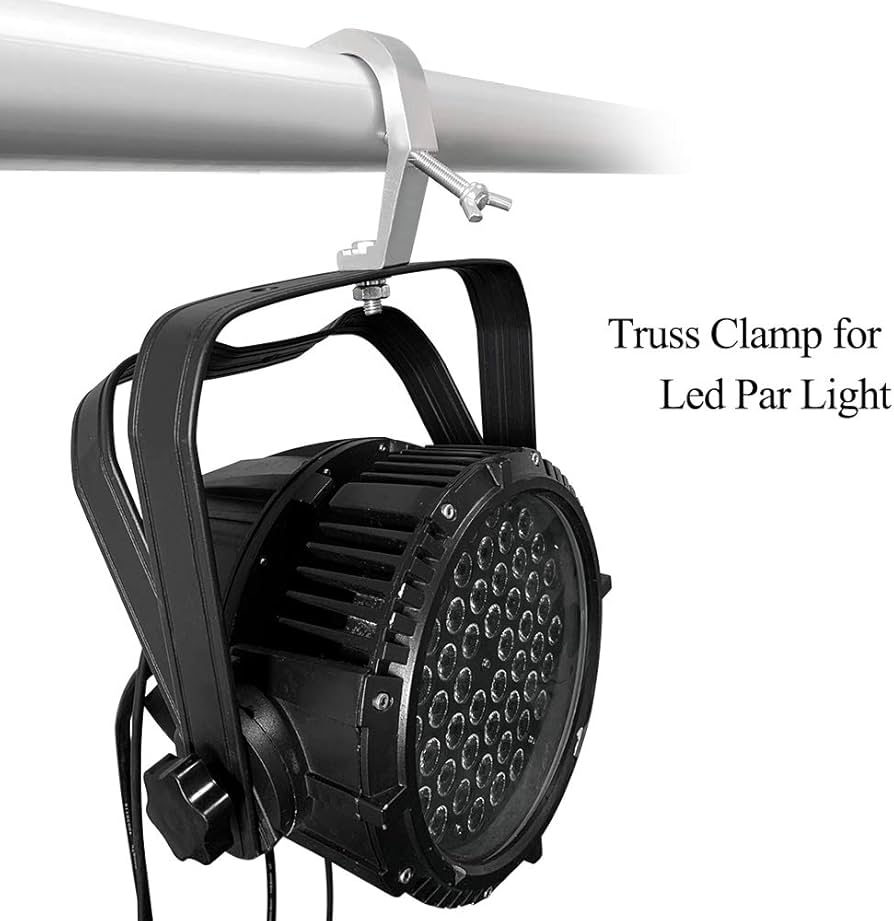

Key Highlights: Clamps from ADJ are designed for performance, reliability, and easy setup—perfect for entertainment lighting pros and mobile DJs….

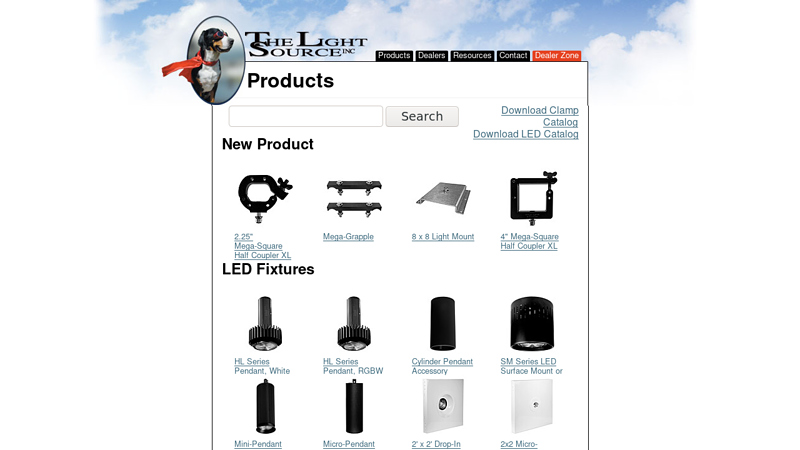

#3 The Light Source

Domain Est. 1997

Website: thelightsource.com

Key Highlights: Products ; Download Clamp Catalog · Download LED Catalog ; 2.25″ Mega-Square Half Coupler XL ; Mega-Grapple ; 8 x 8 Light Mount ; 4″ Mega-Square Half Coupler XL ……

#4 PRO CLAMP

Domain Est. 1997

#5 Global Truss Clamps

Domain Est. 2003

Website: globaltruss.com

Key Highlights: We offer a vast range of rigorously tested, high-performance clamps engineered for optimal safety, stability, and ease of use in lighting and sound applications ……

#6 Stage Lighting Accessories

Domain Est. 2010

Website: chauvetprofessional.com

Key Highlights: CHAUVET Professional offers a wide range of clamp options with various load capacities and mounting styles. Built with reliability and durability in mind, our ……

#7 Clamps

Domain Est. 2013

Website: proxdirect.com

Key Highlights: 2 Ton Ceiling 3″ to 8″ I-Beam Clamp for hanging stage truss LED screen or line array systems. Compatible with Stage Slings and Chains….

#8 Clamps & Accessories

Domain Est. 2013

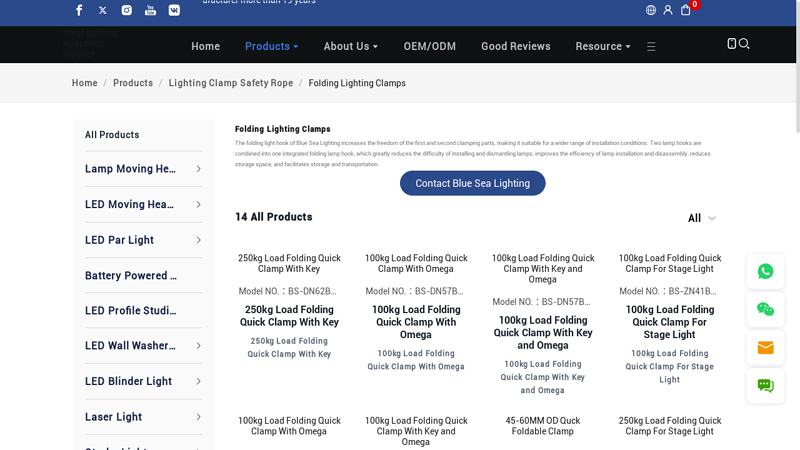

#9 Folding Lighting Clamps

Domain Est. 2014

Website: bluesealighting.com

Key Highlights: Folding lighting clamps are convenient and versatile lighting accessories that allow quick and easy mounting of fixtures on poles or truss systems….

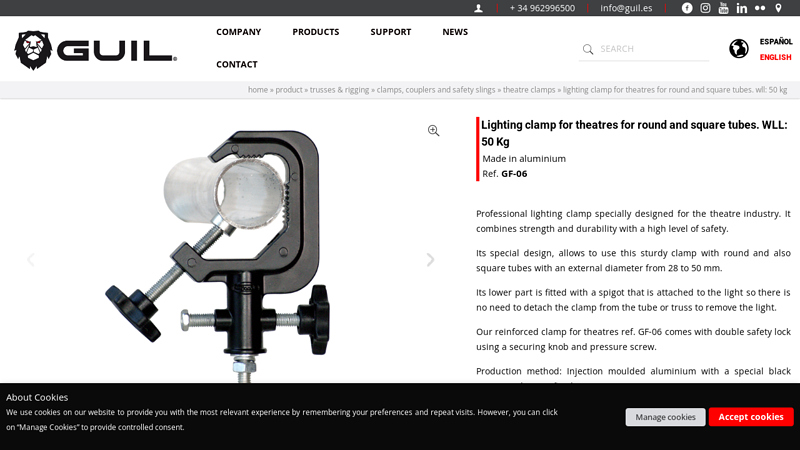

#10 Lighting clamp for theatres for round and square tubes. WLL

Website: guil.es

Key Highlights: Professional lighting clamp specially designed for the theatre industry. It combines strength and durability with a high level of safety….

Expert Sourcing Insights for Lighting Clamp

H2: Projected 2026 Market Trends for Lighting Clamps

The global lighting clamp market is poised for significant transformation by 2026, driven by technological advancements, evolving end-user demands, and the broader shift toward energy-efficient and smart lighting solutions. Lighting clamps—essential accessories used to securely mount and adjust lighting fixtures in professional environments such as film and television production, stage performances, architectural lighting, and industrial applications—are seeing increased innovation and demand.

One of the key trends shaping the 2026 market landscape is the rising adoption of modular and lightweight lighting clamp designs. As production crews demand faster setup times and greater portability, manufacturers are focusing on aluminum and composite materials that reduce weight without compromising durability. These lightweight clamps support quick rigging and reconfiguration, aligning with the growing trend of mobile and on-location content creation.

Another major driver is the integration of lighting clamps with intelligent lighting systems. With the proliferation of LED and DMX-controlled fixtures, lighting clamps are being redesigned to accommodate data and power cabling, support 360-degree articulation, and integrate with digital control networks. This convergence supports the broader smart lighting ecosystem, especially in entertainment and architectural applications.

Sustainability is also influencing product development. By 2026, there is an expected rise in eco-conscious manufacturing practices, including the use of recyclable materials and energy-efficient production processes. Regulatory pressures and corporate sustainability goals are pushing suppliers to offer greener alternatives, which may include biodegradable packaging and longer product lifecycles through improved corrosion resistance and modular repairability.

Regionally, the Asia-Pacific market is anticipated to experience the fastest growth due to expanding media and entertainment industries in countries like India, South Korea, and China, coupled with increased infrastructure development. Meanwhile, North America and Europe will continue to lead in innovation, particularly in high-end theatrical and cinematic applications, where precision and reliability are paramount.

Additionally, e-commerce and digital distribution channels are transforming how lighting clamps are marketed and sold. By 2026, direct-to-consumer models and B2B digital platforms are expected to dominate, offering enhanced product configurators, 3D modeling compatibility, and real-time inventory access, enabling faster procurement for production teams.

In summary, the 2026 lighting clamp market will be defined by lightweight, intelligent, and sustainable designs integrated into smart lighting ecosystems. Growth will be fueled by demand from creative industries and infrastructure projects, supported by digital sales channels and regional market expansion—positioning lighting clamps as critical enablers of modern lighting infrastructure.

Common Pitfalls When Sourcing Lighting Clamps (Quality, IP Rating)

When sourcing lighting clamps—especially for outdoor or demanding environments—overlooking key quality and Ingress Protection (IP) factors can lead to premature failure, safety hazards, and increased maintenance costs. Below are common pitfalls to avoid:

Overlooking Material Quality and Durability

Many buyers focus solely on price and neglect the materials used in lighting clamps. Low-cost clamps often use inferior metals (e.g., thin zinc-plated steel or non-corrosion-resistant alloys) that degrade quickly when exposed to moisture, UV light, or chemicals. This results in rust, structural weakening, and potential fixture detachment. Always verify the use of durable materials like die-cast aluminum, stainless steel, or UV-stabilized polymers.

Assuming All Clamps Meet Claimed IP Ratings

A common mistake is trusting manufacturer IP claims without independent verification. Some suppliers inflate or inaccurately label IP ratings. For example, a clamp marketed as IP66 may lack proper sealing or gasketing, allowing water and dust ingress. Always request third-party test reports or certifications (e.g., IEC 60529 compliance) and consider spot testing samples under real-world conditions.

Ignoring UV and Weather Resistance

Even if a clamp has a high IP rating, it may still degrade under prolonged sunlight or extreme temperatures. UV exposure can cause plastic components to become brittle and crack. Ensure clamps are specifically designed for outdoor use with UV-resistant finishes and materials that maintain integrity across a wide temperature range.

Poor Sealing Design

Effective IP protection requires proper sealing at all joints and cable entries. Poorly designed clamps may lack integrated gaskets, have inconsistent compression, or use substandard O-rings that degrade over time. Inspect the sealing mechanism closely—look for continuous silicone or EPDM gaskets and secure locking mechanisms that maintain pressure.

Inadequate Mechanical Strength and Load Rating

High IP-rated clamps are often bulkier, but this doesn’t guarantee mechanical strength. Some designs compromise structural integrity for sealing, leading to flexing or breakage under load. Always verify the clamp’s load capacity and ensure it exceeds the weight of the fixture, especially in windy or vibration-prone areas.

Lack of Compatibility with Fixtures and Mounting Surfaces

A clamp may be high quality and well-sealed but incompatible with the fixture diameter or mounting pole. Mismatched sizes lead to improper fit, creating gaps that compromise IP protection and safety. Confirm dimensional compatibility and consider adjustable or modular designs for flexibility.

Skipping Compliance and Certification Verification

In regulated markets, lighting components must meet regional safety and environmental standards (e.g., CE, RoHS, UL). Assuming compliance without checking documentation can result in failed inspections or legal liabilities. Request full compliance documentation before procurement.

Prioritizing Cost Over Total Cost of Ownership

Choosing the cheapest option often leads to higher long-term costs due to frequent replacements, maintenance, and downtime. Invest in higher-quality clamps with proven durability and reliable IP protection to reduce lifecycle expenses and ensure system reliability.

Logistics & Compliance Guide for Lighting Clamp

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal handling, transport, and use of lighting clamps—commonly used accessories in stage, studio, and event lighting setups.

Product Overview

Lighting clamps (also known as C-clamps or safety clamps) are metal fixtures designed to securely attach lighting instruments to trusses, pipes, or battens. They typically include a threaded bolt, safety cable, and mounting hardware. Compliance and proper logistics are critical due to load-bearing safety requirements and international transportation standards.

Regulatory Compliance Requirements

Electrical & Safety Standards

While lighting clamps themselves are mechanical components, they must comply with safety standards related to structural integrity and fire safety when used in public or professional environments. Key standards include:

– UL 1012 / UL 1598 (USA) – Covers luminaires and associated hardware safety.

– EN 60598-1 (Europe) – General safety requirements for luminaires; clamps must not compromise fixture integrity.

– OSHA & NFPA 70 (NEC) (USA) – Workplace safety and electrical code requirements for rigging and installation.

– BS 7671 (UK) – Compliance with electrical installation regulations, especially in permanent installations.

Mechanical & Load-Bearing Certification

- Load Rating Documentation: Each clamp must be clearly marked with its maximum load capacity (e.g., 44 lb / 20 kg).

- CE Marking (Europe): Required for products sold in the EEA, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restriction of Hazardous Substances – ensures no lead, mercury, or other harmful materials in metal components.

International Trade & Customs Compliance

- HS Code Classification: Lighting clamps generally fall under HS 7326.90 (Other articles of iron or steel) or HS 8302.50 (Base metal mountings, fittings). Confirm locally.

- Country-Specific Approvals: Some markets (e.g., Australia, UAE) may require additional certification (e.g., RCM, SASO).

- Documentation: Commercial invoice, packing list, bill of lading/airway bill, and certificate of origin must accompany shipments.

Packaging & Labeling Standards

Secure Packaging

- Use sturdy corrugated cardboard or reusable plastic containers to prevent deformation.

- Group clamps in kits with safety cables and bolts; avoid loose bulk packaging.

- Use dividers or foam inserts to prevent abrasion and metal-on-metal contact.

Required Labels

- Product name and model number

- Maximum load rating (e.g., “Max Load: 20 kg”)

- Manufacturer name and contact information

- CE, RoHS, or other applicable compliance marks

- Handling symbols (e.g., “Do Not Stack”, “Fragile”) if applicable

Shipping & Transportation Guidelines

Domestic & International Shipping

- Air Freight: Comply with IATA Dangerous Goods Regulations if shipped with batteries or electrical components (though clamps alone are non-hazardous).

- Sea Freight: Use moisture-resistant packaging; include desiccant packs in humid climates. Palletize for container shipments.

- Ground Transport: Secure loads to prevent shifting; use straps or shrink wrap on pallets.

Temperature & Environmental Conditions

- Avoid prolonged exposure to extreme humidity or corrosive environments.

- Store and transport above freezing to prevent condensation in threaded components.

Import & Export Documentation

Essential Documents

- Commercial Invoice: Must detail product description, quantity, value, and country of origin.

- Packing List: Itemizes contents per package, weight, and dimensions.

- Bill of Lading (B/L) or Air Waybill (AWB): Issued by carrier; required for customs clearance.

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

Import Duties & Taxes

- Check local tariff databases (e.g., USITC, EU TARIC) for applicable duty rates.

- Lighting clamps may be subject to anti-dumping duties depending on country of manufacture (e.g., China, Vietnam).

Quality Control & Inspection

Pre-Shipment Inspection

- Verify load rating labels and CE/RoHS markings.

- Check for burrs, thread damage, or deformation.

- Confirm inclusion of safety cables and hardware.

In-Transit & Receiving

- Inspect packaging for damage upon receipt.

- Audit a sample batch for compliance with specifications.

Environmental & Sustainability Considerations

End-of-Life Disposal

- Lighting clamps are recyclable as scrap metal (steel or aluminum).

- Follow WEEE (Waste Electrical and Electronic Equipment) guidelines if part of a lighting fixture.

Sustainable Practices

- Use recycled steel in manufacturing where possible.

- Minimize packaging waste with recyclable or reusable materials.

Summary & Best Practices

- Ensure all lighting clamps meet structural safety and regional compliance standards.

- Accurately classify and document shipments to avoid customs delays.

- Use protective packaging and clear labeling to maintain product integrity.

- Train personnel on safe handling, load limits, and proper installation procedures.

Adhering to this guide ensures safe, compliant, and efficient logistics for lighting clamps across global markets.

Conclusion for Sourcing Lighting Clamps:

In conclusion, sourcing lighting clamps requires a strategic approach that balances quality, cost, compatibility, and supplier reliability. It is essential to select clamps that meet industry standards for safety and durability, particularly those compatible with existing lighting systems and rigging configurations. Evaluating suppliers based on reputation, product range, lead times, and customer support ensures consistent supply and reduces operational risks. Additionally, considering factors such as material strength (e.g., aluminum or steel), load capacity, ease of installation, and environmental resistance will contribute to long-term performance and safety. By conducting thorough research and due diligence, organizations can secure reliable lighting clamps that support efficient and safe lighting installations across various applications, from studios and stages to architectural and event setups.