The global packaging industry is undergoing rapid transformation, driven by increasing demand for sustainable, durable, and tamper-evident solutions—particularly in the food and beverage, pharmaceutical, and personal care sectors. Caps and lids, though often overlooked, play a critical role in product integrity, consumer safety, and user experience. According to a 2023 report by Mordor Intelligence, the global bottle caps and closures market was valued at USD 43.6 billion in 2022 and is projected to grow at a CAGR of 4.8% through 2028. This growth is fueled by rising e-commerce sales, evolving packaging standards, and a shift toward lightweight, recyclable materials.

As demand expands, manufacturers are investing heavily in automation, innovative sealing technologies, and environmentally friendly materials such as bioplastics and recycled resins. In this evolving landscape, a select group of lid cap manufacturers have emerged as industry leaders—combining scale, technological expertise, and global supply chain capabilities. The following list highlights the top nine manufacturers shaping the future of closure systems across key end-use verticals.

Top 9 Lid Cap Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Premium Closures and Lids for Packaging

Domain Est. 1992

Website: dow.com

Key Highlights: Explore Dow’s versatile polyethylene materials for caps and closures, tailored for industries like food and beverage, personal care, and more….

#2 Metal caps

Domain Est. 2014

Website: keycapco.com

Key Highlights: Competitive manufacturer of quality threaded metal closures. Also called caps. Or jar lids. Caps—you need ’em. We make ’em….

#3 Silgan Closures

Domain Est. 2014

Website: silgan-closures.com

Key Highlights: Leading manufacturer of rigid packaging for shelf-stable food and other consumer goods. Annual net sales of approximately $5,68 billion in 2021….

#4 Caps & Closures

Domain Est. 1997

Website: berlinpackaging.com

Key Highlights: Free delivery over $300 · 30-day returnsAt Berlin Packaging, we offer a wide range of caps and closures, including spout caps, Mason jar lids, beer caps, corks, dropper caps, and …

#5 Lids Custom Hats, Personalized Hats, Custom Baseball Caps

Domain Est. 1998

#6 Container Lids, Closures & Caps

Domain Est. 1999

Website: paramountglobal.com

Key Highlights: At Paramount Global, we are proud to offer a wide selection of container lids, closures, and caps. Common styles featured on our website are typically in stock….

#7 Neenah Foundry

Domain Est. 2000

Website: neenahfoundry.com

Key Highlights: Neenah Foundry has been a consistent leader in delivering durable and highly engineered, structural, and sustainable casting solutions for customers….

#8 Metal Caps – CT and Lug Metal Lids

Domain Est. 2001

Website: kaufmancontainer.com

Key Highlights: Kaufman Container offers a large selection of metal caps and metal lids including CT and Lug finishes. Available in a variety of colors and neck finishes….

#9 Custom Lids: Custom Hats

Domain Est. 2004

Website: customlids.com

Key Highlights: Customize your hats with our new Lids™ customizable store. Just provide us with your logo and let our team take it from there. Click to get started!…

Expert Sourcing Insights for Lid Cap

H2: 2026 Market Trends for Lid Cap

The global lid cap market is poised for significant evolution by 2026, driven by technological advancements, sustainability mandates, and shifting consumer preferences. As industries from food and beverage to pharmaceuticals and personal care continue to prioritize packaging integrity and user convenience, lid caps—critical components in container sealing—are undergoing transformative changes. The following analysis outlines key market trends expected to shape the lid cap industry in 2026.

-

Sustainability and Eco-Friendly Materials

A dominant trend in 2026 will be the accelerated shift toward sustainable lid cap solutions. Regulatory pressures and consumer demand for environmentally responsible packaging are compelling manufacturers to adopt biodegradable, recyclable, and compostable materials. Bio-based plastics (e.g., PLA, PHA), recycled aluminum, and paper-based composites are gaining traction. Major brands are expected to commit to 100% recyclable or reusable closure systems, pushing innovation in mono-material designs that simplify end-of-life processing. -

Smart and Functional Packaging Integration

Lid caps are increasingly becoming platforms for smart technology. In 2026, we anticipate wider adoption of intelligent features such as tamper-evident seals with digital verification, time-temperature indicators, and NFC/RFID-enabled caps for product authentication and consumer engagement. These “smart lids” are particularly relevant in pharmaceuticals and premium beverages, where traceability and anti-counterfeiting are critical. -

Lightweighting and Material Efficiency

Driven by cost optimization and carbon footprint reduction, manufacturers are focusing on lightweight lid cap designs without compromising performance. Advances in polymer engineering and thin-wall molding technologies allow for reduced material use while maintaining sealing integrity and durability. This trend supports sustainability goals and reduces shipping costs across supply chains. -

Customization and Brand Differentiation

Brands are leveraging lid caps as key touchpoints for consumer engagement. In 2026, highly customized, aesthetically appealing caps—featuring embossing, color effects, ergonomic shapes, and brand-specific textures—will be increasingly common. This trend is especially strong in the premium beverage and cosmetics sectors, where unboxing experiences influence purchasing decisions. -

Growth in Emerging Markets

Asia-Pacific, Latin America, and Africa are expected to be high-growth regions for lid caps in 2026 due to rising urbanization, expanding middle classes, and growth in packaged food and beverage consumption. Localized production and adaptation to regional regulatory standards will be critical for global suppliers aiming to capture market share. -

Regulatory Compliance and Safety Standards

Stricter global regulations on food contact materials and child-resistant packaging (especially in pharmaceuticals and household chemicals) will drive innovation in compliant lid cap designs. In 2026, manufacturers will need to ensure adherence to evolving standards such as FDA, EU 10/2011, and ISO 8317, influencing material selection and production processes. -

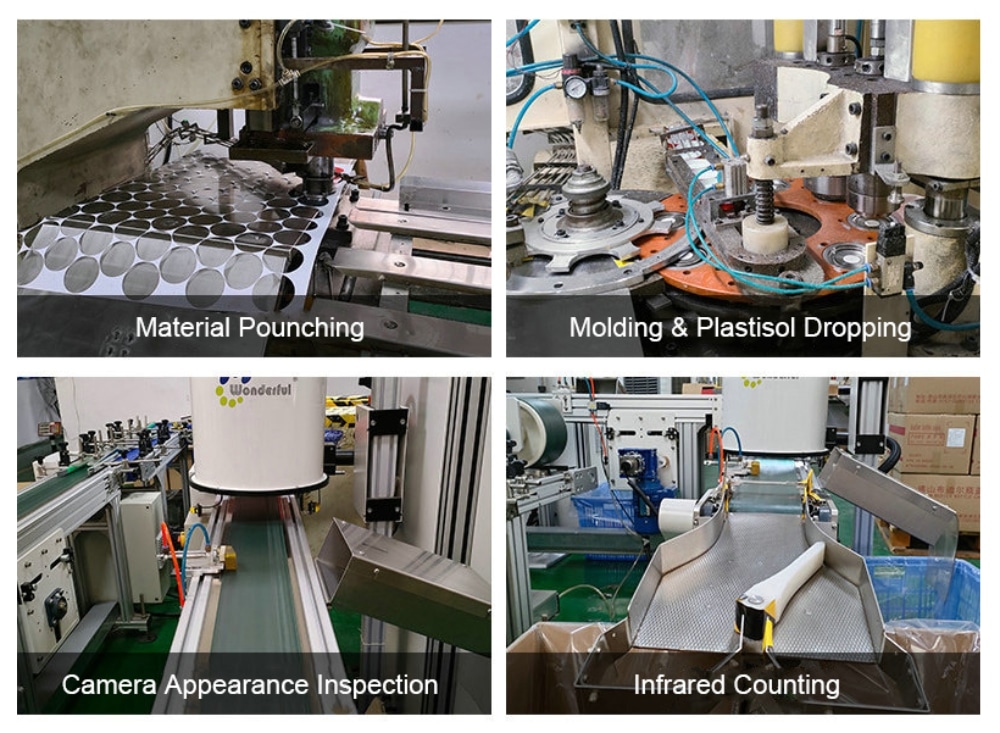

Automation and Digitalization in Manufacturing

The lid cap industry will increasingly adopt Industry 4.0 practices by 2026, including automated quality control, AI-driven defect detection, and digital twin technologies in production. These advancements improve efficiency, reduce waste, and support rapid prototyping of complex cap designs.

In conclusion, the 2026 lid cap market will be defined by sustainability, innovation, and digital transformation. Companies that invest in eco-conscious materials, smart functionalities, and agile manufacturing will be best positioned to lead in this dynamic landscape.

Common Pitfalls Sourcing Lid Cap (Quality, IP)

Sourcing lid caps—whether for containers, packaging, or industrial applications—can involve significant risks related to both product quality and intellectual property (IP). Avoiding these pitfalls is crucial for ensuring product integrity, regulatory compliance, and legal protection.

Poor Material Quality and Durability

One of the most frequent issues when sourcing lid caps is receiving substandard materials. Low-quality plastics or metals may degrade quickly, leading to brittleness, cracking, or inadequate sealing. This compromises product safety, shelf life, and customer satisfaction—especially in food, pharmaceutical, or chemical applications.

Inconsistent Manufacturing Tolerances

Inconsistent dimensions due to poor mold control or lack of quality assurance can result in improper fit, leakage, or difficulty in assembly. Even minor deviations in thread pitch or diameter can render a lid cap incompatible with its intended container, leading to costly rework or recalls.

Lack of Compliance with Industry Standards

Many lid caps must meet specific regulatory standards (e.g., FDA, EU 10/2011 for food contact, child-resistant packaging requirements). Sourcing from suppliers unfamiliar with these regulations risks non-compliance, legal penalties, and market access issues.

Inadequate Sealing Performance

A lid cap’s primary function is to seal effectively. Poorly designed or manufactured caps may fail under temperature changes, pressure differentials, or long-term storage. This can result in contamination, evaporation, or spoilage—particularly damaging in sensitive industries.

Intellectual Property Infringement

Sourcing lid caps from third parties, especially overseas, increases the risk of inadvertently using designs that infringe on existing patents or trademarks. Using a cap design that mimics a competitor’s patented product—even unintentionally—can lead to legal disputes, injunctions, and costly damages.

Counterfeit or Unauthorized Production

Some suppliers may produce lid caps using stolen or reverse-engineered molds, especially in regions with weak IP enforcement. Purchasing such products makes the buyer complicit in IP violations and exposes them to supply chain disruptions and reputational damage.

Insufficient Documentation and Traceability

Without proper documentation—such as material certifications, mold ownership records, or design IP clearances—it’s difficult to verify authenticity or defend against IP claims. Lack of traceability also complicates recalls and quality investigations.

Overlooking Design Ownership in Supplier Agreements

Many companies fail to secure formal ownership or licensing rights to the molds or designs used for their lid caps. If the supplier retains IP rights, they may produce identical caps for competitors or demand higher fees for future production.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier audits, require material and performance testing, ensure compliance certifications, and establish clear contractual terms regarding IP ownership and confidentiality. Engaging legal counsel to review design rights and mold usage agreements is also recommended.

Logistics & Compliance Guide for Lid Cap

Product Overview

The lid cap is a critical component used to seal containers, ensuring product integrity, safety, and compliance with regulatory standards. This guide outlines the logistics handling, storage, transportation, and compliance requirements specific to lid caps.

Packaging Requirements

Lid caps must be packaged in sealed, moisture-resistant materials to prevent contamination and deformation. Use of anti-static packaging is recommended for plastic variants. Bulk packaging should be palletized with stretch-wrapping and corner boards for stability during transit.

Storage Conditions

Store lid caps in a clean, dry, temperature-controlled environment (15°C to 25°C). Avoid direct sunlight and high humidity. Keep away from chemicals and strong odors. Shelf life varies by material; inspect expiration dates regularly, especially for food-grade or medical-grade caps.

Transportation Guidelines

Use enclosed, clean vehicles for transportation. Protect from physical damage, moisture, and extreme temperatures. Stack pallets no higher than three high unless otherwise specified. Ensure proper load securing to prevent shifting during transit.

Handling Procedures

Handle lid caps with clean, gloved hands or automated tools to prevent contamination. Use designated areas for loading/unloading. Avoid dropping or crushing containers. Follow FIFO (First In, First Out) inventory management.

Regulatory Compliance

Lid caps used in food, pharmaceutical, or medical applications must comply with relevant regulations:

– FDA 21 CFR for food-contact compliance (if applicable)

– USP Class VI for medical-grade materials

– EU Regulation (EC) No 1935/2004 for food-contact materials in Europe

– REACH and RoHS compliance for restricted substances

Certifications must be documented and available upon request.

Labeling & Traceability

Each batch must be labeled with:

– Product name and part number

– Batch/lot number

– Manufacturing and expiration dates

– Compliance markings (e.g., FDA, CE)

– Storage instructions

Maintain full traceability from raw material to finished product using a documented quality management system.

Import/Export Documentation

For international shipments, ensure the following documents are prepared:

– Commercial invoice

– Packing list

– Certificate of Conformance (CoC)

– Material Safety Data Sheet (MSDS), if required

– Declaration of compliance with destination country regulations

Classify under correct HS code (e.g., 3923.50 for plastic caps) to ensure accurate customs clearance.

Quality Assurance

Conduct regular incoming and outgoing inspections per ISO 9001 standards. Test for dimensional accuracy, material integrity, and sealing performance. Maintain records for at least five years.

Environmental & Safety Considerations

Dispose of damaged or expired lid caps in accordance with local waste regulations. Recycle where possible based on material type (e.g., PP, PE, HDPE). Ensure workplace safety by providing proper PPE during handling and inspection.

Contact Information

For compliance inquiries or quality issues, contact:

[Your Company Name] Quality & Compliance Department

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Lid Cap:

After a comprehensive evaluation of potential suppliers, material options, production capabilities, and cost considerations, sourcing the lid cap has been strategically aligned with our quality, scalability, and cost-efficiency objectives. The selected supplier demonstrates strong manufacturing capabilities, consistent quality control, compliance with industry standards, and favorable lead times. Additionally, the chosen material ensures durability, compatibility with the product, and sustainability goals. Moving forward, establishing a long-term partnership with periodic performance reviews will ensure reliability and support future growth. Overall, the sourcing decision for the lid cap is sound, balancing performance, cost, and supply chain resilience.