The global polycarbonate market, driven by rising demand in automotive, electronics, and construction sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. With Lexan—a high-performance polycarbonate brand developed by SABIC—remaining a benchmark for durability, clarity, and heat resistance, the ecosystem of manufacturers producing and distributing Lexan-grade materials has expanded significantly. As industries prioritize materials that meet stringent safety and sustainability standards, the competitive landscape has intensified among key players scaling production, enhancing resin quality, and investing in recycling technologies. Based on market presence, innovation, and product consistency, here are the top six Lexan material manufacturers shaping the future of engineering thermoplastics.

Top 6 Lexan Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LEXAN™ Resin

Domain Est. 1998

Website: sabic.com

Key Highlights: Lexan polycarbonate is a high-performance thermoplastic that offers exceptional strength, impact resistance, and transparency….

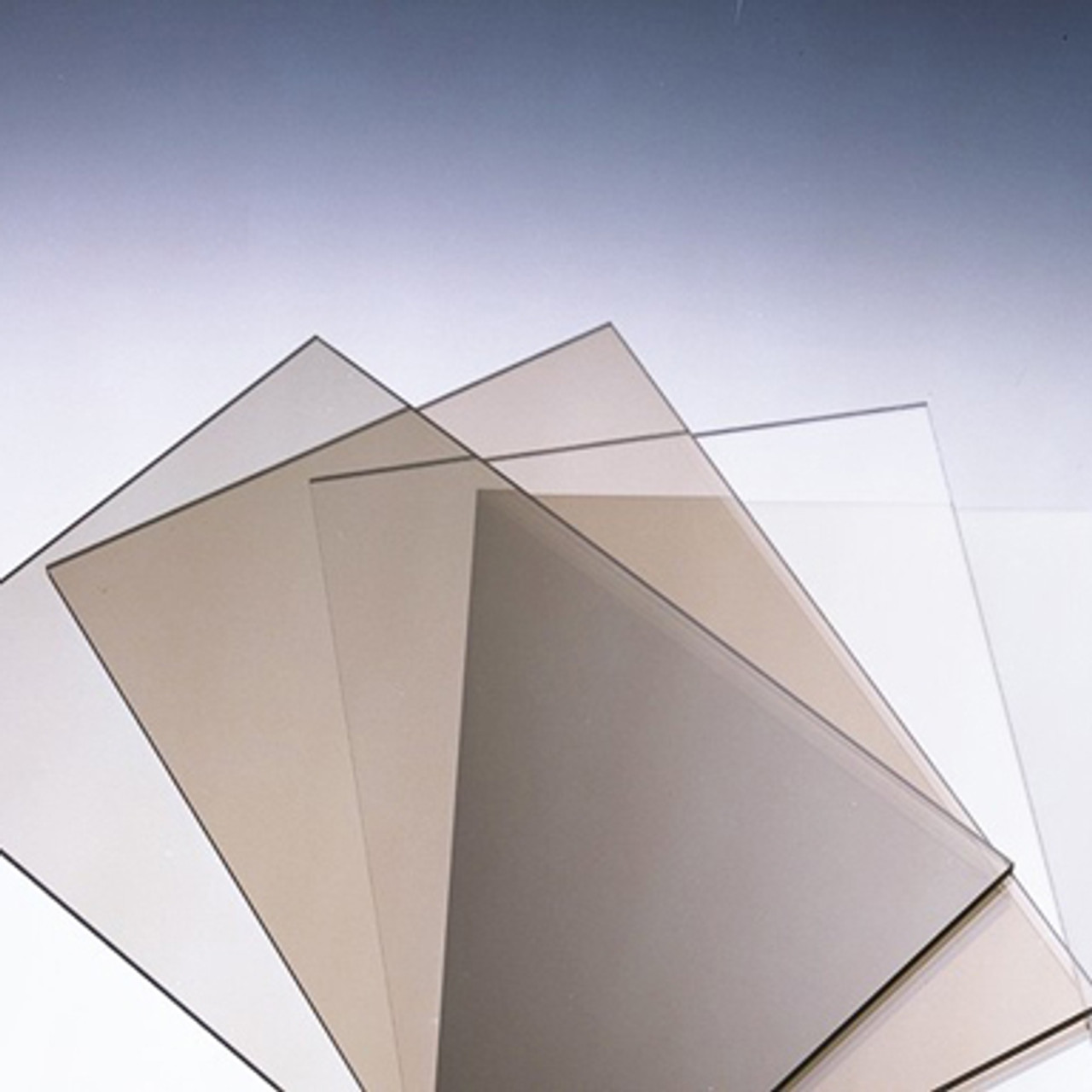

#2 LEXAN Polycarbonate Sheet

Domain Est. 2000

Website: polymershapes.com

Key Highlights: Polymershapes stocks the world’s leading PC sheet brand, LEXAN Polycarbonate Sheet. LEXAN, is a polycarbonate resin thermoplastic material that is known ……

#3 POLYVANTIS® LEXAN™ Polycarbonate Sheets & Films, Acrylic …

Domain Est. 2008

Website: kapoorplastics.com

Key Highlights: We are an authorized distributor of POLYVANTIS®; LEXANTM polycarbonate sheets and films, as well as PLEXIGLAS® acrylic sheets and films….

#4

Domain Est. 2023

Website: polyvantis.com

Key Highlights: LEXAN™ Thermoplastic sheet or aircraft interior provides lightweight and exceptional FST (fire, smoke, and toxicity) performance….

#5 Lexan® Sheet, Polycarbonate Sheet, Pc Sheet, Windshield Official …

Domain Est. 2024

Website: thelexan.com

Key Highlights: We source top-grade Lexan sheets manufactured in the USA to ensure maximum quality and purity. Our suppliers like SABIC and Covestro are industry leaders when ……

#6 LEXAN™ Film & Sheet Products

Domain Est. 2024

Website: film-sheet-products.com

Key Highlights: POLYVANTIS offers high-quality, engineered thermoplastic LEXAN™ film & sheet products. Visit our site to find your polycarbonate film or sheet solution….

Expert Sourcing Insights for Lexan Material

H2 2026 Market Trends for Lexan Material

As the global economy progresses into the second half of 2026, the market for Lexan (a family of high-performance polycarbonate thermoplastics produced by SABIC) is shaped by a confluence of technological advancements, evolving regulatory landscapes, and shifting industry demands. Below is an analysis of key trends influencing the Lexan material market during this period:

1. Accelerated Demand in Electric Vehicles (EVs) and Lightweighting

The automotive sector remains a major driver for Lexan in H2 2026. With automakers intensifying efforts to improve energy efficiency and extend battery range, the demand for lightweight, durable materials continues to rise. Lexan is increasingly used in EV components such as panoramic roofs, headlamp lenses, interior glazing, and battery enclosures due to its excellent impact resistance, optical clarity, and thermal stability. Innovations in multi-layer co-extruded Lexan sheets with enhanced UV protection and reduced flammability are particularly sought after for next-generation EV designs.

2. Growth in Consumer Electronics and 5G Infrastructure

The rollout of 5G networks and the proliferation of smart devices are fueling demand for materials that support high-frequency signal transmission and durability. Lexan’s electromagnetic transparency and ability to be molded into complex, thin-walled designs make it ideal for 5G-enabled smartphones, wearable tech, and base station components. In H2 2026, manufacturers are favoring Lexan resins with improved thermal management properties and reduced signal loss, especially in mmWave applications.

3. Sustainability and Circular Economy Pressures

Environmental regulations and corporate sustainability goals are significantly impacting material selection. In H2 2026, SABIC and other stakeholders are promoting Lexan grades made with certified circular content—utilizing chemical recycling technologies to reintroduce post-consumer waste into the production stream. Demand is rising for Lexan materials with Environmental Product Declarations (EPDs) and lower carbon footprints. Additionally, design-for-recycling initiatives are encouraging the use of mono-material solutions where Lexan can serve as a standalone, recyclable component.

4. Expansion in Medical and Healthcare Applications

The medical device sector is adopting Lexan for reusable surgical instruments, diagnostic equipment housings, and transparent face shields due to its sterilizability (via autoclaving and gamma radiation), clarity, and resistance to repeated use. In H2 2026, regulatory approvals for new biocompatible Lexan grades are facilitating broader use in minimally invasive devices and point-of-care testing systems, particularly in emerging markets.

5. Regional Market Shifts and Supply Chain Resilience

Asia-Pacific, especially China and India, continues to lead in Lexan consumption, driven by electronics manufacturing and infrastructure development. Meanwhile, nearshoring trends in North America and Europe are prompting SABIC and converters to enhance local production and distribution networks to mitigate geopolitical and logistical risks. This shift supports faster turnaround times and customized material solutions for regional OEMs.

6. Advancements in Additive Manufacturing

The integration of Lexan into industrial 3D printing is gaining momentum. In H2 2026, high-heat and impact-resistant Lexan filaments and powders are being adopted for rapid prototyping and low-volume production in aerospace, automotive, and industrial equipment. Compatibility with laser sintering and FDM technologies is expanding design flexibility and reducing time-to-market.

Conclusion

In H2 2026, the Lexan material market is characterized by innovation driven by performance, sustainability, and digital transformation. While competition from alternative polymers persists, Lexan’s unique balance of optical, mechanical, and thermal properties ensures its relevance across high-growth sectors. Continued investment in recyclable and bio-based variants will be critical for maintaining long-term market leadership amid tightening environmental standards and evolving customer expectations.

Common Pitfalls When Sourcing Lexan Material (Quality, IP)

Sourcing Lexan—a high-performance polycarbonate resin developed and trademarked by SABIC—requires careful attention to avoid quality issues and intellectual property (IP) risks. Here are common pitfalls to watch for:

Confusing Lexan with Generic Polycarbonate

One of the most frequent mistakes is assuming that any polycarbonate sheet or resin is equivalent to Lexan. Lexan is a branded material with tightly controlled manufacturing standards, consistent quality, and specific performance characteristics. Generic or off-brand polycarbonates may not meet the same impact resistance, clarity, thermal stability, or UV resistance specifications, leading to product failure in demanding applications.

Falling for Counterfeit or Gray Market Lexan

Due to its reputation and performance, Lexan is a target for counterfeit materials. Unauthorized suppliers may repackage lower-grade polycarbonate or source diverted (gray market) material without proper certification. These materials often lack traceability, batch testing data, and compliance documentation, increasing the risk of inconsistent quality and failure in critical applications.

Overlooking Material Certification and Documentation

Proper sourcing requires full documentation, including Certificates of Conformance (CoC), material test reports, and lot traceability. Failing to obtain these documents makes it difficult to verify authenticity, ensure regulatory compliance (e.g., FDA, UL, RoHS), or support quality audits. Without them, you risk using substandard or non-compliant material.

Ignoring Intellectual Property and Trademark Violations

“Lexan” is a registered trademark of SABIC. Using the name to describe non-SABIC materials—even if they are polycarbonate—can expose your company to IP infringement claims. Marketing or labeling products as “Lexan” when they use generic polycarbonate may also mislead customers and damage brand credibility.

Relying on Unverified Distributors

Purchasing from uncertified or unverified resellers increases the risk of receiving counterfeit or degraded material. Always source Lexan through SABIC-authorized distributors who can provide chain-of-custody assurance, proper storage conditions, and technical support.

Neglecting Application-Specific Grades

Lexan comes in numerous grades tailored for different applications—flame-retardant, UV-protected, medical-grade, etc. Selecting the wrong grade due to inadequate technical vetting can lead to premature failure, safety issues, or non-compliance with industry standards.

Underestimating the Impact of Poor Supply Chain Control

Inconsistent batch quality, delayed deliveries, or lack of technical support from unreliable suppliers can disrupt production and compromise final product performance. A stable, transparent supply chain is essential when relying on high-performance materials like Lexan.

By recognizing these pitfalls and sourcing strategically through authorized channels with proper verification, companies can ensure they receive genuine, high-quality Lexan material while protecting themselves from IP and quality risks.

Logistics & Compliance Guide for Lexan Material

Lexan is a high-performance polycarbonate thermoplastic manufactured by SABIC, widely used in industries such as automotive, electronics, construction, and healthcare due to its impact resistance, clarity, and thermal stability. Proper logistics handling and compliance with regulatory standards are critical to ensure safety, quality, and legal adherence throughout the supply chain.

Material Handling & Storage

- Storage Conditions: Store Lexan sheets, pellets, or fabricated parts in a clean, dry, and well-ventilated area away from direct sunlight and moisture. Ideal storage temperature ranges from 15°C to 30°C (59°F to 86°F).

- UV Protection: Since prolonged UV exposure can degrade polycarbonate, store materials in opaque or UV-protected packaging or under cover.

- Stacking & Support: When storing sheets, use flat, level racks with adequate support to prevent warping or sagging. Avoid placing heavy objects on top.

- Pellet Handling: Keep Lexan resin pellets in sealed containers or original packaging to prevent moisture absorption, which can affect processing quality.

Transportation & Packaging

- Packaging Standards: Use robust packaging such as wooden crates, corrugated boxes with edge protectors, or stretch-wrapped pallets to prevent scratches, dents, and contamination.

- Moisture Protection: Include desiccants when shipping resin pellets and ensure packaging is moisture-resistant to avoid hydrolysis during transit.

- Labeling: Clearly label packages with handling instructions (e.g., “Fragile,” “Protect from Moisture,” “This Side Up”) and include product identification, batch numbers, and safety information.

- Temperature Control: Avoid extreme temperatures during transport. When shipping in cold climates, ensure materials are protected from freezing; in hot climates, prevent prolonged exposure to heat sources.

Regulatory Compliance

- REACH (EU): Lexan materials comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. Ensure that all formulations are registered and that Safety Data Sheets (SDS) are available.

- RoHS (EU): Lexan is generally RoHS-compliant, meaning it does not contain restricted substances such as lead, mercury, cadmium, or certain brominated flame retardants. Confirm compliance for specific grades.

- FDA Compliance: Certain Lexan grades are FDA-compliant for food contact applications (e.g., NSF/ANSI 51). Verify the specific grade and intended use before deployment in food or medical environments.

- Proposition 65 (California): Check if any Lexan grades contain chemicals listed under California’s Proposition 65. While polycarbonate itself is not on the list, additives may be. Consult the SDS for details.

Safety Data & Documentation

- Safety Data Sheets (SDS): Maintain up-to-date SDS for all Lexan materials. SDS includes hazard identification, first-aid measures, fire-fighting procedures, accidental release measures, and handling precautions.

- Hazard Communication (HazCom): Ensure all personnel handling Lexan are trained according to OSHA HazCom standards, especially when machining or processing generates dust or fumes.

- Fumes & Dust Control: During cutting, drilling, or thermoforming, polycarbonate can emit fumes. Use local exhaust ventilation and appropriate PPE (respirators, goggles, gloves).

Environmental & Disposal Considerations

- Recyclability: Lexan is recyclable. Follow local regulations for sorting and recycling polycarbonate waste. Use recycling code #7 (Other Plastics) with identification as “PC”.

- Waste Disposal: Do not incinerate without proper emission controls, as burning polycarbonate can release carbon monoxide and phenolic compounds. Dispose of waste in accordance with local, state, and federal environmental regulations.

- Sustainability: SABIC offers certified circular and renewable polycarbonate grades (e.g., from biomass or recycled feedstocks). Consider sustainable alternatives where applicable.

Import/Export Requirements

- Customs Documentation: Provide accurate Harmonized System (HS) codes (e.g., 3901.30 for polycarbonate in primary forms) and commercial invoices detailing material composition.

- Country-Specific Regulations: Verify compliance with import regulations in destination countries, including chemical registration (e.g., K-REACH in South Korea, China REACH).

- Restricted Substances: Confirm that the specific Lexan grade does not contain substances restricted under local laws (e.g., certain flame retardants in electronics).

Following this logistics and compliance guide ensures safe handling, regulatory adherence, and environmental responsibility when managing Lexan materials across the supply chain. Always consult SABIC’s technical data sheets and regulatory documentation for grade-specific guidance.

Conclusion for Sourcing Lexan Material:

After a thorough evaluation of available options, sourcing Lexan (polycarbonate) material should be guided by a balance of quality, cost, supplier reliability, and application requirements. Lexan’s exceptional impact resistance, optical clarity, and thermal stability make it an ideal choice for industries such as automotive, electronics, construction, and medical devices. Key considerations in the sourcing process include selecting certified suppliers with consistent material traceability, ensuring compliance with relevant industry standards (e.g., ISO, UL), and assessing the need for specific grades (e.g., flame-retardant, UV-protected, or food-grade).

Local suppliers may offer advantages in lead time and logistics, while global manufacturers could provide cost savings and large-scale supply capabilities. It is recommended to establish long-term partnerships with suppliers who demonstrate technical support, quality assurance, and sustainability practices. Additionally, conducting periodic material testing and maintaining a qualified alternate source can mitigate supply chain risks.

In conclusion, a strategic sourcing approach—centered on quality, reliability, and total cost of ownership—will ensure optimal performance of Lexan in end-use applications and support continuous operational efficiency.