The global prefabricated steel trusses market is experiencing robust growth, driven by rising demand for cost-effective, durable, and rapidly deployable structural solutions in residential, commercial, and agricultural construction. According to a report by Mordor Intelligence, the Prefabricated Steel Structure Market is projected to grow at a CAGR of 7.2% from 2023 to 2028, with metal trusses forming a critical component due to their strength-to-weight ratio and ease of installation. Similarly, Grand View Research estimates that the global cold-formed steel framing market—closely aligned with metal truss applications—will expand at a CAGR of 5.9% from 2024 to 2030, fueled by trends in modular construction and sustainable building practices. As lean-to metal trusses gain traction for their adaptability in expanding existing structures, manufacturers specializing in precision-engineered, high-strength solutions are increasingly shaping the industry. The following list highlights the top 10 lean-to metal trusses manufacturers emerging as leaders through innovation, scalability, and consistent quality in this expanding market landscape.

Top 10 Lean To Metal Trusses Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Steel & Metal Buildings in Gentry, AR

Domain Est. 1998

Website: adamstruss.com

Key Highlights: Looking for steel & metal buildings in Gentry, AR? We offer a range of steel and metal building kits from garages to barns and hangars! Call today….

#2 US Steel Truss

Domain Est. 2006

Website: ussteeltruss.com

Key Highlights: US Steel truss is a direct source for steel truss and components for contactors and private labelers that want to put their own building packages together….

#3 Midwest Manufacturing

Domain Est. 2000

Website: midwestmanufacturing.com

Key Highlights: MM Truss. Residential, Pole Barn, or Floor Trusses; MM Truss can produce a truss for any application. Check out our easy ways to design and buy….

#4 Steel Trusses

Domain Est. 2002

Website: georgiametals.com

Key Highlights: Georgia Metals offers steel trusses that are both stronger and long-lasting. Made from high-quality metals, our trusses are resistant to environmental factors ……

#5 to SteelBarnTruss.com

Domain Est. 2013

Website: steelbarntruss.com

Key Highlights: We are a steel truss manufacturing company that strives to produce the best steel trusses in the industry. Using only certified welders, we weld (not burn) ……

#6 Strouds Steel Truss

Domain Est. 2013

Website: stroudsbuildingsupply.com

Key Highlights: STEEL TRUSSES · INFORMATIONAL DRAWINGS · GABLES · LEANS · HEADERS & SNOOTS….

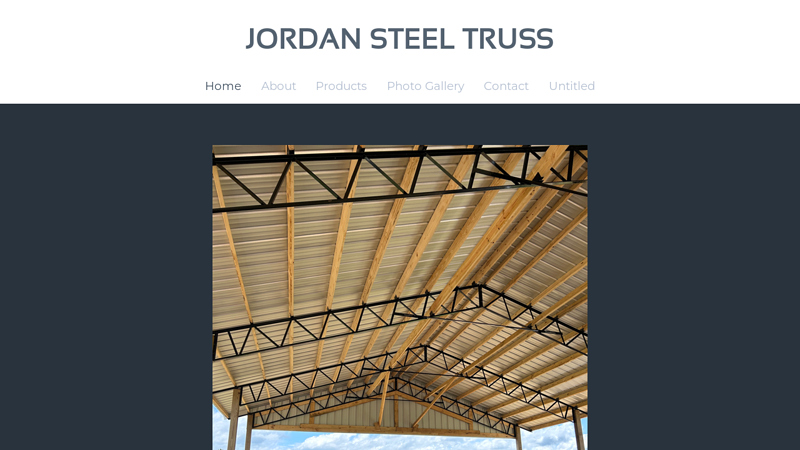

#7 JORDAN STEEL TRUSS

Domain Est. 2016

Website: jordansteeltrussinc.com

Key Highlights: Home · About · Products · Photo Gallery · Contact · Untitled. Picture. Products · Contact · Photos. Jason Jordan – (318) 413-0304 jordansteeltruss@outlook….

#8 Tri State Steel Truss

Domain Est. 2016

Website: tristatesteeltruss.com

Key Highlights: We sell steel trusses for agricultural & residential buildings in Michigan, Ohio & Pennsylvania. Steel Trusses built here in the USA with top-quality American ……

#9 Truss US

Domain Est. 2017

Website: steeltruss.us

Key Highlights: At Truss US, our lightweight square tube trusses are easy to install and tested for quality and safety that will last for generations….

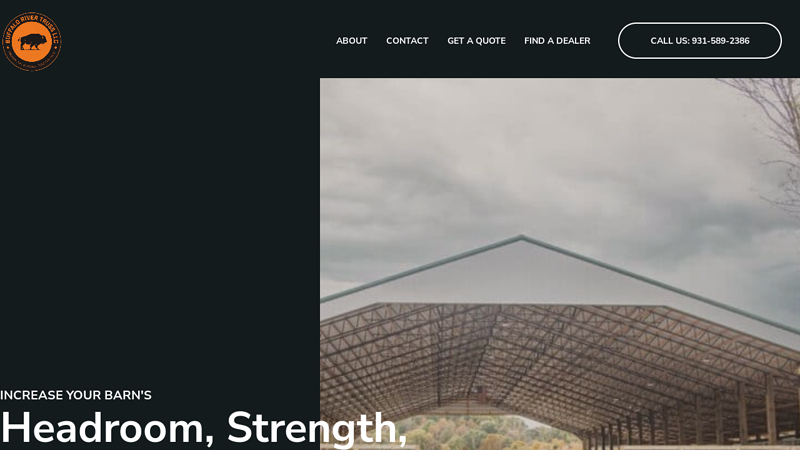

#10 Steel & Metal Trusses in Oklahoma

Domain Est. 2020

Website: buffalorivertruss.com

Key Highlights: Increase the headroom, strengths, and aesthetics of your pole barn, riding arena, and other ag structures in Oklahoma with steel and metal trusses!…

Expert Sourcing Insights for Lean To Metal Trusses

H2: Projected Market Trends for Lean-To Metal Trusses in 2026

By 2026, the market for lean-to metal trusses is expected to experience steady growth, driven by advancements in construction technology, increasing demand for cost-effective and durable building solutions, and shifting preferences in commercial, industrial, and agricultural infrastructure. Lean-to metal trusses—known for their simplicity, structural efficiency, and adaptability—will play a pivotal role in supporting the expansion of auxiliary structures such as warehouse extensions, equipment shelters, livestock barns, and residential carports.

One of the primary drivers of growth will be the continued rise in modular and prefabricated construction methods. Lean-to metal trusses align well with off-site fabrication processes due to their standardized designs and ease of assembly. As construction timelines shorten and labor costs rise, contractors and developers are increasingly turning to metal truss systems that offer fast installation and long-term durability, particularly in regions prone to harsh weather conditions.

Additionally, sustainability trends will influence material choices. Steel, the dominant material in metal trusses, is highly recyclable and increasingly produced using low-carbon methods. By 2026, building codes and green certification programs (such as LEED and BREEAM) are expected to place greater emphasis on sustainable materials, boosting demand for energy-efficient and eco-conscious structural components like lean-to metal trusses.

Geographically, growth will be strongest in emerging markets across Asia-Pacific, Latin America, and parts of Africa, where urbanization and industrial development are accelerating. In North America and Europe, retrofitting and expansion projects—especially in agriculture and logistics sectors—will sustain demand for lean-to solutions as cost-effective additions to existing buildings.

Technological integration, including the use of Building Information Modeling (BIM) and automated fabrication, will further enhance precision and reduce waste in truss production. Customization capabilities will improve, allowing lean-to trusses to be tailored to specific architectural and load-bearing requirements without significantly increasing costs.

In summary, the 2026 market for lean-to metal trusses will be shaped by efficiency, sustainability, and adaptability. As construction practices evolve, these truss systems will remain a go-to solution for economical, resilient, and scalable structures across multiple industries.

Common Pitfalls Sourcing Lean-To Metal Trusses (Quality, IP)

Sourcing lean-to metal trusses requires careful attention to avoid costly mistakes related to quality, design integrity, and intellectual property. Overlooking these aspects can lead to structural failures, project delays, and legal complications. Below are the most common pitfalls buyers encounter.

Poor Material Quality and Fabrication Standards

One of the top risks is receiving trusses made from substandard steel or with inadequate fabrication. Some suppliers may use lower-grade steel than specified, reducing load capacity and corrosion resistance. Inconsistent welding, improper hole punching, or inaccurate cutting can compromise structural integrity. Always verify that materials meet ASTM standards (e.g., ASTM A36 or A572) and that fabrication adheres to AWS D1.1 welding codes.

Lack of Engineering Certification and Stamped Drawings

Lean-to trusses must be engineered for specific load conditions, including snow, wind, and seismic forces. A common pitfall is accepting trusses without sealed, professional engineering drawings. Without a licensed engineer’s stamp, trusses may not comply with local building codes, leading to permit denials or liability issues during inspections. Ensure each truss design is certified for your project’s geographic and structural requirements.

Inadequate Connection Details and Compatibility

Lean-to trusses connect to a primary structure, often requiring precise compatibility with existing beams or columns. Poorly designed connection plates, undersized bolts, or mismatched profiles can result in weak joints or installation failures. Confirm that connection details are clearly specified in the drawings and compatible with the host building’s framing system.

Intellectual Property (IP) Infringement Risks

Using truss designs without proper licensing or copying patented configurations can lead to IP violations. Some manufacturers develop proprietary truss systems protected by patents or design rights. Sourcing from unauthorized suppliers—or allowing third parties to replicate protected designs—can expose your project to legal action, fines, or forced replacement of components. Always verify that the supplier owns or is licensed to use the truss design.

Incomplete or Ambiguous Documentation

Missing or unclear assembly instructions, material certifications, and load performance data can delay installation and raise safety concerns. Lack of traceability (e.g., lot numbers, mill test reports) makes quality verification difficult. Ensure all documentation is comprehensive, up-to-date, and provided before shipment.

Choosing Low-Cost Suppliers Without Due Diligence

While cost is a factor, selecting the cheapest option often sacrifices quality and reliability. Unverified suppliers, especially offshore vendors, may lack quality control systems or accountability. Conduct supplier audits, request references, and verify certifications (e.g., ICC-ES, AISC) to ensure compliance and reliability.

Failure to Account for Environmental and Corrosion Protection

Lean-to trusses are often exposed to harsh weather. A frequent oversight is inadequate corrosion protection, such as insufficient galvanizing (e.g., ASTM A123) or improper powder coating. This leads to premature rust and structural degradation, especially in coastal or high-moisture environments. Specify appropriate finishes based on environmental exposure.

By proactively addressing these pitfalls, buyers can ensure they receive high-quality, code-compliant, and legally sound lean-to metal trusses that support safe and durable construction.

Logistics & Compliance Guide for Lean-To Metal Trusses

Lean-to metal trusses are widely used in commercial, industrial, and agricultural construction due to their durability and ease of installation. Proper logistics planning and adherence to compliance standards are essential to ensure safe delivery, handling, and structural integrity. This guide outlines key considerations for transporting, storing, and installing lean-to metal trusses in accordance with industry regulations and best practices.

Transportation Requirements

Ensure that lean-to metal trusses are securely fastened during transit to prevent shifting, deformation, or damage. Use padded straps and load bars to avoid scratching or denting the metal components. Transport trusses in a flat, horizontal position whenever possible to maintain structural alignment. Coordinate deliveries with site readiness to minimize on-site storage time and exposure to weather elements.

Handling & On-Site Storage

Handle trusses with care using appropriate lifting equipment such as forklifts with truss cradles or lifting beams to avoid point loading. Never drag trusses along the ground. Store trusses on level, elevated surfaces protected from moisture, such as wooden skids, and cover with breathable construction-grade tarps to prevent rust while allowing ventilation. Avoid direct contact with soil or standing water.

Regulatory Compliance

Lean-to metal trusses must comply with local, state, and national building codes, including the International Building Code (IBC) and standards from the American Institute of Steel Construction (AISC) and the Metal Building Manufacturers Association (MBMA). Trusses should be engineered and stamped by a licensed structural engineer to ensure they meet load requirements (dead, live, wind, and snow loads) specific to the project location.

Permits & Inspections

Verify that all required building permits are obtained prior to delivery and installation. Schedule inspections at key stages—after truss placement and prior to roofing installation—to confirm compliance with approved structural drawings. Maintain documentation of engineering certifications, material test reports, and inspection records for audit purposes.

Safety Protocols

All personnel involved in handling and installing metal trusses must follow OSHA safety regulations, including fall protection when working at heights and proper use of personal protective equipment (PPE). Ensure that only trained and qualified workers perform truss installation, and conduct pre-lift safety briefings to review lifting plans and site hazards.

Environmental & Sustainability Considerations

Use recyclable packaging materials and recycle scrap metal generated during installation. Follow local environmental regulations for the disposal of protective coatings or sealants. Consider specifying trusses made from recycled steel content to support sustainability goals and qualify for green building certifications such as LEED.

Documentation & Traceability

Maintain a complete logistics and compliance file including bills of lading, delivery receipts, engineering drawings, material certifications, and inspection reports. Assign unique identification tags to each truss or bundle to ensure traceability throughout the supply chain and during installation.

Conclusion: Sourcing Lean-to Metal Trusses

Sourcing lean-to metal trusses requires a strategic approach that balances cost, quality, durability, and design compatibility. These structures offer a cost-effective, low-maintenance, and versatile solution for expanding existing buildings or creating new covered spaces. When procuring lean-to metal trusses, it is essential to work with reputable suppliers or manufacturers who adhere to industry standards and provide engineered designs tailored to site-specific requirements such as wind, snow, and seismic loads.

Key considerations include material quality (typically galvanized or coated steel), proper engineering certification, lead times, and logistics for delivery and installation. Prefabricated trusses can significantly reduce on-site labor and construction time, improving overall project efficiency. Additionally, ensuring compliance with local building codes and obtaining necessary permits are critical to long-term structural integrity and safety.

In conclusion, sourcing lean-to metal trusses is a practical and efficient choice for many commercial, agricultural, and industrial applications. With careful planning, due diligence in supplier selection, and attention to engineering details, lean-to metal truss systems can deliver a durable, scalable, and economical solution that meets both current and future spatial needs.