The global leak detection market is experiencing robust growth, driven by increasing regulatory scrutiny, rising industrial safety standards, and the need for predictive maintenance across oil & gas, manufacturing, and utilities sectors. According to Grand View Research, the global leak detection systems market was valued at USD 4.2 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. A key enabler of this growth is the rising adoption of ultrasonic technology, prized for its ability to detect leaks in pressurized systems without direct contact or system shutdown. Mordor Intelligence further highlights that the demand for non-destructive testing (NDT) methods, including ultrasonic leak detection, is accelerating—especially in aging infrastructure and high-risk industrial environments—projecting a CAGR of over 7% for the NDT equipment market through 2029. As industries prioritize efficiency, safety, and sustainability, leading manufacturers are advancing ultrasound-based solutions with improved sensitivity, portability, and data integration. The following profile highlights nine of the top ultrasonic leak detection manufacturers shaping this evolving landscape.

Top 9 Leak Detection Ultrasonic Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ultrasonic Leak Detection

Domain Est. 1994

Website: draeger.com

Key Highlights: Ultrasonic leak detectors are an early warning area monitor for detecting high-pressure gas leaks in outdoor industrial process environments….

#2 What is Ultrasonic Leak Detection?

Domain Est. 1995

Website: advancedtech.com

Key Highlights: Ultrasonic leak detection is the fastest and most reliable way to identify even the smallest leak in a system — which can later become a major problem. Safety ……

#3 Ultrasonic Leak Detector

Domain Est. 1997

Website: ctrlsys.com

Key Highlights: We have spent the past 30+ years designing, manufacturing, and delivering the world’s best acoustic ultrasound technology….

#4 Whisper®

Domain Est. 1995

Website: inficon.com

Key Highlights: Whisper is ideal for detecting and locating ultrasonic frequencies generated when the following common situations occur: leaks of any gas under pressure or ……

#5 UE Systems

Domain Est. 1996

Website: uesystems.com

Key Highlights: Prevent downtime, reduce costs and save energy with our ultrasonic instruments, software and training for predictive maintenance and condition monitoring….

#6 Superior Signal Company LLC

Domain Est. 1996

Website: superiorsignal.com

Key Highlights: Our American made, Superior® Smoke Generators and AccuTrak® Ultrasonic Leak Detectors are the professionals choice for literally hundreds of applications….

#7 Ultrasonic Leak Detection

Domain Est. 2012

Website: sonotecusa.com

Key Highlights: Our ultrasonic testing devices and our acoustic cameras are made for fast and reliable leak detection….

#8 Ultrasonic Leak Detection

Domain Est. 2016

Website: cicndt.com

Key Highlights: Ultrasonic leak detection employs high-frequency sound waves that detect the sonic disturbances caused by escaping gases. Specialized sensors ……

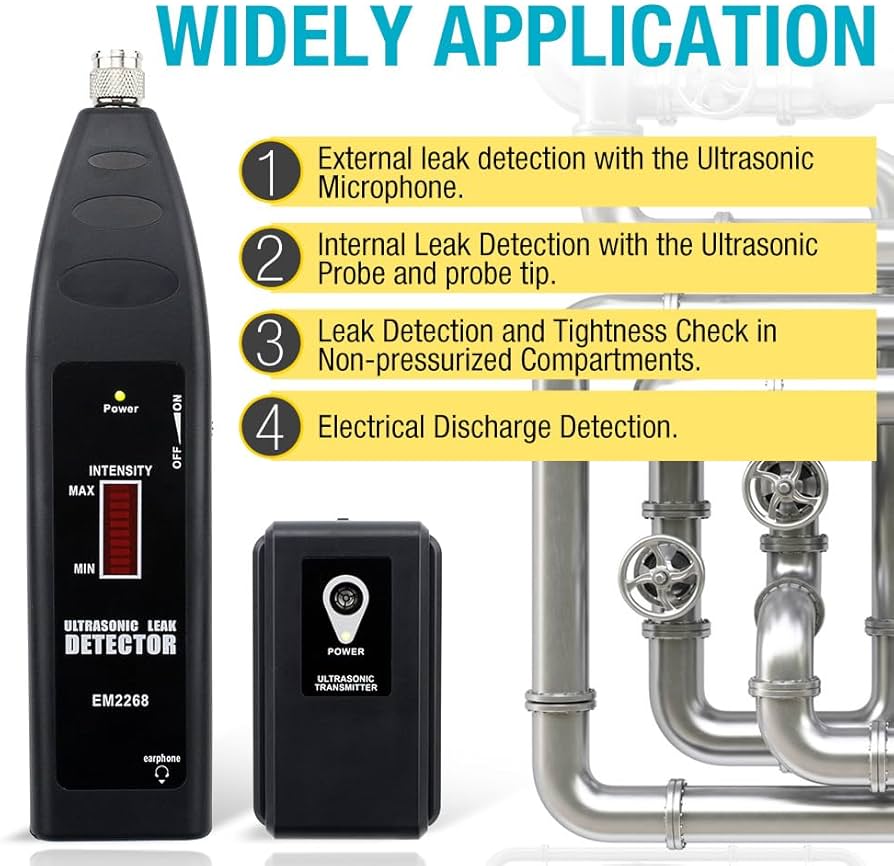

#9 DUOYI Ultrasonic Leak Detector Tool

Domain Est. 2022

Website: duoyitool.com

Key Highlights: In stock Rating 5.0 4 DY26A is designed to locate leaks in pressure and vacuum system. It can be used to detect and locate the source of the ultrasonic emission generated by gas …

Expert Sourcing Insights for Leak Detection Ultrasonic

H2: 2026 Market Trends for Leak Detection Ultrasonic

The global ultrasonic leak detection market is poised for significant growth and transformation by 2026, driven by technological advancements, increasing industrial automation, and heightened regulatory and efficiency demands. Key trends shaping this market include:

1. Integration with IIoT and Smart Manufacturing:

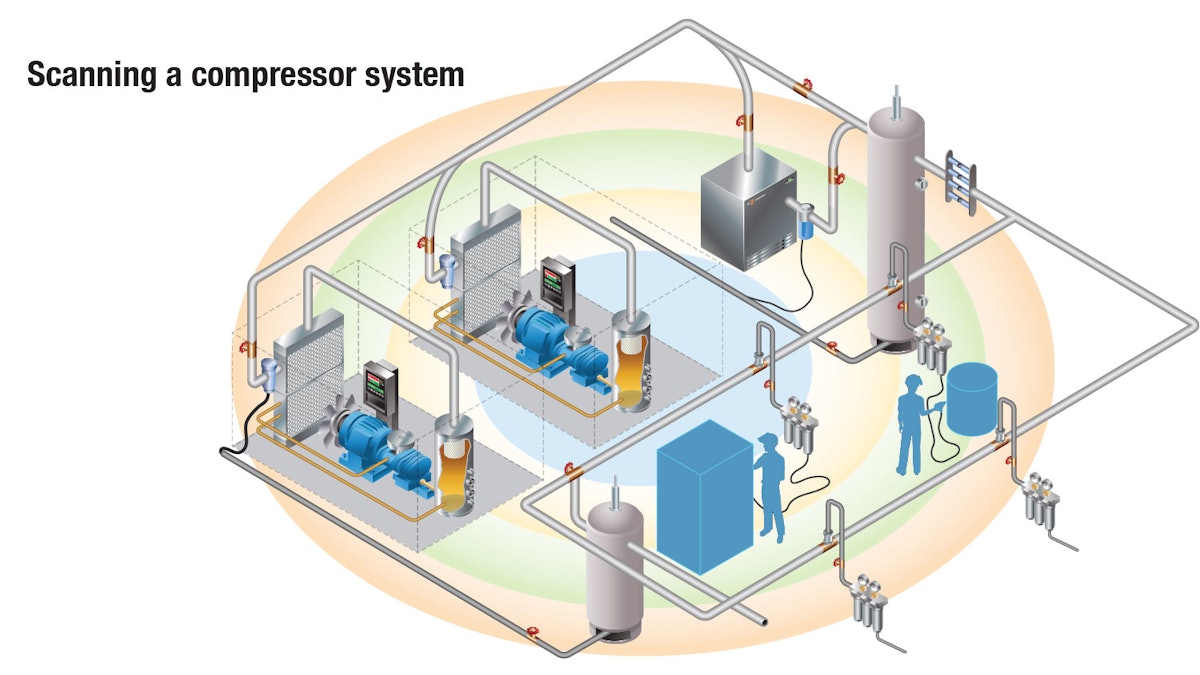

Ultrasonic leak detection systems are increasingly being integrated into Industrial Internet of Things (IIoT) platforms. By 2026, expect widespread adoption of connected ultrasonic sensors that feed real-time data into predictive maintenance systems and digital twins. This enables proactive leak identification, remote monitoring, and enhanced asset management across manufacturing, oil & gas, and utilities.

2. Miniaturization and Handheld Innovation:

The demand for portable, easy-to-use handheld ultrasonic detectors will continue to grow. Advancements in sensor technology and battery life are driving the development of compact, high-sensitivity devices with improved ergonomics and intuitive interfaces. These tools empower maintenance teams to perform rapid leak surveys with greater accuracy and reduced training time.

3. Enhanced Data Analytics and AI Integration:

Artificial intelligence and machine learning algorithms will play a larger role in analyzing ultrasonic data. By 2026, AI-powered systems will be capable of distinguishing between true leaks and background noise, reducing false positives. Predictive analytics will help prioritize repairs based on severity and potential impact, optimizing maintenance workflows.

4. Expansion into New Industry Verticals:

While traditionally dominant in oil & gas and power generation, ultrasonic leak detection is gaining traction in emerging sectors such as renewable energy (e.g., hydrogen infrastructure, biogas plants), HVAC/R, semiconductor manufacturing, and pharmaceuticals. Stringent environmental regulations and the need for energy efficiency are accelerating adoption in these areas.

5. Focus on Sustainability and Emissions Reduction:

With growing global emphasis on reducing greenhouse gas emissions, ultrasonic technology—especially for detecting fugitive emissions of gases like methane and SF6—will become a critical tool for compliance. Regulatory frameworks like the U.S. EPA’s methane rules and EU Green Deal will drive investment in advanced leak detection solutions.

6. Advancements in Sensor Technology and Sensitivity:

Ongoing R&D is improving the sensitivity and frequency range of ultrasonic sensors, allowing detection of smaller leaks at greater distances. Directional microphones and beam-forming technologies will enhance localization accuracy, reducing inspection time and improving safety in hazardous environments.

7. Rise of Drone- and Robot-Based Inspections:

By 2026, autonomous drones and robotic platforms equipped with ultrasonic sensors will be increasingly deployed for inspecting hard-to-reach or dangerous areas (e.g., flare stacks, offshore platforms, tall structures). This trend improves safety, reduces downtime, and increases inspection frequency.

8. Market Consolidation and Strategic Partnerships:

The competitive landscape is likely to see increased mergers, acquisitions, and partnerships as major players seek to expand their technology portfolios and global reach. Collaboration between sensor manufacturers, software developers, and industrial automation companies will accelerate innovation and solution integration.

In summary, by 2026, the ultrasonic leak detection market will be characterized by smarter, more connected, and more versatile solutions. The convergence of hardware innovation, digitalization, and sustainability imperatives will position ultrasonic technology as a cornerstone of modern industrial maintenance and environmental compliance strategies.

Common Pitfalls When Sourcing Leak Detection Ultrasonic Equipment (Quality, IP)

Sourcing ultrasonic leak detection equipment requires careful evaluation to ensure reliability, accuracy, and suitability for intended environments—especially when considering quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to ineffective inspections, safety risks, and increased long-term costs. Below are common pitfalls to avoid:

1. Prioritizing Price Over Quality and Performance

Choosing the lowest-cost option often results in compromised sensor sensitivity, poor audio fidelity, and unreliable detection capabilities. Low-quality components may fail prematurely in industrial environments, leading to downtime and inaccurate results. Invest in reputable brands with proven performance and calibration standards.

2. Ignoring IP Rating Requirements

Failing to match the device’s IP rating to the operating environment is a critical error. Using an IP54-rated device in a high-humidity or washdown area (requiring IP65 or higher) may result in moisture ingress, sensor damage, and electrical hazards. Always assess environmental conditions—dust, water exposure, and chemical contact—and select equipment with appropriate IP protection.

3. Overlooking Sensor Sensitivity and Frequency Range

Not all ultrasonic sensors perform equally. Some devices lack the sensitivity to detect small or distant leaks, especially in noisy environments. Ensure the equipment covers a suitable frequency range (typically 20–100 kHz) and offers adjustable sensitivity to distinguish background noise from actual leaks.

4. Assuming All Ultrasonic Detectors Are Intrinsically Safe

In hazardous areas (e.g., oil & gas, chemical plants), using non-certified equipment can pose explosion risks. Verify that the device carries the required certifications (e.g., ATEX, IECEx) for use in classified zones. Never assume intrinsic safety—always check documentation.

5. Neglecting Calibration and Maintenance Support

Poor-quality or uncertified equipment may lack traceable calibration or manufacturer support. Without regular calibration, readings become unreliable. Choose suppliers that offer calibration services, software updates, and technical support to maintain long-term accuracy.

6. Inadequate Training and User Interface

Even high-quality equipment is ineffective if operators aren’t properly trained. Devices with complex interfaces or poor ergonomics can lead to user error. Opt for intuitive designs with visual/audio feedback and ensure training is included or readily available.

7. Failing to Verify Real-World Performance

Datasheet specifications don’t always reflect field performance. Request demo units or case studies to test the equipment in your actual operating conditions. Evaluate battery life, durability, and detection range under real-world noise and environmental stress.

By addressing these pitfalls early in the sourcing process, organizations can ensure they select ultrasonic leak detection equipment that delivers accurate, safe, and reliable performance over its lifespan.

Logistics & Compliance Guide for Ultrasonic Leak Detection Equipment

Equipment Overview and Applications

Ultrasonic leak detection systems utilize high-frequency sound waves to identify gas or vacuum leaks that are inaudible to the human ear. These non-invasive tools are widely used across industries such as oil and gas, chemical processing, pharmaceuticals, and HVAC to ensure system integrity, improve safety, and reduce environmental emissions. The equipment typically includes a handheld detector with a parabolic microphone, headphones, and visual display for leak intensity measurement.

Regulatory Compliance Requirements

Ultrasonic leak detection must comply with various national and international regulations depending on the application and industry. Key standards include:

– OSHA 29 CFR 1910: General industry standards for workplace safety, including hazard communication and process safety management (PSM) for flammable or toxic materials.

– EPA Method 21: Standard reference method for detecting volatile organic compound (VOC) leaks using instrumental monitoring, often applicable in conjunction with ultrasonic technology for initial screening.

– ISO 15848-1: Specifies leakage measurement and type testing for valve stem seals and shaft seals, where ultrasonic testing may support fugitive emissions programs.

– ATEX/IECEx: Required for equipment used in potentially explosive atmospheres; ensure detectors are certified for use in hazardous areas if applicable.

Transportation and Shipping Logistics

When shipping ultrasonic leak detectors domestically or internationally:

– Packaging: Use manufacturer-approved packaging with shock-absorbing materials to protect sensitive acoustic components. Include desiccants if shipping to high-humidity regions.

– Battery Compliance: Lithium-ion batteries (common in portable units) must comply with IATA Dangerous Goods Regulations (DGR) for air transport. Units should be shipped at <30% charge and individually protected against short circuits.

– Export Controls: Verify if equipment contains technology subject to export regulations such as U.S. EAR (Export Administration Regulations) or ITAR. Most standard detectors are EAR99, but confirm classification before export.

Import and Customs Documentation

For international deployment:

– Provide a detailed commercial invoice specifying equipment use (e.g., “Ultrasonic Leak Detector for Industrial Maintenance”).

– Include Harmonized System (HS) code 9026.20 (instruments for detecting/controlling leaks) to ensure accurate tariff classification.

– Supply certificates of conformity (CE, UKCA, or other regional marks) and user manuals in the local language if required by destination country.

On-Site Handling and Storage

- Store detectors in a clean, dry environment with stable temperatures (typically 0°C to 40°C). Avoid exposure to dust, moisture, or extreme temperatures.

- Calibrate annually or per manufacturer’s recommendations using certified calibration sources (e.g., ultrasonic calibrators or reference leak standards). Maintain calibration records for audit purposes.

- Conduct pre-use inspections to verify microphone integrity, battery condition, and functionality of audio/visual outputs.

Training and Personnel Certification

- Personnel using ultrasonic leak detectors should receive formal training on equipment operation, safety procedures, and interpretation of results.

- In regulated industries (e.g., refineries), documentation of operator competency may be required under OSHA PSM or EPA LDAR (Leak Detection and Repair) programs.

- Maintain training records and ensure refresher courses are conducted periodically.

Recordkeeping and Reporting

- Document all leak surveys, including date, location, equipment used, detected leaks, and corrective actions taken.

- Retain records for a minimum of 5 years (or as required by local regulations such as EPA 40 CFR Part 60, Subpart VV).

- Integrate findings into facility LDAR programs, ensuring timely repair and retesting within regulatory timelines (e.g., 15 days for most VOC leaks under EPA rules).

Environmental and Safety Considerations

- While ultrasonic detection itself is non-emissive and safe, its use supports broader environmental compliance by minimizing fugitive emissions of greenhouse gases (e.g., methane) and hazardous air pollutants.

- Always follow site-specific safety protocols when inspecting pressurized systems, including lockout/tagout (LOTO) and wearing appropriate PPE.

- Do not rely solely on ultrasonic detection for life-safety gas monitoring (e.g., H2S or CO); use dedicated gas detectors for toxic or explosive atmospheres.

Maintenance and End-of-Life Disposal

- Follow manufacturer guidelines for cleaning and maintenance. Replace worn components (e.g., windshields, earphone cushions) promptly.

- Dispose of end-of-life equipment in compliance with local e-waste regulations (e.g., WEEE Directive in the EU). Recycle batteries separately through certified programs.

This guide ensures safe, compliant, and effective use of ultrasonic leak detection equipment across the logistics and operational lifecycle.

Conclusion for Sourcing Leak Detection Ultrasonic Equipment:

In conclusion, sourcing ultrasonic leak detection equipment is a strategic decision that enhances the efficiency, safety, and cost-effectiveness of maintenance and quality control operations across various industries. Ultrasonic detectors offer a non-invasive, highly sensitive method for identifying compressed air, gas, vacuum, and steam leaks—even in noisy environments or hard-to-reach areas—allowing for early detection and timely repairs.

When sourcing such equipment, key considerations include sensitivity and frequency range, ease of use, durability, data logging capabilities, and compatibility with existing maintenance programs. Additionally, evaluating supplier reliability, training support, and after-sales service ensures long-term operational success.

Investing in high-quality ultrasonic leak detection technology not only reduces energy waste and operational costs but also supports sustainability goals by minimizing greenhouse gas emissions. Ultimately, a well-sourced ultrasonic leak detection solution strengthens preventive maintenance programs, improves system reliability, and delivers significant return on investment over time.