The global laser rust removal tools market is experiencing robust growth, driven by increasing demand for precision cleaning solutions in industrial maintenance, automotive restoration, and heritage conservation. According to a 2023 report by Mordor Intelligence, the industrial laser cleaning market—of which rust removal is a key application—is projected to grow at a CAGR of over 15% from 2023 to 2028. This surge is fueled by stricter environmental regulations and the industry’s shift away from abrasive or chemical cleaning methods toward eco-friendly, non-contact alternatives. Laser rust removal tools offer superior accuracy, minimal substrate damage, and reduced waste, making them increasingly indispensable across high-value manufacturing and repair sectors. With Asia-Pacific emerging as a key growth region due to expanding industrial automation, manufacturers are innovating rapidly to enhance power efficiency, portability, and usability. As adoption accelerates, identifying the leading players shaping this transformative space becomes critical for stakeholders across the supply chain.

Top 10 Lazer Rust Removal Tool Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: An innovative laser cleaner that revolutionizes the maintenance and restoration of large vehicles and industrial equipment….

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Clean smarter with laser light. Fully cleaning rust of machine parts with the help of laser cleaning. WHY LASER CLEANING? Embrace the future of sustainable ……

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#6 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#7 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#8 Laser Rust Removal

Website: powerlase-limited.com

Key Highlights: Achieve super fast rust removal rates with out lasers. Watch this super fast rust removal from carbon steel panel with the new ultra-lightweight Vulcan handheld ……

#9 Laser Rust Removal

Website: keyence.com

Key Highlights: The laser rust removal machine uses a focused laser beam with high peak power and short pulse to heat the external surface (the rust) to its evaporation point….

#10 Laser Cleaning

Website: ipgphotonics.com

Key Highlights: Laser cleaning is used across a variety of industries to remove unwanted surface materials like coatings, paints, rust, oil, and for surface preparation for ……

Expert Sourcing Insights for Lazer Rust Removal Tool

2026 Market Trends for Lazer Rust Removal Tool

The global market for laser rust removal tools is poised for significant transformation by 2026, driven by advancements in laser technology, increasing demand for eco-friendly surface treatment solutions, and growing adoption across key industrial sectors. This analysis explores the major trends expected to shape the market landscape for laser rust removal tools in 2026.

Technological Advancements and Efficiency Improvements

By 2026, laser rust removal tools are expected to feature enhanced efficiency, portability, and automation. Innovations in fiber laser technology will lead to higher pulse frequencies and improved beam quality, enabling faster rust ablation with minimal substrate damage. Integration with artificial intelligence (AI) and machine vision systems will allow for smart surface scanning, automatic defect detection, and adaptive cleaning protocols. These improvements will reduce operator dependency and increase repeatability, making laser rust removal more accessible to small and medium enterprises (SMEs).

Rising Environmental and Regulatory Pressure

Environmental regulations are tightening worldwide, particularly in North America and Europe, where chemical-based rust removal methods face increasing scrutiny due to hazardous waste and worker safety concerns. Laser rust removal, being a dry, chemical-free, and waste-minimizing process, aligns with sustainability goals and regulatory compliance. By 2026, stricter enforcement of environmental standards is expected to accelerate the shift from traditional blasting and chemical stripping to laser-based solutions in automotive, aerospace, and marine industries.

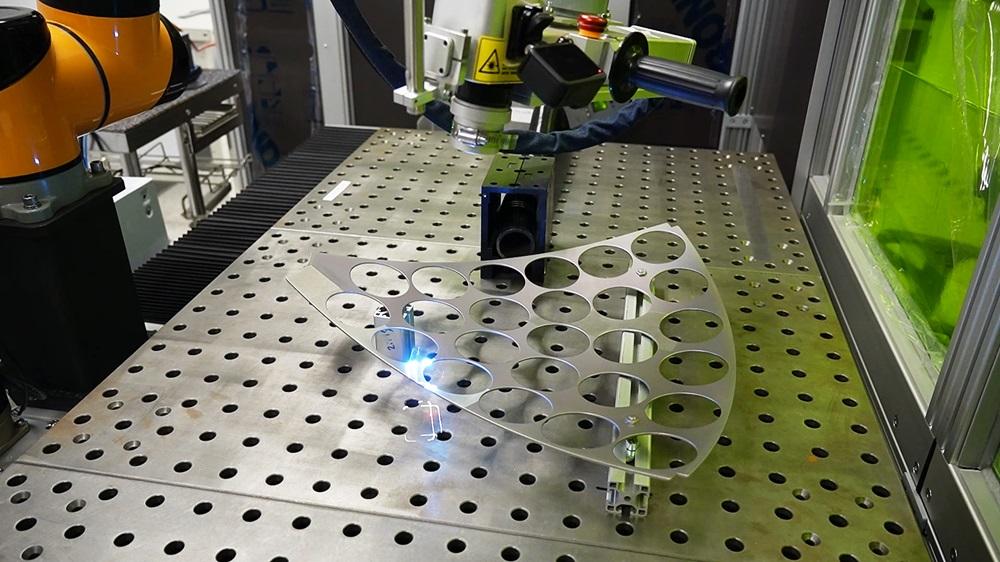

Expansion in Industrial Applications

The adoption of laser rust removal tools is expanding beyond niche applications into mainstream industrial maintenance. By 2026, key sectors such as automotive restoration, shipbuilding, historical preservation, and oil & gas infrastructure maintenance are projected to be major growth drivers. The precision and non-abrasive nature of lasers make them ideal for delicate components and heritage structures where preserving original material is critical. Additionally, robotics integration will enable automated rust removal in large-scale production and maintenance environments.

Cost Reduction and Market Accessibility

One of the primary barriers to adoption—high initial investment—is expected to diminish by 2026. As production scales and competition increases, the cost of laser systems is projected to decline. Modular and handheld laser rust removal tools will become more affordable, opening the market to individual artisans, restoration shops, and field service technicians. Rental and service-as-a-product models may also emerge, further lowering entry barriers and expanding market reach.

Regional Market Growth

Asia-Pacific, particularly China and India, is anticipated to be the fastest-growing region for laser rust removal tools by 2026, fueled by rapid industrialization, infrastructure development, and government initiatives promoting advanced manufacturing. North America and Europe will maintain strong demand due to high regulatory standards and early adoption of green technologies. Meanwhile, Latin America and the Middle East are expected to see gradual uptake, especially in offshore and energy sectors.

Competitive Landscape and Innovation

The competitive landscape will intensify, with established laser equipment manufacturers and new entrants focusing on differentiation through smart features, user-friendly interfaces, and after-sales support. Strategic partnerships with industrial automation firms and integration into Industry 4.0 ecosystems will be key success factors. By 2026, companies offering comprehensive solutions—hardware, software, and training—will likely dominate the market.

In conclusion, the 2026 market for laser rust removal tools will be characterized by technological maturity, broader industrial adoption, and strong environmental tailwinds. As the technology becomes more efficient and cost-effective, it is set to redefine surface preparation standards across multiple industries.

Common Pitfalls When Sourcing the Lazer Rust Removal Tool (Quality, IP)

Sourcing innovative tools like the Lazer Rust Removal Tool—especially those involving laser technology—comes with significant risks related to quality control and intellectual property (IP). Being aware of these pitfalls is essential to avoid financial loss, legal issues, and reputational damage.

Poor Manufacturing Quality and Performance Inconsistencies

One of the most common issues when sourcing laser-based tools is inconsistent product quality. Many manufacturers, particularly in regions with less stringent oversight, may cut corners on component quality (e.g., diode lasers, cooling systems, optics) to reduce costs. This can result in underperforming units, short lifespans, or safety hazards. Buyers may receive products that do not meet the advertised rust-removal efficiency or fail prematurely under normal use. Additionally, lack of proper quality assurance processes can lead to variability between units, making bulk procurement unreliable.

Intellectual Property Infringement and Counterfeit Products

The Lazer Rust Removal Tool is likely protected by patents, trademarks, or proprietary designs. Sourcing from unauthorized suppliers—especially third-party manufacturers on global marketplaces—poses a high risk of purchasing or distributing counterfeit or cloned versions. These replicas often violate IP rights and may expose the buyer to legal liability, including cease-and-desist orders, customs seizures, or lawsuits. Moreover, counterfeit tools typically lack safety certifications and technical support, increasing operational and compliance risks.

Lack of Technical Support and Documentation

Many low-cost suppliers fail to provide comprehensive technical documentation, calibration data, or after-sales support. This absence can hinder integration into industrial workflows and make troubleshooting difficult. Without proper manuals, safety guidelines, or firmware updates, users may face operational inefficiencies or regulatory non-compliance, especially in industries with strict safety standards.

Non-Compliance with Safety and Regulatory Standards

Laser tools are subject to strict international regulations (e.g., FDA, IEC 60825, CE marking). Unauthorized or poorly sourced versions may not meet these safety requirements, posing risks of eye or skin injury and liability in the workplace. Sourcing from non-compliant suppliers can result in failed audits, import restrictions, or fines—particularly in regulated industries such as automotive, aerospace, or marine maintenance.

Hidden Costs and Supply Chain Vulnerabilities

Initial pricing from dubious suppliers may appear attractive, but hidden costs often emerge in the form of warranty claims, replacements, shipping delays, or import duties due to misdeclared goods. Additionally, reliance on single, unverified sources increases supply chain fragility. If the supplier disappears or changes production quality, businesses may face operational disruptions with no recourse.

Inadequate Verification and Due Diligence

Failing to conduct thorough due diligence on suppliers—such as onsite audits, sample testing, or IP clearance checks—can lead to sourcing failures. Buyers may assume a product is legitimate based on marketing materials alone, only to discover after purchase that it infringes on patents or performs poorly in real-world conditions. Proper vetting is essential to ensure both compliance and performance.

Logistics & Compliance Guide for Lazer Rust Removal Tool

This guide outlines the essential logistics and compliance requirements for the distribution, handling, and sale of the Lazer Rust Removal Tool. Adherence ensures regulatory compliance, safe operations, and efficient supply chain management.

Product Classification & Documentation

Ensure the Lazer Rust Removal Tool is correctly classified under the Harmonized System (HS) Code for laser-based industrial tools (typically 8543.70 or similar, verify regionally). Maintain accurate product specifications, technical data sheets, and safety documentation, including conformity declarations and user manuals in required languages.

Regulatory Compliance

The tool must comply with relevant regional and international regulations. Key standards include:

– Electrical Safety: IEC 60335 or UL 60950-1 (depending on region and power source)

– Laser Safety: IEC 60825-1 (Class 1 or Class 2, depending on output), with FDA compliance (CDRH) for U.S. market

– EMC (Electromagnetic Compatibility): FCC Part 15 (U.S.), CE EMC Directive (EU)

– RoHS & REACH: Ensure restricted substances are below allowable limits for EU and other regulated markets

Packaging & Labeling Requirements

Package the tool in durable, shock-resistant materials suitable for industrial equipment. Include:

– Product name and model number

– Manufacturer/importer details

– Laser class warning label (e.g., “Laser Radiation – Do Not Stare Into Beam”)

– CE, FCC, or other required certification marks

– Voltage and power requirements

– Safety warnings and handling instructions

Shipping & Transportation

Ship via carriers compliant with IATA (for air) or IMDG (for sea) regulations if applicable. Although the tool is not hazardous, ensure:

– Batteries (if included) are properly installed and meet UN38.3 testing standards

– Equipment is securely packed to prevent movement

– Shipping documents include accurate commodity descriptions and HS codes

Import/Export Documentation

Prepare and retain:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin

– Import/export licenses (if required by destination country)

– Proof of conformity (CE, FCC, etc.)

Storage & Handling

Store in a dry, temperature-controlled environment (10°C to 30°C recommended). Avoid exposure to moisture, dust, and direct sunlight. Handle with care to protect optical components and electrical connections. Use appropriate personal protective equipment (PPE) during handling if batteries or electrical components are exposed.

End-of-Life & Environmental Responsibility

Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Provide end-users with information on proper disposal and recycling options. Ensure take-back programs are available where mandated.

Record Keeping & Audit Readiness

Maintain records of compliance certifications, test reports, shipping documents, and quality audits for a minimum of 5–10 years, depending on jurisdiction. Be prepared for regulatory inspections or customer audits.

Contact & Support

For compliance inquiries or documentation requests, contact:

Compliance Team

Email: [email protected]

Phone: +1 (800) 555-0199

Conclusion on Sourcing a Laser Rust Removal Tool

After evaluating various suppliers, technologies, and market options, sourcing a laser rust removal tool presents a promising investment for enhancing efficiency, precision, and sustainability in surface cleaning processes. Laser rust removal offers significant advantages over traditional methods—such as sandblasting or chemical treatments—by minimizing material damage, reducing waste, and eliminating the need for consumables.

Key considerations in the sourcing decision include laser power (typically 100W–2000W), beam control systems, portability, safety features, and after-sales support. Leading suppliers from China, Europe, and North America offer reliable systems, with brands like CleanLASER, Laser Photonics, and Adapt Laser gaining recognition for performance and durability.

While the initial cost of laser systems is higher than conventional tools, the long-term return on investment is favorable due to lower operational costs, increased productivity, and compliance with environmental and safety regulations.

In conclusion, sourcing a laser rust removal tool is a strategic move for industries seeking advanced, eco-friendly, and cost-effective surface preparation solutions. Careful vetting of suppliers, thorough testing, and proper operator training are essential to maximize the benefits and ensure successful integration into existing workflows.