The global paint and coating removal market is undergoing a transformative shift as industries increasingly adopt advanced, eco-friendly technologies to meet regulatory standards and operational efficiency goals. According to a 2023 report by Mordor Intelligence, the global paint stripping market was valued at approximately USD 3.8 billion in 2022 and is projected to grow at a CAGR of 5.2% through 2028. A key driver behind this growth is the rising adoption of laser paint stripping technology—especially in aerospace, automotive, and marine sectors—due to its precision, reduced environmental impact, and lower long-term operational costs compared to traditional chemical or abrasive methods. Grand View Research further highlights that innovations in fiber laser systems and increasing demand for non-destructive surface treatment solutions are accelerating market expansion. As the technology matures and becomes more accessible, a select group of manufacturers are leading the charge in R&D, application engineering, and commercial deployment. Below, we profile the top 9 laser paint stripper manufacturers shaping the future of industrial surface preparation.

Top 9 Lazer Paint Stripper Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 China Laser Paint Stripper

Website: laserstripper.com

Key Highlights: Industrial-grade laser paint stripper and laser rust stripper with continuous wave technology for heavy-duty cleaning applications and large-scale operations….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: With over 35 years of expertise in surface treatment and more than 450 systems installed worldwide, P-Laser is at the forefront of industrial laser cleaning ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: Explore PULSAR Laser P CL laser cleaning machines for industrial rust removal and paint stripping. Compare SHARK P CL, PANDA P CL and FOX P CL….

#5 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#6 Laser Paint Removal

Website: keyence.com

Key Highlights: Achieve fast, precise laser paint removal with minimal waste. Discover advanced paint removal with laser for industrial and manufacturing needs….

#7 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#8 Laser Paint Stripper

Website: laserrustremovals.com

Key Highlights: Remove paint safely with a laser paint stripper. Our laser cleaning machines offer precise, non-damaging laser removal for any surface….

#9 Best Laser Paint Remover

Website: laserchina.com

Key Highlights: Our laser paint remover offers a powerful and precise solution for removing unwanted paint from various surfaces like wood, metal, plastic, etc….

Expert Sourcing Insights for Lazer Paint Stripper

2026 Market Trends for Laser Paint Stripper Technology

The global market for laser paint stripper technology is poised for significant transformation by 2026, driven by advancements in automation, sustainability imperatives, and growing demand across aerospace, automotive, and heritage restoration sectors. As industries seek environmentally friendly and precision-focused alternatives to chemical and abrasive paint removal methods, laser-based solutions are emerging as a high-growth segment. This analysis explores key trends shaping the laser paint stripper market through 2026.

Rising Demand for Eco-Friendly Surface Preparation

Environmental regulations are tightening worldwide, with increasing restrictions on volatile organic compounds (VOCs) and hazardous waste from chemical strippers. Laser paint removal offers a clean, solvent-free alternative that produces minimal secondary waste—only ablated paint particles, which can be efficiently captured via integrated filtration systems. By 2026, compliance with environmental standards such as EPA and REACH is expected to accelerate adoption of laser systems, particularly in Europe and North America, where sustainability goals are most stringent.

Advancements in Fiber Laser Technology and Portability

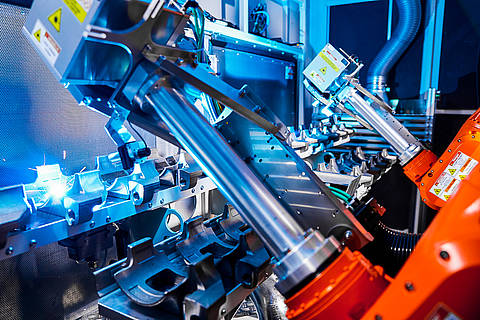

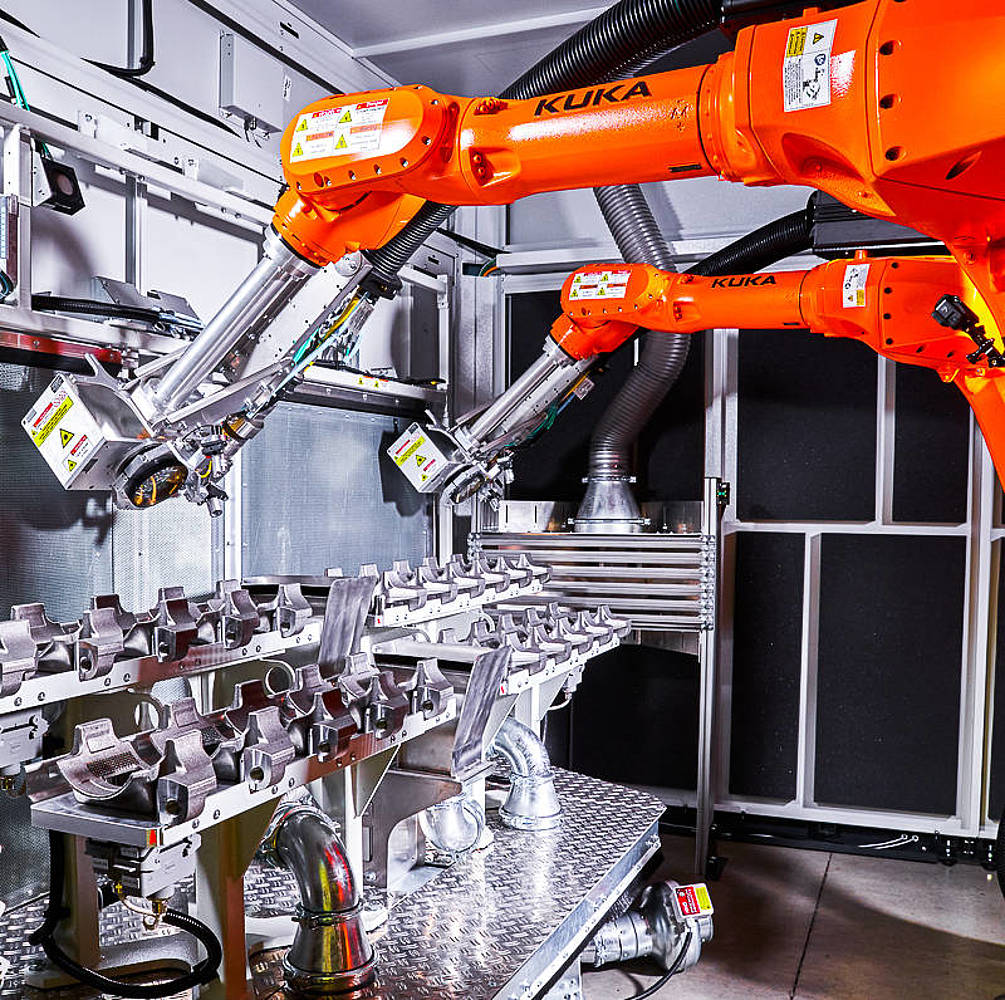

Recent improvements in fiber laser efficiency, beam control, and cooling systems are making laser paint strippers more powerful, reliable, and compact. By 2026, handheld and robotic-mounted laser units are expected to become more affordable and user-friendly, expanding access beyond large industrial facilities to mid-sized workshops and on-site restoration projects. Enhanced real-time monitoring and AI-assisted scanning will allow for selective paint removal with minimal substrate damage, increasing precision in sensitive applications like aircraft maintenance and historic building conservation.

Growth in Aerospace and Defense Applications

The aerospace industry remains the largest adopter of laser paint stripping, driven by the need for non-destructive maintenance of aluminum and composite airframes. With aging aircraft fleets requiring more frequent repainting and inspection, laser systems reduce downtime and extend component life. Defense contractors are also investing in automation-compatible laser solutions to streamline fleet maintenance. By 2026, integration with digital twin technologies and predictive maintenance platforms is expected to further embed laser stripping into smart manufacturing ecosystems.

Expansion into Automotive and Maritime Sectors

Beyond aerospace, the automotive and maritime industries are beginning to adopt laser paint removal for high-value restoration, EV battery housing preparation, and ship hull maintenance. As electric vehicle production scales, manufacturers require clean, residue-free surfaces for adhesive bonding—areas where lasers excel. In maritime, the ability to strip anti-fouling coatings without damaging steel substrates or releasing toxic runoff makes laser systems increasingly attractive. This cross-sector expansion will diversify the customer base and drive market growth.

Cost Reduction and ROI Improvement

Although initial investment in laser systems remains high, declining costs of laser components and rising operational efficiency are improving return on investment (ROI). By 2026, total cost of ownership is projected to favor laser solutions over traditional methods due to lower labor requirements, reduced waste disposal costs, and decreased health and safety liabilities. Leasing models and service-as-a-solution offerings are also expected to lower entry barriers for small and medium enterprises.

Regulatory and Safety Standardization

As the technology matures, industry-specific safety standards and operational guidelines for laser paint stripping are being developed. By 2026, clearer regulatory frameworks around laser safety (e.g., IEC 60825), fume extraction, and operator training will enhance user confidence and facilitate wider deployment. Certification programs for laser technicians and equipment will likely become more prevalent, supporting market professionalism and scalability.

Conclusion

By 2026, the laser paint stripper market is anticipated to experience robust growth, driven by technological innovation, regulatory pressures, and cross-industry demand for sustainable and precise surface treatment. Key players will focus on enhancing system intelligence, reducing costs, and expanding application versatility to capture emerging opportunities. As laser technology becomes more accessible and integrated into industrial workflows, it is set to redefine surface preparation standards across multiple sectors.

Common Pitfalls When Sourcing Lazer Paint Stripper (Quality, IP)

When sourcing Lazer Paint Stripper—a powerful chemical solution used for removing coatings from surfaces—businesses often encounter significant challenges related to both product quality and intellectual property (IP) concerns. Overlooking these aspects can lead to operational inefficiencies, safety risks, legal disputes, and reputational damage. Below are key pitfalls to watch for:

Poor or Inconsistent Product Quality

One of the most frequent issues when sourcing Lazer Paint Stripper is receiving substandard or inconsistent formulations. Generic or counterfeit versions may lack the chemical potency, safety profile, or material compatibility of genuine products. This can result in incomplete stripping, surface damage, or increased rework. Variations in viscosity, evaporation rate, or active ingredient concentration may not be immediately apparent but can severely impact performance, especially in industrial or precision applications.

Additionally, suppliers may not provide adequate batch testing or Material Safety Data Sheets (MSDS), making it difficult to verify consistency or ensure workplace safety compliance. Relying on unverified manufacturers, particularly from regions with lax regulatory oversight, increases the risk of receiving adulterated or expired products.

Intellectual Property Infringement Risks

Lazer Paint Stripper is a proprietary formulation, and sourcing from unauthorized suppliers often involves IP violations. Counterfeit or knockoff versions may infringe on registered trademarks, patented chemical compositions, or trade secrets. Purchasing such products—knowingly or unknowingly—can expose your company to legal liability, including cease-and-desist orders, fines, or even supply chain disruptions during litigation.

Moreover, using non-genuine products may void warranties or compliance certifications required in regulated industries (e.g., aerospace, automotive). If an IP dispute arises, your organization could face reputational harm, especially if linked to supporting counterfeit operations.

Lack of Supply Chain Transparency

Many suppliers obscure the origin of their products, making it difficult to trace whether the Lazer Paint Stripper is manufactured under license or produced illicitly. This lack of transparency also complicates quality assurance and due diligence. Without verifiable documentation—such as authenticity certificates, chain-of-custody records, or official distributor agreements—buyers cannot confidently assess the legitimacy or reliability of the product.

Inadequate Regulatory Compliance

Genuine Lazer Paint Stripper formulations typically comply with environmental, health, and safety regulations (e.g., REACH, OSHA, EPA). Sourcing from unauthorized vendors increases the risk of non-compliant products that may contain banned substances or fail to meet disposal requirements. This exposes the buyer to regulatory penalties and environmental liability.

To mitigate these pitfalls, always source Lazer Paint Stripper through authorized distributors, verify supplier credentials, request quality certifications, and conduct due diligence on IP rights. Engaging legal counsel to review procurement agreements can further safeguard against inadvertent IP violations.

Logistics & Compliance Guide for Lazer Paint Stripper

Product Classification and Regulatory Overview

Lazer Paint Stripper is a chemical formulation designed for efficient paint removal from various surfaces. Due to its chemical composition, it may contain solvents or active ingredients regulated under national and international safety, transportation, and environmental standards. Proper classification under systems such as GHS (Globally Harmonized System) and adherence to OSHA, EPA, and DOT regulations in the U.S. (or equivalent bodies internationally) is required.

Safety Data Sheet (SDS) Requirements

A current Safety Data Sheet (SDS) compliant with GHS and local regulatory standards (e.g., OSHA 29 CFR 1910.1200 in the U.S.) must accompany every shipment. The SDS must include:

– Hazard identification

– Composition/information on ingredients

– First-aid and firefighting measures

– Accidental release measures

– Handling and storage instructions

– Exposure controls/personal protection

– Physical and chemical properties

– Stability and reactivity

– Toxicological and ecological information

– Disposal considerations

– Transport information

– Regulatory information

Ensure all personnel handling the product have access to the SDS and are trained accordingly.

Packaging and Labeling Standards

Lazer Paint Stripper must be packaged in UN-certified containers suitable for flammable or corrosive liquids, depending on formulation. All containers must be:

– Leak-proof and securely sealed

– Labeled with GHS-compliant pictograms, signal words, hazard statements, and precautionary statements

– Marked with product identifier, supplier information, and batch/lot number

– Accompanied by transport labels indicating hazard class (e.g., Class 3 Flammable Liquid or Class 8 Corrosive, as applicable)

Secondary packaging must provide additional containment and protection during transit.

Transportation and Shipping Regulations

Transportation of Lazer Paint Stripper is subject to regulations including:

– DOT (U.S. Department of Transportation): Compliance with 49 CFR for hazardous materials transport, including proper shipping name, UN number (e.g., UN1263 or UN1993, depending on formulation), hazard class, packing group, and placarding requirements.

– IATA/ICAO (Air Transport): If shipped internationally by air, adherence to IATA Dangerous Goods Regulations is mandatory.

– IMDG Code (Sea Transport): For ocean freight, compliance with the International Maritime Dangerous Goods Code is required.

– ADR (Road Transport in Europe): Applicable for shipments within Europe.

Use only carriers authorized to transport hazardous materials and ensure proper documentation (e.g., Dangerous Goods Note) is provided.

Storage and Handling Procedures

Store Lazer Paint Stripper in a well-ventilated, cool, dry area away from direct sunlight, heat sources, and incompatible materials (e.g., oxidizers, strong bases). Use dedicated storage cabinets for flammable liquids if applicable. Implement spill containment measures (e.g., secondary containment trays, absorbent materials). Personnel must wear appropriate PPE, including chemical-resistant gloves, goggles, and protective clothing.

Environmental and Disposal Compliance

Dispose of Lazer Paint Stripper and contaminated materials in accordance with local, state, and federal environmental regulations (e.g., RCRA in the U.S.). Do not pour down drains or release into the environment. Use licensed hazardous waste disposal services. Spill cleanup must follow EPA or equivalent guidelines to prevent soil and water contamination.

Training and Documentation

All personnel involved in handling, storing, or transporting Lazer Paint Stripper must receive comprehensive training on:

– Hazard communication (HazCom)

– Spill response procedures

– Emergency protocols

– Use of PPE

– Regulatory compliance

Maintain records of training, SDS access, shipping manifests, and waste disposal for audit and compliance purposes.

International Trade Considerations

For export/import, verify compliance with destination country regulations (e.g., REACH in the EU, WHMIS in Canada). Obtain necessary permits, import licenses, and ensure accurate customs declarations including HS codes and chemical composition. Monitor regulatory updates that may affect shipment eligibility or labeling requirements.

Conclusion: Sourcing Laser Paint Stripper

After a thorough evaluation of the market for laser paint stripping technology, it is evident that this innovative solution offers significant advantages over traditional methods, including precision, reduced environmental impact, minimized substrate damage, and improved worker safety. While the initial investment in laser paint stripping systems is higher than conventional alternatives, the long-term benefits—such as lower operational costs, compliance with environmental regulations, and increased efficiency—make it a strategically sound choice for industries such as aerospace, automotive restoration, maritime, and cultural heritage conservation.

Sourcing a laser paint stripper requires careful consideration of technical specifications, vendor reliability, service and support capabilities, and total cost of ownership. Leading suppliers offer customizable systems with varying power outputs and portability options to suit different operational needs. Additionally, partnerships with experienced providers that offer training and maintenance support are crucial for successful integration into existing workflows.

In conclusion, sourcing a laser paint stripper represents a forward-thinking investment in sustainable, high-precision surface preparation. Organizations seeking to enhance their operational efficiency, meet environmental standards, and adopt advanced technologies should strongly consider integrating laser paint stripping into their processes, ensuring they select a reputable supplier aligned with their technical and strategic objectives.