The global fiber laser market, a core enabler of advanced laser welding technology including lazer kaynak makinesi (laser welding machines), is experiencing robust expansion driven by rising demand for high-precision joining solutions in automotive, electronics, and heavy manufacturing sectors. According to Mordor Intelligence, the global laser welding machine market was valued at USD 3.41 billion in 2023 and is projected to reach USD 5.68 billion by 2029, growing at a CAGR of 8.9% over the forecast period. Meanwhile, Grand View Research reports that the broader industrial laser market, fueled by advancements in fiber laser efficiency and automation integration, is expected to expand at a CAGR of 7.9% from 2024 to 2030. This sustained growth reflects increasing adoption of laser-based manufacturing processes across Europe, North America, and Asia-Pacific, where precision, speed, and minimal thermal distortion are critical. As demand surges, a select group of manufacturers has emerged as leaders, combining innovative engineering with scalable production to dominate the competitive landscape of lazer kaynak makinesi technology.

Top 9 Lazer Kaynak Makinesi Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Welding Machine

Website: jqlaser.com

Key Highlights: Laser welding machines have emerged as a game-changing technology in modern industrial applications, offering unparalleled precision and efficiency….

#2 Lazer Kaynak Makinesi

Website: xianminglaser.com

Key Highlights: Fiber Laser kaynaklı birleştirmede çeşitli metal malzemeleri birleştirmek için kullanılır, bu da işleri daha verimli, daha doğru ve daha enerji tasarrufu ……

#3 El metal lazer kaynak makinesi Manufacturer & Supplier in China …

Website: laserdmk.com

Key Highlights: Elde Tutarak Metal Laser Kaynak Makinesi, kaynak alanlarını devrimleştiren bir birimdir. Bu cihaz, kaynak alanlarını devrimleştiren bir teknoloji ile gelmiştir….

#4 Çin Metal Fiber Lazer Boru Kesme Makinesi Üreticisi

Website: dwlaser.net

Key Highlights: DOWELL fiber lazer tüp kesme makinesi fabrikası, yuvarlak, kare, dikdörtgen, oval ve özel şekilli tüpleri kesebilen lazer tüp kesme makineleri sunmaktadır….

#5 En İyi Lazer Kaynak Makinesi Üreticileri 2025

Website: kirinlaser.com

Key Highlights: En iyi el tipi lazer kaynak makinelerini kimin ürettiğini keşfedin. En iyi markaları, pazar trendlerini ve Kirin Laser’in hassasiyet ve ……

#6 Laser Welding Machine

Website: bogonglazer.com

Key Highlights: The BOGONG Handheld laser welding machines with feature of lexible and user-friendly. it can weld stainless steel, mild steel, carbon steel, aluminum alloy, and ……

#7 Biem Laser

Website: biemlaser.com.tr

Key Highlights: Biem Laser , lazer markalama, kesim ve kaynak makineleri alanında uzmanlaşmış bir teknoloji şirketidir….

#8 Pro 1500 El Tipi Lazer Kaynak Makinesi

Website: bodor.com

Key Highlights: Pro 1500, %90 hava nemine sahip aşırı ortamlarda istikrarlı ve olağanüstü bir kaynak deneyimi sağlayabilir. Farklı çalışma durumları için yüksek verimlilik. Tek ……

#9 News

Website: xtlaser.com

Key Highlights: This innovative welding machine stands at the forefront of technological progress, meeting the rigorous demands of modern manufacturing. … lazer kaynak makinesi ……

Expert Sourcing Insights for Lazer Kaynak Makinesi

H2: 2026 Market Trends for Lazer Kaynak Makinesi (Laser Welding Machines)

The global market for Lazer Kaynak Makinesi (laser welding machines) is projected to undergo significant transformation by 2026, driven by technological advancements, rising industrial automation, and growing demand across key sectors such as automotive, aerospace, electronics, and medical devices. This analysis outlines the prominent market trends shaping the laser welding machine industry in 2026, with a focus on innovation, regional dynamics, competitive landscape, and emerging applications.

1. Increased Adoption of Fiber Laser Technology

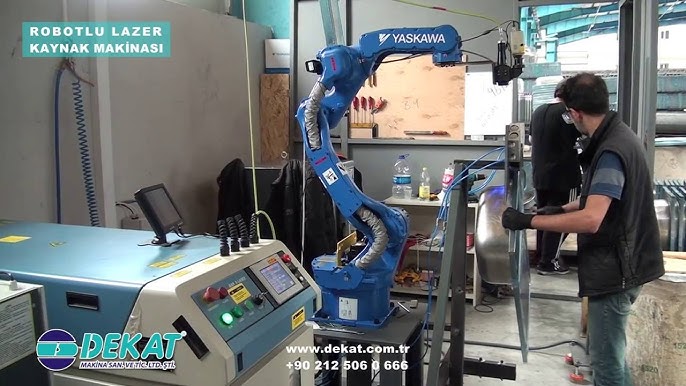

By 2026, fiber laser welding machines are expected to dominate the market due to their superior energy efficiency, higher precision, lower maintenance, and compatibility with automated manufacturing systems. Fiber lasers offer improved beam quality and deeper penetration, making them ideal for high-speed and high-strength welding applications. Their integration with robotics is accelerating in smart factories, particularly in Turkey and Europe, where manufacturers are upgrading legacy systems.

2. Surge in Demand from the Electric Vehicle (EV) Sector

The rapid expansion of the electric vehicle industry is a major driver for laser welding machines. Precision welding is critical in battery pack assembly, power electronics, and lightweight vehicle structures. By 2026, demand for hermetic sealing and conductive joining in EV components will boost the need for high-accuracy laser welding solutions, particularly in countries with strong automotive manufacturing bases like Germany, China, and Turkey.

3. Growth of Hybrid and Remote Laser Welding Systems

Hybrid laser-arc welding and remote laser scanning technologies are gaining traction due to their ability to combine speed, flexibility, and cost-efficiency. Remote welding systems, which use scanning optics to direct the laser beam without moving the entire machine, are increasingly adopted in high-volume production environments. These systems reduce cycle times and increase throughput—key benefits for mass production lines.

4. Expansion in Emerging Markets

While Europe and North America remain key markets, regions such as Southeast Asia, India, and Turkey are expected to see accelerated growth in laser welding machine adoption by 2026. Government initiatives to promote advanced manufacturing, coupled with foreign investment in industrial parks, are fueling demand. Turkish manufacturers, in particular, are investing in laser technology to enhance competitiveness in export-oriented sectors.

5. Integration with Industry 4.0 and Smart Manufacturing

Laser welding machines are becoming integral components of Industry 4.0 ecosystems. By 2026, most new systems will feature IoT connectivity, real-time monitoring, predictive maintenance, and AI-driven process optimization. This digital integration allows for greater process control, reduced scrap rates, and improved traceability—critical for quality-sensitive industries such as medical device manufacturing.

6. Focus on Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt energy-efficient welding solutions. Laser welding consumes less power than traditional methods and produces minimal waste, aligning with green manufacturing standards. This trend is expected to influence procurement decisions, especially in EU markets with strict carbon reduction targets.

7. Competitive Landscape and Local Manufacturing in Turkey

Turkey is emerging as a regional hub for industrial laser technology, with local companies developing cost-effective lazer kaynak makinesi solutions tailored to SMEs. By 2026, domestic production is expected to reduce reliance on imports while increasing accessibility. However, high-end applications will still depend on German, Japanese, and Chinese systems due to their technological superiority.

Conclusion

By 2026, the lazer kaynak makinesi market will be characterized by technological convergence, sector-specific customization, and digital integration. The synergy between laser welding and automation will redefine manufacturing standards, especially in high-growth industries like EVs and electronics. Companies that invest in R&D, sustainability, and smart manufacturing capabilities will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Lazer Kaynak Makinesi (Quality and Intellectual Property)

Sourcing a laser welding machine (Lazer Kaynak Makinesi) requires careful evaluation to avoid costly mistakes. Two critical areas where buyers often encounter problems are quality inconsistencies and intellectual property (IP) risks. Being aware of these pitfalls can help ensure a successful procurement process.

Poor Build Quality and Component Selection

Many suppliers, especially low-cost manufacturers, use substandard materials and components to cut prices. This can include inferior laser sources, unstable motion systems, or poorly designed cooling units. Such machines may fail prematurely, require frequent maintenance, or deliver inconsistent weld quality, ultimately increasing total cost of ownership.

Inadequate Power and Performance Verification

Some suppliers exaggerate laser output power or welding speed capabilities. Without independent testing or verified performance data, buyers may receive a machine that cannot meet production requirements. Always request real-world test results or conduct on-site validation before finalizing a purchase.

Lack of Safety and Compliance Certifications

Laser welding machines must comply with international safety standards (e.g., IEC 60825 for laser safety, CE, ISO). Sourcing from suppliers who lack proper certifications can pose serious health risks and result in legal or operational issues, especially in regulated industries.

Hidden Software Limitations and Lock-ins

Some machines come with proprietary software that limits functionality or requires expensive licensing for updates or support. Buyers may find themselves locked into a single vendor for maintenance and upgrades, reducing flexibility and increasing long-term costs.

Intellectual Property (IP) Infringement Risks

Purchasing machines that incorporate copied or reverse-engineered technology can expose buyers to legal liability. If the supplier has violated patents or trademarks—especially in core laser or control systems—your company could face lawsuits or be forced to discontinue use of the equipment.

Insufficient After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance. Sourcing from suppliers without a local service network or reliable spare parts supply can lead to extended downtime. Always verify the availability of technical support and replacement components before making a decision.

Absence of Clear IP Ownership and Documentation

Ensure the supplier provides full documentation, including schematics, user manuals, and proof of legitimate IP ownership. Lack of transparency here may indicate gray-market components or unauthorized technology use, which can compromise warranty validity and future scalability.

By carefully evaluating suppliers on these points, businesses can mitigate risks and invest in a laser welding solution that is both reliable and legally sound.

Logistics & Compliance Guide for Lazer Kaynak Makinesi

Product Overview

Lazer Kaynak Makinesi (Laser Welding Machine) refers to industrial equipment used for precision welding through laser technology. These machines are commonly used in automotive, aerospace, medical device, and electronics manufacturing. Due to their technical complexity, high power requirements, and potential laser radiation hazards, specific logistics and compliance considerations must be observed during import, export, transportation, and operation.

Regulatory Compliance

Laser welding machines are subject to multiple international and national regulations. Key compliance areas include:

- Laser Safety Standards (IEC 60825-1): Ensures safe emission levels and proper labeling of laser classes. Machines must be classified (e.g., Class 1, 4) and equipped with safety interlocks, warning labels, and protective housings.

- Electrical Safety (IEC 61010-1): Applies to electrical equipment for measurement, control, and laboratory use. Required for CE, UKCA, and other regional certifications.

- EMC Compliance (IEC 61326-1): Ensures electromagnetic compatibility to prevent interference with other devices.

- Machinery Directive (EU 2006/42/EC): Required for CE marking in the European Union. Includes risk assessment, technical file preparation, and conformity declaration.

- RoHS & REACH (EU): Restricts hazardous substances and ensures chemical safety in components.

- FDA Registration (USA): Required for laser products under 21 CFR 1040.10 and 1040.11. Manufacturers must file product reports and certify compliance.

- NRCan (Canada): Energy efficiency and safety compliance via the Canadian Electrical Code and SOR/2016-136 for laser products.

Import & Export Documentation

Ensure all necessary documents accompany the shipment:

- Commercial Invoice

- Packing List

- Bill of Lading / Air Waybill

- Certificate of Origin

- Technical Datasheet (including laser class, power, wavelength)

- CE, UKCA, or FCC Declaration of Conformity

- FDA Accession Number (for U.S. imports)

- Import License (if required by destination country)

- HS Code: Typically 8462.21 or 8515.21, depending on machine functionality

Packaging & Handling

Due to sensitivity of optical and electronic components:

- Use shock-absorbent, anti-static packaging.

- Secure optics with protective caps and immobilize moving parts.

- Label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.”

- Include desiccants to prevent condensation during transit.

- Avoid exposure to extreme temperatures or humidity during storage and transport.

Transportation Requirements

- Mode of Transport: Air freight requires compliance with IATA Dangerous Goods Regulations if batteries or high-pressure components are included. Sea freight is common for heavy machinery.

- Hazard Classification: Most laser welding machines are not classified as dangerous goods unless they include lithium batteries or cooling systems with hazardous refrigerants.

- Climate Control: Recommended for long-distance shipping, especially in tropical or arctic regions.

- Insurance: Full-value cargo insurance covering damage, delay, and customs-related losses.

Customs Clearance

- Verify tariff classification and applicable duties in the destination country.

- Some countries (e.g., China, India, Russia) may require additional certifications:

- China: CCC Mark (if applicable), though industrial lasers may be exempt under certain conditions.

- India: BIS certification may be required; check MEIS/DEPB schemes for duty benefits.

- Turkey: CE marking accepted, but conformity verification by authorized bodies may be needed.

- Provide detailed technical specifications to avoid customs delays.

On-Site Installation & Compliance

- Conduct site survey to confirm power supply (voltage, phase, grounding), ventilation, and space requirements.

- Install in accordance with local occupational safety regulations (e.g., OSHA in the U.S., DGUV in Germany).

- Provide laser safety training for operators. Use protective enclosures, interlocks, and personal protective equipment (PPE).

- Register the machine with national radiation protection authorities if required (e.g., in Germany, notification to LASORS).

Maintenance & Record-Keeping

- Maintain logs of laser performance, safety checks, and maintenance.

- Retain technical files and conformity documents for at least 10 years (as per EU directives).

- Update compliance status if modifications are made to the machine.

Summary

Shipping and operating a Lazer Kaynak Makinesi requires strict adherence to technical, safety, and regulatory standards. Proper documentation, secure packaging, and compliance with regional regulations are essential for smooth logistics and legal operation. Always consult local authorities and certified conformity assessment bodies before shipment or deployment.

Conclusion for Sourcing Lazer Kaynak Makinesi (Laser Welding Machine):

Sonuç olarak, lazer kaynak makinesi satın almak stratejik bir yatırım olup, yüksek hassasiyet, verimlilik ve üretim kalitesi sağlar. Yüksek başlangıç maliyetine rağmen, uzun vadede malzeme tasarrufu, düşük işletme maliyetleri ve süreç otomasyonu sayesinde geri dönüşüm süresi kısadır. Doğru tedarikçi seçimi, teknik destek, hizmet sonrası bakım ve makinenin üretim ihtiyaçlarını karşılayabilmesi açısından kritiktir. Ayrıca, endüstriyel ihtiyaçlar doğrultusunda fiber lazer teknolojisi gibi ileri çözümler tercih edilerek dayanıklılık ve enerji verimliliği artırılabilir. Sonuç olarak, doğru modelin ve güvenilir bir tedarikçinin seçilmesiyle lazer kaynak makinesi, üretim süreçlerinde rekabet avantajı sağlamaya yönelik etkili bir çözüm olarak konumlanır.