The global seal and gasket market, which includes latch rubber components widely used in automotive, electronics, and construction industries, is experiencing steady growth driven by rising demand for energy-efficient and vibration-dampening materials. According to Grand View Research, the global rubber seals market was valued at USD 9.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing vehicle production, infrastructure development, and the need for durable sealing solutions in consumer appliances. As demand rises, manufacturers are focusing on innovation in material composition, durability, and customization—leading to the emergence of key players known for quality and scalability. In this evolving landscape, the following seven companies have distinguished themselves as leading latch rubber manufacturers, combining technological expertise with strong global supply chains to meet industry-specific requirements.

Top 7 Latch Rubber Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rubber T

Domain Est. 1997

Website: spep.com

Key Highlights: SPEP designs and manufactures rubber t-handle latches and rubber pulls for OEMs & distributors. Browse our online product catalog and order today….

#2 Leading Rubber Latch Manufacturers

Domain Est. 2015

Website: latchmanufacturers.com

Key Highlights: At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of ……

#3 Custom Engineered Rubber Latches

Domain Est. 2017

Website: ebcoinc.com

Key Highlights: We create common industrial parts such as rubber seals as well as customizable parts like floor mats, hoses, and latches….

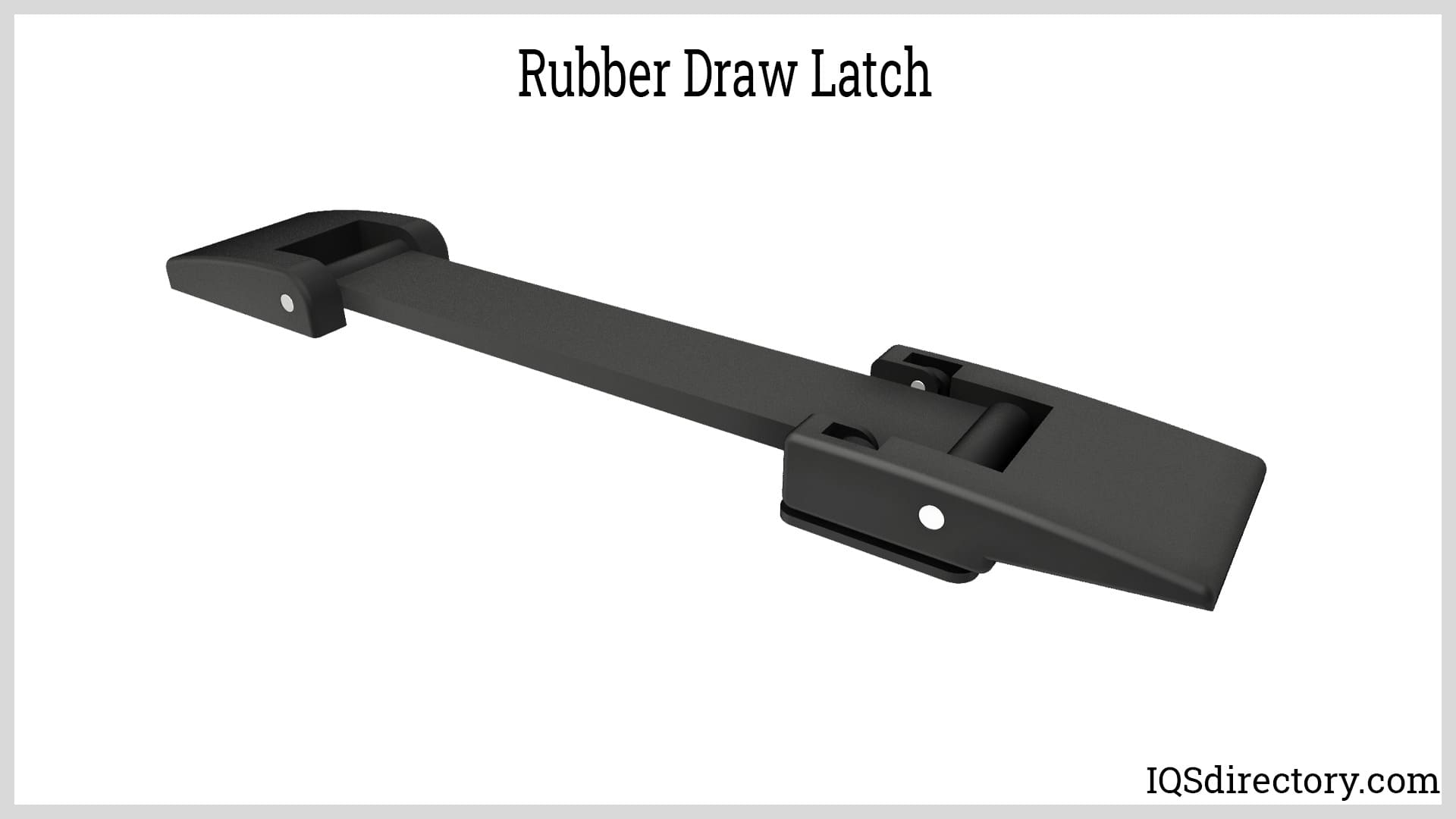

#4 Flexible Draw Latches

Domain Est. 1996

Website: southco.com

Key Highlights: 30-day returnsSouthco’s Flexible Draw Latches have a flexible latching blade that provides tension to absorb shock, vibration, or variations in mounting dimensions….

#5 Draw Latch, T

Domain Est. 1996

Website: protex.com

Key Highlights: In stock 30-day returnsThe PX-37-20-086-20 is a zinc plated mild steel draw latch with a front mount rubber T-handle. View the full range of draw latches online….

#6 Over Center Rubber Draw Latch TS

Domain Est. 2008

Website: tai-sam.com

Key Highlights: Over Center Rubber Draw Latch ; Product No · TS-609-UV ; Material · Black Rubber Handle, Stainless Steel Mounting Hook & Bracket ; Maximum Static Load · 45N….

#7 Rubber Latch Manufacturers Suppliers

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: These rubber latch companies can design, engineer and manufacture rubber latches to your specifications and application need. A quick and easy to use request ……

Expert Sourcing Insights for Latch Rubber

H2: Market Trends Forecast for Latch Rubber in 2026

As we approach 2026, the global latch rubber market is poised for significant transformation driven by technological advancements, evolving consumer demands, and sustainability imperatives. Latch rubber—commonly used in automotive, construction, electronics, and consumer goods for sealing, vibration dampening, and noise reduction—is adapting to broader industrial shifts. Below is an analysis of key market trends expected to shape the latch rubber sector in 2026:

-

Increased Demand from the Automotive Sector

The automotive industry remains a primary consumer of latch rubber components, particularly in doors, trunks, and hood seals. With the continued rise of electric vehicles (EVs), demand for high-performance, noise-dampening rubber materials is growing. EV manufacturers prioritize quiet interiors, boosting the need for advanced latch rubber with superior acoustic insulation. Additionally, lightweight and durable rubber formulations support fuel efficiency and vehicle longevity, further driving adoption. -

Sustainability and Material Innovation

Environmental regulations and consumer preferences are pushing manufacturers toward sustainable alternatives. Bio-based and recyclable rubber materials—such as natural rubber blends, thermoplastic elastomers (TPE), and recycled EPDM—are gaining traction. By 2026, companies investing in eco-friendly latch rubber solutions are expected to gain competitive advantage, especially in regions with strict emissions and waste standards (e.g., EU, North America). -

Growth in Construction and Smart Home Technologies

The global construction boom, particularly in emerging economies, is increasing demand for weather-resistant and energy-efficient sealing solutions. Latch rubber is critical in windows, doors, and HVAC systems. Moreover, the proliferation of smart homes and automated entry systems is creating new applications for durable, flexible rubber components that integrate seamlessly with electronic latching mechanisms. -

Regional Market Dynamics

Asia-Pacific is projected to dominate the latch rubber market in 2026 due to rapid industrialization, expanding automotive production (especially in China, India, and Southeast Asia), and urban construction growth. Meanwhile, North America and Europe are focusing on high-value, specialty rubber products with enhanced performance characteristics, driven by stringent safety and environmental standards. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to localize production and diversify sourcing. By 2026, companies are expected to strengthen regional supply chains for raw materials like synthetic rubber and reinforcing agents. This trend enhances responsiveness and reduces dependency on volatile global markets. -

Digitalization and Smart Manufacturing

Adoption of Industry 4.0 technologies—such as IoT-enabled monitoring, predictive maintenance, and AI-driven quality control—is improving production efficiency in rubber manufacturing. These innovations enable precise control over material properties, ensuring consistent performance of latch rubber components under varying environmental conditions. -

Regulatory Pressures and Compliance

Increasing regulations on volatile organic compounds (VOCs), halogenated materials, and end-of-life recyclability are shaping product development. Latch rubber producers must comply with standards such as REACH (EU), RoHS, and ISO 14001. By 2026, compliance will be a baseline requirement, influencing material selection and manufacturing processes.

Conclusion

In 2026, the latch rubber market will be characterized by innovation, sustainability, and sector-specific customization. Companies that invest in advanced materials, reduce environmental impact, and align with automotive and construction trends will be best positioned for growth. As global industries continue to evolve, latch rubber will remain a critical, albeit often overlooked, enabler of performance, safety, and efficiency across multiple sectors.

Common Pitfalls Sourcing Latch Rubber (Quality, IP)

Sourcing latch rubber components presents several potential pitfalls, particularly concerning quality consistency and intellectual property (IP) protection. Overlooking these can lead to product failures, legal disputes, and reputational damage.

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues is receiving latch rubber that doesn’t meet the required material standards. Low-quality rubber may degrade prematurely due to exposure to UV light, temperature extremes, or chemicals, leading to brittleness, cracking, or loss of elasticity. Inconsistent hardness (Shore A), tensile strength, or compression set can result in poor sealing performance, increased noise, or failure to maintain latch integrity over time. Suppliers may substitute cheaper materials or vary formulations without notice, especially when cost pressures are high.

Lack of Compliance with Industry Standards

Latch rubber used in automotive, aerospace, or medical applications must often comply with specific regulatory standards (e.g., UL, RoHS, REACH, FDA). Sourcing from suppliers who cannot provide valid certifications or material test reports (MTRs) risks non-compliance, which can halt production or lead to recalls. Failing to verify regulatory alignment upfront is a critical oversight.

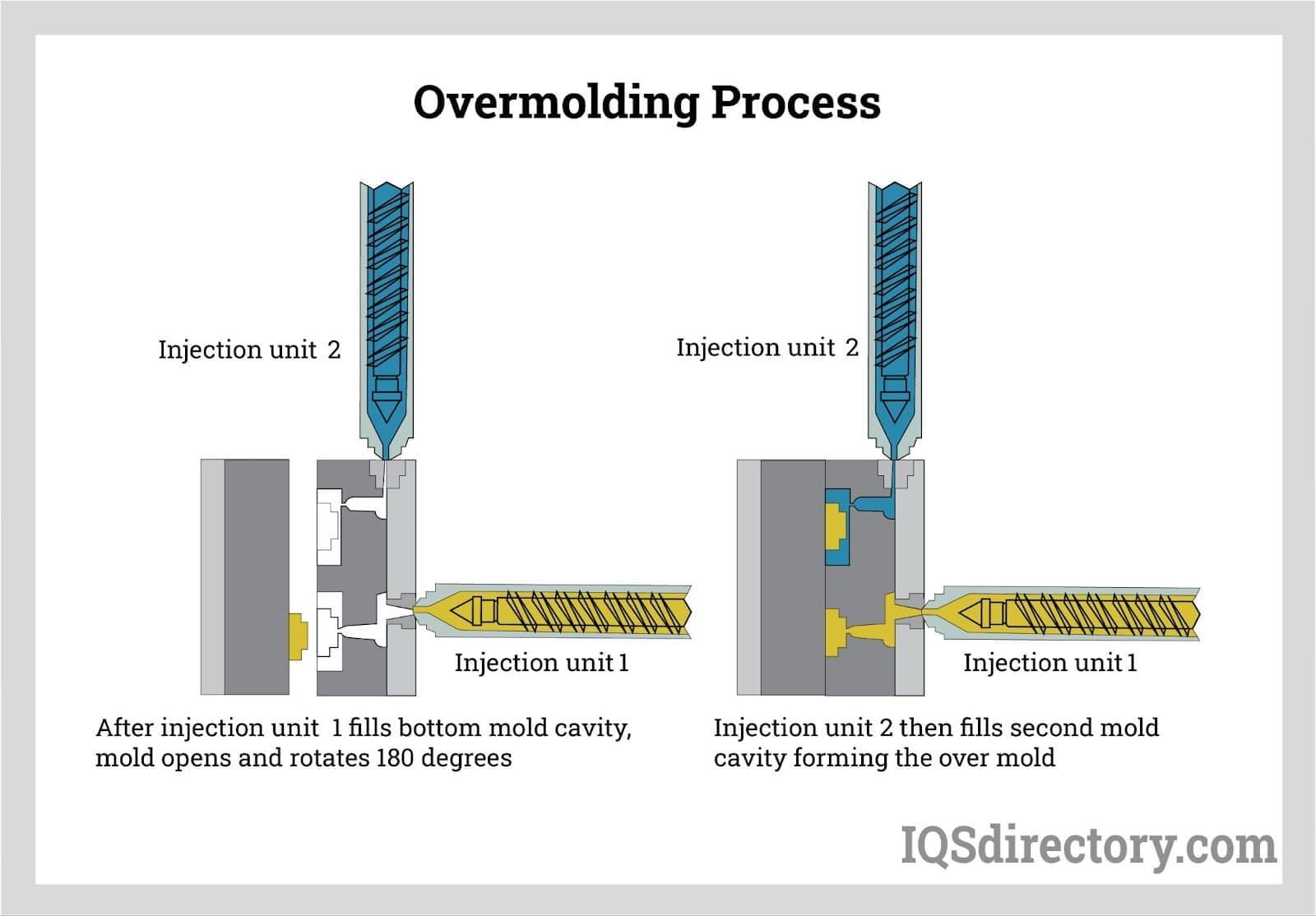

Inadequate Tooling and Molding Process Control

Poor mold design or inconsistent injection molding processes can introduce defects such as flash, voids, or dimensional inaccuracies. Without proper process validation (e.g., PPAP, capability studies), batch-to-batch variations become likely. Suppliers with outdated equipment or limited quality control infrastructure often struggle to maintain tight tolerances essential for latch functionality.

Intellectual Property Risks and Design Infringement

Using a supplier to manufacture custom latch rubber designs carries significant IP risks. Without clear contractual agreements (e.g., IP ownership clauses, NDAs), suppliers may replicate or resell the design to competitors. Additionally, sourcing from regions with weak IP enforcement increases the risk of unauthorized production or counterfeiting. Reverse engineering by suppliers, especially in offshore manufacturing, is a common concern.

Insufficient Testing and Validation

Many buyers assume supplier-provided test data is reliable without independent verification. Skipping functional testing—such as durability, compression force, or environmental aging—can result in field failures. Validating performance under real-world conditions is essential but often neglected in cost-driven sourcing decisions.

Supply Chain Transparency and Traceability Gaps

Lack of visibility into the rubber’s origin—particularly raw materials like synthetic or natural rubber—can expose buyers to supply disruptions, ethical sourcing issues, or contamination risks. Without full traceability, it’s difficult to address quality problems or respond to customer audits effectively.

Avoiding these pitfalls requires thorough supplier vetting, robust quality agreements, clear IP protections, and ongoing performance monitoring.

Logistics & Compliance Guide for Latch Rubber

This guide outlines the key logistics and compliance considerations for handling, storing, transporting, and documenting Latch Rubber components within your supply chain. Adhering to these standards ensures product integrity, regulatory compliance, and operational efficiency.

Product Handling & Storage

Latch Rubber must be handled and stored under controlled conditions to maintain performance characteristics and prevent degradation. Always use clean gloves and tools to avoid contamination. Store in a cool, dry, and well-ventilated area away from direct sunlight, ozone sources (e.g., electric motors), and extreme temperatures. Ideal storage conditions are between 10°C and 25°C with relative humidity below 65%. Keep containers sealed when not in use to prevent exposure to moisture and airborne contaminants.

Packaging Requirements

All Latch Rubber components must be packaged in moisture-resistant, non-reactive materials such as polyethylene bags or sealed corrugated boxes with internal liners. Packaging must provide adequate cushioning to prevent physical damage during transit. Clearly label each package with product name, part number, batch/lot number, manufacturing date, and handling instructions (e.g., “Keep Dry,” “Do Not Stack”). Ensure labels are durable and resistant to smudging or fading.

Transportation Standards

Transport Latch Rubber via temperature-controlled freight whenever ambient conditions exceed recommended storage limits. Avoid prolonged exposure to high heat, freezing temperatures, or high humidity during transit. Use carriers experienced in handling sensitive rubber components. Secure loads to prevent shifting and ensure proper ventilation in shipping containers. For international shipments, comply with IATA, IMDG, or other relevant transport regulations if applicable.

Regulatory Compliance

Latch Rubber may be subject to regional and international regulations depending on formulation and destination. Confirm compliance with REACH (EU), RoHS, TSCA (USA), and other applicable chemical regulations. Provide Safety Data Sheets (SDS) in the required local language(s) for all shipments. Ensure all products are free from restricted substances and meet environmental and health standards. Maintain documentation for audits and customs clearance.

Import/Export Documentation

For cross-border shipments, prepare complete documentation including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Include SDS and any required regulatory certifications (e.g., REACH compliance statement). Classify Latch Rubber under the appropriate Harmonized System (HS) code—typically within Chapter 40 (Rubber and Articles Thereof). Verify export controls and obtain necessary licenses if shipping to restricted regions.

Quality Assurance & Traceability

Implement a traceability system that links each batch of Latch Rubber to its manufacturing records, test results, and shipping documentation. Conduct periodic quality checks for hardness, tensile strength, and dimensional accuracy per ASTM or ISO standards. Retain samples and records for a minimum of five years to support compliance audits and customer inquiries.

Environmental & Disposal Compliance

Dispose of damaged or expired Latch Rubber in accordance with local environmental regulations. Do not incinerate without proper emission controls, as rubber combustion may release harmful substances. Work with certified waste handlers for responsible disposal or recycling. Document all disposal activities to ensure compliance with waste management laws.

Supplier & Vendor Management

Ensure all suppliers and logistics partners adhere to this compliance guide. Conduct periodic audits of storage facilities, transport methods, and handling procedures. Require suppliers to provide material certifications and SDS updates as formulations change. Maintain a qualified vendor list with compliance status reviews at least annually.

Incident Reporting & Corrective Actions

Establish a process for reporting and investigating logistics incidents such as contamination, temperature excursions, or packaging failures. Implement corrective and preventive actions (CAPA) promptly to avoid recurrence. Document all incidents and resolutions for compliance and continuous improvement purposes.

Conclusion for Sourcing Latch Rubber:

After evaluating various suppliers, material specifications, cost structures, and quality standards, sourcing latch rubber requires a balanced approach that ensures durability, compatibility, and cost-efficiency. The selection should prioritize materials with excellent resistance to wear, temperature fluctuations, and compression set—such as EPDM or silicone rubber—to guarantee long-term performance in diverse operating conditions.

Key considerations include supplier reliability, consistency in material quality, compliance with industry standards, and the ability to scale supply as needed. Local sourcing may offer logistical advantages and reduced lead times, while overseas suppliers might provide cost benefits, albeit with potential risks related to quality control and supply chain disruptions.

In conclusion, the optimal sourcing strategy involves partnering with a vetted supplier that offers high-quality, application-specific latch rubber with strong technical support and responsive service. Implementing strict quality assurance protocols and maintaining strong supplier relationships will ensure consistent performance, reduce maintenance costs, and enhance the overall reliability of the end product.