The global laser cutting machines market is experiencing robust expansion, driven by increasing demand for precision manufacturing across industries such as automotive, aerospace, and industrial machinery. According to Grand View Research, the market size was valued at USD 2.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This surge is fueled by technological advancements in fiber laser systems, rising adoption of automation in metal fabrication, and the growing need for high-efficiency, low-waste cutting solutions. As manufacturers seek greater accuracy and productivity in sheet metal processing, laserskärning plåt (laser cutting sheet metal) has become a cornerstone of modern fabrication. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, reliability, and global reach to dominate the competitive field.

Top 6 Laserskärning Plåt Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Punching and laser cutting of sheet metal

Website: alumbrasmaland.se

Key Highlights: Punching and laser cutting of sheet metal. BK Produkter is a well-established contract manufacturer of sheet metal processing, machining and assembly systems….

#2 Manufacturing of Sheet metal Components

Website: bpi.be-ge.se

Key Highlights: Be-Ge Plåtindustri AB can offer a modern subject department consisting of three laser cutting machines, one of which with an integrated punching unit a so- ……

#3 Laserskärning

Website: platmodul.se

Key Highlights: Med laserskärningstekniken kan vi uppnå enastående precision, snabbhet och flexibilitet. Laserns tunna stråle skär perfekt komplexa konturer med hög ……

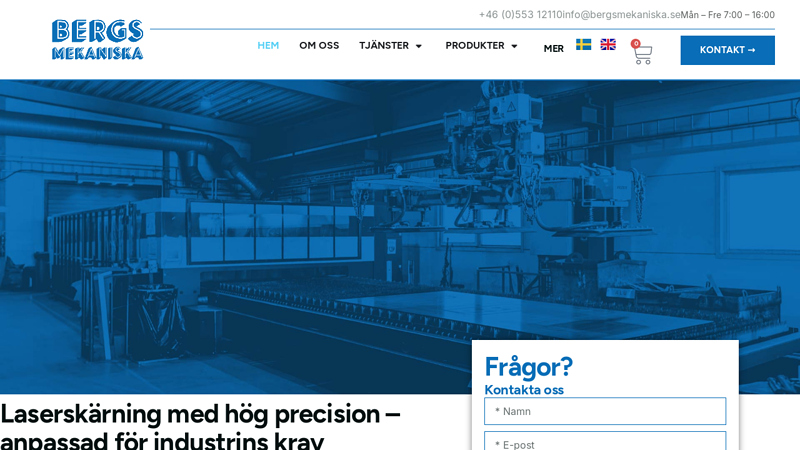

#4 Laserskärning med hög precision

Website: bergsmekaniska.se

Key Highlights: Effektiv och exakt laserskärning för komplexa plåtdetaljer. Perfekt för serietillverkning och prototyper med snäva toleranser….

#5 Levstal Group

Website: levstal.com

Key Highlights: Laserskärning av plåt: Typer, fördelar och material. laser marking example. Introduktion till laserskärning. Skärning är en integrerad del av en ……

#6 Plåtbearbetning och laserskärning

Website: diac.se

Key Highlights: Diac hanterar plåtbearbetning med hjälp av stansning, pressning, laserskärning, kantbock, valsning och svets. Vår maskinutrustning ger oss resurser att ……

Expert Sourcing Insights for Laserskärning Plåt

H2: Market Trends for Laser Cutting of Sheet Metal (Laserskärning Plåt) in 2026

The laser cutting of sheet metal—commonly referred to as laserskärning plåt in Swedish—continues to evolve rapidly, driven by advancements in technology, increasing demand for precision manufacturing, and a global shift toward automation and sustainable production. As we approach 2026, several key market trends are shaping the future of this critical industrial process, particularly in Europe and industrialized markets such as Sweden, Germany, and the broader Nordic region.

1. Increased Adoption of High-Power and Fiber Laser Technology

By 2026, fiber laser systems are expected to dominate the sheet metal cutting market, surpassing traditional CO₂ lasers in both performance and efficiency. Modern fiber lasers offer higher cutting speeds (up to 3–4 times faster), lower energy consumption, and improved cut quality—especially on reflective materials like copper and aluminum. The availability of multi-kilowatt fiber lasers (10–20 kW) enables faster processing of thick plate materials (up to 40 mm), broadening the application scope in heavy industries such as shipbuilding, energy, and construction.

2. Integration with Industry 4.0 and Smart Manufacturing

Laser cutting systems are increasingly integrated into smart factories, leveraging IoT connectivity, real-time monitoring, and predictive maintenance. By 2026, most new laser cutting machines will feature digital twin capabilities, cloud-based production planning, and AI-driven optimization tools. This allows manufacturers to reduce downtime, improve yield, and enable remote diagnostics. Swedish manufacturers, known for their advanced automation ecosystems, are at the forefront of this trend, adopting platforms that link laser cutting directly to CAD/CAM and ERP systems.

3. Growth in Customization and On-Demand Production

The demand for customized, low-volume, and on-demand manufacturing—especially in sectors like medical devices, robotics, and electric vehicle (EV) components—is driving investment in flexible laser cutting solutions. These systems support rapid retooling and short lead times, aligning with just-in-time (JIT) production models. The rise of digital marketplaces for sheet metal fabrication (e.g., platforms like Xometry or local Nordic equivalents) is also accelerating the trend toward agile, customer-centric manufacturing.

4. Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt greener technologies. Laser cutting is inherently more energy-efficient than mechanical cutting methods, and by 2026, machine producers are focusing on reducing CO₂ emissions through improved laser source efficiency, energy recovery systems, and sustainable material handling. Additionally, advancements in nesting software minimize material waste, contributing to circular economy objectives.

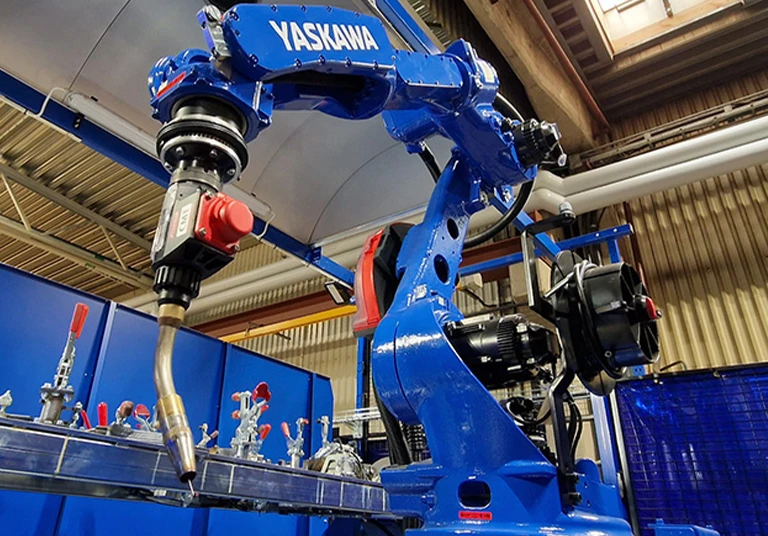

5. Expansion of Automation and Robotics

Fully automated laser cutting cells—including automatic loading/unloading systems, robotic part handling, and integrated sorting—are becoming standard in high-volume operations. By 2026, mid-sized workshops are also adopting modular automation solutions to remain competitive. In Sweden and neighboring countries, where labor costs are high, automation not only improves productivity but also addresses labor shortages in technical roles.

6. Growing Demand in Renewable Energy and EV Sectors

The rapid expansion of wind, solar, and electric mobility industries is creating new opportunities for precision sheet metal fabrication. Components such as battery enclosures, power electronics housings, and turbine parts require high-accuracy laser cutting. As Europe intensifies its green transition, demand for laser-cut metal parts in these sectors is expected to grow steadily through 2026.

7. Regional Market Dynamics in Scandinavia

In Sweden and the Nordic region, the laserskärning plåt market benefits from a strong industrial base, government support for innovation, and a skilled workforce. Local manufacturers are investing in nearshoring and reshoring strategies, reducing dependency on global supply chains. This supports regional service hubs offering advanced laser cutting as a subcontracted service, particularly for SMEs lacking in-house capabilities.

Conclusion

By 2026, the laser cutting of sheet metal will be characterized by smarter, faster, and more sustainable operations. Technological innovation, digital integration, and evolving industry demands will continue to drive the market forward, positioning laserskärning plåt as a cornerstone of modern precision manufacturing—especially in technologically advanced markets like Sweden. Companies that embrace automation, sustainability, and digital connectivity will be best positioned to lead in this dynamic landscape.

Common Pitfalls When Sourcing Laser Cutting of Sheet Metal (Quality and Intellectual Property)

Logistics & Compliance Guide for Laserskärning Plåt

This guide outlines key logistics and compliance considerations for laser cutting of sheet metal (Laserskärning Plåt) in industrial manufacturing environments. Adhering to these standards ensures safety, quality, and regulatory compliance.

Material Handling and Storage

Proper handling and storage of sheet metal prior to and after laser cutting are essential to maintain material integrity and ensure operational efficiency.

- Store sheet metal in a dry, controlled environment to prevent rust and contamination.

- Use protective coatings or packaging for sensitive materials (e.g., stainless steel, aluminum).

- Label all materials clearly with grade, thickness, and batch number for traceability.

- Stack sheets evenly using appropriate supports to avoid warping or edge damage.

- Implement first-in, first-out (FIFO) inventory practices to minimize material aging.

Equipment and Facility Compliance

Laser cutting facilities must meet national and international safety and environmental regulations.

- Ensure laser cutting machines comply with IEC 60825 (laser safety standards) and CE marking requirements.

- Install proper fume extraction and filtration systems to meet workplace air quality standards (e.g., ACGIH TLVs or EU Directive 2004/37/EC).

- Conduct regular maintenance and calibration of laser equipment in accordance with manufacturer guidelines.

- Equip facilities with emergency shut-offs, fire suppression systems, and protective enclosures.

- Perform risk assessments for laser radiation, electrical hazards, and mechanical risks.

Operational Safety Procedures

Personnel involved in laser cutting operations must follow strict safety protocols.

- Require operators to wear appropriate PPE, including laser safety glasses, gloves, and flame-resistant clothing.

- Limit access to the laser cutting area during operation using interlocks and warning signs.

- Train staff on laser safety (ANSI Z136.1 or equivalent) and emergency response procedures.

- Establish lockout/tagout (LOTO) procedures for maintenance and servicing.

- Monitor noise levels and implement hearing protection where necessary.

Environmental and Waste Management

Laser cutting generates waste materials and emissions that must be managed responsibly.

- Collect and recycle metal offcuts and scrap through certified recycling partners.

- Dispose of filter residues (e.g., from fume extractors) as hazardous waste if contaminated with oils or coatings.

- Monitor and document emissions to comply with local environmental regulations (e.g., EPA or ECHA standards).

- Use energy-efficient laser systems to reduce carbon footprint.

- Maintain records of waste disposal and environmental compliance audits.

Quality Control and Documentation

Traceability and quality assurance are critical for compliance with industry standards.

- Follow ISO 9001 guidelines for quality management in manufacturing processes.

- Implement in-process inspections using calibrated measurement tools (e.g., micrometers, coordinate measuring machines).

- Document cutting parameters (power, speed, gas type) for each job to ensure consistency.

- Provide material certification (e.g., EN 10204 3.1) and inspection reports upon request.

- Conduct periodic audits of production processes and supplier materials.

Transportation and Packaging

Finished laser-cut parts must be transported safely to prevent damage and ensure delivery compliance.

- Package parts using edge protectors, anti-corrosion paper, or VCI packaging as needed.

- Secure loads on pallets or in containers to prevent shifting during transit.

- Label shipments with handling instructions (e.g., “Fragile,” “This Side Up”) and content details.

- Comply with transportation regulations for hazardous materials if applicable (e.g., sharp edges requiring special labeling).

- Use logistics partners certified in ISO 28000 (security management) for high-value or sensitive shipments.

Regulatory and Industry Standards

Ensure all operations align with relevant regional and sector-specific regulations.

- Adhere to EU Machinery Directive 2006/42/EC for equipment used in the European market.

- Comply with REACH and RoHS regulations regarding restricted substances in materials.

- Meet industry-specific requirements (e.g., automotive: IATF 16949; aerospace: AS9100).

- Stay updated on changes in national laser safety and environmental legislation.

- Conduct regular compliance training and internal audits.

Following this guide ensures safe, efficient, and legally compliant laser cutting operations for sheet metal fabrication. Regular review and continuous improvement are recommended to adapt to evolving standards and technologies.

Slutsats för inköp av laserskärning av plåt

Efter genomgång av olika leverantörer, prisnivåer, kvalitet, leveranstid och teknisk kapacitet inom laserskärning av plåt, kan följande slutsatser dras:

-

Kvalitet och precision – De flesta aktuella leverantörer levererar god kvalitet i sitt laserskärningsarbete med hög noggrannhet och rent snitt. Val av lämplig laserutrustning (t.ex. fiber- eller CO₂-laser) påverkar resultatet, särskilt vid olika material och tjocklek.

-

Kostnadseffektivitet – Priserna varierar beroende på material, plåttjocklek, geometri och beställningsvolym. Genom att samarbeta med en stabil leverantör med konkurrenskraftiga priser och god kapacitet kan vi uppnå långsiktig kostnadseffektivitet.

-

Leveranssäkerhet och kapacitet – Leveranstid och flexibilitet är avgörande faktorer. Leverantörer med digitala offertsystem och automatiserad produktion har visat sig kunna erbjuda snabbare svar och kortare ledtider.

-

Geografisk placering – Nära geografisk placering minskar transportkostnader och leveranstid, vilket ökar lämningsprecision och minskar risken för skador under transport.

-

Hållbarhet och samarbetspotential – Leverantörer som investerar i energieffektiv teknik och återvunnet material kan stödja våra egna hållbarhetsmål och bygga ett mer långsiktigt samarbete.

Rekommendation: Det är fördelaktigt att etablera ett strategiskt samarbete med en eller flera pålitliga leverantörer som erbjuder bra kombination av kvalitet, pris och leveransförmåga. Detta gör att vi kan säkerställa konsekvent produktionsstöd, snabba iterationer vid behov samt möjlighet att skala upp vid ökad volym.

Ett samarbete med en lokal, tekniskt försedd laserskärningsleverantör med digitala verktyg för offert och beställning bedöms ge bäst hela-årskostnad och samarbetsmässiga fördelar.