The global plastic laser cutting market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as automotive, electronics, and medical devices. According to Grand View Research, the global laser cutting market size was valued at USD 5.53 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030, with plastic processing representing a significant segment. This growth is fueled by advancements in laser technology, rising adoption of automation, and the need for clean, burr-free cuts in high-tolerance applications. As manufacturers seek greater accuracy and efficiency, plastic laser cutting has emerged as a preferred solution over traditional mechanical methods. In this evolving landscape, a select group of manufacturers have distinguished themselves through innovation, precision engineering, and specialized capabilities in handling diverse polymer materials. Below are the top 9 laserskärning (laser cutting) plastic manufacturers shaping the industry today.

Top 9 Laserskärning Plast Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 HGLASER

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading provider of laser cutting machine, laser marking mahcine and laser cleaning machine.Email:[email protected]….

#3 Trestad Laser AB

Website: trestadlaser.se

Key Highlights: We perform TIG, MIG/MAG, Plasma, Laser, resistance and distance welding in all materials such as Aluminum, Titan, Inconel, Hastelloy and many more….

#4 Laserskärare

Website: epiloglaser.com

Key Highlights: Lasermaskiner kan skära trä, papper, plast, tyg, skum och mycket mer med hög precision och hastighet, vilket ger lasrar en tydlig fördel över andra typer av ……

#5 Laserskärning i olika plåtkvaliteter

Website: dpt.se

Key Highlights: Vi laserskär i en mängd olika material. Med laserskärning kan man arbeta i material som plåt, varmförzinkat, rostfritt, aluminium, titan, aluminium, mässing, ……

#6 Laserskärning av metall och plåt

Website: moracontractmanufacturing.se

Key Highlights: Laserskärning – effektiv och precisionssäker teknik. Laserskärning är en automatiserad och högprecisionsmetod för att bearbeta metaller och andra material….

#7 Laserskärning i plast, plåt, aluminium, 3D i Gnosjöregionen

Website: gnosjoregion.se

Key Highlights: Laserskärning i Gnosjöregionen. Här hittar du leverantörer, du kan lägga gratis offertförfrågningar och få 5 snabba tips om laserskärning….

#8 Laserskärning av plast

Website: entreprenad.com

Key Highlights: Alla · Kompetenser · Underleverantör · Plast, gummi, kompositer och glas · Bearbetning av plastmaterial · Laserskärning av plast….

#9 Laser Cutting vs Water Jet Cutting

Website: etcnmachining.com

Key Highlights: This article will compare them based on their mechanisms, limitations, strong points, and areas where they are best applied….

Expert Sourcing Insights for Laserskärning Plast

H2: Market Trends for Plastics Laser Cutting in 2026

As the manufacturing and industrial sectors continue to evolve, the demand for precision, efficiency, and sustainability is reshaping the landscape of plastics laser cutting (Laserskärning Plast) by 2026. Several key trends are expected to define the market dynamics in this niche yet growing segment:

-

Increased Adoption in Automotive and Electronics Industries

The automotive and electronics sectors are driving demand for high-precision cutting of plastic components. With the rise of electric vehicles (EVs) and advanced consumer electronics, manufacturers are increasingly relying on laser cutting for intricate designs, lightweighting, and thermal management components. By 2026, laser-cut plastic parts—such as sensor housings, connectors, and interior trims—are projected to see higher integration due to improved accuracy and clean edge quality. -

Growth in Automation and Smart Manufacturing

Integration with Industry 4.0 technologies is transforming laserskärning processes. Automated laser cutting systems connected via IoT platforms allow for real-time monitoring, predictive maintenance, and higher throughput. By 2026, a significant portion of plastic laser cutting operations in Europe and North America will feature robotic loading/unloading and AI-driven process optimization, reducing waste and labor costs. -

Demand for Sustainable and Eco-Friendly Processing

Environmental regulations and corporate sustainability goals are pushing manufacturers toward cleaner production methods. Laser cutting offers advantages over mechanical cutting by minimizing material waste and eliminating the need for lubricants. Additionally, advancements in laser sources (e.g., fiber and UV lasers) have improved energy efficiency and reduced harmful emissions during plastic processing, making the technology more attractive in eco-conscious markets. -

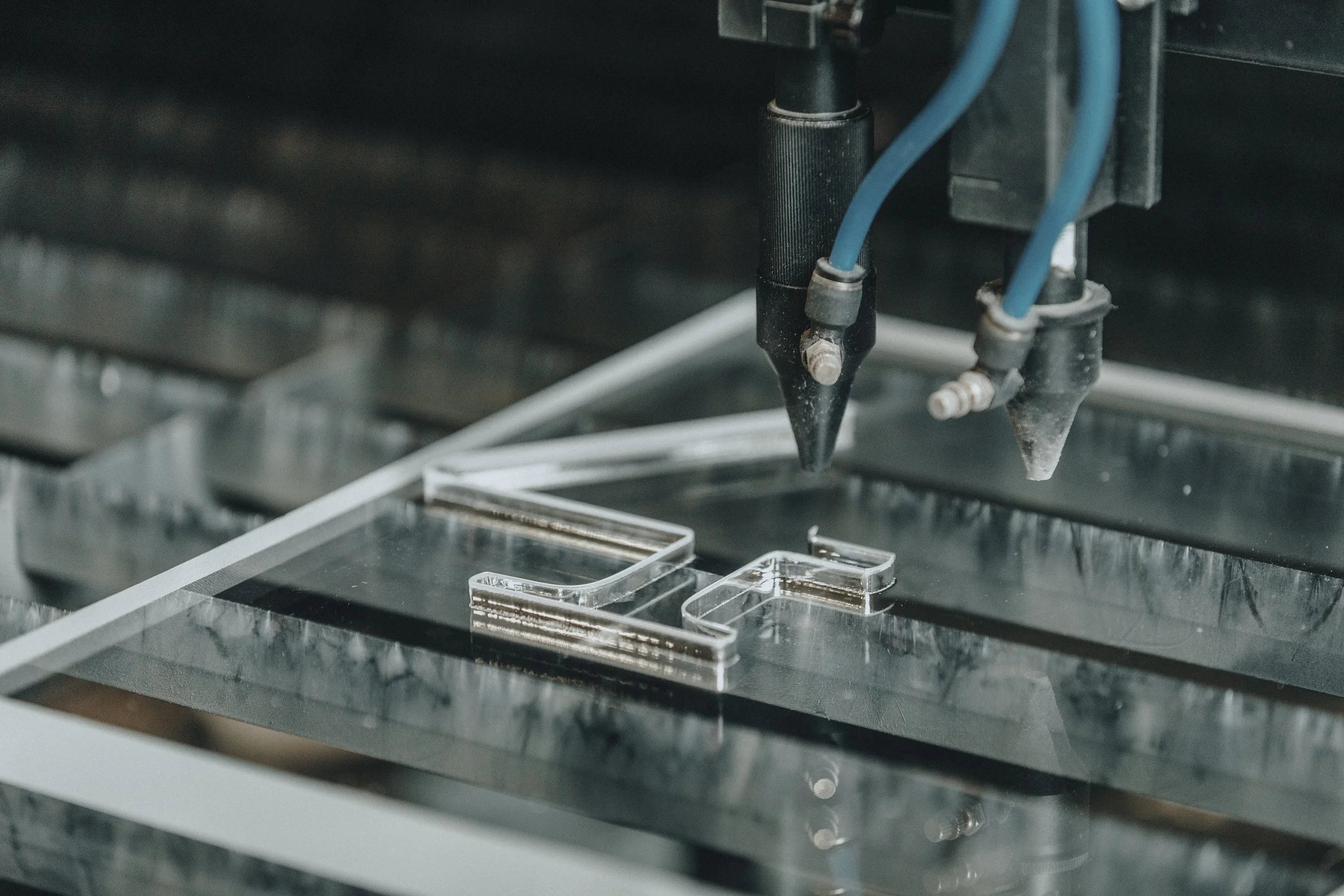

Advancements in Laser Technology for Diverse Plastics

Technological improvements in laser systems—especially in wavelength control and pulse duration—are enabling more effective cutting of challenging plastic materials such as polycarbonate, PTFE, and multi-layer composites. By 2026, UV and green lasers are expected to gain traction for cutting sensitive or transparent plastics with minimal thermal damage, expanding application possibilities in medical devices and optical components. -

Regional Market Expansion and Localized Production

Nearshoring and reshoring trends are leading to increased investments in localized plastic fabrication, particularly in Europe and North America. Countries like Sweden, Germany, and the U.S. are expected to see growth in laser cutting services for plastics, driven by demand for shorter supply chains and rapid prototyping. This shift supports smaller-scale, high-mix production models suitable for laser technology. -

Rising Competition and Service Customization

The market is becoming more competitive, with service providers differentiating through customization, faster turnaround times, and digital quoting platforms. By 2026, companies offering online design-to-production workflows—including CAD integration and instant pricing—will have a competitive edge, particularly in SME segments.

Conclusion:

By 2026, the laserskärning plast market will be characterized by technological sophistication, environmental responsibility, and alignment with advanced manufacturing ecosystems. Companies that invest in precision laser systems, automation, and sustainable practices will be best positioned to capitalize on growing demand across high-tech industries.

H2: Common Pitfalls When Sourcing Laser Cutting of Plastic (Quality and Intellectual Property)

Sourcing laser cutting services for plastic components offers precision and efficiency, but it comes with several potential pitfalls—especially concerning quality consistency and intellectual property (IP) protection. Being aware of these risks helps ensure a successful outsourcing experience.

1. Inconsistent Cut Quality Due to Material Variability

Plastics vary widely in composition, melting points, and laser absorption rates. Sourcing from a supplier without expertise in specific plastic types (e.g., acrylic, polycarbonate, or ABS) can result in poor edge quality, melting, charring, or inaccuracies. Ensure the vendor has proven experience with your material and conducts material-specific parameter calibration.

2. Lack of Process Control and Quality Assurance

Some suppliers may lack standardized quality control procedures, such as regular machine calibration, environmental control (temperature/humidity), or in-process inspections. This can lead to dimensional inaccuracies or batch inconsistencies. Verify that the supplier follows documented quality processes and provides inspection reports.

3. Inadequate Equipment or Outdated Technology

Using underpowered or poorly maintained lasers can result in incomplete cuts, irregular edges, or excessive heat-affected zones. Confirm that the supplier uses modern, well-maintained CNC laser systems with appropriate power and beam quality for your application.

4. Poor Tolerance Management

Plastics expand and contract with temperature changes, and laser cutting induces heat stress. Suppliers unfamiliar with thermal dynamics in plastics might not account for warping or dimensional drift. Clearly communicate required tolerances and confirm the supplier can achieve them consistently.

5. Intellectual Property Risks in Design Sharing

Sharing CAD or technical drawings with external vendors exposes your designs to potential IP theft or unauthorized replication. This is especially concerning when sourcing internationally. Always use non-disclosure agreements (NDAs) and work with reputable suppliers who respect IP rights.

6. Unauthorized Subcontracting

Some vendors may subcontract work without your knowledge, increasing IP exposure and reducing quality control. Ensure contracts explicitly prohibit unauthorized subcontracting and require transparency in the manufacturing chain.

7. Insufficient Traceability and Documentation

Without proper documentation (e.g., batch records, material certifications, or process logs), it’s difficult to trace defects or verify compliance. Demand full traceability, especially for regulated industries like medical or aerospace.

8. Language and Communication Barriers

Misunderstandings about specifications, tolerances, or delivery timelines can compromise quality and project success. Choose suppliers with clear communication channels and technical fluency in your language.

Avoiding these pitfalls requires due diligence in supplier selection, clear contractual terms, and ongoing quality monitoring—ensuring both high-quality output and strong IP protection.

Logistics & Compliance Guide for Laserskärning Plast

This guide outlines the key logistics and compliance considerations for businesses involved in laser cutting of plastic materials. It covers transportation, handling, regulatory standards, environmental compliance, and safety requirements to ensure smooth and lawful operations.

Transportation and Handling

Proper transportation and handling of plastic materials before and after laser cutting are essential to maintain product quality and ensure workplace safety.

- Packaging Requirements: Use protective packaging (e.g., anti-static wraps, foam padding, or sealed containers) to prevent scratches, warping, or contamination during transit.

- Labeling: Clearly label packages with material type, dimensions, batch numbers, and any hazard warnings (e.g., flammable if applicable).

- Stacking and Storage: Store plastic sheets flat to avoid warping. Keep materials in a dry, temperature-controlled environment away from direct sunlight or heat sources.

- Forklift and Pallet Safety: Ensure proper training for handling large plastic sheets. Use appropriate lifting equipment to avoid damage or injury.

Regulatory Compliance

Adherence to national and international regulations is critical when processing and distributing laser-cut plastic components.

- REACH (EU Regulation): Comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) if operating in or exporting to the EU. Ensure all plastic materials are registered and do not contain restricted substances.

- RoHS Compliance: If producing parts for electronics or consumer goods, verify that plastics do not contain prohibited substances such as lead, cadmium, or certain flame retardants.

- Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date Safety Data Sheets for all plastic materials used, detailing composition, hazards, and handling instructions.

- Customs and Import/Export Regulations: For international shipping, ensure proper documentation (e.g., commercial invoices, certificates of origin) and classification under the correct HS codes (e.g., 3926.30 for plastic parts).

Environmental and Emissions Compliance

Laser cutting plastics can produce fumes and particulates, making environmental controls mandatory.

- Fume Extraction Systems: Install certified fume extractors with HEPA and activated carbon filters to capture hazardous emissions (e.g., hydrogen chloride from PVC).

- Waste Management: Classify and dispose of plastic waste according to local regulations. Recycle whenever possible and keep records of waste disposal.

- Air Quality Standards: Comply with workplace air quality regulations (e.g., OSHA in the U.S., AFS in Sweden). Monitor exposure levels to volatile organic compounds (VOCs).

- Prohibited Materials: Avoid laser cutting plastics that release toxic fumes, such as PVC (polyvinyl chloride) or PTFE (Teflon), unless using specialized containment systems.

Workplace Safety and Certification

Ensure a safe working environment and meet industry safety standards.

- Personal Protective Equipment (PPE): Provide employees with appropriate PPE, including safety goggles, gloves, and respiratory protection when necessary.

- Machine Safety Standards: Comply with laser safety standards such as IEC 60825 (laser product classification) and ISO 11553 (safety of laser processing machines).

- Operator Training: Train all personnel on laser cutter operation, emergency procedures, and material-specific hazards.

- CE Marking (EU): If selling laser-cut machinery or systems, ensure they are CE-marked and comply with the Machinery Directive and other relevant EU legislation.

Quality Assurance and Traceability

Maintain high product quality and traceability across the supply chain.

- Batch Tracking: Implement a system to track plastic materials from receipt through cutting and delivery.

- Dimensional Accuracy: Use calibrated tools and periodic inspections to ensure cuts meet specified tolerances.

- Customer Compliance Requirements: Confirm any specific compliance or documentation needs from clients (e.g., ISO 9001 certification, material traceability reports).

Summary

Proper logistics and compliance management in laser cutting of plastics ensures legal operation, worker safety, environmental protection, and customer satisfaction. Regular audits, staff training, and up-to-date documentation are essential to maintain adherence to evolving regulations.

Slutsats – Inköp av laserskärning av plast

Efter genomförd utvärdering av leverantörer och processer för laserskärning av plast kan slutsatsen dras att denna teknik erbjuder hög precision, reproducerbarhet och möjlighet till detaljerade formgivningar, vilket gör den idealisk för prototypframställning och mindre serietillverkning. Genom att välja rätt material och samarbeta med kompetenta leverantörer med erfarenhet inom laserbearbetning av plast kan kvaliteten, kostnadseffektiviteten och leveranstiderna optimeras.

Det är viktigt att redan i projektstart klargöra krav på noggrannhet, ytfinish och materialspecifikationer för att undvika onödiga iterationer. Samverkan med leverantörer som erbjuder snabb prototypning, digital filhantering och flexibla produktionslösningar stärker agiliteten i utvecklingsprocessen.

Sammanfattningsvis är laserskärning av plast en väl lämpad och ekonomiskt försvarbar lösning för specifika tillämpningar, särskilt där precision och designfrihet är avgörande. En genomtänkt leverantörsstrategi säkerställer hög kvalitet och långsiktig tillförlitlighet i komponenttillverkningen.