The global laser welding market is experiencing robust growth, driven by increasing demand for high-precision joining technologies in industries such as automotive, aerospace, and electronics. According to Grand View Research, the global laser welding market size was valued at USD 4.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A key driver behind this expansion is the rising adoption of laser welding for aluminum—a material favored for its lightweight and corrosion-resistant properties—particularly in electric vehicle (EV) manufacturing and advanced mobility solutions. As automakers shift toward aluminum-intensive designs to improve fuel efficiency and battery range, the need for reliable, high-speed, and low-distortion welding processes has intensified. This growing demand has positioned laser beam welding (LBW) as a preferred method for aluminum joining, spurring innovation and competition among equipment manufacturers worldwide. In this evolving landscape, a select group of companies are leading the way in developing advanced Laserschweißen (laser welding) solutions specifically optimized for aluminum applications.

Top 10 Laserschweißen Aluminium Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Company for Industrial Laser Solutions

Website: laserline.com

Key Highlights: The leading laser company for integrated & customized diode laser manufacturing solutions for various industries & applications.Missing: laserschweißen aluminium…

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 Lorch welding equipment and automation

Website: lorch.eu

Key Highlights: Welding solutions for industry, production and assembly: with welding processes and welding equipment from Lorch, you get more out of your weld seam….

#4 We are lasers.

Website: ak-industry.de

Key Highlights: AK Industry offers its customers a wide range of laser accessories and safety equipment specifically designed for welding to ensure the safety and health of ……

#5 Laserschweißen archivos

Website: laserwelding.eu

Key Highlights: Laser welding of stainless steel filter to an aluminum casing. Solid shaft laser welded to a sintered cam. With 5mm penetration the solid shaft is ……

#6 Laser Welding Aluminum

Website: ebindustries.com

Key Highlights: Aluminum is laser weldable. Certified ISO 13485:2016 laser welding services. Fast quote and and turn-around. Automated, semi-automated, CAD/CAM design, ……

#7 Laser welding

Website: jutz-lasertechnik.at

Key Highlights: Im Dienstleistungszentrum von Jutz Lasertechnik in Wien wird Ihnen die entsprechende Ausstattung an Laserschweißgeräten und das technische Know-how geboten….

#8 News & Press

Website: bbw-lasertechnik.de

Key Highlights: BBW Lasertechnik is a highly specialized B2B contract manufacturer with a focus on laser welding, fine laser cutting, laser drilling, laser turning and surface ……

#9 Laser Welding Aluminum Guide

Website: megmeet-welding.com

Key Highlights: In this guide, we’ll explore the best aluminum laser welding machines, common welding problems, and the ideal settings to get the job done right….

#10 News

Website: mig-weld.eu

Key Highlights: Welcome to the new MIG WELD website! Résumé MIG WELD’s website was revamped… Ask for our catalog Logo Mig Weld 20, rue Colbert F-21600 LONGVIC…

Expert Sourcing Insights for Laserschweißen Aluminium

H2: Markttrends für Laserschweißen von Aluminium bis 2026

Bis zum Jahr 2026 wird der globale Markt für das Laserschweißen von Aluminium durch eine Kombination technologischer Fortschritte, gestiegener Nachfrage aus Schlüsselindustrien und der Notwendigkeit nach effizienteren und nachhaltigeren Fertigungsverfahren geprägt sein. Im Folgenden werden die wichtigsten Markttrends identifiziert und analysiert, die das Wachstum und die Entwicklung dieser Technologie bis 2026 beeinflussen werden.

1. Wachstum durch die Automobilindustrie – Elektromobilität als Treiber

Ein zentraler Wachstumstreiber für das Laserschweißen von Aluminium ist die rasante Expansion der Elektromobilität. Hersteller von Elektrofahrzeugen (EVs) setzen verstärkt auf Aluminium, um das Gewicht von Fahrzeugkarosserien und Batteriegehäusen zu reduzieren und somit die Reichweite zu erhöhen. Das präzise und hochfeste Laserschweißen ist hierfür eine Schlüsseltechnologie. Bis 2026 wird ein deutlicher Anstieg der Nachfrage nach automatisierten, hochdurchsatzfähigen Laserschweißlösungen in der EV-Produktion erwartet, insbesondere für Batteriemodule, Leichtbau-Rahmen und Aluminium-Strukturkomponenten.

2. Fortschritte bei Laserquellen und Prozessstabilität

Die Entwicklung leistungsstarker, effizienter und kostengünstiger Laserquellen – insbesondere von Faserlasern und grünen Lasern – verbessert die Schweißbarkeit von Aluminium erheblich. Aluminium reflektiert herkömmliche Infrarotlaser stark, was Prozessinstabilität verursachen kann. Die zunehmende Verfügbarkeit von grünen Lasern (Wellenlänge ~515–532 nm), die besser von Aluminium absorbiert werden, ermöglicht stabilere Schweißnähte mit geringerem Aufwand für Vorbehandlung oder Zusatzmaterial. Bis 2026 wird erwartet, dass grüne Laser in Serienfertigungen Einzug halten, was die Qualität und Wirtschaftlichkeit des Verfahrens steigert.

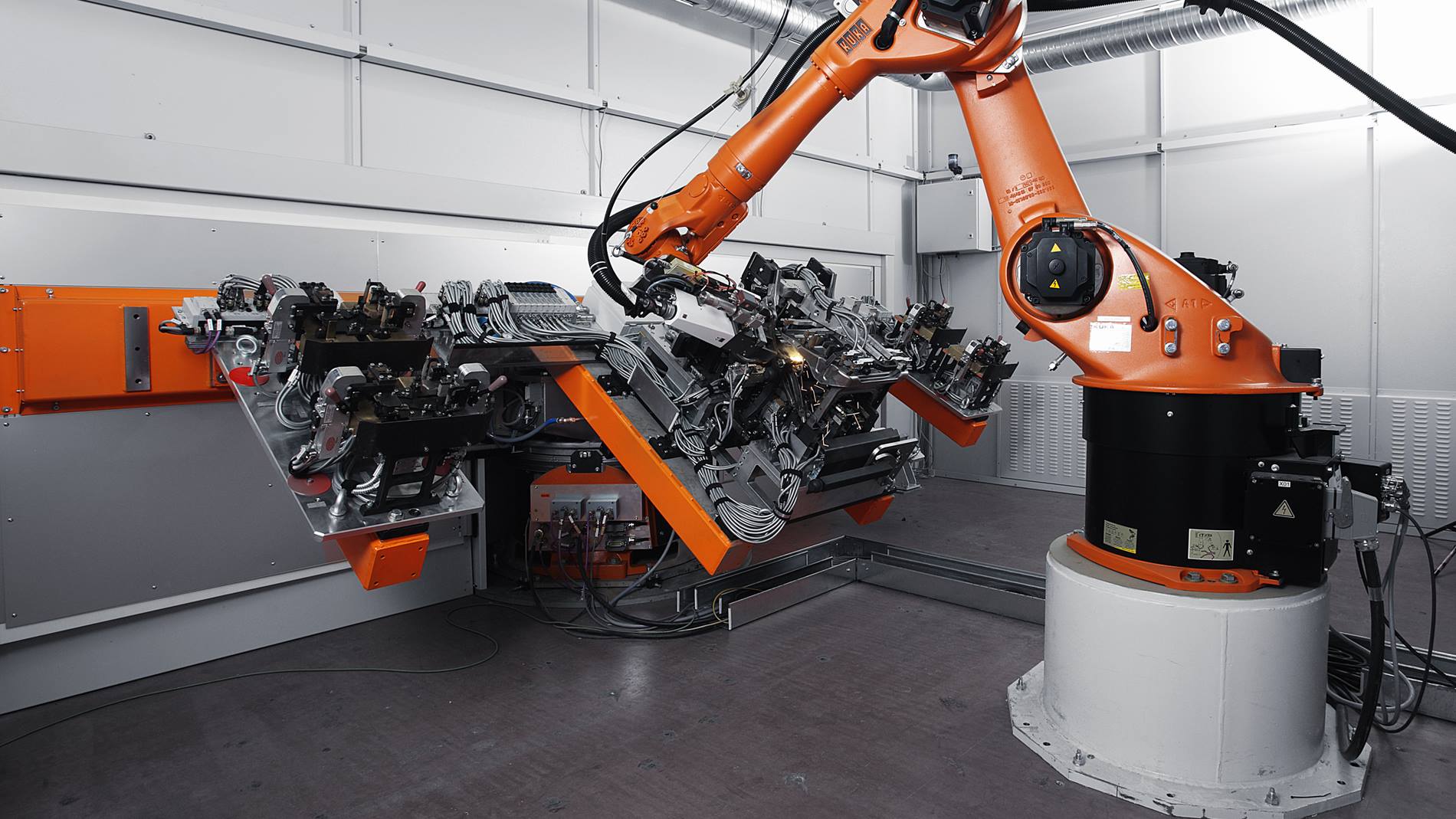

3. Automatisierung und Integration in Industrie-4.0-Umgebungen

Die Digitalisierung der Fertigung führt zu einer stärkeren Integration von Laserschweißprozessen in vernetzte Produktionslinien. Bis 2026 werden intelligente Systeme mit Echtzeit-Monitoring (z. B. durch Coaxial-Sensoren), KI-gestützter Prozessoptimierung und Predictive Maintenance Standard sein. Diese Entwicklung erhöht die Prozesssicherheit, reduziert Ausschussraten und senkt die Betriebskosten – besonders wichtig bei der Bearbeitung anspruchsvoller Materialien wie Aluminium.

4. Nachhaltigkeit und Energieeffizienz im Fokus

Unternehmen sind zunehmend auf nachhaltige Fertigungsmethoden angewiesen. Das Laserschweißen verbraucht weniger Energie als konventionelle Schweißverfahren wie MIG und produziert weniger Abfall. Zudem ermöglicht der Einsatz von Aluminium eine Gewichtsreduktion in Endprodukten, was den CO₂-Ausstoß über den Lebenszyklus senkt. Diese ökologischen Vorteile stärken die Attraktivität der Technologie, insbesondere in regulierten Märkten wie Europa.

5. Expansion in neue Anwendungsbereiche

Neben Automobil und Luftfahrt gewinnt das Laserschweißen von Aluminium auch in anderen Branchen an Bedeutung. Beispiele sind:

– Luft- und Raumfahrt: Für leichtgewichtige Strukturen in Flugzeugen und Drohnen.

– Energiespeicher: Bei der Fertigung von Aluminiumgehäusen für Batterien und Brennstoffzellen.

– Konsumgüter und Elektronik: Für hochwertige, ästhetische Gehäuse (z. B. Smartphones, Laptops).

Diese Diversifizierung der Anwendungen trägt bis 2026 zu einer breiteren Marktdurchdringung bei.

6. Regionale Entwicklungen und Wettbewerbsdynamik

Asien-Pazifik, insbesondere China, bleibt der größte Markt für Laserschweißtechnologie, getrieben durch die lokale EV-Produktion und staatliche Förderprogramme. Gleichzeitig investieren europäische und nordamerikanische Hersteller stark in lokale Fertigungskapazitäten, um Lieferketten zu sichern. Dies führt zu einem wachsenden Wettbewerb zwischen globalen Lasersystemanbietern wie TRUMPF, IPG Photonics und Coherent sowie regionalen Playern.

Fazit:

Bis 2026 wird der Markt für das Laserschweißen von Aluminium dynamisch wachsen, angetrieben durch technologische Innovationen, die Energiewende und die Nachfrage nach Leichtbau. Unternehmen, die in Automatisierung, Prozesskontrolle und grüne Laser investieren, werden strategische Vorteile erlangen. Die Integration von Aluminium-Laserschweißen in nachhaltige und digitale Fertigungsstrategien wird zum Standard in modernen Industrien.

When sourcing Laser welding (Laserschweißen) of aluminum components, especially with the use of hydrogen (H₂) as a shielding or process gas, several common pitfalls related to quality and intellectual property (IP) must be carefully managed. Below is a structured overview of these pitfalls and recommendations to mitigate them:

🔹 1. Quality Pitfalls in Laser Welding of Aluminum with H₂

1.1 Porosity and Hydrogen Embrittlement

- Pitfall: Aluminum is highly sensitive to hydrogen, which can dissolve in the molten pool and lead to porosity (gas pores) upon solidification. Using H₂-containing shielding gases (e.g., Ar-H₂ mixtures) can increase hydrogen pickup, especially if not properly controlled.

- Mitigation:

- Limit H₂ concentration (typically ≤2–5% in argon).

- Ensure precise control of gas flow, purity, and shielding efficiency.

- Use pre-weld cleaning (degreasing, oxide removal) to reduce moisture and contaminants.

- Optimize laser parameters (power, speed, focus) to minimize melt pool lifetime.

1.2 Oxide Layer Interference

- Pitfall: Aluminum forms a tenacious Al₂O₃ oxide layer that disrupts weld penetration, causes instability, and promotes defects.

- Mitigation:

- Mechanical or chemical cleaning before welding.

- Use high-power density lasers (e.g., fiber or disk lasers) to break through the oxide layer.

- Ensure consistent beam alignment and focus.

1.3 Cracking (Hot Cracking)

- Pitfall: Aluminum alloys (especially 5xxx, 6xxx series) are prone to solidification cracking due to thermal stress and alloying elements (e.g., Mg).

- Mitigation:

- Choose crack-resistant filler materials (e.g., 4047 – AlSi12).

- Control cooling rates via preheating or pulse modulation.

- Avoid excessive welding speeds that increase thermal gradients.

1.4 Inconsistent Shielding Gas Application

- Pitfall: Inadequate shielding with Ar-H₂ mixtures leads to oxidation, nitride formation, or contamination.

- Mitigation:

- Use trailing shields and properly designed nozzles.

- Monitor gas purity (dew point ≤ -40°C) and flow rates.

- Avoid ambient drafts in the welding environment.

1.5 Process Validation and Repeatability

- Pitfall: Lack of standardized procedures leads to inconsistent weld quality, especially in high-volume production.

- Mitigation:

- Implement in-process monitoring (e.g., weld seam tracking, plasma monitoring).

- Conduct destructive and non-destructive testing (NDT): X-ray, ultrasound, dye penetrant.

- Establish qualified welding procedures (WPQR/WPS) per standards (e.g., ISO 15614, AWS D1.2).

🔹 2. Intellectual Property (IP) Pitfalls

2.1 Unclear Ownership of Process Know-How

- Pitfall: Suppliers may claim ownership of custom welding parameters, tooling, or H₂-assisted techniques developed during production.

- Mitigation:

- Define IP ownership in contracts (e.g., customer retains IP on product design and process specs).

- Use work-for-hire clauses.

- Require technology transfer agreements if process knowledge is critical.

2.2 Use of Proprietary Techniques Without Licensing

- Pitfall: Some suppliers use patented laser-H₂ processes (e.g., for porosity reduction or surface activation) without proper licensing, exposing the buyer to infringement risks.

- Mitigation:

- Require suppliers to disclose patented technologies used in production.

- Conduct freedom-to-operate (FTO) analysis, especially for high-volume or export products.

- Include indemnification clauses in supply contracts.

2.3 Reverse Engineering and Trade Secrets

- Pitfall: Sharing detailed technical drawings or process specs with suppliers may lead to misuse or replication of proprietary designs.

- Mitigation:

- Share only necessary information (e.g., use step files instead of native CAD).

- Apply NDAs and restrict access to critical data.

- Consider dual sourcing or split production to limit exposure.

2.4 Lack of Documentation and Traceability

- Pitfall: Missing records of welding procedures, H₂ gas specs, or quality controls can hinder IP defense or product liability cases.

- Mitigation:

- Require full documentation packages (process parameters, material certs, test reports).

- Use digital traceability systems (e.g., QR codes, MES integration).

🔹 3. Best Practices Summary

| Area | Best Practice |

|——|—————|

| Quality | Use ≤5% H₂ in Ar shielding; clean surfaces; optimize laser parameters; apply NDT. |

| Gas Handling | Ensure dry, high-purity H₂/Ar; proper gas delivery setup. |

| Alloy Selection | Avoid highly crack-prone alloys; use fillers like AlSi12. |

| IP Protection | Define IP ownership; use NDAs; conduct FTO analysis. |

| Supplier Management | Audit welding capabilities; require certifications (e.g., ISO 3834, EN 15085). |

✅ Conclusion

When sourcing Laser welding of aluminum with H₂, the benefits (e.g., improved arc stability, reduced oxides) must be balanced against quality risks like porosity and cracking, and IP risks from unlicensed or poorly protected technologies. A proactive approach with clear contracts, technical oversight, and process validation is essential to ensure both product quality and IP security.

Let me know if you’d like a checklist or contract clause examples.

Logistics & Compliance Guide for Laser Welding Aluminum Using Hydrogen (H₂)

This guide outlines the essential logistics and compliance considerations when performing laser welding of aluminum using a hydrogen (H₂) shielding or process gas environment. While hydrogen is not commonly used as a primary shielding gas in industrial laser welding due to safety and metallurgical concerns, it can be used in specific applications (e.g., hybrid gas mixtures or specialized research environments). This document ensures safe, efficient, and compliant operations.

1. Overview of the Process

- Process: Laser beam welding (LBW) of aluminum alloys (e.g., 5xxx, 6xxx series)

- Gas Use: Hydrogen (H₂) in controlled mixtures (e.g., Ar/H₂ or He/H₂) as shielding or plasma suppression gas

- Purpose of H₂:

- Improved arc stability in hybrid processes

- Reduced plasma formation in high-power laser welding

- Enhanced weld penetration (in some experimental setups)

- Note: Pure H₂ is not recommended for aluminum welding due to hydrogen embrittlement and porosity risks.

2. Safety & Hazard Management

A. Hydrogen (H₂) Hazards

| Hazard | Description | Mitigation |

|——-|————-|———-|

| Flammability | H₂ has a wide flammability range (4–75% in air) and low ignition energy (0.02 mJ) | – Use gas detection systems

– Ensure ventilation >12 air changes/hour

– Eliminate ignition sources (sparks, static) |

| Embrittlement | H₂ can diffuse into aluminum, causing porosity or cracking | – Limit H₂ concentration (<5% in Ar/H₂ mixtures)

– Post-weld inspection (UT, X-ray) |

| Asphyxiation Risk | High H₂ concentrations displace oxygen | – Monitor O₂ levels (>19.5%)

– Use confined space entry protocols |

| Leakage | H₂ molecules are small and prone to leakage | – Use H₂-rated fittings (VCR, CGA-350)

– Perform regular leak tests with soap solution or H₂ detectors |

B. Laser Hazards

- Class 4 Laser Radiation – Can cause burns, eye damage, fire

- Implement interlocked enclosures

- Use appropriate laser safety eyewear (OD 6+ for wavelength used)

- Post warning signs (EN 60825-1)

3. Gas Handling & Storage (H₂ Compliance)

A. Storage

- Store H₂ cylinders in:

- Well-ventilated, outdoor gas cabinets or dedicated storage areas

- Upright with valve protection caps

- Away from oxidizers (minimum 6 m separation)

- Maximum storage quantity per area must comply with local fire codes (e.g., NFPA 55, IBC)

B. Transport

- Use certified gas cylinder carts with chains

- Secure cylinders during transport

- Follow ADR (Europe), DOT 49 CFR (USA), or local transport regulations for hazardous gases

C. Piping & Delivery

- Use stainless steel tubing (SS 316), clean for oxygen service

- Install flashback arrestors and pressure relief valves

- Purge lines before use to avoid air-H₂ mixtures

4. Welding Process Parameters & Quality Control

Recommended Practices:

- Gas Mixtures: Ar + 2–5% H₂ (never >5% for aluminum)

- Flow Rate: 15–20 L/min (optimize to prevent turbulence)

- Laser Type: Fiber or disk laser (1 µm wavelength), 3–8 kW power

- Shielding: Dual-shield setup (leading and trailing gas nozzles)

Quality Assurance:

- Pre-weld: Clean aluminum surface (remove oxides, oils) via brushing or solvent

- In-process monitoring: Use coaxial cameras, plasma monitoring

- Post-weld inspection:

- Visual inspection (ISO 17637)

- Radiographic testing (ISO 17636) or ultrasonic (ISO 11666)

- Hardness and tensile testing (ISO 4136, ISO 6892-1)

5. Regulatory Compliance

| Regulation | Requirement | Action |

|———-|————-|——–|

| OSHA (USA) | Hazard communication, PPE, ventilation | Provide SDS, train workers (29 CFR 1910) |

| NFPA 55 / 51B | Storage, fire safety for compressed gases | Follow distance, fire suppression rules |

| ATEX (EU) | Equipment in explosive atmospheres | Use ATEX-certified detectors and tools |

| ISO 13577 (Heated Workplaces) | Safe use of combustion and heating equipment | Apply to H₂-assisted heating processes |

| ISO 15004-2 | Laser safety in industrial environments | Implement engineering controls |

6. Environmental & Emergency Preparedness

- Ventilation: Use local exhaust ventilation (LEV) near welding zone

- Gas Detection: Install fixed H₂ sensors with alarms (set at 1% LEL)

- Emergency Response:

- Emergency shutoff valves for H₂ supply

- Fire suppression: Class D extinguishers for metal fires; CO₂ or dry chemical for H₂ fires

- Evacuation plan and drills (annually)

- Spill/Leak Response:

- Isolate area, eliminate ignition sources

- Evacuate and ventilate

- Notify emergency services if uncontrolled

7. Training & Documentation

- Personnel Training:

- Laser safety (ANSI Z136.1 or IEC 60825)

- Hydrogen handling (GAWDA or equivalent)

- Emergency procedures

- Documentation:

- Welding procedure specifications (WPS) per ISO 15609-4

- Gas handling logs

- Inspection and NDT reports

- Safety data sheets (SDS) for H₂ and consumables

8. Alternatives & Best Practices

- Consider Alternatives: Use pure argon or argon-helium mixtures instead of H₂ unless technically justified

- Best Practices:

- Minimize H₂ use; only where benefits outweigh risks

- Use closed-loop gas recycling systems if feasible

- Conduct risk assessment (HIRA or FMEA) before process implementation

Conclusion

Laser welding of aluminum using hydrogen requires rigorous safety, compliance, and process control. Due to the inherent risks of hydrogen, its use should be limited to justified applications with strict engineering and administrative controls. Always prioritize safer shielding gas alternatives unless H₂ provides a documented technical advantage.

Prepared by: [Your Name / Safety Officer]

Revision Date: April 2025

Compliance Standards Referenced: ISO, NFPA, OSHA, ADR, ATEX, ANSI

⚠️ Disclaimer: This guide is for informational purposes. Always consult site-specific risk assessments and local regulations before implementation.

Conclusion on Sourcing Laser Welding for Aluminum

Sourcing laser welding services for aluminum requires careful consideration of technological capabilities, material-specific challenges, and supplier expertise. Aluminum’s high thermal conductivity, reflectivity, and susceptibility to porosity and cracking necessitate advanced laser welding technologies—such as fiber or disk lasers—along with precise process control and skilled operation. When sourcing externally, it is essential to partner with suppliers who have proven experience in laser welding aluminum, possess the appropriate equipment, and implement rigorous quality assurance protocols.

Additionally, factors such as joint design, surface preparation, shielding gas use, and post-weld inspection should be clearly addressed in supplier evaluations. While in-house laser welding offers greater control and long-term cost benefits for high-volume production, outsourcing can be a flexible and efficient solution for low to medium volumes or specialized applications.

In conclusion, successful sourcing of laser welding for aluminum hinges on selecting technically competent partners, ensuring process reliability, and maintaining close collaboration to achieve consistent, high-quality welds that meet performance and industry standards.