The global lasermärkning (laser marking) market is experiencing robust expansion, driven by increasing demand for permanent, high-precision marking solutions across industries such as automotive, electronics, medical devices, and aerospace. According to Mordor Intelligence, the global laser marking market was valued at approximately USD 2.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 5.8% through 2029. This upward trajectory is fueled by the rising adoption of fiber laser systems, advancements in automation, and stricter regulatory requirements for product traceability. Grand View Research further supports this outlook, noting that innovations in ultrafast lasers and the integration of laser systems with Industry 4.0 technologies are accelerating market growth. As demand intensifies, a select group of manufacturers has emerged as leaders, combining technological innovation, global reach, and scalable solutions. Below are the top 9 lasermärkning manufacturers shaping the future of industrial traceability and precision marking.

Top 9 Lasermärkning Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Marking Machine & Industrial Laser Marking Systems

Website: videojet.com

Key Highlights: Laser marking systems provide manufacturers with a safe, ink-free method of marking permanent codes, text, and graphics for product identification and branding….

#2 Laser marking on all materials

Website: lasitlaser.com

Key Highlights: Laser marking is the ideal tool for ensuring traceability and durability of logos and designs on all materials….

#3 Print

Website: rea-jet.com

Key Highlights: We manufacture customized systems for the marking, labeling, laser marking and code verification of your products, offer a cross-technology operating ……

#4 Laserevo

Website: laserevo.com

Key Highlights: A complete range of marking solutions: high-performance lasers with active fiber sources, solutions for marking with CO2 sources, dot peen and scratch markers….

#5 Clariant launches antimony

Website: clariant.com

Key Highlights: Clariant is introducing a new antimony-trioxide-free system for molding and laser-marking thermoplastic urethane (TPU) ear tags used for identifying cattle and ……

#6 Laser Marking Machine

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading provider of laser cutting machine, laser marking mahcine and laser cleaning machine.Email:[email protected]….

#7 Lasermärkning

Website: phoenixcontact.com

Key Highlights: Motståndskraftig märkning för höga krav. Modern laserteknik används för att skapa märkningsmaterial för höga krav i industriella miljöer….

#8 Cajo Technologies joins the Batteries European Partnership …

Website: cajotechnologies.com

Key Highlights: Cajo will contribute to BEPA goals, by bringing in its expertise in traceability solutions. Company is providing turn-key laser marking solutions for ……

#9 Gravyr & Lasermärkning i Stockholm

Website: manufacturingguide.com

Key Highlights: Gravyr & Lasermärkning i Stockholm. Org.nr. 556678-2479. Employees. 1 pcs. Revenue. 1 426 kSEK. Registration. 2005. HideContacts. Visiting address….

Expert Sourcing Insights for Lasermärkning

H2: Key Market Trends Shaping the Lasermärkning (Laser Marking) Industry in 2026

As we approach 2026, the global lasermärkning (laser marking) market is undergoing significant transformation, driven by technological advancements, evolving regulatory landscapes, and shifting industrial demands. This analysis identifies and examines the most critical trends expected to define the market in the coming years.

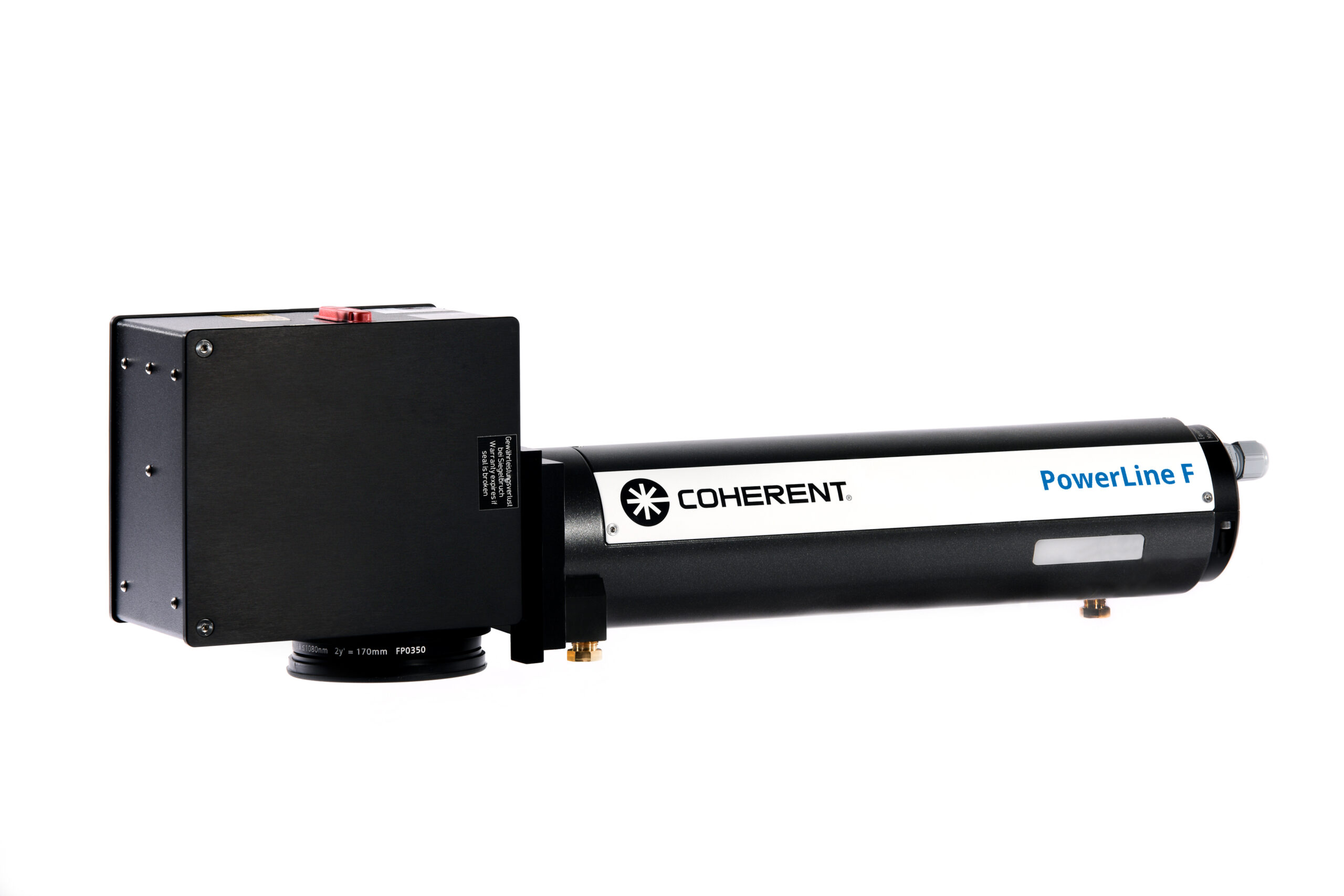

1. Dominance of Fiber Lasers and Advancements in Laser Sources:

Fiber lasers will continue their reign as the technology of choice for most industrial marking applications due to their superior reliability, lower maintenance, high efficiency, and excellent beam quality for metals and many plastics. By 2026, expect:

* Increased Power & Speed: Higher-power fiber lasers enabling faster marking on challenging materials and larger surfaces.

* Ultrafast (Picosecond/Femtosecond) Laser Maturation: Wider adoption of ultrafast lasers for high-precision, cold ablation marking on sensitive materials (medical devices, electronics, glass) without thermal damage, moving beyond niche applications into broader industrial use.

* Green and UV Fiber Lasers: Growth in green (532nm) and UV (355nm) fiber lasers for superior marking on plastics, semiconductors, and other materials where traditional IR lasers struggle, offering better contrast and finer detail.

2. Surge in Demand Driven by Traceability & Serialization:

Regulatory mandates (e.g., UDI for medical devices, FDA’s Drug Supply Chain Security Act, EU MDR/IVDR, automotive part tracking) are the primary growth engine. The need for unique, permanent, and machine-readable codes (Data Matrix, QR codes) is non-negotiable.

* Mass Customization & Anti-Counterfeiting: Consumers and brands demand product authenticity and personalized items. Laser marking provides secure, tamper-proof serialization and unique identifiers, crucial for combating counterfeiting in pharmaceuticals, luxury goods, and electronics.

* Supply Chain Transparency: Laser marks enable full product lifecycle tracking from component to end-of-life, enhancing quality control, recalls, and sustainability reporting.

3. Integration with Industry 4.0 and Smart Manufacturing:

Laser marking systems are becoming integral nodes in connected factories.

* Seamless Data Exchange: Tight integration with MES (Manufacturing Execution Systems), ERP, and PLM software via IIoT protocols. Marking data (job parameters, results) is automatically logged for traceability and process optimization.

* Real-Time Process Monitoring & Control: In-process verification using integrated cameras and sensors to read and validate marks immediately after creation, feeding data back for closed-loop quality control and reducing scrap.

* Remote Monitoring & Predictive Maintenance: Cloud connectivity allows OEMs and users to monitor machine health, performance, and consumables remotely, enabling predictive maintenance to minimize downtime.

4. Focus on Sustainability and Eco-Friendly Processes:

Environmental concerns are reshaping manufacturing. Laser marking offers inherent advantages:

* No Consumables: Eliminates the need for inks, solvents, or labels, reducing waste and chemical handling (a major advantage over inkjet or labeling).

* Material Savings: Eliminates the need for separate labels or tags.

* Energy Efficiency: Modern fiber lasers are highly energy-efficient compared to older technologies.

* Permanent & Durable: Reduces the need for rework or replacement due to mark wear, contributing to product longevity.

5. Expansion into New Materials and Applications:

The versatility of laser marking continues to expand.

* Advanced Materials: Increased marking of composites (CFRP, GFRP), ceramics, and new high-performance polymers used in aerospace, automotive, and electronics.

* Surface Engineering: Beyond simple codes, lasers are used for functional marking like creating hydrophobic/hydrophilic surfaces, friction modification, or aesthetic textures (color marking on stainless steel, annealing colors on titanium).

* Consumer Electronics: Proliferation of micro-marking on tiny components (chips, connectors) and intricate designs on device housings.

6. Automation and Robotics Integration:

Labor costs and the need for consistent quality drive automation.

* Robotic Cells: Increased deployment of laser markers integrated with collaborative robots (cobots) and traditional industrial robots for marking complex 3D surfaces, large parts, or in dynamic production lines.

* Modular & Flexible Systems: Development of more compact, modular laser sources and scanning heads for easier integration into existing automated lines and flexible manufacturing systems.

Challenges & Considerations for 2026:

* Total Cost of Ownership (TCO): While operating costs are low, the initial investment, especially for ultrafast lasers, remains high. Demonstrating clear ROI based on traceability, quality, and efficiency is crucial.

* Skill Gap: Demand for technicians skilled in laser technology, system integration, and data management will outpace supply.

* Material Compatibility & Process Development: Optimizing parameters for new or complex materials requires expertise and time.

* Security: Securing connected laser systems and the sensitive data they handle (serial numbers, production data) is paramount.

Conclusion:

By 2026, the lasermärkning market will be characterized by sophisticated, connected, and sustainable solutions driven by the inescapable need for traceability and the integration imperative of Industry 4.0. While fiber lasers remain the workhorse, the adoption of ultrafast lasers and specialized wavelengths will accelerate. Success will belong to providers who offer not just hardware, but integrated solutions combining advanced lasers, smart software, seamless data connectivity, and expertise in solving complex industrial marking challenges across diverse and demanding applications. The focus will shift from simply “making a mark” to providing verifiable, data-rich, and integral traceability solutions within the smart factory ecosystem.

Common Pitfalls When Sourcing Laser Marking Equipment (Quality and Intellectual Property)

Sourcing laser marking systems, especially from international suppliers, involves several potential risks related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls can help organizations avoid costly mistakes.

Inadequate Quality Control and Performance Issues

One of the most frequent challenges is receiving laser marking equipment that fails to meet expected performance standards. Suppliers, particularly low-cost manufacturers, may use substandard components such as inferior laser sources, unstable optics, or poorly designed cooling systems. This can result in inconsistent marking depth, poor contrast, or premature system failure. Additionally, lack of proper calibration and testing before shipment often leads to extended commissioning times and production delays upon arrival.

Misrepresentation of Technical Specifications

Some suppliers exaggerate key specifications like laser power, marking speed, or durability to win contracts. For example, a system advertised as a “30W fiber laser” may deliver significantly less actual output due to inefficient components or power throttling. Buyers may only discover this after deployment, when the machine struggles to mark harder materials or maintain throughput, undermining production efficiency.

Lack of Compliance and Safety Certifications

Many budget suppliers do not provide equipment compliant with international safety and electromagnetic compatibility standards (e.g., CE, FDA, IEC). Using non-certified laser systems can pose safety hazards, lead to workplace incidents, and expose the buyer to legal liability. Non-compliant equipment may also be blocked at customs or require costly modifications to meet local regulations.

Insufficient After-Sales Support and Spare Parts Availability

A major hidden cost arises when suppliers offer little to no technical support, training, or spare parts post-purchase. Downtime due to component failure can be prolonged if replacement parts take weeks to arrive or are unavailable altogether. Language barriers and time zone differences further complicate troubleshooting, reducing overall equipment effectiveness.

Intellectual Property Risks and Reverse Engineering

Purchasing laser marking systems from certain regions can expose companies to IP vulnerabilities. Some suppliers may reverse-engineer proprietary technology or incorporate copied firmware/software without proper licensing. Using such equipment could inadvertently involve your organization in IP infringement, especially if the system includes unauthorized software or control algorithms protected by patents or copyrights.

Risk of Counterfeit or Rebranded Equipment

Some suppliers rebrand lower-tier or obsolete laser systems as premium models, misleading buyers about origin and performance. This includes using fake brand labels or falsifying documentation. Without proper due diligence, companies may pay premium prices for outdated or non-genuine equipment, impacting long-term reliability and resale value.

Poor Documentation and Software Localization

Incomplete or poorly translated manuals, software interfaces, and error messages hinder usability and maintenance. Proprietary software may lack API access or integration capabilities, limiting automation and data tracking within existing manufacturing systems. This can reduce flexibility and increase the total cost of ownership.

Conclusion

To mitigate these risks, conduct thorough supplier vetting, request third-party quality certifications, perform on-site audits if possible, and include clear contractual terms regarding performance, warranty, and IP indemnity. Investing time in due diligence helps ensure reliable, compliant, and legally safe laser marking solutions.

Logistics & Compliance Guide for Lasermärkning

Laser marking (Lasermärkning) is a critical process in manufacturing and product identification, offering permanent, high-precision marking for traceability, branding, and regulatory compliance. To ensure smooth operations and adherence to legal and safety standards, both logistical and compliance aspects must be carefully managed. This guide outlines key considerations for implementing and managing lasermärkning within your supply chain and production environment.

Equipment and Installation Logistics

Selecting and installing laser marking systems requires precise planning. Ensure the workspace meets technical requirements such as power supply stability, ventilation, and space for the laser system and integration with existing production lines. Coordinate with suppliers for timely delivery, site preparation, and technician support during installation. Consider modular systems for scalability and ease of maintenance.

Supply Chain Integration

Integrate lasermärkning seamlessly into your production workflow. This includes synchronizing marking operations with upstream processes (e.g., part manufacturing) and downstream logistics (e.g., packaging, labeling). Use automated conveyors or robotic handling to feed components into the marking station, minimizing bottlenecks. Ensure data connectivity (e.g., via MES or ERP systems) for real-time job control and traceability.

Material Compatibility and Marking Parameters

Verify compatibility between laser types (fiber, CO₂, UV) and the materials being marked (metals, plastics, ceramics). Define and document optimal marking parameters (speed, power, frequency) to ensure consistent, legible, and durable marks. Maintain a material database accessible to operators, and update it when materials or specifications change.

Regulatory Compliance and Standards

Adhere to international and regional standards relevant to laser marking. Key regulations include:

- ISO 9001: Quality management systems for consistent marking output.

- ISO 13485 (if applicable): For medical device marking.

- REACH and RoHS: Ensure marking processes do not introduce hazardous substances.

- FDA 21 CFR Part 11: For electronic records and signatures in regulated industries (e.g., pharmaceuticals, medical devices).

- UDI (Unique Device Identification): Mandatory for medical devices in the EU (MDR) and US (FDA); ensure lasermärkning supports compliant UDI codes (e.g., Data Matrix).

Safety and Environmental Compliance

Laser systems pose risks such as eye/skin exposure and fume emissions. Comply with:

- IEC 60825-1: Laser safety classifications and protective measures.

- OSHA (US) / AFS (Sweden): Workplace safety regulations for laser use.

- Install proper enclosures, interlocks, warning signs, and emergency stops.

- Use fume extraction systems to capture airborne particulates; conduct regular maintenance and filter changes.

- Train all personnel on laser safety procedures and provide appropriate PPE (e.g., laser safety goggles).

Data Integrity and Traceability

Ensure all marked identifiers (serial numbers, barcodes, QR codes) are unique, machine-readable, and verifiable. Implement automated inspection systems (e.g., vision systems) to validate mark quality. Store marking logs securely with timestamps and job metadata to support traceability and audits.

Maintenance and Calibration

Schedule regular preventive maintenance and calibration of laser systems to ensure accuracy and longevity. Maintain logs of service activities and component replacements. Use OEM-recommended parts and procedures to avoid voiding warranties or compromising compliance.

Documentation and Audit Readiness

Keep comprehensive documentation, including:

- Equipment specifications and manuals

- Standard Operating Procedures (SOPs) for lasermärkning

- Operator training records

- Calibration and maintenance logs

- Compliance certificates (e.g., CE, FDA)

- Risk assessments and safety protocols

This documentation supports internal audits and regulatory inspections.

Personnel Training and Competency

Train all operators, technicians, and supervisors on safe and correct use of laser marking equipment. Training should cover operation, safety protocols, troubleshooting, and compliance requirements. Assess competency regularly and update training as systems or regulations evolve.

Continuous Improvement and Compliance Monitoring

Regularly review lasermärkning processes for efficiency, quality, and compliance. Use feedback from audits, customer complaints, or internal checks to drive improvements. Stay informed about changes in regulations (e.g., updated MDR or environmental laws) and adapt procedures accordingly.

By following this logistics and compliance guide, organizations can ensure their lasermärkning processes are efficient, safe, and fully compliant with applicable standards and regulations.

Conclusion on Sourcing Laser Marking Solutions

Sourcing laser marking solutions requires a strategic evaluation of several key factors, including marking requirements, material compatibility, production volume, automation integration, and total cost of ownership. Laser marking offers significant advantages over traditional methods, such as high precision, permanent markings, minimal maintenance, and eco-friendliness, making it a preferred choice across industries like automotive, medical devices, electronics, and aerospace.

When sourcing, it is essential to consider reputable suppliers with proven expertise, technical support, and service capabilities. Evaluating both in-house manufacturing needs and the potential benefits of outsourcing to specialized service providers can help determine the most cost-effective and efficient approach. Additionally, advancements in fiber, UV, and MOPA laser technologies provide flexibility for diverse applications, from simple serial number engraving to high-contrast markings on sensitive materials.

Ultimately, the right sourcing decision balances performance, scalability, and long-term reliability. Investing time in thorough supplier assessment and technology comparison ensures that the selected laser marking solution enhances product traceability, meets regulatory standards, and supports overall operational efficiency.