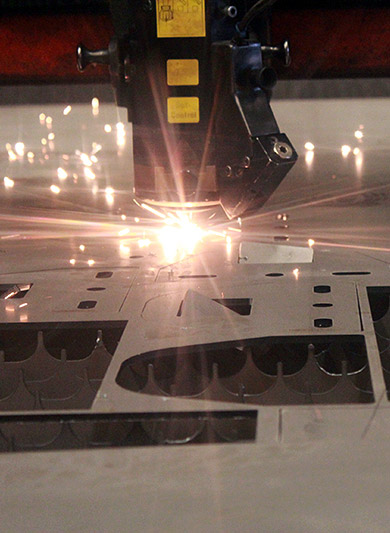

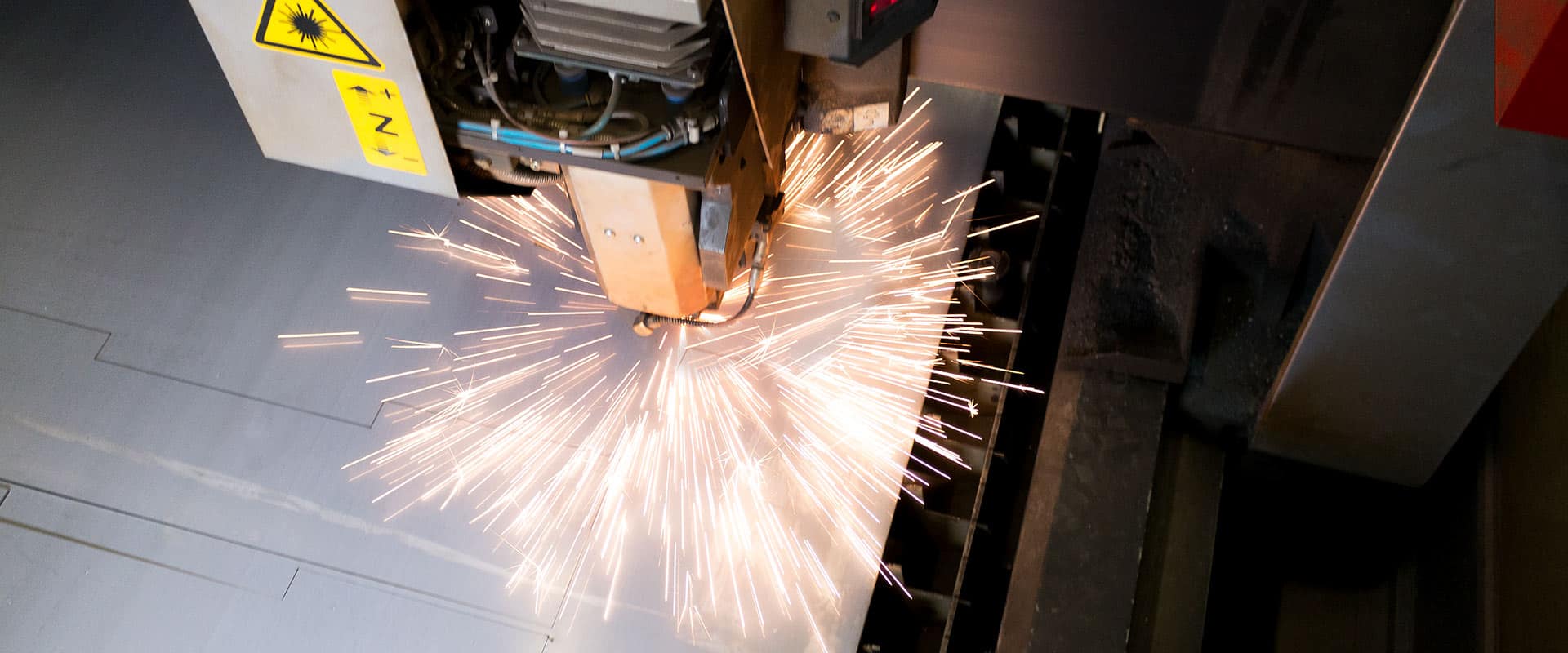

The global laser cutting machine market is experiencing robust expansion, driven by rising demand for high-precision fabrication across industries such as automotive, aerospace, and electronics. According to Grand View Research, the market was valued at USD 3.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2030. This growth is fueled by advancements in fiber laser technology, increasing automation in manufacturing, and the need for energy-efficient cutting solutions. As industries prioritize accuracy, speed, and cost-efficiency, leading manufacturers are innovating to deliver next-generation laser cutting systems. In this competitive landscape, nine companies have emerged as key players, setting industry benchmarks through technological excellence, global reach, and scalable solutions.

Top 9 Laserleikkaus Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 HGLASER

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading provider of laser cutting machine, laser marking mahcine and laser cleaning machine.Email:[email protected]….

#2 Ehdot

Website: fractory.com

Key Highlights: Fractory maintains a vendor manufacturing program consisting of a network of third party manufacturers (“Suppliers”) capable of performing manufacturing ……

#3 manufacturing of fiber laser machines for metal …

Website: fanuci-falcon.com

Key Highlights: We offer, among others, laser welders, cleaning lasers, laser cutters for pipes, profiles, and sheet metal, nitrogen generators, and 3D laser printers for ……

#4 Laser Cut Studio

Website: lasercutstudio.com

Key Highlights: Laser cutting, CNC, printing services. Range of customizable wooden products made in Helsinki, Finland….

#5 Metallin laserleikkaus, metallituotteiden valmistus, lasermerkkaus

Website: linjalaser.fi

Key Highlights: Our diverse manufacturing services · Laser cutting · Press-Brake Bending · Welding · Laser marking….

#6 Laserleikkaus

Website: bystronic.com

Key Highlights: Hyödynnä kuitulaserteknologian koko potentiaali. Leikkaa terästä jopa 30 kW:n laserteholla ja jopa 50 mm:n levyjen paksuudella….

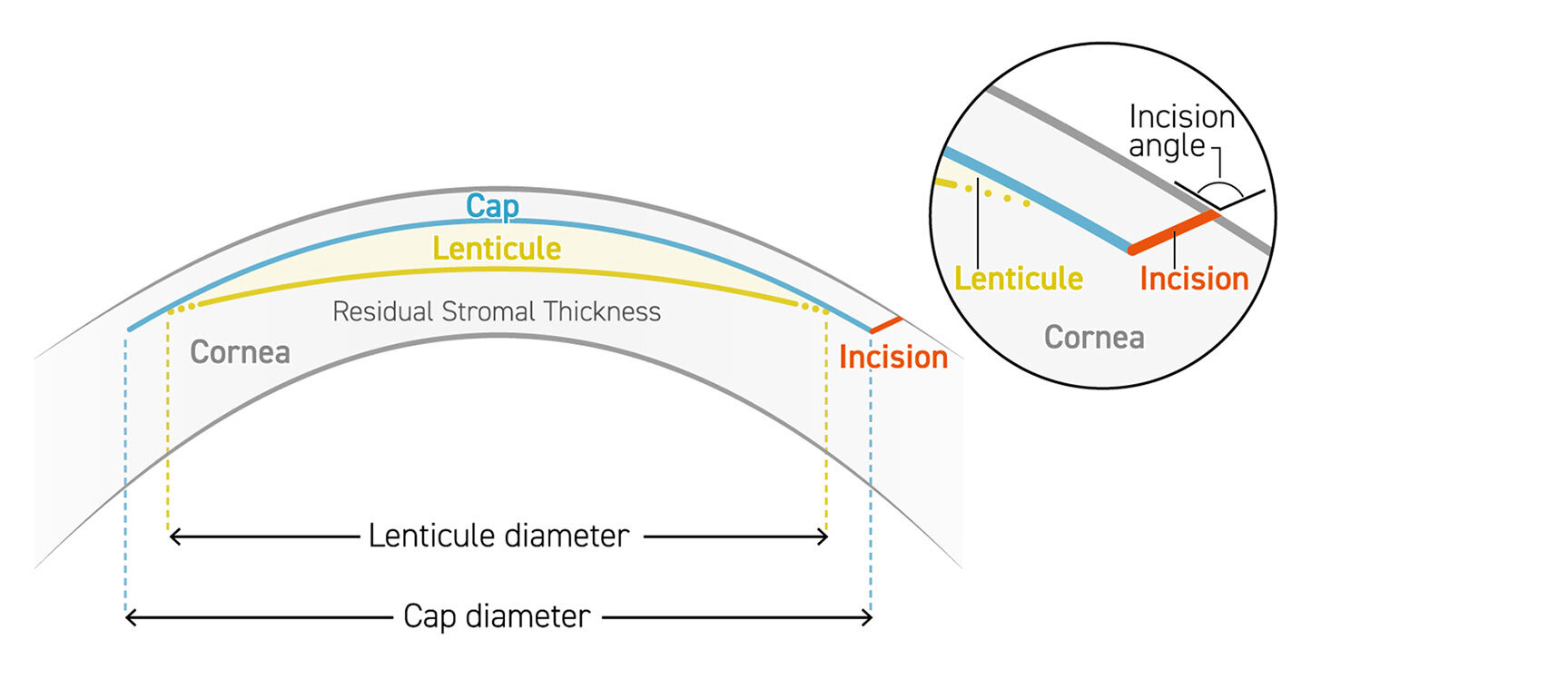

#7 SmartSight – minimally invasive lenticule extraction

Website: eye-tech-solutions.com

Key Highlights: SmartSight is an advanced flapless femtosecond laser procedure. This advancement in minimally invasive lenticule extraction features intelligent eye tracking….

#8 xTool Gallery

#9 2D-laserleikkausteknologia

Website: primapower.com

Key Highlights: Laserleikkaus on uskomattoman joustava valmistustekniikka. Sillä voidaan käsitellä monia erilaisia materiaaleja ja paksuuksia, ja sillä voit luoda minkä tahansa ……

Expert Sourcing Insights for Laserleikkaus

H2: Market Trends in Laser Cutting (Laserleikkaus) for 2026

As we approach 2026, the global laser cutting (laserleikkaus) market is undergoing significant transformation, driven by technological innovation, increasing industrial automation, and rising demand across key manufacturing sectors. Here are the major market trends shaping the future of laser cutting:

-

Growth in High-Power Fiber Laser Adoption

Fiber lasers continue to dominate the laser cutting industry, particularly those with power outputs exceeding 6 kW. By 2026, high-power fiber lasers are expected to account for over 70% of industrial laser cutting systems due to their superior energy efficiency, lower maintenance requirements, and faster cutting speeds—especially for thick metals. This trend is heavily supported by advancements in photonic technology and decreasing component costs. -

Integration with Industry 4.0 and Smart Manufacturing

Laser cutting systems are increasingly being integrated into smart factory ecosystems. By 2026, most new laser cutting machines will feature IoT connectivity, real-time monitoring, predictive maintenance, and AI-driven optimization. These capabilities allow manufacturers to improve operational efficiency, reduce downtime, and achieve higher precision through adaptive control systems. -

Expansion in Electric Vehicle (EV) and Battery Manufacturing

The rapid growth of the EV market is creating new demand for precision laser cutting in battery component fabrication, such as electrode cutting and casing manufacturing. Laser systems offer the cleanliness and accuracy required for sensitive battery materials, and this application segment is projected to grow at a CAGR of over 15% through 2026. -

Rise of Hybrid and Multi-Functional Machines

To enhance flexibility and reduce footprint, manufacturers are adopting hybrid laser systems that combine cutting with welding, marking, or additive manufacturing in a single platform. These multi-functional machines are particularly attractive to job shops and contract manufacturers looking to streamline production processes. -

Increased Demand in Renewable Energy and Aerospace

The renewable energy sector—especially wind turbine and solar panel production—and the aerospace industry are driving demand for laser cutting of advanced materials like titanium, aluminum alloys, and composites. These industries require high-precision, low-heat-input cutting methods, making fiber and ultrafast lasers increasingly essential. -

Sustainability and Energy Efficiency as Key Drivers

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt more energy-efficient and low-emission production technologies. Modern laser cutting systems consume up to 30% less energy than older CO₂ models, and their precision reduces material waste—factors that enhance their appeal in eco-conscious markets. -

Regional Market Shifts

While Europe and North America remain strong markets due to advanced manufacturing infrastructure, the Asia-Pacific region—particularly China, India, and South Korea—is expected to see the fastest growth in laser cutting adoption. Government initiatives to boost local manufacturing and technological self-reliance are accelerating investments in laser-based systems. -

Advancements in Software and Automation

By 2026, AI-powered nesting software, automated material handling, and robotic integration will be standard in mid- to high-end laser cutting systems. These software improvements significantly boost productivity and reduce reliance on skilled labor, making laser cutting more accessible to smaller enterprises.

Conclusion:

The 2026 laser cutting market is defined by smarter, faster, and more sustainable solutions. As industries demand greater precision and efficiency, laserleikkaus technology will remain at the forefront of advanced manufacturing, with fiber lasers, digital integration, and green production practices leading the evolution. Companies investing in these trends now are well-positioned to capitalize on the expanding global demand for high-performance cutting solutions.

Yleisiä ansaita laserkäyttöön liittyvässä hankinnassa (laatu, IP)

Laserleikkaus on tarkka valmistusmenetelmä, jossa hankinnassa on tärkeää huomioida sekä tekniset että oikeudelliset näkökohdat. Alla on listattu yleisiä haasteita ja ansaita, joita kannattaa varautua erityisesti laadun ja immateriaalioikeuksien (IP) suhteen.

Laadunvarmistuksen puutteet

Monet hankinnassa tehdään virheitä laadun varmistamisessa. Yleinen ongelma on epätarkat tai puutteelliset tekniset piirustukset, jotka johtavat virheellisiin leikkaustuloksiin. Myös toleranssien puuttuminen tai liian löysät toleranssit voivat aiheuttaa komponenttien soveltumattomuutta lopputuotteeseen. Lisäksi materiaalin laadun ja puhdistuksen tarkistamatta jättäminen voi johtaa epätasaisiin leikkauksiin tai reunavaurioihin.

IP-oikeuksien huomioimatta jättäminen

Immaterialioikeudelliset riskit ovat usein huonosti tunnettuja hankinnassa. Esimerkiksi ulkoistettuun laserkäyttöön liittyy vaara, että toimittaja tallentaa asiakkaan CAD-tiedostot tai käyttää niitä myöhemmin ilman lupaa. Ilman asianmukaista luottamuksellisuussopimusta (NDA) tai IP-käytännön selkeyttä, yritys saattaa menettää hallinnan suunnitelmistaan. Tämä on erityisen riskialtista innovatiivisissa tuotekehityksissä.

Puutteellinen toimittajavalinta ja auditointi

Monet hankkijat valitsevat laserkäyttötoimittajia pelkästään hinnan perusteella, jättäen huomiotta laadunvarmistusjärjestelmät, sertifikaatit (esim. ISO 9001) tai laitteiston iän ja tarkan. Vanhentunut laitteisto voi tuottaa heikompaa leikkaustarkkuutta tai pinnanlaatua. Myös toimittajan kyky hallita eri materiaaleja (esim. ruostumaton teräs, alumiini) jätetään usein arvioimatta ennen hankintapäätöstä.

Kommunikoinnin puutteet

Epäselkeä viestintä toimittajan kanssa aiheuttaa usein lisäkustannuksia ja viivästyksiä. Esimerkiksi leikkausreunoihin liittyvät vaatimukset (esim. sulamareuna, läpivalo) jäävät usein määrittelemättä, mikä johtaa tulkintavirheisiin. Myös läpimurron tai jäännöspisteen sijainnin puuttuminen piirustuksista voi johtaa komponenttien hylkäämiseen.

Puutteellinen näytteenotto ja vastaanottotarkastus

Toimitusten vastaanotto vaiheessa ei aina tehdä riittäviä tarkastuksia. Tämä voi johtaa huonolaatuisten osien hyväksymiseen sarjatuotantoon. Ilman satunnaisia mittauksia tai tarkastuksia, toistuvat virheet jäävät havaitsematta liian pitkäksi aikaa, kasvattaen korjauskustannuksia.

Logistics & Compliance Guide for Laserleikkaus

Laserleikkaus, a provider of laser cutting and sheet metal processing services, must adhere to strict logistics and compliance standards to ensure operational efficiency, regulatory adherence, and customer satisfaction. This guide outlines key considerations across logistics management and regulatory compliance for the company’s operations.

Supply Chain and Material Logistics

Effective material handling is critical for maintaining production timelines and minimizing waste in laser cutting operations.

- Raw Material Sourcing: Ensure reliable supply of sheet metal (steel, stainless steel, aluminum) from certified suppliers meeting material grade specifications.

- Inventory Management: Implement just-in-time (JIT) inventory systems to reduce storage costs and optimize material turnover.

- Receiving & Inspection: All incoming materials must be inspected for quality, thickness, and dimensional accuracy upon delivery.

- Internal Material Flow: Use optimized warehouse layouts and automated handling systems (e.g., cranes, lifters) to move materials safely between storage, cutting, and post-processing areas.

Production & Work-in-Process Logistics

Streamlining workflow within the production facility enhances throughput and reduces lead times.

- Job Scheduling: Utilize production planning software to sequence laser cutting jobs based on material type, job complexity, and delivery deadlines.

- Batch Processing: Group similar jobs to minimize machine setup time and optimize laser cutter utilization.

- Traceability: Maintain digital logs for each work order, including material batch numbers, machine settings, and operator details for full traceability.

Finished Goods & Outbound Logistics

Timely and secure delivery of finished parts is essential for customer satisfaction.

- Packaging Standards: Use protective packaging (e.g., edge protectors, anti-corrosion wraps) to prevent damage during transit.

- Labeling: Clearly label packages with customer name, order number, part descriptions, and handling instructions.

- Shipping & Delivery: Partner with reliable freight carriers offering tracking, insurance, and on-time delivery. Offer options for express shipping when required.

- Export Documentation: For international shipments, prepare commercial invoices, packing lists, and export declarations compliant with destination country regulations.

Regulatory Compliance

Laserleikkaus must comply with Finnish and EU-wide regulations across environmental, safety, and industry standards.

- Workplace Safety (Työturvallisuus): Adhere to Finnish Occupational Safety and Health Act (Työturvallisuuslaki). Ensure proper training, use of PPE, and machine guarding for laser operations.

- Machinery Directive (2006/42/EY): Ensure all laser cutting machines meet CE marking requirements and are regularly maintained and inspected.

- Environmental Regulations: Comply with waste management laws (e.g., handling of metal scrap, cutting oils). Recycle metal waste through licensed recyclers and maintain records of disposal.

- REACH & RoHS Compliance: Confirm that materials and surface treatments comply with EU chemical regulations, especially for export to sensitive markets.

- Quality Management: Maintain ISO 9001 certification to ensure consistent quality in production and service delivery.

Documentation & Recordkeeping

Proper documentation supports compliance, quality assurance, and audit readiness.

- Production Records: Archive job tickets, inspection reports, and material certifications for minimum 5 years.

- Compliance Certificates: Keep updated copies of CE declarations, ISO certificates, and safety data sheets (SDS).

- Customer Documentation: Provide material test reports (MTRs), inspection certificates, and conformity statements upon request.

Continuous Improvement

Regularly review and enhance logistics and compliance practices.

- Conduct internal audits and risk assessments annually.

- Train employees on updated safety and compliance procedures.

- Monitor KPIs such as on-time delivery rate, material waste percentage, and incident reports.

By following this guide, Laserleikkaus can ensure efficient operations, regulatory compliance, and high standards of quality and safety across all stages of its logistics chain.

Conclusion for Sourcing Laser Cutting (Laserleikkaus):

Sourcing laser cutting (laserleikkaus) services requires a strategic approach that balances precision, cost-efficiency, material compatibility, and supplier reliability. After evaluating potential suppliers, key factors such as technological capabilities (CO2 vs. fiber lasers), accuracy, production capacity, lead times, and quality certifications must align with project requirements. Additionally, geographic proximity, communication efficiency, and scalability are essential for maintaining a smooth supply chain.

In conclusion, selecting the right laser cutting partner involves more than just competitive pricing — it demands a comprehensive assessment of technical expertise, quality control measures, and long-term collaboration potential. By prioritizing these aspects, businesses can ensure high-precision results, reduced waste, timely delivery, and overall manufacturing success. Effective sourcing of laser cutting services ultimately enhances product quality and operational efficiency in industries ranging from automotive and engineering to electronics and architecture.