The global laser marking machine market is experiencing robust growth, driven by rising demand for permanent, high-precision labeling across industries such as automotive, aerospace, electronics, and medical devices. According to Grand View Research, the market size was valued at USD 1.78 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 7.6% from 2024 to 2030. A key application area fueling this expansion is laser marking on aluminum—a lightweight, durable material widely used in high-performance sectors. Aluminum’s reflective properties and popularity in mass production have spurred the need for advanced laser systems capable of delivering clear, corrosion-resistant marks without compromising material integrity. As industries adopt Industry 4.0 standards and traceability requirements grow, fiber and UV lasers have become the preferred technologies for direct part marking on aluminum surfaces. With Germany, China, and the United States leading in technological innovation, a select group of manufacturers have emerged as leaders in producing high-efficiency, reliable laser marking solutions tailored for aluminum applications. This list highlights the top five manufacturers leveraging cutting-edge technology and strong market presence to dominate this growing niche.

Top 5 Laserbeschriftung Aluminium Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserbeschriftung

Website: fot.de

Key Highlights: Laserbeschriftung für Aluminium & Metalle – präzise, abriebfest & langlebig. Perfekt für Industrie, Maschinenbau & Feinmechanik!Missing: aluminium manufacturer…

#2 Laserbeschriftung Aluminium, Kunststoffschilder & mehr

Website: schilder-buhl.de

Key Highlights: Laserbeschriftung für Schilder: Kunststoffschilder, Edelstahl- und Aluminiumschilder sowie jegliche Materialien für die industrielle Kennzeichnung von BUHL….

#3 Die Laserbeschriftung von Aluminium

Website: laserax.com

Key Highlights: LASERBESCHRIFTEN UND -GRAVIEREN VON ALUMINIUM. Zur Kennzeichnung und Rückverfolgbarkeit erzeugen Glasfaser-Lasergravierer eine breite Palette von Grautönen ……

#4 Aluminium mit einem Laser beschriften

Website: axnum.ch

Key Highlights: Werkstücke aus Aluminium laserbeschriften: Schwarzgravur, Weissgravur, Tiefengravur von Aluminium für die Druckgussindustrie oder Mechanische Verarbeitung….

#5 Laserbeschriftung auf Metallen

Website: lasitlaser.de

Key Highlights: Die Lasermarkierung auf Metallen ist die beste Technologie zum Markieren von 2D-Codes, Logos und Schriften auf allen Arten von Legierungen….

Expert Sourcing Insights for Laserbeschriftung Aluminium

H2: 2026 Market Trends for Laser Marking on Aluminum

The global market for laser marking on aluminum is poised for robust growth and transformation by 2026, driven by converging technological advancements, stringent regulatory demands, and shifting industrial priorities. Key trends shaping this landscape include:

-

Increased Demand for Permanent, High-Contrast Marking: Regulatory requirements (e.g., UDI in medical, traceability in aerospace/automotive, anti-counterfeiting) and consumer demand for product authenticity are driving the need for permanent, tamper-proof, and highly legible marks on aluminum components. Laser marking excels here, offering superior durability compared to inks or labels. Expect a surge in demand for high-contrast black, white, or colored marks on anodized and bare aluminum, particularly using fiber and green lasers.

-

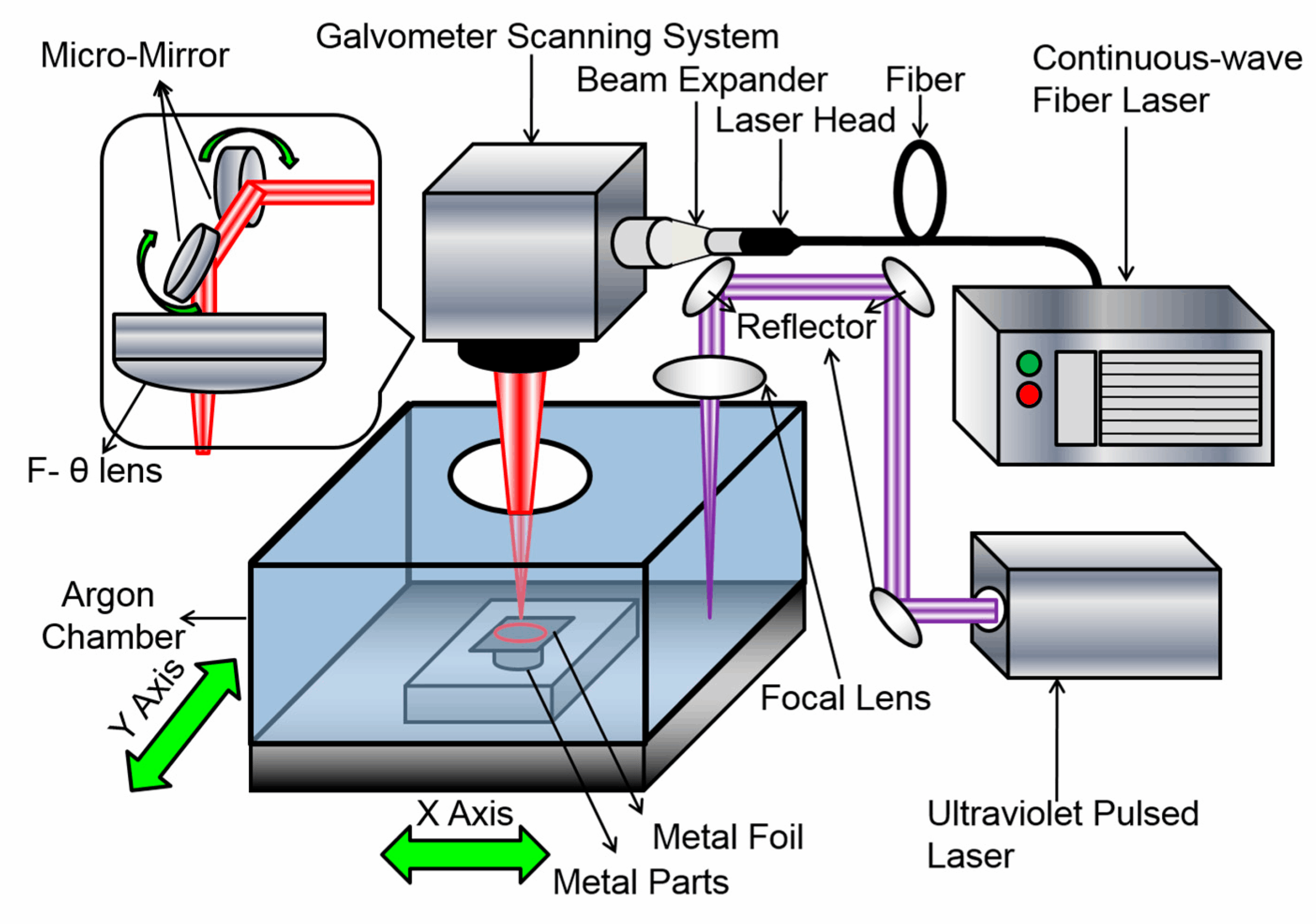

Dominance of Fiber Lasers with Green Laser Growth: Fiber lasers will remain the dominant technology due to their reliability, efficiency, and excellent performance on bare and anodized aluminum for standard engraving and annealing marks. However, green lasers (532 nm) will see significant growth, especially in high-precision applications. Their shorter wavelength is absorbed more efficiently by untreated aluminum and allows for finer details, higher contrast marks (especially dark/black marks without surface ablation), and minimal heat-affected zones, crucial for sensitive electronics and medical devices.

-

Rise of Ultrafast (Pico/Femtosecond) Lasers for Micro-Processing: The demand for miniaturization in electronics, medical implants, and high-value consumer goods will accelerate the adoption of ultrafast lasers. These lasers enable cold ablation, creating intricate micro-features, high-resolution barcodes (Data Matrix, QR), decorative finishes, and functional surface structures (e.g., hydrophobic surfaces) on aluminum with virtually no thermal damage or burr formation. While cost remains a barrier, prices are decreasing, making them more accessible for premium applications.

-

Integration with Smart Manufacturing (Industry 4.0): Laser marking systems will become deeply integrated into automated production lines and digital factory ecosystems. Key trends include:

- Seamless Data Flow: Direct integration with MES/ERP systems for real-time job scheduling, traceability data (serial numbers, batch codes, QR codes) generation, and automatic parameter setting based on part type.

- Increased Automation & Robotics: More systems will feature integrated robotics for handling complex part geometries and high-throughput applications, reducing labor costs and improving consistency.

- Enhanced Monitoring & Quality Control: Built-in vision systems for automatic mark verification (readability, placement, contrast) and process monitoring will become standard, ensuring 100% quality control and reducing scrap.

-

Focus on Sustainability and Process Efficiency: Environmental regulations and corporate sustainability goals will push demand for ink-free, chemical-free marking solutions. Laser marking aligns perfectly with this trend. Efforts will focus on:

- Reducing Energy Consumption: Development of more energy-efficient laser sources and system designs.

- Minimizing Waste: Elimination of consumables (inks, labels, solvents) and reduced scrap rates due to higher precision and reliability.

- Improved Fume Extraction: More efficient and integrated fume extraction systems to handle aluminum oxide particles, ensuring operator safety and compliance.

-

Expansion into New Applications and Industries:

- Electric Vehicles (EVs): Marking battery components (casing, busbars, connectors), motor parts, and power electronics with high durability requirements.

- Consumer Electronics: High-precision, aesthetically pleasing marking on smartphones, laptops, wearables, and appliances (logos, serial numbers, decorative elements).

- Renewable Energy: Marking components for solar panels and wind turbines for traceability and maintenance.

- Additive Manufacturing: Post-processing marking of complex, often fragile, 3D-printed aluminum parts.

-

Software Advancements for Ease of Use and Flexibility: User-friendly software with advanced graphic capabilities, automated job setup, cloud connectivity for remote monitoring/updates, and AI-powered features for optimizing mark parameters and predictive maintenance will lower the barrier to entry and improve operational efficiency.

Conclusion for 2026: The laser marking market for aluminum will be characterized by technological sophistication, deep integration, and a strong focus on traceability, quality, and sustainability. While fiber lasers will hold the mainstream position, the adoption of green and ultrafast lasers will grow significantly in high-value segments. Success will depend on offering integrated, smart, and efficient solutions that meet the evolving demands for precision, permanence, and seamless data flow within modern manufacturing environments.

Common Pitfalls When Sourcing Laser-Beschriftung Aluminium (Quality & Intellectual Property)

Sourcing laser-marked aluminum components, especially for industrial, automotive, or consumer electronics applications, involves several critical considerations. Overlooking key aspects related to quality and intellectual property (IP) can lead to costly delays, legal disputes, or compromised product performance. Below are common pitfalls to avoid:

Quality-Related Pitfalls

1. Inconsistent Laser Marking Durability

A frequent issue is the variability in the permanence and legibility of laser markings. Poor-quality laser engraving may fade, corrode, or become unreadable under environmental stress (e.g., UV exposure, moisture, or abrasion). This is often due to incorrect laser parameters (wavelength, power, speed) or unsuitable aluminum surface treatments (e.g., anodizing thickness or type).

2. Substandard Aluminum Material Specifications

Suppliers may use lower-grade aluminum alloys (e.g., non-6000 or 7000 series) that don’t meet mechanical or aesthetic requirements. This affects not only the laser marking result but also the component’s structural integrity and corrosion resistance.

3. Lack of Process Documentation and Traceability

Many suppliers fail to provide documentation for laser parameters, material certifications (e.g., RoHS, REACH), or batch traceability. This lack of transparency makes it difficult to ensure consistent quality or conduct root-cause analysis in case of failure.

4. Inadequate Surface Preparation

Surface contamination (oils, oxides) or inconsistent anodization layers can lead to uneven or blotchy laser marking. Without proper pre-treatment processes, the final appearance and readability of markings suffer significantly.

5. Absence of Quality Control Protocols

Some suppliers, particularly low-cost manufacturers, lack standardized inspection procedures for laser marking (e.g., contrast measurement, adhesion tests). This increases the risk of receiving non-compliant batches.

Intellectual Property (IP) Risks

1. Unauthorized Use or Replication of Marking Designs

Laser marking often includes logos, serial numbers, barcodes, or proprietary identifiers. Sharing design files (e.g., vector files or mark templates) with suppliers without proper legal agreements can lead to IP theft or unauthorized production of marked parts for third parties.

2. Weak or Missing IP Clauses in Contracts

Many procurement agreements fail to explicitly assign ownership of custom marking designs or prohibit the reuse of tooling/data. Without clear IP protection clauses, suppliers may claim partial rights or replicate designs for competitors.

3. Insecure Data Transfer and Storage

Transferring sensitive marking files via unsecured channels (e.g., email, unencrypted cloud) exposes companies to data leaks. Suppliers with poor IT security practices may inadvertently or deliberately expose IP.

4. Grey Market Production Using Stolen Marking Data

If a supplier duplicates laser marking programs or retains design data post-contract, they may produce counterfeit or grey-market parts bearing legitimate markings—damaging brand reputation and customer trust.

5. Lack of Audit Rights and Compliance Monitoring

Without contractual rights to audit the supplier’s production and data handling processes, buyers have limited visibility into how their IP is being used or protected.

Mitigation Strategies

- Specify detailed technical requirements (alloy type, surface finish, laser type—fiber vs. CO₂).

- Require material and process certifications (e.g., ISO 9001, IATF 16949).

- Conduct pre-production sample approvals with durability testing.

- Use NDAs and include strong IP ownership and data security clauses in supplier contracts.

- Limit access to design files and use watermarking or encrypted formats.

- Perform periodic supplier audits for quality and IP compliance.

Avoiding these pitfalls ensures reliable product performance, protects brand integrity, and minimizes legal and operational risks in the supply chain.

Logistics & Compliance Guide for Laserbeschriftung Aluminium

Overview

Laserbeschriftung (laser marking) of aluminium components is widely used across industries such as automotive, aerospace, medical devices, and consumer electronics for permanent identification, traceability, and branding. This guide outlines key logistics and compliance considerations for handling, transporting, and ensuring regulatory adherence of laser-marked aluminium parts.

Material and Process Characteristics

Laser marking on aluminium involves using high-intensity laser beams to create durable, high-contrast marks without removing material (in annealing or coloration methods) or with minimal ablation. The process is non-contact, precise, and environmentally friendly, but requires attention to surface condition, alloy type, and finishing.

Regulatory Compliance

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

- Ensure that any surface treatments or coatings applied to aluminium prior to laser marking (e.g., anodizing, primers) comply with REACH regulations.

- Verify that no restricted substances (e.g., heavy metals like cadmium, lead) are present in the aluminium alloy or associated processing aids.

- Maintain documentation (e.g., SDS, compliance declarations) for traceability.

RoHS (Restriction of Hazardous Substances)

- Confirm that laser-marked aluminium components intended for electronic or electrical applications meet RoHS directives (2011/65/EU and amendments).

- Ensure that marking processes do not introduce prohibited substances such as hexavalent chromium or polybrominated biphenyls (PBBs).

ISO Standards

- Adhere to ISO 9001 for quality management throughout the marking and logistics process.

- Follow ISO 10110-7 or ISO 13485 (if applicable for medical devices) for marking legibility and process validation.

- Implement process control and documentation per ISO/TS 16949 standards in automotive supply chains.

Traceability and Marking Standards

- Comply with industry-specific marking requirements:

- UDI (Unique Device Identification) for medical devices per FDA and EU MDR.

- AIAG or IATF 16949 standards for automotive part identification.

- MIL-STD-130 for U.S. defense applications.

- Ensure laser marks are permanent, readable, and resistant to environmental factors (e.g., UV exposure, chemicals, abrasion).

Logistics Handling & Packaging

Handling

- Use non-abrasive tools and gloves to prevent surface damage to marked areas.

- Avoid direct contact with contaminants (e.g., oils, salts) that could degrade mark readability or corrode aluminium.

- Segregate marked parts from unmarked or differently treated batches to prevent mix-ups.

Packaging

- Use anti-static, corrosion-inhibiting (VCI) packaging if transporting over long distances or in humid environments.

- Employ rigid containers or custom trays to prevent part-on-part contact and mechanical damage.

- Clearly label packaging with handling instructions (e.g., “Fragile – Laser Marked Surface,” “Do Not Stack”).

- Include humidity indicators if sensitive to moisture.

Storage Conditions

- Store in a dry, temperature-controlled environment (15–25°C, RH < 60%).

- Avoid exposure to direct sunlight or aggressive chemicals (e.g., chlorine, strong acids).

- Use first-in, first-out (FIFO) inventory practice to minimize aging effects.

Transportation

Domestic & International Shipping

- Comply with IATA, IMDG, or ADR regulations if shipping by air, sea, or road—even for non-hazardous goods, proper classification and documentation are required.

- Declare aluminium parts accurately (HS code typically 7616.99 or specific to finished goods).

- Laser-marked parts are generally non-hazardous, but confirm with local regulations.

Marking Visibility & Protection

- Ensure protective film (if used) does not interfere with barcodes, QR codes, or datamatrix readability during scanning.

- Remove protective film only at final assembly or point of use to preserve mark integrity.

Environmental & Safety Considerations

Laser Safety

- Operate laser marking equipment in compliance with IEC 60825-1 (laser safety standards).

- Use appropriate enclosures, interlocks, and PPE (protective eyewear) during marking operations.

Waste & Recycling

- Aluminium is highly recyclable. Collect scrap and offcuts for proper recycling.

- No hazardous waste is typically generated from the laser marking process itself (no inks or chemicals), making it environmentally favorable.

Documentation & Audit Readiness

- Maintain records of:

- Laser marking parameters (wavelength, power, speed).

- Material certifications (alloy type, surface finish).

- Process validation and quality control checks.

- Compliance certificates (RoHS, REACH, ISO).

- Be audit-ready for customer or regulatory inspections (e.g., notified bodies, OEMs).

Conclusion

Proper logistics and compliance management for laser-marked aluminium ensures product integrity, regulatory adherence, and customer satisfaction. By following this guide, manufacturers and distributors can streamline operations, reduce risk, and support sustainable, high-quality production practices.

Conclusion for Sourcing Laserbeschriftung (Laser Marking) on Aluminum

In conclusion, sourcing laser marking services for aluminum components requires a careful evaluation of technical capabilities, material compatibility, quality standards, and supplier reliability. Aluminum, while highly suitable for laser marking due to its reflective properties and durability, demands appropriate laser technology—typically fiber or UV lasers—to achieve high-contrast, permanent, and precise markings such as serial numbers, barcodes, logos, or data matrix codes.

Key considerations when selecting a supplier include their experience with aluminum alloys, marking speed and precision, compliance with industry standards (e.g., aerospace, automotive, medical), and the ability to integrate marking into existing production workflows. Additionally, cost-effectiveness, scalability, and post-marking inspection processes should be assessed.

Ultimately, partnering with a qualified and technologically equipped laser marking service provider ensures legible, durable, and tamper-proof identification of aluminum parts, enhancing traceability, quality control, and brand integrity across industrial applications.