The global laser cleaning equipment market, which encompasses precision tools used in applications such as wood restoration, was valued at USD 678.2 million in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 8.4% from 2024 to 2030, according to Grand View Research. Increasing demand for non-abrasive, eco-friendly restoration methods in heritage conservation and the woodworking industry is driving adoption of laser-based solutions. As sustainability and precision become paramount, laser wood restoration tools have emerged as a preferred alternative to traditional sanding or chemical stripping. This growth trajectory reflects not only technological advancement but also a shift in industry standards toward minimally invasive preservation techniques. In this evolving landscape, nine key manufacturers are leading innovation, combining engineering excellence with data-backed performance metrics to meet rising global demand.

Top 9 Laser Wood Restoration Tool Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: PULSAR Laser is a manufacturer of professional laser cleaning machines, developed and engineered for industrial maintenance, manufacturing, restoration and ……

#2 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#3 Laser Cleaning Machines

Website: acctekgroup.com

Key Highlights: The laser cleaning machine is an advanced industrial tool that removes rust, paint, oxides, grease, and other surface contaminants using a focused laser beam….

#4 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#5 Laser Revive

Website: laserrevive.com

Key Highlights: Experience cutting-edge laser cleaning and restoration solutions tailored to meet your needs with unmatched accuracy and efficiency….

#6 Laser Wood Cleaning & Restoration

Website: advancedlaserrestoration.com

Key Highlights: Advanced Laser Restoration offers eco-friendly laser wood cleaning for cabinets, floors, beams, and decks. Remove paint, stain, mold, soot, ……

#7 Clean Laser Technologies

Website: cleanlasertechnologies.com

Key Highlights: Discover advanced laser cleaning machines and rust removal systems trusted by industries across the USA. Eco-friendly, precise, and OSHA-compliant surface ……

#8 Laser Cleaning Machine

Website: lmelaser.com

Key Highlights: The pulse laser cleaning machine have 100w, 200w, 300w, 500w, 1000w, Mainly used to rust, thin paint layer, wood, oil removal, It will no impact on the surface….

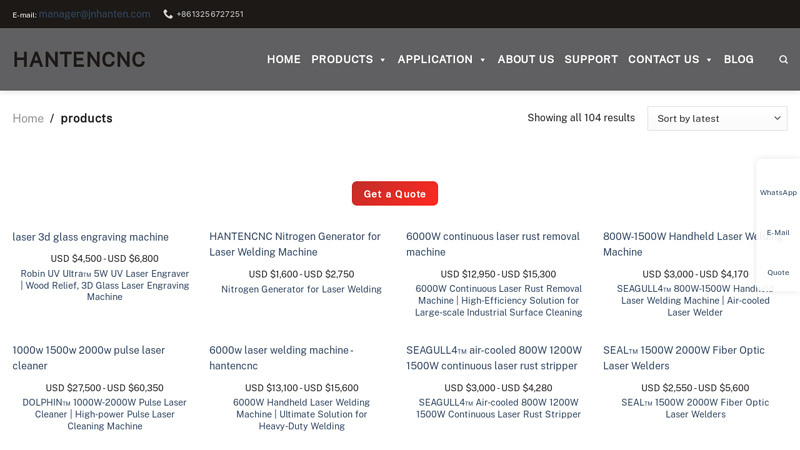

#9 Full List of Laser Machines

Website: hantencnc.com

Key Highlights: We are a laser machine manufacturer. Our products include laser cleaning machines, laser welding machines and laser marking machines. As a laser machine ……

Expert Sourcing Insights for Laser Wood Restoration Tool

2026 Market Trends for Laser Wood Restoration Tool

Rising Demand for Non-Invasive Restoration Techniques

The global market for laser wood restoration tools is projected to experience significant growth by 2026, driven by increasing demand for non-invasive, eco-friendly restoration methods. As cultural heritage preservation gains priority and consumers become more environmentally conscious, traditional abrasive techniques such as sanding and chemical stripping are being replaced by precision laser technologies. These tools offer controlled material removal without damaging underlying wood structures, making them ideal for historic buildings, antique furniture, and fine art restoration.

Technological Advancements Driving Efficiency and Accessibility

By 2026, advancements in portable laser systems, automated scanning, and AI-driven surface analysis are expected to enhance the efficiency and accuracy of wood restoration. Manufacturers are focusing on compact, user-friendly devices with adjustable wavelengths and power settings, enabling precise treatment across various wood types and finishes. Integration with digital imaging allows technicians to map decay or contamination areas and apply targeted laser pulses, minimizing human error and improving restoration outcomes.

Expansion in Commercial and Residential Applications

While initially limited to museums and conservation labs, laser wood restoration tools are now entering commercial and residential markets. Restoration contractors, flooring specialists, and preservation firms are adopting these tools for large-scale projects, including heritage hotels, heritage-listed homes, and commercial interiors. The scalability of newer models supports broader applications, from restoring ornate wooden facades to rejuvenating hardwood floors without full replacement—offering cost and time savings.

Regulatory and Environmental Support

Environmental regulations restricting the use of chemical strippers and sandblasting in urban and heritage zones are accelerating the shift toward laser-based solutions. Governments and preservation councils in Europe, North America, and parts of Asia are promoting sustainable restoration technologies, with some offering incentives for adopting green tools. This regulatory tailwind is expected to boost market penetration of laser wood restoration systems through 2026.

Competitive Landscape and Market Growth Projections

The market is witnessing increased competition among specialized laser technology firms and established industrial tool manufacturers. Key players are investing in R&D and strategic partnerships with conservation institutions to refine applications and expand product lines. According to industry forecasts, the global laser restoration equipment market—including wood, stone, and masonry—is expected to grow at a CAGR of 8–10% from 2022 to 2026, with wood-specific tools capturing a growing share due to rising awareness and affordability.

In conclusion, the 2026 outlook for laser wood restoration tools is highly positive, marked by technological innovation, expanding applications, and strong environmental and regulatory support—positioning the sector for sustained growth and mainstream adoption.

Common Pitfalls When Sourcing a Laser Wood Restoration Tool (Quality, IP)

When sourcing a laser wood restoration tool, overlooking critical aspects related to quality and intellectual property (IP) can lead to performance issues, legal risks, and financial losses. Being aware of these common pitfalls helps ensure a reliable and compliant acquisition.

Poor Build Quality and Inconsistent Performance

Many low-cost or untested laser tools suffer from subpar construction, including inadequate cooling systems, weak housings, and unreliable components. This often results in inconsistent laser output, overheating, or premature failure—especially under prolonged use. Tools lacking precision optics may deliver uneven restoration results, damaging delicate wood surfaces instead of rejuvenating them.

Lack of Certification and Safety Compliance

A frequent oversight is sourcing tools without proper safety certifications (e.g., FDA, CE, or IEC standards). Non-compliant lasers may emit unsafe radiation levels or lack essential safety features like emergency shutoffs and protective enclosures. Using uncertified equipment increases liability risks and may violate workplace safety regulations.

Inadequate After-Sales Support and Service

Some suppliers, particularly smaller or offshore manufacturers, offer limited technical support, training, or spare parts availability. When a tool malfunctions, extended downtime can disrupt operations. Ensure the vendor provides comprehensive documentation, accessible customer service, and maintenance programs before finalizing a purchase.

Risk of Intellectual Property Infringement

Sourcing laser tools from unknown or unverified manufacturers raises the risk of IP violations. Some low-cost tools replicate patented laser control systems, software algorithms, or mechanical designs without authorization. Purchasing such products—even unknowingly—can expose your business to legal action, product seizures, or reputational damage.

Proprietary Software and Lock-In

Many laser restoration tools rely on proprietary software for control and calibration. Vendors may restrict access to code, prevent third-party integration, or require costly licensing fees. This can limit customization, hinder long-term usability, and create dependency on a single supplier.

Insufficient Documentation and IP Transparency

Suppliers may fail to provide clear documentation on component origins, software licensing, or patent disclaimers. Without this transparency, verifying the tool’s legal standing and technical reliability becomes difficult, increasing the risk of using counterfeit or infringing technology.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify certifications, assess build quality through demos or references, audit the supplier’s IP compliance, and ensure long-term support is available. Choosing a reputable supplier with transparent practices safeguards both the performance and legality of your laser wood restoration investment.

Logistics & Compliance Guide for Laser Wood Restoration Tool

This guide outlines key logistics and compliance considerations for the distribution, import/export, and safe use of a Laser Wood Restoration Tool. Adherence to these guidelines ensures regulatory compliance, operational efficiency, and user safety.

Product Classification & Regulatory Overview

Determine the correct classification of the laser wood restoration tool under international and national regulatory frameworks. The product may be classified under:

- Harmonized System (HS) Code: Typically 8515.21 (Laser welding, cutting or other working machines) or 8465.95 (Machines for working wood) depending on primary function.

- Laser Product Class: According to IEC 60825-1 and FDA 21 CFR 1040.10, classify the laser (e.g., Class 1, 3R, or 4). Most industrial laser restoration tools are Class 4 and require strict controls.

- Regulatory Agencies: Compliance may be required with FDA (U.S.), Health Canada, EU Notified Bodies (under Machinery Directive 2006/42/EC and EMF Directive 2014/30/EU), and other regional authorities.

Import/Export Documentation & Requirements

Ensure all necessary documentation is prepared and retained for international shipments:

- Commercial Invoice: Must include product description, HS code, value, country of origin, and end-use statement.

- Packing List: Details weight, dimensions, and packaging materials.

- Certificate of Origin: Required by many countries for tariff assessment.

- Laser Safety Certification: Include IEC 60825 or FDA compliance documentation.

- Export Licenses: Verify if the laser power output requires export controls (e.g., under U.S. Department of Commerce, Bureau of Industry and Security – EAR).

- Import Permits: Some countries require import licenses for laser devices (e.g., India, Brazil, Saudi Arabia).

Shipping & Transportation Logistics

Plan transportation to ensure product integrity and compliance with hazardous materials regulations:

- Packaging: Use robust, shock-resistant packaging with internal cushioning. Include moisture barriers if shipping to humid climates.

- Labeling: Clearly label with:

- “Fragile”

- “This Side Up”

- Laser warning labels (e.g., “Laser Radiation – Avoid Direct Exposure”)

- Proper shipping name and UN number if applicable (e.g., for lithium batteries in portable units)

- Carrier Selection: Use carriers experienced in handling precision equipment and laser products. Confirm adherence to IATA (air) or IMDG (sea) regulations if batteries or controlled components are included.

- Insurance: Obtain comprehensive cargo insurance covering loss, damage, and customs delays.

Compliance with Safety & Environmental Standards

Ensure the product meets all regional safety and environmental directives:

- Electrical Safety: Comply with standards such as UL 61010 (North America), IEC 61010 (International), and EN 61010 (Europe).

- EMC (Electromagnetic Compatibility): Meet EN 55011 (Europe) or FCC Part 15 (U.S.) to avoid interference with other devices.

- RoHS & REACH (EU): Confirm absence of restricted substances (lead, cadmium, phthalates, etc.).

- WEEE Compliance: Provide information on proper end-of-life disposal and recycling options in applicable markets.

- Laser Safety Features: Include key interlocks, emergency stop, beam shielding, and user-accessible safety labels in local languages.

User Training & Documentation

Provide comprehensive documentation to ensure safe and compliant operation:

- User Manual: Include:

- Safety warnings and laser hazard information

- Step-by-step setup and operation

- Maintenance procedures

- Troubleshooting guide

- Compliance statements (FCC, CE, ICES, etc.)

- Training Programs: Offer on-site or virtual training for professional users, emphasizing laser safety and PPE requirements.

- PPE Requirements: Specify necessary personal protective equipment (e.g., laser safety goggles with appropriate optical density, gloves, respiratory protection if fumes are generated).

Market-Specific Compliance Requirements

Adapt logistics and compliance to target markets:

- United States: FDA laser product reporting (CDRH), FCC certification, UL listing.

- European Union: CE marking under Machinery Directive and EMC Directive, notified body involvement if required.

- Canada: ICES-001 EMC compliance, Health Canada laser safety registration.

- Australia/NZ: RCM marking, compliance with AS/NZS IEC 60825.

- China: CCC certification may apply depending on voltage and function.

After-Sales & Service Logistics

Establish support infrastructure to maintain compliance post-sale:

- Warranty & Repairs: Define service channels, spare parts availability, and return logistics.

- Field Safety Notices: Procedures for issuing updates or recalls if compliance or safety issues arise.

- Software Updates: Secure and documented update process, especially if firmware affects laser control or safety interlocks.

Recordkeeping & Audits

Maintain detailed records for regulatory audits and traceability:

- Product test reports (laser, electrical, EMC)

- Certificates of conformity

- Shipping and customs documentation

- Customer delivery and training records

- Post-market surveillance logs

By following this guide, distributors, importers, and manufacturers can ensure the safe, legal, and efficient global deployment of Laser Wood Restoration Tools. Regular review of evolving regulations is recommended to maintain compliance.

Conclusion: Sourcing a Laser Wood Restoration Tool

After a comprehensive evaluation of available laser wood restoration tools, it is evident that investing in such advanced technology offers significant benefits for precision, efficiency, and preservation in wood restoration projects. Laser systems provide a non-abrasive, highly controlled method for removing contaminants, old finishes, and surface damage without compromising the integrity of historic or delicate wooden surfaces.

Sourcing the right tool requires careful consideration of factors such as laser power, wavelength, portability, safety features, support, and cost. While the initial investment may be substantial, the long-term advantages—such as reduced labor time, minimal material waste, and superior restoration outcomes—justify the expense, especially for professional conservators, restorers, or specialized woodworking businesses.

Ultimately, partnering with reputable manufacturers or suppliers offering technical support, training, and reliable after-sales service is crucial to maximizing the tool’s performance and longevity. As laser technology continues to advance, early adoption positions restoration professionals at the forefront of innovation, ensuring higher quality results and a sustainable approach to preserving wooden artifacts and structures.

Therefore, sourcing a laser wood restoration tool is a strategic and forward-thinking decision that enhances craftsmanship, efficiency, and conservation standards in wood restoration practices.