The global laser cleaning market is experiencing robust growth, driven by increasing demand for non-abrasive, eco-friendly surface treatment solutions across industries such as automotive, aerospace, and heritage conservation. According to Grand View Research, the global laser cleaning market size was valued at USD 882.3 million in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 18.6% from 2023 to 2030. This surge is fueled by stricter environmental regulations and the growing adoption of laser technology as a sustainable alternative to chemical and mechanical cleaning methods. Within this expanding landscape, laser wood cleaning has emerged as a niche yet rapidly growing application—particularly in restoration, furniture manufacturing, and architectural woodworking—where precision and material preservation are paramount. As industries pivot toward automation and clean technology, manufacturers specializing in laser wood cleaning systems are positioned at the forefront of innovation. Below, we spotlight the top nine manufacturers leading this transformation through advanced engineering, reliability, and scalable solutions.

Top 9 Laser Wood Cleaning Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: With over 35 years of expertise in surface treatment and more than 450 systems installed worldwide, P-Laser is at the forefront of industrial laser cleaning ……

#3 Laser cleaning

Website: narran.cz

Key Highlights: We can design and integrate a laser cleaning system into production, build a robotic workstation or supply a mobile laser for a wide range of applications….

#4 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#5 Laser cleaning wood

Website: pulsar-laser.com

Key Highlights: A laser cleaner is a device that uses high-intensity light to remove dirt, grime and stains from wood surfaces. It is a non-abrasive method of cleaning….

#6 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#7 Laser Cleaning Machines

Website: wattsan.com

Key Highlights: Laser cleaning uses powerful laser beams to remove contaminants such as rust, paint, dirt or oxidation from a variety of surfaces….

#8 Laser cleaning

Website: p-laserusa.com

Key Highlights: Our laser machines are mainly used to remove the following contaminants: Rust – Paint – Coatings – Release Agents – Grease, Oils – Soot – Rubber- Organic ……

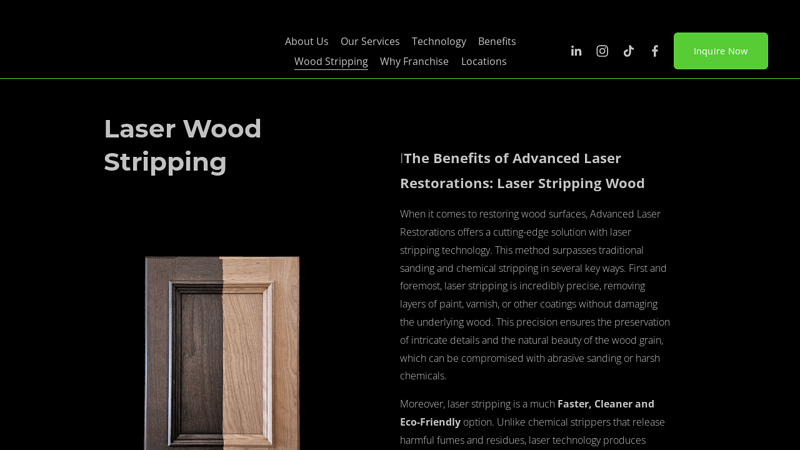

#9 Laser Wood Cleaning & Restoration

Website: advancedlaserrestoration.com

Key Highlights: Advanced Laser Restoration offers eco-friendly laser wood cleaning for cabinets, floors, beams, and decks. Remove paint, stain, mold, soot, ……

Expert Sourcing Insights for Laser Wood Cleaning

H2: Projected Market Trends for Laser Wood Cleaning in 2026

By 2026, the global laser wood cleaning market is poised for significant transformation, driven by technological advancements, shifting sustainability priorities, and expanding industrial applications. Key trends shaping this market include:

1. Accelerated Adoption Driven by Eco-Regulations:

Stringent environmental regulations worldwide, particularly in North America and Europe, are pushing industries away from chemical-based and abrasive cleaning methods. Laser wood cleaning offers a dry, chemical-free, and waste-minimizing alternative, making it increasingly attractive for heritage restoration, furniture manufacturing, and outdoor timber maintenance. Compliance with regulations like REACH and EPA guidelines will be a major market driver.

2. Technological Advancements Enhancing Efficiency and Accessibility:

Ongoing improvements in fiber laser technology—such as higher power outputs (up to 2kW+), improved beam quality, and intelligent pulse control—are making systems faster, more precise, and capable of handling larger surfaces. Integration with AI-powered vision systems and robotics is enabling automated, real-time defect detection and adaptive cleaning, reducing labor costs and increasing consistency. These innovations are lowering the total cost of ownership and making laser solutions viable for mid-sized enterprises.

3. Expansion into New Application Verticals:

While restoration and architectural woodworking remain core applications, the market is diversifying. Growth is expected in sectors such as:

– Marine and shipbuilding: For cleaning wooden decks and historic vessels.

– Renewable energy: Maintenance of wooden components in wind turbine structures and biomass facilities.

– Urban infrastructure: Graffiti removal from wooden public structures and bridges.

– Custom fabrication: High-end woodworking studios adopting lasers for precision surface prep and detailing.

4. Rising Demand in Emerging Economies:

Countries in Asia-Pacific (e.g., China, India, South Korea) and the Middle East are investing heavily in urban development and cultural preservation. Government-backed heritage projects and growing manufacturing sectors are creating new opportunities for laser cleaning adoption. Local manufacturing of laser systems is also expected to reduce costs and improve market penetration.

5. Focus on Portability and User-Friendliness:

To meet field-service demands, manufacturers are developing lighter, more ergonomic handheld laser systems with intuitive interfaces and enhanced safety features. This shift supports on-site restoration work, particularly in hard-to-reach areas, and reduces the need for dismantling wooden structures.

6. Integration with Industry 4.0 and Digital Workflows:

Laser wood cleaning systems are increasingly being incorporated into digital manufacturing ecosystems. Connectivity via IoT enables remote monitoring, predictive maintenance, and data logging for quality assurance—critical for compliance in regulated industries.

In summary, the 2026 laser wood cleaning market will be defined by sustainability-driven demand, smarter and more efficient technology, and broader industrial integration, positioning it as a key solution in the future of non-destructive surface treatment.

Common Pitfalls in Sourcing Laser Wood Cleaning Systems (Quality, IP)

Sourcing laser wood cleaning systems presents unique challenges, especially concerning quality assurance and intellectual property (IP) protection. Failing to address these can result in subpar performance, legal risks, and long-term operational setbacks. Below are key pitfalls to avoid:

Inadequate Quality Verification

Many suppliers, particularly in competitive or emerging markets, may exaggerate performance claims. Without rigorous due diligence, buyers risk acquiring systems that fail to meet cleaning efficiency, speed, or wood preservation standards. Common quality issues include inconsistent ablation, surface charring, or damage to delicate wood grains. Always request third-party test reports, conduct on-site demonstrations with your specific wood types, and verify component quality (e.g., laser source brand, cooling systems, motion control).

Overlooking Intellectual Property Risks

Laser cleaning technology often incorporates proprietary software, optical configurations, and control algorithms. Sourcing from manufacturers with unclear IP ownership—such as those using copied designs or unlicensed software—exposes buyers to legal liability, import restrictions, or forced system shutdowns. Ensure suppliers provide documentation proving legitimate IP rights, including patents, software licenses, and design registrations. Avoid vendors unwilling to sign IP indemnification clauses in contracts.

Selecting Under-Specified Systems

Not all laser systems are suitable for wood cleaning, which requires precise control to remove contaminants without damaging the substrate. Buyers may inadvertently choose systems optimized for metal cleaning, which use higher peak powers and inappropriate wavelengths. This can degrade wood integrity and finish quality. Confirm that the laser wavelength (commonly fiber lasers around 1064 nm) and pulse parameters are specifically tuned for organic materials like wood.

Neglecting After-Sales Support and Spare Parts

A high-quality laser system is only as reliable as its support network. Sourcing from distant or unknown suppliers may lead to long downtimes due to delayed technical assistance or unavailable spare parts. Evaluate the supplier’s service infrastructure, warranty terms, and availability of local technicians before purchase. Lack of adequate support compromises system uptime and return on investment.

Assuming Compliance Without Verification

Laser systems must comply with international safety standards (e.g., IEC 60825) and regional regulations (e.g., FDA, CE). Non-compliant systems pose safety risks and may be barred from operation. Verify that the supplier provides full compliance documentation and that safety features—such as emergency stops, interlocks, and fume extraction integration—are properly implemented.

By proactively addressing these pitfalls, businesses can ensure they source reliable, high-performing laser wood cleaning systems that align with both quality expectations and IP integrity.

Logistics & Compliance Guide for Laser Wood Cleaning

Equipment Handling and Transportation

Ensure laser wood cleaning systems are securely packaged and protected during shipping to prevent damage to sensitive optical components. Use shock-absorbing materials and climate-controlled transport where necessary. Follow manufacturer guidelines for orientation during transit—many units must remain upright. Verify that all power and cooling requirements match the destination facility’s capabilities prior to delivery. Conduct a thorough inspection upon receipt, documenting any shipping damage for insurance claims.

Site Installation and Setup Requirements

Install laser wood cleaning systems in a clean, dry, and temperature-regulated environment free from dust and vibrations. Provide stable power supply with surge protection, and ensure adequate ventilation or fume extraction systems are in place. Designate a controlled access area with appropriate warning signs and interlocks. Perform calibration and safety checks as specified by the manufacturer before initial operation. Maintain clear access to emergency shut-offs and service panels.

Operator Training and Safety Protocols

Only trained and authorized personnel should operate laser wood cleaning equipment. Mandatory training must cover laser safety (including ANSI Z136.1 standards), proper use of personal protective equipment (PPE) such as laser safety goggles with appropriate optical density, fire prevention, and emergency procedures. Implement lockout/tagout (LOTO) procedures for maintenance. Conduct regular refresher training and maintain training records for compliance audits.

Regulatory Compliance and Standards

Ensure compliance with relevant regulations including OSHA (Occupational Safety and Health Administration) standards for workplace safety, FDA/CDRH regulations for laser products (21 CFR 1040.10 and 1040.11), and local environmental protection codes. Classify the laser system according to IEC 60825-1 and affix required warning labels. Maintain a Laser Safety Officer (LSO) if required by jurisdiction or workplace scale. Document all safety measures, maintenance logs, and incident reports.

Waste Management and Environmental Considerations

Laser wood cleaning generates particulate matter and potentially hazardous fumes (e.g., from treated or painted wood). Use certified fume extraction systems with HEPA and/or activated carbon filtration. Dispose of collected debris and filters as hazardous or non-hazardous waste in accordance with EPA and local regulations. Test wood substrates beforehand to identify presence of lead-based paint, pesticides, or flame retardants—these may require special handling under RCRA (Resource Conservation and Recovery Act).

Documentation and Recordkeeping

Maintain comprehensive records including equipment manuals, safety data sheets (SDS) for any auxiliary materials, maintenance logs, operator certifications, and compliance documentation. Keep a laser operation log detailing usage, settings, and any anomalies. Store records securely and ensure accessibility for inspections by regulatory authorities or internal audits.

International Shipping and Import Compliance

When shipping laser wood cleaning equipment across borders, comply with International Air Transport Association (IATA) and International Maritime Organization (IMO) regulations. Declare laser systems appropriately under Harmonized System (HS) codes—commonly 8515.21 or 8465.99, depending on configuration. Verify destination country’s import requirements, including certification (e.g., CE, UKCA, or CCC) and potential restrictions on high-powered lasers. Include technical specifications and safety certifications in shipping documentation.

Conclusion for Sourcing Laser Wood Cleaning Equipment

Sourcing laser wood cleaning technology represents a forward-thinking investment in precision, sustainability, and efficiency for wood restoration and conservation. Compared to traditional methods like sandblasting or chemical cleaning, laser cleaning offers non-abrasive, eco-friendly, and highly controllable removal of contaminants, coatings, and weathered layers—preserving the integrity and texture of the underlying wood. When sourcing such equipment, it is essential to evaluate key factors including laser power, wavelength suitability for organic materials, ease of integration into existing workflows, safety features, and after-sales support.

Suppliers should be assessed not only on product specifications but also on their industry experience, technical training offerings, and service reliability. While the initial investment may be higher than conventional tools, the long-term benefits—reduced waste, minimal consumables, repeatable results, and compliance with environmental regulations—justify the cost for restoration businesses, heritage conservation projects, and high-end woodworking operations.

In conclusion, sourcing laser wood cleaning systems offers a strategic advantage in quality, precision, and sustainability. With proper due diligence in supplier selection and operator training, organizations can elevate their wood treatment processes to meet the demands of modern craftsmanship and environmental responsibility.