The global laser welding market is experiencing robust expansion, driven by increasing demand for high-precision, high-speed joining technologies in industries such as automotive, aerospace, and medical devices. According to a 2023 report by Mordor Intelligence, the laser welding market was valued at USD 2.7 billion in 2022 and is projected to grow at a CAGR of over 8.3% from 2023 to 2028. This growth is fueled by advancements in fiber laser technology and rising adoption in stainless steel fabrication, where weld integrity, corrosion resistance, and minimal heat distortion are critical. Similarly, Grand View Research highlights that the demand for laser welding in metal fabrication—particularly for stainless steel—is escalating due to its superior repeatability and automation compatibility in high-volume manufacturing environments. As competition intensifies, a select group of manufacturers has emerged as leaders, combining cutting-edge laser systems with material expertise to deliver consistent, high-quality welds. The following list highlights the top 10 laser welding stainless steel manufacturers leading this technological transformation, evaluated based on innovation, global footprint, technical capabilities, and market impact.

Top 10 Laser Welding Stainless Steel Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 United Industries, Inc.

Website: unitedindustries.com

Key Highlights: We use a fourth generation laser process that has set the standard for laser welded stainless steel tubing. Laser welds are superior to TIG welds in the ……

#2 Laser Hybrid Welding of Stainless Steel

Website: stainless-structurals.com

Key Highlights: Laser hybrid welding is a new state-of-the-art technology which is best to create special profiles made of duplex stainless steel….

#3 Steel Welding

Website: cailabs.com

Key Highlights: Steel laser welding is a welding process that uses a concentrated laser beam to melt and fuse steel parts such as bipolar plates….

#4 Laser Machines

Website: lclasers.com

Key Highlights: We offer comprehensive solutions in cleaning, welding and laser marking. At LC Lasers we seek laser solutions for our customers and distributors….

#5 Laser-welded steel: Stainless steel & Duplex sections

Website: montanstahl.com

Key Highlights: Laser welded sections are produced at Montanstahl by welding individual material strips to make one complete section, by means of powerful lasers….

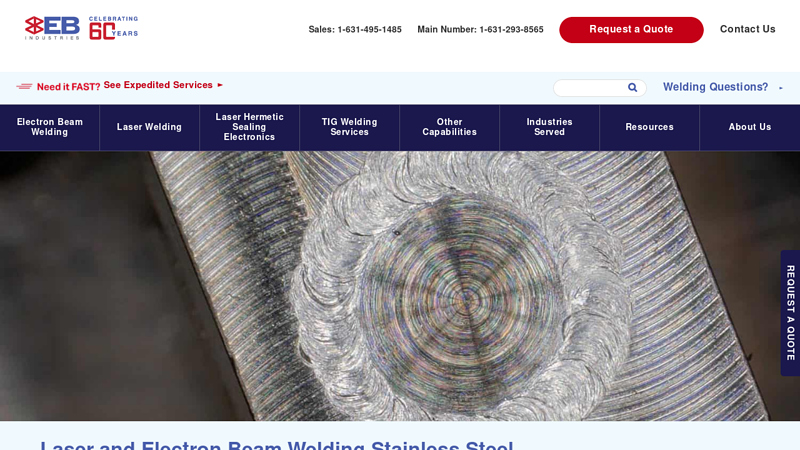

#6 EB and Laser Welding Stainless Steel

Website: ebindustries.com

Key Highlights: Stainless steel is electron beam and laser beam weldable. Certified AS9100D services. Fast quote and and turn-around. Automated, semi-automated, CAD/CAM ……

#7 Laser Welding Solutions

Website: laserweldingsolutions.com

Key Highlights: Laser Welding Solutions provides state-of-the-art surface technologies and 3D printing to assist in the product improvement efforts of our goal-driven ……

#8 Laser Welding Machine

Website: varisigns.com

Key Highlights: Varisigns laser welding machine is perfect for channel letter welding and sheet metal fabrications in high accuracy and efficiency!…

#9 Laser Welding Services

Website: accumet.com

Key Highlights: Accumet provides expert laser welding services for steel, aluminum, and stainless steel, ensuring strong, high-precision welds for various industries….

#10 Laser Welding Stainless Steel

Website: lasermaxwave.com

Key Highlights: Laser welding produces cleaner, stronger stainless-steel welds with minimal heat, distortion, and spatter. Traditional welding generates more ……

Expert Sourcing Insights for Laser Welding Stainless Steel

H2: 2026 Market Trends in Laser Welding of Stainless Steel

The market for laser welding stainless steel is poised for significant evolution by 2026, driven by technological advancements, shifting industrial demands, and global economic factors. Key trends shaping this landscape include:

1. Dominance of High-Power Fiber Lasers & Process Optimization:

* Power & Efficiency: High-power (6 kW – 20+ kW) single-mode and multi-mode fiber lasers will become the standard, enabling faster welding speeds, deeper penetration, and reduced cycle times, particularly for thick-section stainless steel (common in industrial equipment, energy, and shipbuilding). This directly translates to lower cost-per-meter.

* Process Stability & Quality: Advanced beam shaping (e.g., wobbling, oscillation, multi-beam optics) and real-time process monitoring (using integrated sensors for melt pool, seam tracking, plasma monitoring) will be increasingly adopted. This ensures consistent, high-quality, spatter-free welds with minimal distortion and post-processing, crucial for demanding applications in automotive and medical devices.

* Hybrid & Adaptive Processes: Integration of laser welding with other technologies (e.g., laser-MIG hybrid) will grow, combining the speed/depth of laser with the gap-bridging tolerance of arc welding, offering greater flexibility for stainless steel fabrication.

2. Expansion into New Applications & Industries:

* Electrification & Energy: The surge in electric vehicles (EVs) and battery manufacturing will drive demand for high-speed, precise laser welding of stainless steel battery enclosures, busbars, and cooling plates. Similarly, renewable energy sectors (solar thermal, hydrogen production/storage) require reliable, corrosion-resistant stainless steel welds for reactors, piping, and tanks.

* Medical Device Manufacturing: Stringent requirements for biocompatibility, hermeticity, and minimal heat-affected zones (HAZ) will solidify laser welding as the preferred method for complex stainless steel implants (stents, surgical tools) and fluidic components.

* Consumer & Appliance: Increased focus on design, durability, and efficiency will push laser welding adoption for high-end stainless steel appliances (refrigerators, cooktops) and consumer electronics enclosures, enabling seamless joints and reduced material waste.

3. Automation, Digitalization, and Smart Manufacturing Integration:

* Robotic & Cobotic Systems: Laser welding cells will be increasingly integrated into fully automated robotic lines, especially in automotive and appliance manufacturing. Collaborative robots (cobots) will facilitate safer integration into smaller workshops and for complex 3D part manipulation.

* Digital Twins & AI: Simulation software for weld parameter optimization and digital twins of welding processes will become more sophisticated. AI-driven analytics will leverage real-time monitoring data to predict defects, optimize parameters autonomously, and enable predictive maintenance, maximizing uptime and quality.

* Industry 4.0 Connectivity: Seamless data exchange (via OPC UA, MTConnect) between laser sources, motion systems, robots, and factory MES/ERP systems will be essential for traceability, quality control, and overall production efficiency.

4. Sustainability and Material Efficiency Focus:

* Reduced Energy Consumption: Fiber lasers offer significantly higher wall-plug efficiency (often >40%) compared to older CO2 lasers (<10%), making them the environmentally and economically preferred choice.

* Minimal Waste: The precision of laser welding minimizes heat input, reduces distortion, and often eliminates the need for post-weld grinding or rework, leading to substantial material and energy savings in stainless steel fabrication.

* Recyclability: The clean, oxide-free nature of laser welds (especially with proper shielding) enhances the recyclability of stainless steel products at end-of-life.

5. Regional Market Dynamics & Competitive Landscape:

* Asia-Pacific Leadership: China, Japan, and South Korea will remain dominant manufacturing hubs, driving significant demand for laser welding systems, particularly in EVs and electronics. India will see accelerated growth.

* North America & Europe: Strong growth driven by automotive (especially EVs), energy transition projects, and high-value industrial manufacturing. Emphasis on automation and quality will sustain demand for advanced laser solutions.

* Consolidation & Specialization: The market will likely see further consolidation among laser source and system integrators. Niche players focusing on specific applications (e.g., medical, battery welding) or advanced process control will thrive.

Conclusion:

By 2026, laser welding of stainless steel will be characterized by higher power, greater intelligence, deeper automation, and broader application reach. The convergence of advanced laser technology, digitalization, and the push towards electrification and sustainability will solidify laser welding as the cornerstone technology for high-quality, efficient, and cost-effective stainless steel joining across critical global industries. Success will depend on continuous innovation in process control, system integration, and addressing the specific needs of emerging high-growth sectors.

H2: Common Pitfalls in Sourcing Laser Welding of Stainless Steel – Quality and Intellectual Property Concerns

Sourcing laser welding services for stainless steel involves several critical considerations, particularly regarding quality assurance and intellectual property (IP) protection. Failing to address these areas can lead to compromised product integrity, legal risks, and loss of competitive advantage. Below are common pitfalls in both domains:

1. Quality-Related Pitfalls

a. Inconsistent Weld Quality Due to Poor Process Control

Laser welding demands precise control over parameters such as laser power, travel speed, shielding gas flow, and beam focus. Sourcing from suppliers with inadequate process documentation or inconsistent calibration may result in defects like porosity, cracking, or incomplete fusion—especially problematic in stainless steel due to its thermal sensitivity.

Avoidance Tip: Require detailed Weld Procedure Specifications (WPS) and evidence of process validation (e.g., through destructive and non-destructive testing).

b. Lack of Material Traceability and Certification

Stainless steel grades (e.g., 304, 316) must be properly certified to ensure corrosion resistance and mechanical performance. Suppliers who do not provide mill test reports (MTRs) or adhere to ASTM/ASME standards risk introducing substandard materials.

Avoidance Tip: Enforce material traceability and mandate compliance with relevant standards (e.g., ASTM A240 for stainless steel plates).

c. Inadequate Post-Weld Treatment and Inspection

Improper cleaning, passivation, or lack of inspection (e.g., dye penetrant, X-ray) can leave welds vulnerable to corrosion and structural failure. Some suppliers may skip these steps to reduce costs.

Avoidance Tip: Include post-weld requirements in procurement contracts and perform independent audits or third-party inspections.

d. Inexperienced or Underqualified Personnel

Laser welding requires skilled operators and certified welding engineers. Offshore or low-cost suppliers may lack certified personnel (e.g., AWS D1.6 for stainless steel structural welding), compromising weld integrity.

Avoidance Tip: Verify certifications and request evidence of operator training and qualification records.

2. Intellectual Property (IP)-Related Pitfalls

a. Unprotected Design and Process IP

Sharing detailed drawings, CAD models, or proprietary welding procedures with suppliers without legal safeguards can expose sensitive IP to theft or unauthorized use.

Avoidance Tip: Execute robust Non-Disclosure Agreements (NDAs) and limit data access to a need-to-know basis. Use watermarked or restricted digital files.

b. Lack of IP Ownership Clauses in Contracts

Without clear contractual terms, custom tooling, jigs, or process innovations developed during production may become jointly owned or claimed by the supplier.

Avoidance Tip: Include explicit IP ownership clauses stating that all developments related to your product remain your exclusive property.

c. Risk of Reverse Engineering

Suppliers with access to finished components may reverse engineer designs, especially in industries with high margins (e.g., medical, aerospace). Laser-welded stainless steel assemblies often have unique geometries that can be replicated if not protected.

Avoidance Tip: Segment production processes across multiple trusted partners and avoid sharing complete system designs.

d. Jurisdictional IP Enforcement Challenges

Sourcing internationally may place IP in jurisdictions with weak enforcement of IP laws, making legal recourse difficult in case of infringement.

Avoidance Tip: Prefer suppliers in countries with strong IP protections or establish legal representation in their region. Register IP (e.g., patents, trademarks) locally if long-term sourcing is planned.

Conclusion

To mitigate risks in sourcing laser welding for stainless steel, a dual focus on quality control and IP protection is essential. Implement rigorous supplier qualification processes, enforce contractual safeguards, and conduct regular audits. Proactive management of both technical and legal aspects ensures reliable, secure, and high-performance outcomes.

Logistics & Compliance Guide for Laser Welding Stainless Steel

Overview

Laser welding of stainless steel is a high-precision joining process widely used in industries such as automotive, aerospace, medical devices, and food processing due to its accuracy, speed, and strong weld quality. However, effective logistics planning and strict compliance with safety, environmental, and industry-specific regulations are essential to ensure operational efficiency, worker safety, and product integrity.

Regulatory Compliance

Safety Standards & Personal Protective Equipment (PPE)

Laser welding involves high-intensity radiation, fumes, and electrical hazards. Compliance with safety standards is mandatory:

- OSHA (Occupational Safety and Health Administration) – 29 CFR 1910 Subpart I (PPE) and Subpart Q (Welding, Cutting, and Brazing): Requires proper PPE including laser safety eyewear (rated for the laser wavelength used), flame-resistant clothing, gloves, and face shields.

- ANSI Z136.1 (Safe Use of Lasers) – Specifies classification of lasers and required controls (e.g., interlocks, warning signs, beam enclosures) based on laser class (typically Class 4 for industrial laser welders).

- NFPA 70 (National Electrical Code) – Ensures proper electrical installation and grounding of laser welding equipment.

Fume and Ventilation Requirements

Stainless steel welding generates hazardous fumes containing chromium (including hexavalent chromium, Cr(VI)) and nickel, which are known carcinogens.

- OSHA PEL (Permissible Exposure Limit) – Cr(VI) exposure limit is 5 µg/m³ as an 8-hour TWA (time-weighted average).

- NIOSH REL (Recommended Exposure Limit) – Recommends even lower exposure levels.

- Local Exhaust Ventilation (LEV) – Must be used at the source (fume extraction arms or integrated fume hoods). Systems should be tested and certified annually.

- Air Monitoring – Periodic air sampling is required to ensure compliance with exposure limits.

Environmental Compliance

- EPA Regulations (40 CFR) – Proper handling and disposal of metal particulates and filter waste (potentially classified as hazardous waste under RCRA if Cr(VI) levels exceed thresholds).

- Spill Prevention – Coolant and lubricant leaks must be contained; secondary containment may be required.

Equipment & Facility Requirements

Laser System Classification & Installation

- Industrial laser welding systems are typically Class 4 lasers and require:

- Controlled access areas with interlocks.

- Warning lights and signage (e.g., “Laser in Use”).

- Beam enclosures or curtains with appropriate optical density.

- Equipment must be installed per manufacturer specifications and local fire codes.

Facility Layout

- Dedicated Welding Cells: Isolate laser operations to minimize exposure risks.

- Fire Prevention: Class D fire extinguishers (for metal fires) and non-combustible flooring near welding zones.

- Cooling Systems: Proper chiller units for laser and optics; coolant must be maintained and disposed of according to environmental regulations.

Material Handling & Logistics

Stainless Steel Material Management

- Storage: Keep stainless steel dry and free from contaminants (e.g., carbon steel dust, oils) to prevent corrosion and weld defects.

- Handling: Use non-ferrous tools and lifting equipment to avoid cross-contamination.

- Traceability: Maintain material certifications (e.g., mill test reports) for compliance in regulated industries (e.g., ASME, FDA).

Consumables & Spare Parts

- Optics (lenses, mirrors), protective windows, and nozzles require scheduled replacement.

- Maintain inventory logs and ensure storage in clean, dry conditions to prevent damage.

Process Control & Quality Assurance

Welding Procedure Specifications (WPS)

- Develop and validate WPS per AWS D1.6/D1.6M (Structural Welding Code – Stainless Steel) or ASME BPVC Section IX for pressure-containing components.

- Include parameters: laser power, travel speed, shielding gas type (e.g., argon, helium), gas flow rate, focus position.

Inspection & Testing

- Non-Destructive Testing (NDT): Use methods such as visual inspection, dye penetrant testing (PT), radiographic testing (RT), or ultrasonic testing (UT) as required.

- Documentation: Maintain weld logs, inspection reports, and operator certifications.

Operator Certification

- Welders and laser operators must be trained and certified per company or industry standards (e.g., AWS, ASNT).

- Annual refresher training on laser safety and emergency procedures is recommended.

Waste Management & Sustainability

Waste Streams

- Metal Fumes & Particulates: Collected via LEV filters; dispose as hazardous waste if Cr(VI) is present.

- Used Coolant: Recycle or dispose through licensed hazardous waste handlers.

- Scrap Metal: Segregate stainless steel scrap for recycling; avoid mixing with other metals.

Sustainability Practices

- Optimize laser parameters to reduce energy consumption and material waste.

- Implement closed-loop cooling systems to minimize water usage.

Training & Documentation

Required Training

- Laser safety (ANSI Z136-compliant).

- Hazard communication (HazCom 2012/GHS).

- Emergency response (fire, fume exposure, electrical hazards).

Recordkeeping

- Maintain records of:

- Equipment maintenance and calibration.

- Air monitoring results.

- Operator certifications.

- Welding procedure qualifications.

- Incident reports and corrective actions.

Industry-Specific Considerations

Medical Devices

- Comply with FDA 21 CFR Part 820 (Quality System Regulation) and ISO 13485.

- Use cleanroom-compatible processes if applicable; validate welds for biocompatibility.

Food & Beverage

- Follow 3-A Sanitary Standards; ensure welds are smooth, crevice-free, and passively treated (e.g., pickling, passivation).

Aerospace

- Adhere to NADCAP AC7107 (special processes: laser beam welding).

- Full traceability from raw material to finished weld.

Emergency Preparedness

- Fire Response Plan: Include procedures for metal fires (do not use water on burning metals).

- Fume Exposure Protocol: First aid measures and access to safety data sheets (SDS).

- Laser Incident Response: Immediate shutdown, eye examinations if exposure occurs.

Conclusion

Successful laser welding of stainless steel requires integrated logistics planning and rigorous compliance with safety, environmental, and quality standards. By implementing proper controls, training, and documentation, organizations can ensure safe operations, regulatory adherence, and high-quality weld outcomes across diverse industrial applications.

Conclusion for Sourcing Laser Welding of Stainless Steel

Sourcing laser welding for stainless steel components offers a highly efficient, precise, and reliable joining solution, particularly suited for applications requiring high-quality aesthetics, structural integrity, and minimal heat distortion. The process delivers excellent weld strength, corrosion resistance, and repeatability, making it ideal for industries such as automotive, medical devices, food processing, and aerospace.

When selecting a laser welding partner, key factors to consider include technical expertise, equipment capabilities (such as fiber or disk lasers), material certification compliance, quality control processes, and experience with stainless steel alloys (e.g., 304, 316). Additionally, evaluating lead times, scalability, and cost-efficiency ensures alignment with production goals.

In conclusion, laser welding is a superior choice for stainless steel fabrication, and careful supplier selection—emphasizing technology, quality assurance, and industry experience—will ensure optimal performance, durability, and value for your specific application.