The global laser welding machine market is experiencing robust expansion, driven by increasing demand for precision manufacturing across automotive, aerospace, and electronics industries. According to a 2023 report by Mordor Intelligence, the market was valued at approximately USD 2.5 billion and is projected to grow at a CAGR of over 8.5% from 2024 to 2029. This surge is fueled by advancements in fiber laser technology, automation integration, and the rising adoption of battery welding in electric vehicles. Similarly, Grand View Research highlights the growing shift toward energy-efficient and high-speed welding solutions, positioning laser welding as a critical enabler of modern production efficiency. As competition intensifies, a select group of manufacturers have emerged as leaders, combining innovation, reliability, and global reach to dominate the landscape. Here are the top 10 laser welding machine manufacturers shaping the future of industrial joining technology.

Top 10 Laser Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Technology & Laser Machines from ALPHA LASER

Website: alphalaser.eu

Key Highlights: As a leading manufacturer of mobile, flexible, and high-performance laser systems for laser welding, laser hardening, powder deposit welding and additive metal ……

#2 Focus on laser

Founded: 1996

Website: hanslaser.net

Key Highlights: Han’s Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now became the flagship of Chinese national laser industry ……

#3 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#4 Laser Machines

Website: lclasers.com

Key Highlights: Distribution and manufacture of laser machinery. Sales of laser marking, laser cleaning, laser engraving and welding machines….

#5 Denaliweld

Website: denaliweld.com

Key Highlights: DenaliWeld INC, is a proud employee-owned fiber laser welding machine manufacturer based in Chicago, USA. Bolstered by the most experienced engineers and design ……

#6 Equipment & Systems

Website: amadaweldtech.com

Key Highlights: Manufacturer of equipment and systems for welding, cutting, marking, micromachining, sealing, and bonding. Resistance welding. Laser….

#7 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#8 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

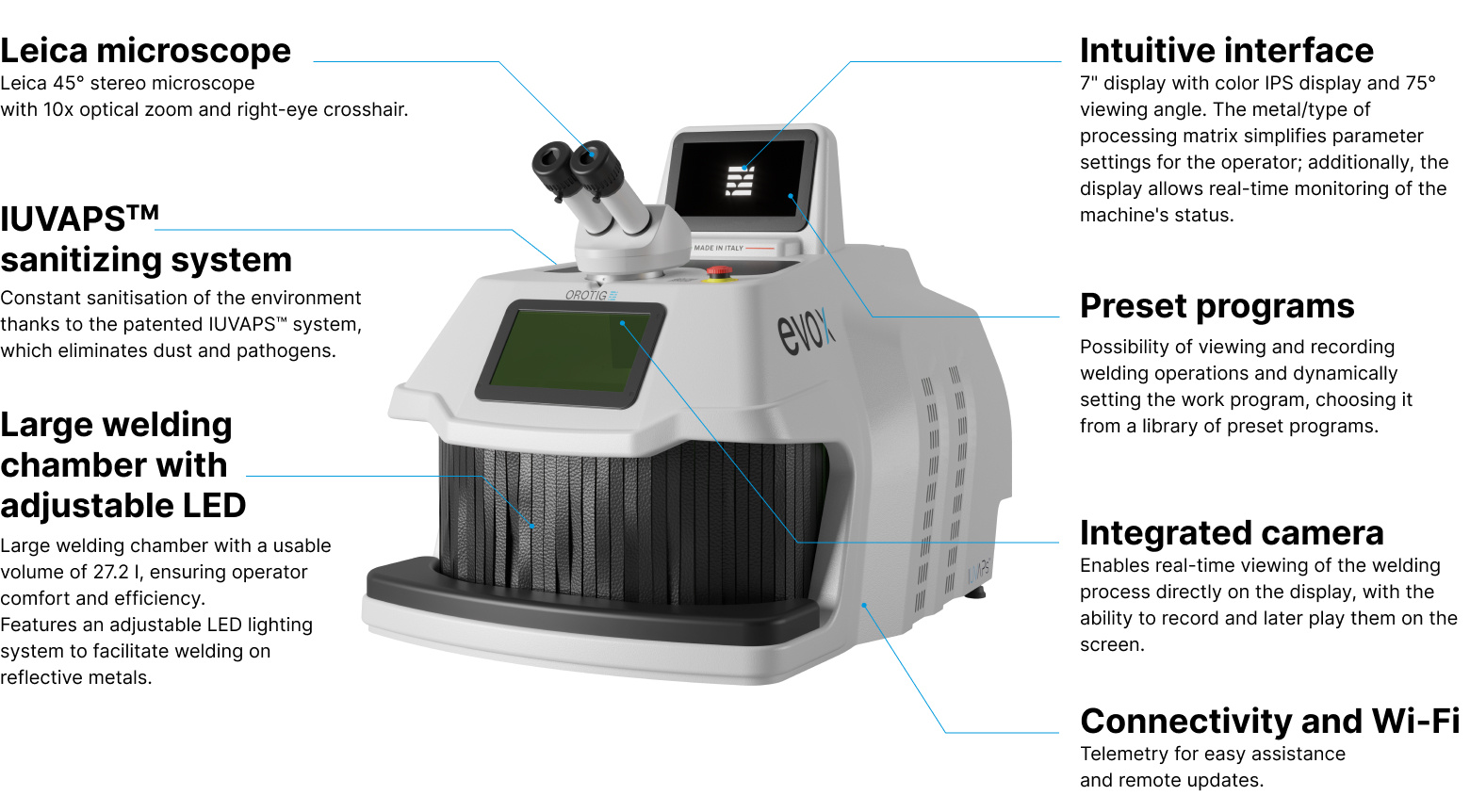

#9 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: Orotig, with +30 years of experience, specializes in engineering and manufacturing laser solutions for welding engraving and casting metals….

#10 Laser Welding Machines

Website: coherent.com

Key Highlights: Get manual to fully automated laser welding machines that weld plastics and metals with speed and precision while improving throughput….

Expert Sourcing Insights for Laser Welding Machine

H2: 2026 Market Trends for Laser Welding Machines

The global laser welding machine market is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and increasing demand across high-growth sectors. Key trends shaping the market include the rise of high-power fiber lasers, integration with artificial intelligence (AI) and Industry 4.0 systems, growing adoption in electric vehicle (EV) manufacturing, and regional shifts in production hubs.

One of the most prominent trends is the transition from traditional CO2 and Nd:YAG lasers to fiber laser technology. Fiber lasers offer higher efficiency, lower maintenance, and improved beam quality, making them ideal for precision welding in automotive, aerospace, and electronics industries. By 2026, fiber laser welding machines are expected to dominate over 60% of the market, particularly in high-volume production environments.

Another critical trend is the integration of smart manufacturing technologies. Laser welding systems are increasingly being equipped with real-time monitoring, adaptive control, and predictive maintenance features powered by AI and IoT. These capabilities enhance process reliability, reduce downtime, and improve weld consistency—key requirements in Industry 4.0-enabled factories.

The electric vehicle revolution is also fueling demand. As automakers scale EV production, laser welding is becoming essential for battery manufacturing, powertrain components, and lightweight body structures. The need for hermetic sealing, precision, and speed in battery pack assembly is driving investment in specialized laser welding solutions, particularly in regions like China, Europe, and North America.

Geographically, Asia-Pacific is expected to maintain its leadership in the laser welding machine market, supported by robust manufacturing ecosystems in China, Japan, and South Korea. However, North America and Europe are witnessing accelerated adoption due to reshoring initiatives and stricter emission standards, which are pushing manufacturers toward advanced, energy-efficient welding technologies.

Sustainability is emerging as a cross-cutting trend. Laser welding, being a non-contact and energy-efficient process, aligns with green manufacturing goals. Equipment manufacturers are focusing on reducing power consumption and improving recyclability of components to meet environmental regulations and customer expectations.

In summary, by 2026, the laser welding machine market will be defined by smarter, faster, and more sustainable solutions, with innovation concentrated in automation, material processing flexibility, and sector-specific applications—especially in EVs and advanced manufacturing.

Common Pitfalls When Sourcing Laser Welding Machines (Quality & IP Risks)

Sourcing laser welding machines, especially from new or non-traditional suppliers, involves significant risks related to both quality and intellectual property (IP). Overlooking these pitfalls can lead to costly downtime, substandard production, legal disputes, and reputational damage.

Poor Build Quality and Component Sourcing

Many low-cost suppliers, particularly in emerging manufacturing regions, cut corners on materials and assembly. This includes using inferior cooling systems, substandard optics, or unreliable motion stages, leading to frequent breakdowns, inconsistent weld quality, and shortened machine lifespan. Machines may also lack proper calibration or fail to meet advertised specifications.

Inadequate or Missing Safety Features

Laser welding involves high-power beams and fumes, requiring strict adherence to safety standards (e.g., IEC 60825, ANSI Z136). Some sourced machines lack proper interlocks, beam enclosures, or fume extraction systems, posing serious safety hazards to operators and violating workplace regulations.

Lack of Technical Support and Spare Parts Availability

Suppliers in distant regions may offer little to no after-sales support, making troubleshooting and maintenance difficult. Long lead times for spare parts or unavailability of critical components can result in prolonged machine downtime, disrupting production schedules and increasing operational costs.

Hidden IP Infringement in Machine Design

A major concern is that the laser welding system may incorporate patented technologies—such as beam delivery mechanisms, motion control software, or cooling designs—without proper licensing. Purchasing such a machine can expose the buyer to legal liability, especially if the original IP holder initiates enforcement actions in the buyer’s country.

Use of Counterfeit or Reverse-Engineered Components

Some suppliers use cloned or counterfeit laser sources (e.g., fiber lasers), control boards, or software that mimic reputable brands. These components often underperform, lack reliability, and may be installed without the manufacturer’s authorization, raising IP infringement issues and voiding warranties.

Incomplete or Fake Certification and Documentation

Machines may be sold with falsified CE, UL, or other compliance marks. Without authentic certification and technical documentation, integration into regulated production environments becomes problematic, and insurance or compliance audits may fail.

Software and Control System IP Risks

Proprietary control software may be pirated or modified without authorization. Buyers risk using unlicensed software, which can lead to legal exposure, lack of updates, and cybersecurity vulnerabilities. Additionally, locked or undocumented software limits customization and integration with existing production systems.

Supply Chain Transparency and Traceability Gaps

Lack of visibility into the supply chain makes it difficult to verify the origin of components and assess compliance with IP and quality standards. This opacity increases the risk of unknowingly sourcing machines with stolen or unauthorized technology.

Mitigation Strategy

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request third-party certifications, audit manufacturing facilities, perform IP clearance checks, and include warranty and indemnification clauses in contracts. Partnering with reputable suppliers and using legal counsel for IP assessment is strongly recommended.

Logistics & Compliance Guide for Laser Welding Machine

Overview

This guide outlines the essential logistics and compliance considerations for the safe and legal transportation, import/export, handling, and operation of a laser welding machine. Adherence to these guidelines ensures regulatory compliance, worker safety, and operational efficiency.

Regulatory Classification and Documentation

Identify the correct Harmonized System (HS) code for international shipping—commonly under HS 8456.20 for laser cutting or welding machines. Prepare all required documentation, including commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and product conformity certificates (e.g., CE, UKCA, or FCC). Include technical specifications and safety data relevant to laser classification (typically Class 4).

Export and Import Compliance

Ensure compliance with export control regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation, as high-power laser systems may be subject to restrictions. Verify destination country import requirements, including electrical standards, customs duties, and local certification (e.g., CCC in China, PSE in Japan). Obtain necessary export licenses if applicable.

Packaging and Handling Requirements

Package the laser welding machine in a sturdy, shock-resistant container with anti-vibration materials to protect sensitive optical and electronic components. Clearly label packages with handling instructions: “Fragile,” “This Side Up,” and “Protect from Moisture.” Include desiccants if shipping over long distances or through humid environments.

Transportation Mode Considerations

Choose appropriate transport modes (air, sea, or land) based on machine weight, dimensions, and urgency. For air freight, comply with IATA Dangerous Goods Regulations if batteries or cooling agents are included. For sea freight, ensure compliance with the IMDG Code and protect against saltwater exposure. Coordinate with freight forwarders experienced in handling industrial machinery.

Import Clearance and Duties

Submit complete customs documentation to avoid delays. Be prepared to pay applicable import duties, value-added taxes (VAT), and processing fees. Engage a licensed customs broker in the destination country if necessary to facilitate clearance, especially for regulated technology.

On-Site Receiving and Unpacking

Inspect the shipment for damage upon arrival. Document and photograph any discrepancies before unpacking. Follow the manufacturer’s unpacking instructions carefully. Verify contents against the packing list and retain all packaging materials for potential return or service needs.

Installation and Site Compliance

Ensure the installation site meets electrical, ventilation, and spatial requirements specified by the manufacturer. Confirm power supply compatibility (voltage, phase, grounding). Install proper laser safety enclosures, interlocks, and warning signs per ANSI Z136.1 (U.S.) or IEC 60825 (international) standards.

Safety and Operational Compliance

Train personnel on laser safety protocols, including use of appropriate personal protective equipment (PPE) such as laser safety goggles. Implement standard operating procedures (SOPs) and conduct regular safety audits. Register the laser system with local regulatory authorities if required (e.g., in some U.S. states or EU member countries).

Maintenance and Regulatory Recordkeeping

Maintain detailed logs of maintenance, calibration, safety inspections, and operator training. Retain compliance documentation (certificates, permits, training records) for the machine’s lifecycle. Update records whenever modifications or repairs are performed.

Disposal and End-of-Life Management

Dispose of the laser welding machine in accordance with local environmental and electronic waste (WEEE) regulations. Safely decommission laser components and batteries. Partner with certified e-waste recyclers to ensure environmentally responsible disposal and compliance with RoHS directives where applicable.

In conclusion, sourcing a reliable laser welding machine manufacturer requires a thorough evaluation of several key factors, including technical expertise, product quality, after-sales support, customization capabilities, and cost-effectiveness. It is essential to prioritize manufacturers with proven experience, international certifications, and a strong track record in delivering durable and high-performance equipment. Conducting on-site visits, requesting product demonstrations, and checking client references can significantly reduce risks and ensure long-term satisfaction. Additionally, considering manufacturers who offer comprehensive training, maintenance services, and software updates will contribute to seamless integration and optimal operation within your production environment. By carefully selecting a reputable and technologically advanced laser welding machine manufacturer, businesses can enhance their manufacturing precision, improve efficiency, and maintain a competitive edge in their respective industries.