The global laser welding machine market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as automotive, medical devices, and notably, jewellery. According to Grand View Research, the global laser welding equipment market size was valued at USD 2.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. Within this trajectory, the jewellery sector is emerging as a key adopter of laser welding technology due to its ability to deliver clean, precise, and non-invasive joins on delicate precious metal components. Mordor Intelligence further highlights that advancements in fiber laser technology and rising demand for intricate, customised jewellery designs are accelerating adoption among manufacturers seeking efficiency and quality. As the industry shifts toward automation and minimally disruptive processes, investment in laser welding systems has become a strategic differentiator. This growing demand has fostered a competitive landscape of specialized manufacturers offering machines tailored specifically for high-precision jewellery fabrication. Below are the top nine laser welding machine manufacturers leading innovation in this niche, combining precision engineering, advanced optics, and user-centric design to meet the evolving needs of modern jewellers.

Top 9 Laser Welding Machine Jewellery Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#2 Laser Technology & Laser Machines from ALPHA LASER

Website: alphalaser.eu

Key Highlights: High-quality laser technology & laser sytems from ALPHA LASER: powerful laser machines for metalworking: mobile, flexible, & precise ✓ technical support ✓….

#3 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals….

#4 Laser Welding Machine

Website: baikeopto.com

Key Highlights: Model:200W YAG laser jewelry welding machine BK-JW200E Pro Voltage:110V/220V Laser Type:1064nm YAG Laser Small size Low weight Easy to operate ……

#5 Machinery and laser systems

Website: sisma.com

Key Highlights: More than 130 machine models for the automatic production of gold chains · Laser systems for marking, welding, cutting and engraving. · Laser systems for welding….

#6 Sunstone Welders

Website: sunstonewelders.com

Key Highlights: Sunstone designs and manufactures high-tech micro welding and engraving solutions for many different industries. In short, wherever a very small spot weld ……

#7 Jewelry Laser Welding Machine

Website: triumphlaser.com

Key Highlights: The jewelry laser welding machine is specifically for jewelry laser welding of a product, mainly used in gold and silver ornaments of the hole and spot welding ……

#8 Jewelry Laser Welder, Gold/Silver Laser Welding Machine Supplier

Website: superbmelt.com

Key Highlights: SuperbMelt offers a wide range of Jewelry Laser Welding Machines, available in handheld, benchtop, tabletop, and portable designs….

#9 Laser machines for cutting, engraving, marking and …

Website: elettrolaser.com

Key Highlights: Laser machines for welding, engraving, marking, and cutting. Elettrolaser creates laser welding machines with engraving lasers that are among the best i……

Expert Sourcing Insights for Laser Welding Machine Jewellery

H2: 2026 Market Trends for Laser Welding Machines in the Jewellery Industry

The global market for laser welding machines in the jewellery sector is poised for significant transformation by 2026, driven by technological innovation, evolving consumer preferences, and increasing demand for precision and efficiency in jewellery manufacturing. This analysis explores key trends expected to shape the industry in the coming years.

-

Increased Adoption of Automation and Smart Manufacturing

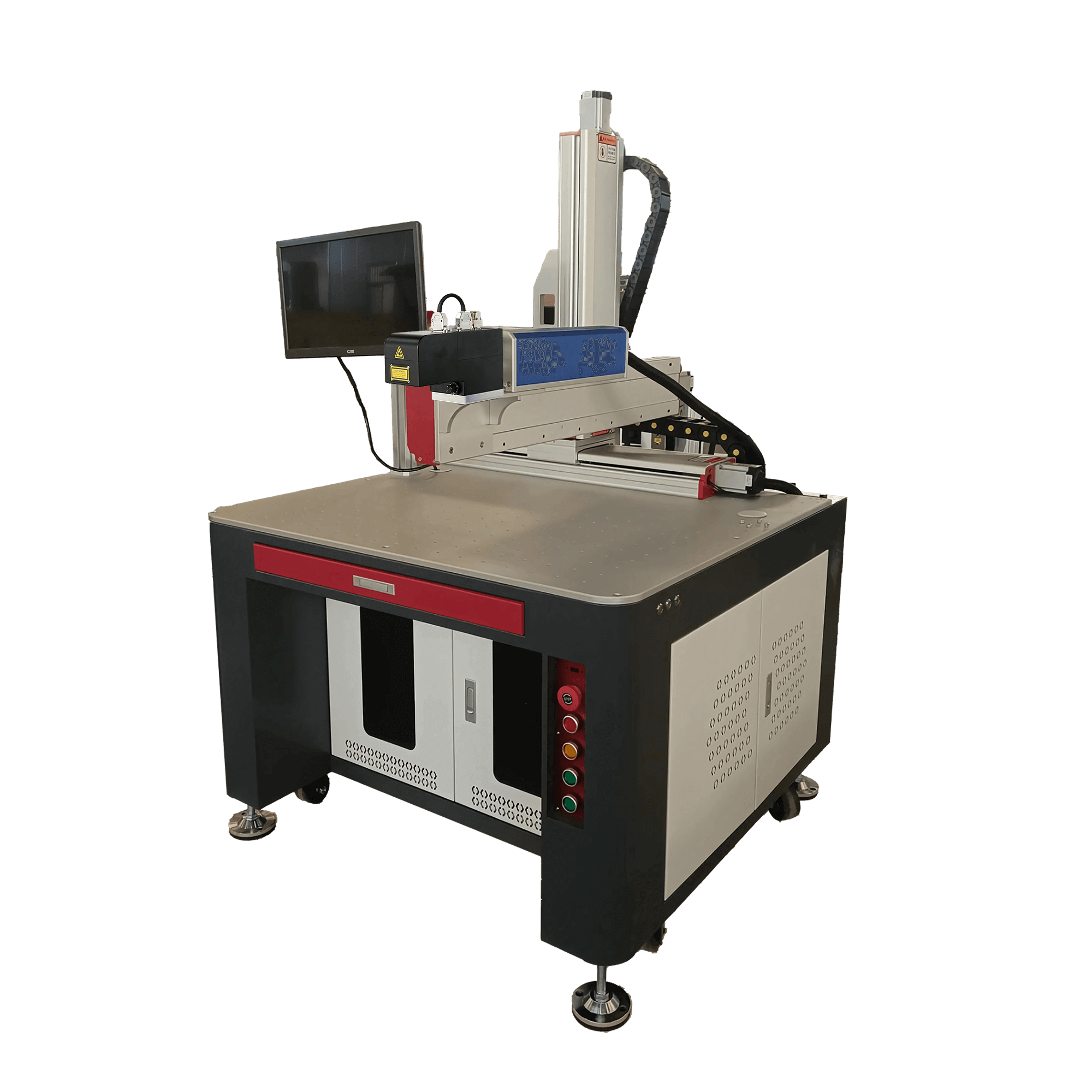

By 2026, automation will play a pivotal role in jewellery production, with laser welding machines integrating seamlessly into smart factory ecosystems. Manufacturers are increasingly adopting Computer Numerical Control (CNC)-based laser systems and IoT-enabled equipment to enhance precision, reduce human error, and enable real-time performance monitoring. This shift supports Industry 4.0 principles and allows for faster turnaround times in custom and batch production. -

Growing Demand for Custom and Bespoke Jewellery

The rising consumer preference for personalized and made-to-order jewellery is propelling the need for flexible and high-precision welding solutions. Laser welding machines offer unmatched accuracy for intricate designs and delicate materials, making them ideal for artisans and small-scale designers. By 2026, the proliferation of online customisation platforms is expected to further boost demand for compact, user-friendly laser welders in artisanal and boutique workshops. -

Advancements in Fiber Laser Technology

Fiber laser welding systems are anticipated to dominate the jewellery segment by 2026 due to their superior beam quality, energy efficiency, and low maintenance requirements. These systems provide finer control over weld penetration and heat input, minimizing damage to sensitive gemstones and thin metal components. Continuous improvements in pulse shaping and beam delivery will enhance weld aesthetics and structural integrity. -

Sustainability and Material Efficiency

As sustainability becomes a key concern across industries, laser welding offers eco-friendly advantages such as reduced material waste, lower energy consumption, and minimal use of consumables (e.g., solder). Jewellery manufacturers are increasingly leveraging laser technology to support green manufacturing initiatives and comply with environmental regulations—trends expected to gain momentum through 2026. -

Expansion in Emerging Markets

Asia-Pacific, particularly India, China, and Southeast Asia, will remain a high-growth region for laser welding machines in jewellery. Rising disposable incomes, urbanization, and a growing middle class are fueling demand for fine jewellery. Local manufacturers are investing in modern equipment to improve craftsmanship and compete globally, accelerating the penetration of laser welding systems in regional supply chains. -

Integration with Additive Manufacturing (3D Printing)

The synergy between laser welding and 3D-printed jewellery is expected to expand significantly by 2026. As 3D printing becomes mainstream for prototyping and production, laser welding will be essential for post-processing tasks such as joining components, repairing prints, and attaching findings. Hybrid systems combining welding and additive capabilities may emerge as a niche but growing segment. -

Focus on Training and Skill Development

Despite technological advances, skilled operators remain crucial. Industry stakeholders are expected to invest in training programs and certification courses focused on laser welding techniques tailored for jewellery. Equipment vendors are likely to offer enhanced technical support and software interfaces to lower the skill barrier and attract new users.

In conclusion, the 2026 landscape for laser welding machines in the jewellery industry will be defined by innovation, customization, and sustainability. With continuous improvements in machine intelligence, portability, and integration with digital workflows, laser welding is set to become an indispensable tool across both artisanal and industrial jewellery production.

Common Pitfalls When Sourcing Laser Welding Machines for Jewellery

Sourcing a laser welding machine for jewellery manufacturing offers precision and efficiency, but several critical pitfalls related to quality and intellectual property (IP) can undermine your investment if not carefully addressed.

Quality-Related Pitfalls

1. Overlooking Machine Precision and Beam Control

Many low-cost or generic laser welders lack the fine beam focus and power stability required for delicate jewellery work. Poor beam control can lead to inconsistent welds, heat damage to gemstones, or weakened joints—especially problematic when working with thin gold or platinum sheets.

2. Insufficient After-Sales Support and Calibration

Some suppliers, particularly those based overseas, offer limited technical support or training. Without proper calibration and maintenance, even a high-spec machine can underperform. Downtime due to unresponsive service can severely disrupt production schedules.

3. Compromised Build Quality and Component Sourcing

Lower-priced machines may use inferior optics, cooling systems, or motion stages that degrade quickly. Using non-industrial-grade lasers or counterfeit components reduces machine lifespan and increases operational costs over time.

4. Inadequate Testing and Validation

Buyers often skip hands-on testing with their actual materials (e.g., 18k gold, platinum alloys). A machine that performs well on steel may fail on reflective precious metals. Without testing under real workshop conditions, performance expectations may not align with reality.

Intellectual Property (IP) Pitfalls

1. Risk of IP Infringement from Clone or Knockoff Machines

Some suppliers, especially in regions with weak IP enforcement, offer machines that copy patented designs or software from reputable brands. Purchasing such equipment may expose your business to legal risks, particularly if operated in countries with strict IP laws.

2. Lack of Software Licensing and Updates

Proprietary software controls precision and user interface. Cloned or pirated software may lack critical updates, security patches, or technical support, limiting functionality and potentially violating licensing agreements.

3. Supplier Misrepresentation of Technology Origin

Be cautious of suppliers falsely claiming OEM partnerships or original technology development. Verifying the manufacturer’s credentials, patents, and certifications (e.g., CE, FDA) is essential to ensure you’re not inadvertently supporting IP theft.

4. Limited Warranty and Legal Recourse

Low-cost suppliers may offer minimal or non-enforceable warranties. If a machine infringes on third-party IP, you may have little legal protection or recourse, especially when sourcing from jurisdictions with underdeveloped IP frameworks.

Mitigation Strategies

- Conduct thorough due diligence on suppliers, including site visits or factory audits.

- Request live demonstrations using your materials.

- Verify patents, certifications, and software licensing.

- Prioritize suppliers with strong local support and transparent technology sourcing.

- Include IP indemnity clauses in procurement contracts.

Avoiding these pitfalls ensures your laser welding investment enhances craftsmanship while protecting your business from technical and legal risks.

Logistics & Compliance Guide for Laser Welding Machines in the Jewellery Industry

Import Regulations and Documentation

When importing a laser welding machine for jewellery manufacturing, strict adherence to international trade regulations is essential. Obtain an accurate HS (Harmonized System) code—typically 8515.21 or 8515.80, depending on the machine’s specifications—to determine applicable tariffs and duties. Required documentation includes a commercial invoice, packing list, bill of lading or airway bill, and a certificate of origin. Some countries may also require an import license or prior notification to customs authorities, especially for high-tech equipment. Always verify destination country requirements with local customs or a licensed customs broker.

Safety and Electrical Compliance Standards

Laser welding machines must comply with regional safety and electrical standards to ensure legal operation and user protection. In the European Union, the machine must carry the CE marking, confirming conformity with the Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive, and Low Voltage Directive. In the United States, compliance with OSHA and FDA regulations for laser products (under 21 CFR 1040.10) is mandatory. Ensure the device includes proper labeling, safety interlocks, and an emergency stop function. Additional certifications such as UL or CSA may be required for North American markets.

Laser Safety and Radiation Compliance

Laser welding machines are classified under specific laser safety classes (typically Class 4), requiring strict adherence to occupational health and safety regulations. Implement engineering controls such as interlocked enclosures, beam shutters, and appropriate warning labels. Operators must use certified laser safety eyewear matching the laser’s wavelength. Facilities must comply with standards such as ANSI Z136.1 (USA) or IEC 60825-1 (international), which govern laser hazard assessments, controlled access areas, and training protocols. Maintain a Laser Safety Officer (LSO) where required by local regulations.

Packaging and Transportation Requirements

Due to the sensitive optics and precision components, laser welding machines require custom packaging to prevent damage during transit. Use shock-absorbent materials, secure internal fixtures, and moisture-resistant wrapping. Clearly label packages as “Fragile,” “This Side Up,” and “Sensitive Equipment.” For international shipping, comply with IATA regulations if transported by air, especially regarding power sources or cooling systems. Consider climate-controlled transport to avoid condensation or thermal stress. Insure the shipment for full replacement value and track it in real time.

Installation and Site Preparation Compliance

Before installation, ensure the facility meets the manufacturer’s environmental and utility specifications. This includes stable power supply (voltage, frequency, grounding), adequate ventilation, and climate control (temperature and humidity). Verify compliance with local electrical codes (e.g., NEC in the U.S. or IEC standards internationally). The installation area should be free from excessive dust, vibrations, and electromagnetic interference. Document all installation steps and obtain a commissioning certificate from the supplier or certified technician to support warranty and regulatory compliance.

Training and Operational Compliance

Provide comprehensive training for all operators and maintenance personnel in accordance with manufacturer guidelines and regulatory requirements. Training should cover safe operation, emergency procedures, maintenance routines, and hazard identification. Maintain training records to demonstrate compliance during audits. Implement standard operating procedures (SOPs) and conduct regular safety drills. Ensure all operators are aware of workplace-specific risks, especially when handling precious metals and working with high-intensity lasers.

Maintenance, Calibration, and Recordkeeping

Maintain a scheduled maintenance program as specified by the manufacturer to ensure operational accuracy and safety. Keep detailed logs of service, laser calibration, and component replacements. Regular calibration ensures welding precision and compliance with quality standards such as ISO 9001. Retain records for at least three years or as required by local regulations. Use only approved spare parts and authorized service providers to preserve compliance and warranty status.

Export Controls and Dual-Use Considerations

Laser welding machines may be subject to export control regulations due to their potential dual-use in military or industrial applications. Check if the machine falls under export control lists such as the Wassenaar Arrangement, or national systems like the U.S. Commerce Control List (CCL). Obtain necessary export licenses or authorizations before shipping internationally. Classify the machine correctly using ECCN (Export Control Classification Number), typically 6A003 or 6A005, depending on laser power and beam characteristics. Consult with export compliance experts to avoid legal penalties.

Conclusion: Sourcing a Laser Welding Machine for Jewellery

Sourcing a laser welding machine for jewellery manufacturing or repair is a strategic investment that significantly enhances precision, efficiency, and product quality. Laser welding technology offers unparalleled advantages over traditional soldering methods, including minimal heat distortion, stronger welds, and the ability to work on delicate or intricate pieces without damaging surrounding areas. When selecting a machine, it is essential to consider factors such as power output, pulse control, ease of use, maintenance requirements, and after-sales support.

Additionally, evaluating suppliers based on reputation, technical expertise, and training offerings ensures long-term success and smooth integration into existing workflows. While the initial cost may be higher compared to conventional tools, the long-term benefits—such as reduced material waste, increased production speed, and improved craftsmanship—justify the investment.

Ultimately, sourcing the right laser welding machine empowers jewellers to meet modern demands for precision and customization, maintain a competitive edge, and deliver superior-quality products. With careful research and a focus on quality and support, investing in laser welding technology marks a forward-thinking step towards innovation and excellence in the jewellery industry.