The global market for precision welding technologies has seen robust expansion in recent years, driven by increasing demand in industries such as automotive, aerospace, and clean energy. According to Grand View Research, the global laser welding market size was valued at USD 4.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. Similarly, TIG (Tungsten Inert Gas) welding, known for its high-quality weld finishes and versatility in handling non-ferrous metals, remains a cornerstone in industrial fabrication. Mordor Intelligence reports that the overall welding equipment market is expected to grow at a CAGR of over 5.2% during the forecast period of 2023–2028, with sustained demand across heavy manufacturing and infrastructure sectors. As laser welding technologies advance—offering faster processing speeds, automation compatibility, and lower heat distortion—manufacturers are increasingly comparing them with traditional TIG systems. This growing convergence of innovation and legacy performance underscores the need to evaluate the top eight manufacturers shaping the laser vs. TIG welding landscape, based on technological differentiation, market reach, and adoption trends.

Top 8 Laser Welder Vs Tig Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

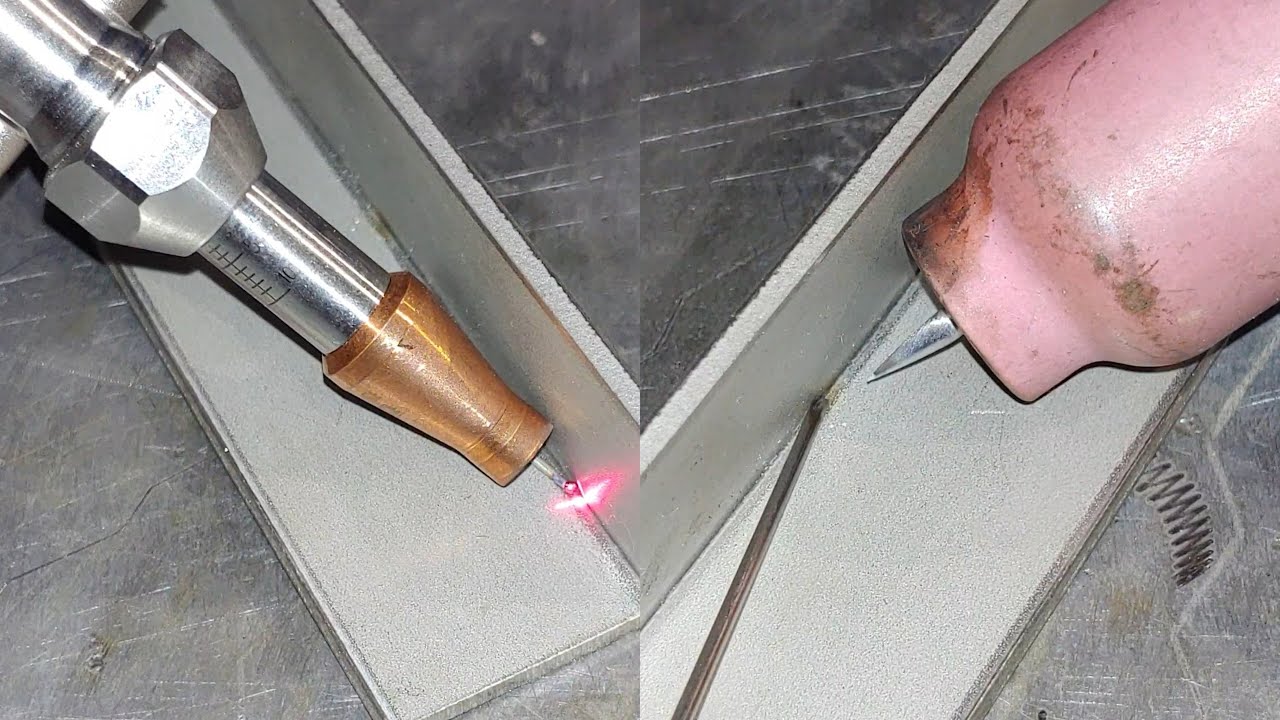

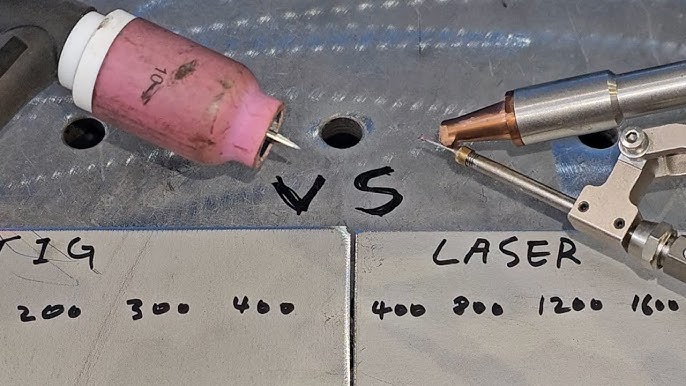

#1 Laser Welding vs. TIG Welding

Website: bodor.com

Key Highlights: In terms of welding speeds, laser welding has proven to be at least 3 to 10 times faster than TIG. The laser component is also more compact and ……

#2 MIG & TIG vs. Laser Welding

Website: smacna.org

Key Highlights: Laser welding is an excellent choice for materials from very thin to roughly 5/16” thick. For thicker materials, MIG is generally a better choice….

#3 Laser Vs. TIG Welding

Website: cobot.systems

Key Highlights: Laser welding is about 4X faster than TIG welding. TIG is one of the slowest welding processes. Laser is much faster than MIG too, so the productivity gain ……

#4 Laser welders

Website: weldingweb.com

Key Highlights: I’m seeing more and more laser welders being advertised and the prices are coming down. Does anyone here already have a laser welder and what’s your opinion?…

#5 Traditional Versus Laser Welding

Website: advancedmanufacturing.org

Key Highlights: With much faster processing speeds and higher quality, you might think laser welding would quickly take over the field. But traditional welding hangs on….

#6 What is Laser Welding and How Does It Work?

Website: laserax.com

Key Highlights: Laser welding offers a wide range of advantages compared to other methods like MIG, TIG, and arc welding. Let’s look at the most important ones….

#7 Laser Welding vs. Traditional Welding

Website: theo.inc

Key Highlights: Laser welding offers numerous benefits over traditional welding methods, including increased efficiency, precision, and reduced training time….

#8 Laser Welding vs. TIG (Arc) Welding

Website: megmeet-welding.com

Key Highlights: While laser welding offers unparalleled speed, precision, and efficiency, TIG welding shines in intricate applications and diverse material ……

Expert Sourcing Insights for Laser Welder Vs Tig

H2: Market Trends in 2026 – Laser Welder vs. TIG Welding Technologies

As industrial manufacturing continues to evolve with advancements in automation, precision, and efficiency, the competition between laser welding and traditional TIG (Tungsten Inert Gas) welding is becoming increasingly pronounced. By 2026, market trends suggest a significant shift toward laser welding technologies, particularly in high-precision and high-volume production environments, while TIG welding maintains a strong foothold in specialized and artisanal applications.

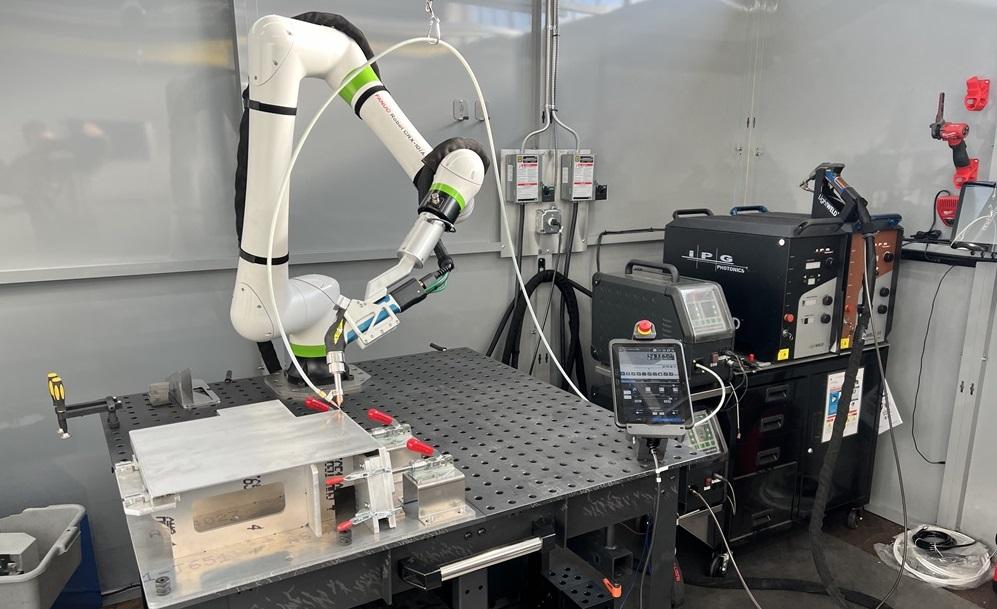

1. Automation and Integration

Laser welding is poised to dominate in automated environments due to its compatibility with robotics and Industry 4.0 standards. By 2026, the integration of laser welding systems with AI-driven process monitoring, real-time feedback loops, and smart manufacturing platforms will enhance repeatability and quality control—key demands in automotive, aerospace, and electronics sectors. In contrast, TIG welding, while highly precise, remains largely manual or semi-automated, limiting its scalability in fully automated lines.

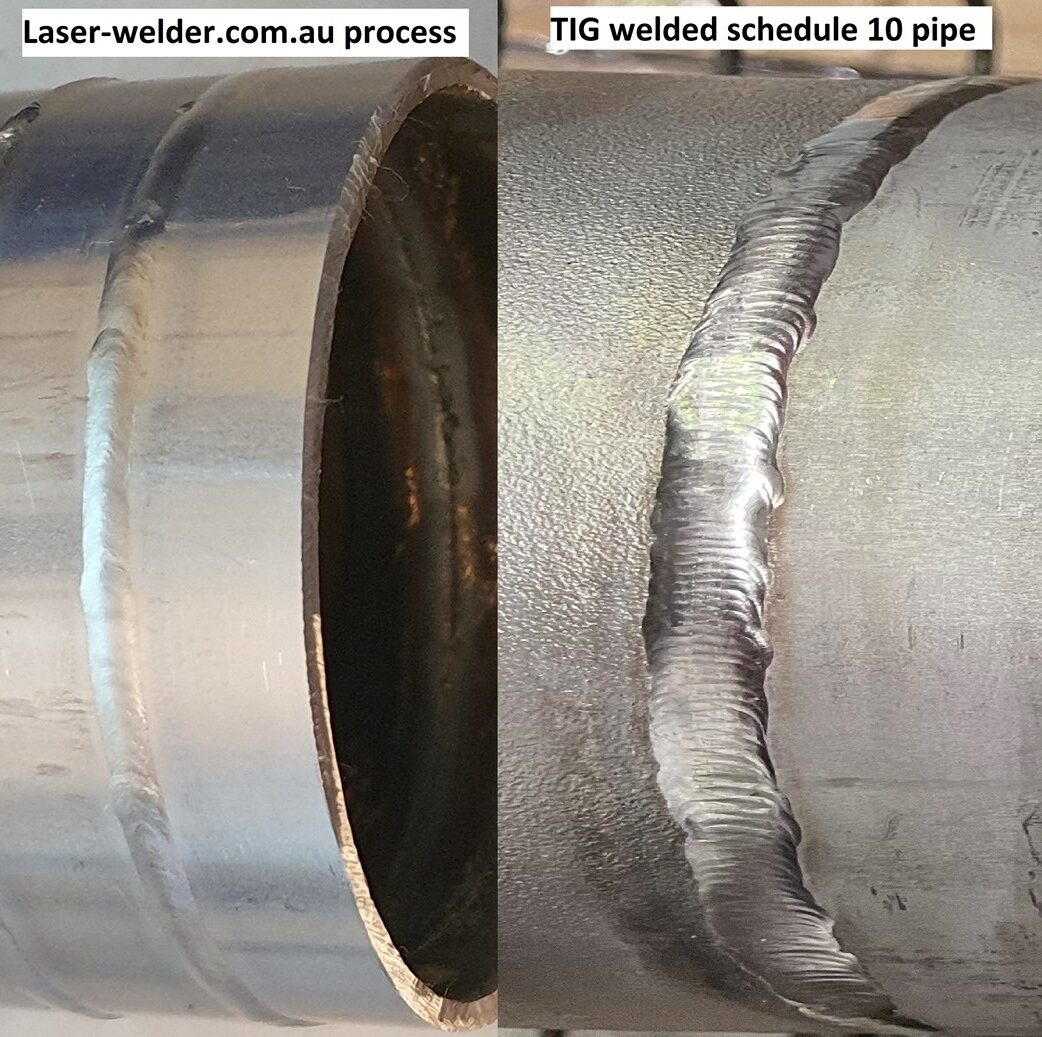

2. Precision and Speed

Laser welding offers superior speed and precision, with narrow heat-affected zones (HAZ) and minimal distortion—critical for thin materials and complex geometries. By 2026, demand for high-speed, low-defect welding in battery manufacturing (e.g., electric vehicles) and medical devices will drive laser adoption. TIG, while capable of excellent finish quality, is slower and more labor-intensive, making it less competitive in high-throughput applications.

3. Cost and Accessibility

TIG welding maintains a cost advantage in low-volume, repair, or custom fabrication settings due to lower initial equipment costs and widespread availability of skilled technicians. However, the total cost of ownership is shifting: declining prices of fiber lasers and increased energy efficiency are making laser systems more accessible. By 2026, mid-sized manufacturers are expected to adopt hybrid or modular laser systems, narrowing the cost gap.

4. Material Flexibility

TIG welding excels in versatility, effectively joining a wide range of metals including aluminum, stainless steel, and exotic alloys—especially in thick sections. It remains the preferred method in shipbuilding, artistic metalwork, and maintenance. Laser welding, while improving in material compatibility (especially with new multi-wavelength and hybrid laser-arc systems), still faces challenges with highly reflective materials like copper and aluminum without specialized setups.

5. Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals will influence 2026 market dynamics. Laser welding systems are generally more energy-efficient and produce less waste (e.g., reduced filler material, lower fumes), aligning with green manufacturing trends. TIG processes, using continuous filler rods and higher energy consumption per weld, may face pressure to innovate for efficiency.

6. Workforce and Skill Development

The global shortage of skilled welders benefits laser automation. As laser systems become more user-friendly with intuitive interfaces and adaptive controls, less operator expertise is required. TIG welding’s reliance on artisan-level skill sets could limit its scalability unless training programs expand significantly.

Conclusion

By 2026, laser welding is expected to capture a growing share of the industrial welding market, particularly in advanced manufacturing sectors that prioritize speed, automation, and precision. TIG welding will remain indispensable in applications requiring high aesthetic quality, versatility, and manual control. The coexistence of both technologies will likely lead to hybrid solutions, where laser systems handle bulk production and TIG is reserved for finishing, repair, and specialized tasks. Market growth will favor laser welding in terms of innovation and investment, but TIG will endure as a critical tool in the welder’s arsenal.

Common Pitfalls Sourcing Laser Welder vs TIG (Quality, IP)

Quality-Related Pitfalls

1. Overestimating Consistency of Laser Welding Without Proper Controls

While laser welding offers high precision and repeatability, sourcing a system without robust process monitoring can lead to undetected defects. Unlike TIG, where weld quality is often visually assessable during the process, laser welding occurs rapidly and may not allow real-time human intervention. Pitfalls include relying solely on machine specifications without verifying closed-loop monitoring (e.g., seam tracking, melt pool monitoring), leading to inconsistent penetration or micro-cracking—especially in high-volume production.

2. Underestimating Operator Skill Requirements for TIG in Precision Applications

TIG welding is often perceived as lower-tech and easier to source, but high-quality TIG demands skilled welders, especially for thin materials or complex joints. Sourcing TIG without evaluating operator availability or training programs can result in variability in bead quality, increased rework, and higher long-term labor costs. Laser systems, while capital-intensive, reduce dependency on operator skill—misjudging this trade-off can compromise quality consistency.

3. Material and Joint Fit-Up Sensitivity in Laser Welding

Laser welding requires tight tolerances in joint fit-up (typically < 0.1 mm gap). Sourcing laser equipment without addressing upstream fabrication capabilities (e.g., CNC cutting, fixturing) often results in poor weld quality due to mismatched edges, porosity, or lack of fusion. TIG is more forgiving of minor misalignments, making it a better fit for low-volume or prototype work where precision fixturing isn’t guaranteed.

Intellectual Property (IP) and Technology Risks

1. Proprietary Software and Locked-Down Systems in Laser Equipment

Many laser welding systems come with proprietary control software that limits user access, customization, or integration with existing MES/SCADA systems. This creates IP risks by making process data ownership unclear and hinders process optimization. Sourcing laser welders without negotiating data access or open API capabilities can lead to long-term dependency on the vendor and restrict innovation.

2. Lack of In-House Expertise to Protect and Leverage IP in Automation

Laser welding systems often include advanced automation and AI-driven quality assurance features. Sourcing such technology without building internal expertise risks exposing proprietary welding parameters or process know-how—especially when relying on vendor support for programming and maintenance. In contrast, TIG processes are typically manual and easier to keep within organizational control, reducing IP leakage risks.

3. Inadequate Protection of Process Parameters When Outsourcing

When outsourcing high-precision welding jobs, choosing laser over TIG—or vice versa—impacts how easily your welding parameters can be replicated. Laser systems store detailed digital recipes, which, if not secured properly, can be copied or reverse-engineered by contract manufacturers. Sourcing decisions must include contractual IP clauses and cybersecurity measures to prevent unauthorized use of proprietary welding data.

Summary

Selecting between laser and TIG welding requires balancing quality expectations with IP protection. Laser offers superior precision but demands tight process control and introduces digital IP risks. TIG is more flexible and less IP-exposed but relies heavily on skilled labor. A successful sourcing strategy evaluates both technical capabilities and long-term ownership of process knowledge.

Logistics & Compliance Guide: Laser Welder vs TIG Welder

Choosing between laser welding and Tungsten Inert Gas (TIG) welding involves more than just technical performance—it significantly impacts logistics, safety, regulatory compliance, and operational efficiency. This guide outlines key considerations for both processes to support informed decision-making in industrial environments.

Equipment Setup & Facility Requirements

Laser Welder:

– Requires a stable, vibration-free environment; sensitive optical components demand clean, climate-controlled spaces.

– High-power laser systems need dedicated electrical circuits (often 480V three-phase) and robust cooling systems (chillers).

– Enclosed safety cells or booths with interlocks are mandatory to contain laser radiation and fumes.

– Integration with robotic arms or CNC systems increases floor space and infrastructure needs.

TIG Welder:

– Portable units available; can be used in diverse environments, including field applications.

– Standard industrial power supply (110V/220V/480V) typically sufficient.

– Requires adequate ventilation or fume extraction systems, especially in confined spaces.

– Less stringent space requirements; welding stations can be modular and reconfigured easily.

Safety & Regulatory Compliance

Laser Welder:

– Must comply with ANSI Z136.1 (Safe Use of Lasers) and IEC 60825 standards.

– Class 4 lasers require engineering controls (interlocks, beam shutters), administrative controls (training, signage), and PPE (laser-safe eyewear with specific wavelength protection).

– Fumes from high-intensity laser vaporization may require specialized filtration (e.g., HEPA + activated carbon).

– Regulatory documentation (Laser Safety Officer designation, hazard assessments) often required.

TIG Welder:

– Governed by OSHA 29 CFR 1910.255 (safety in welding, cutting, and brazing).

– Primary hazards include intense UV radiation, fumes (especially from chromium/nickel alloys), and high-frequency start emissions.

– PPE includes welding helmets (auto-darkening), gloves, flame-resistant clothing, and respiratory protection where ventilation is inadequate.

– Fume extraction systems must meet OSHA permissible exposure limits (PELs) for metals like hexavalent chromium.

Material Handling & Process Logistics

Laser Welder:

– High precision allows minimal joint preparation; tight tolerances reduce fixturing complexity.

– Automated material handling (conveyors, robots) often integrated for consistent part positioning.

– Reflective materials (e.g., copper, aluminum) may require process adjustments or surface treatments.

TIG Welder:

– Manual dexterity required; joint fit-up and cleanliness are critical for quality.

– Slower process speed increases labor time and handling duration.

– Consumables (tungsten electrodes, filler rods, shielding gas) require inventory management and restocking.

Environmental & Waste Management

Laser Welder:

– Generates concentrated metallic fumes and nanoparticles; filtration systems must be maintained and disposed of as hazardous waste if contaminated.

– Minimal consumables reduce waste, but used optics and laser components may be classified as electronic/hazardous waste.

– Energy-intensive operation affects carbon footprint; energy monitoring recommended.

TIG Welder:

– Fumes contain metal oxides and ozone; filtration systems needed, with spent filters potentially classified as hazardous.

– Spent tungsten electrodes (especially thoriated) may require special disposal due to radioactivity.

– Shielding gas cylinders (argon, helium) need proper storage, handling, and return logistics.

Training & Personnel Certification

Laser Welder:

– Operators require specialized training in laser safety, CNC programming, and system maintenance.

– Certification often includes Laser Safety Officer (LSO) training and equipment-specific qualifications.

– High skill threshold; limited pool of trained technicians.

TIG Welder:

– Welders typically require AWS D1.1 or equivalent certification.

– Training focuses on manual dexterity, arc control, and weld bead consistency.

– Widespread availability of certified welders; easier workforce scalability.

Maintenance & Downtime Management

Laser Welder:

– Preventive maintenance critical: optics cleaning, alignment checks, cooling system servicing.

– Downtime can be significant due to complexity; spare parts may have long lead times.

– Service contracts with OEMs common due to technical sophistication.

TIG Welder:

– Routine maintenance includes electrode sharpening, gas nozzle cleaning, and cable inspection.

– Lower repair costs and faster turnaround; most issues field-repairable.

– Greater availability of replacement parts and service technicians.

Regulatory Documentation & Audits

Laser Welder:

– Requires formal Laser Safety Program documentation, including risk assessments, operating procedures, and audit trails.

– Regular compliance audits by internal safety teams or third parties.

– Recordkeeping for training, maintenance, and incident reports essential.

TIG Welder:

– Weld procedure specifications (WPS), welder qualifications (PQR), and inspection records required per ASME or AWS standards.

– OSHA compliance logs for PPE, ventilation, and exposure monitoring.

– Simpler documentation, but still subject to audits in regulated industries (e.g., aerospace, pressure vessels).

Conclusion

While TIG welding offers flexibility, lower initial costs, and simpler compliance for many applications, laser welding provides superior precision and speed at the expense of higher logistical complexity and stricter regulatory demands. The choice depends on production volume, material types, facility capabilities, and compliance resources. A thorough assessment of both technical and operational factors ensures alignment with safety, efficiency, and regulatory standards.

Conclusion: Sourcing a Laser Welder vs. TIG Welder

When deciding between sourcing a laser welder and a TIG (Tungsten Inert Gas) welder, the choice ultimately depends on the specific application, production requirements, material types, budget, and desired weld quality.

Laser welding offers superior precision, higher welding speeds, minimal heat-affected zones, and excellent repeatability—making it ideal for high-volume, automated manufacturing environments, especially in industries like automotive, aerospace, and medical devices. However, it requires a significant upfront investment, specialized training, and tight joint fit-up tolerances, which may not be feasible for smaller operations or variable production needs.

On the other hand, TIG welding provides exceptional weld quality and versatility, particularly for thin materials and exotic metals such as aluminum, stainless steel, and titanium. It is more accessible, cost-effective for low to medium production volumes, and allows for greater flexibility in manual or semi-automated setups. While slower than laser welding, TIG remains the preferred choice for custom fabrication, repair work, and applications where precision craftsmanship is paramount.

In summary, source a laser welder if your priority is high throughput, automation, and precision in a controlled environment. Choose TIG welding for greater flexibility, lower initial costs, and applications requiring fine, detailed work or diverse material compatibility. A careful evaluation of your production scale, technical requirements, and long-term goals will determine the most advantageous welding technology to source.