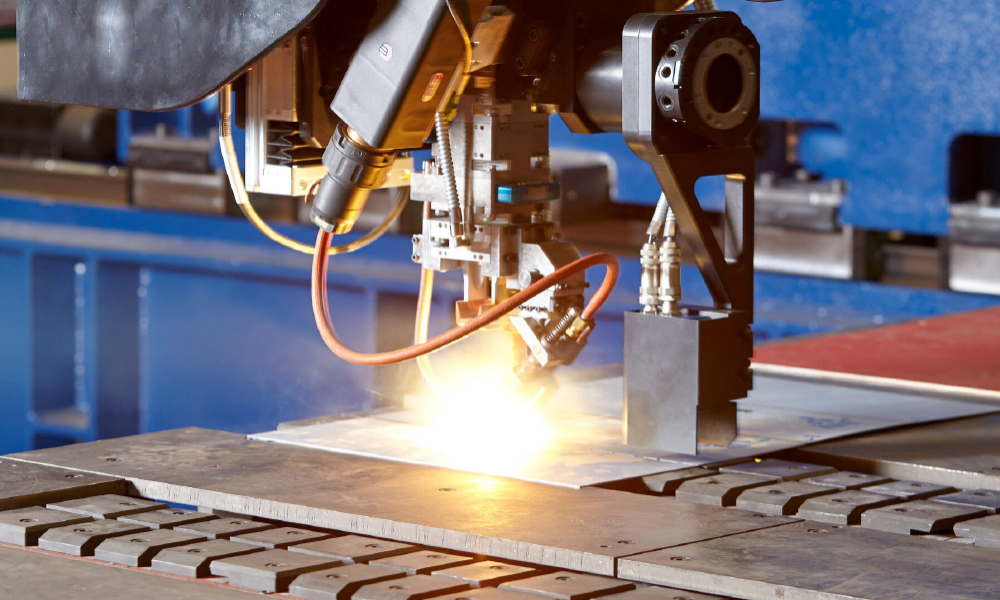

The global laser welding market is experiencing robust growth, driven by rising demand for precision manufacturing across automotive, aerospace, and electronics industries. According to Grand View Research, the global laser welding market size was valued at USD 4.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This surge is fueled by advancements in high-power fiber lasers, increasing automation, and the shift toward energy-efficient manufacturing processes. As industries prioritize faster production cycles and stronger, cleaner welds, the adoption of laser welding technology continues to accelerate. With this growing demand, numerous manufacturers have emerged, offering a range of systems across various price points and capabilities. The following analysis explores the top 9 laser welder manufacturers, evaluating their pricing, technology, and market positioning to help guide procurement and investment decisions in a competitive and evolving landscape.

Top 9 Laser Welder Prices Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#2 Denaliweld

Website: denaliweld.com

Key Highlights: We Specialize in Laser Welding & Cleaning. DenaliWeld INC, is a proud employee-owned fiber laser welding machine manufacturer based in Chicago, USA. Bolstered ……

#3 Laser Welders

Website: everlastgenerators.com

Key Highlights: Free delivery 30-day returnsWelding products for the professional or hobbyist. Everlast Power Equipments full line of welders, welding products and generators will help you complet…

#4 Serra Laser Store – LightWELD

#5 Laser Welders

Website: sunstonewelders.com

Key Highlights: 6–7 day deliveryLaser Welders · Compare. Original price $5,200.00 – Original price $5,700.00 · Compare. Original price $21,900.00 – Original price $21,900.00 · Compare. Original …..

#6 xTool MetalFab Laser Welder/ CNC Cutter

Website: xtool.com

Key Highlights: All-in-One Metal Workshop: Weld, cut, and clean effortlessly with fiber laser precision on stainless steel, aluminum, brass, and more….

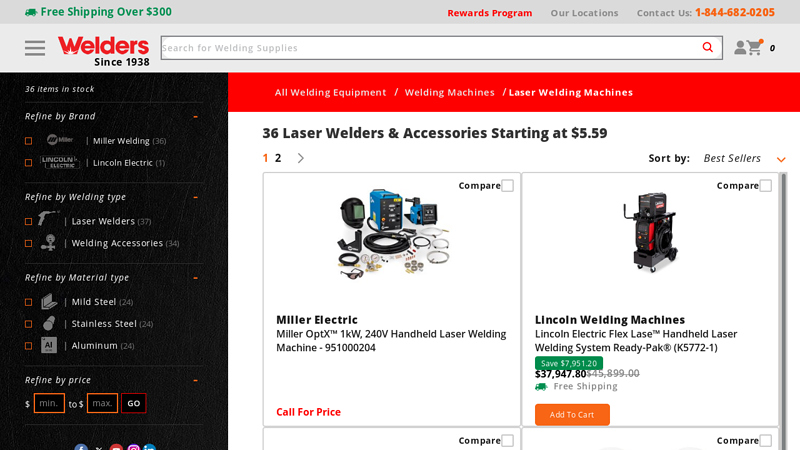

#7 36 Laser Welders & Accessories for sale from $5.59

Website: weldersupply.com

Key Highlights: Free delivery over $300 · 14-day returnsLincoln Welding Machines Lincoln Electric Flex Lase™ Handheld Laser Welding System Ready-Pak® (K5772-1). Save $7,951.20. $37,947.80. $45,89…

#8 Laser Welder

Website: laser-welder.net

Key Highlights: IPG Lightweld 1500 Laser Welder cost VS Our range The IPG with closest performance to our 1500W welders is Lightweld XR. As of 2024 this sells for around $34, ……

#9 Full Spectrum Laser

Expert Sourcing Insights for Laser Welder Prices

2026 Market Trends for Laser Welder Prices

Looking ahead to 2026, the global laser welder market is poised for continued evolution, with pricing influenced by a confluence of technological advancements, supply chain dynamics, and shifting industrial demands. While predicting exact prices remains challenging, several key trends are expected to shape the cost landscape:

1. Gradual Price Stabilization Amid Technological Maturation

By 2026, laser welding technology—particularly fiber laser systems—will have reached a higher level of maturity. Widespread adoption across automotive, aerospace, electronics, and medical device manufacturing will drive economies of scale, leading to a gradual stabilization or modest decline in the average selling price (ASP) for standard industrial models. However, this trend will be most pronounced in the mid-power segment (1–6 kW), where competition among manufacturers from China, Europe, and North America intensifies.

2. Premium Pricing for High-Power and Smart Systems

High-power laser welders (10 kW and above), especially those incorporating remote welding, real-time monitoring, and AI-driven process optimization, will maintain premium price points. Demand for these advanced systems in electric vehicle (EV) battery manufacturing and lightweight automotive structures will support higher margins. Integration with Industry 4.0 platforms—enabling predictive maintenance and data analytics—will further justify elevated prices for smart, connected laser welding solutions.

3. Regional Price Divergence and Supply Chain Impacts

Geopolitical factors and regional supply chain resilience will influence pricing. Manufacturers in China are expected to offer competitively priced systems, pressuring global vendors to reduce costs. Conversely, laser welders produced in North America and Europe may carry higher price tags due to labor costs and stricter regulatory compliance, though they will emphasize reliability, service, and customization. Ongoing semiconductor availability and rare earth material costs could cause short-term price volatility, particularly for components like laser diodes.

4. Growth of Compact and Portable Systems Affecting Entry-Level Pricing

The rise of compact, modular, and portable laser welders—targeting small and medium enterprises (SMEs) and field repair operations—will expand the lower end of the market. Increased competition in this segment is likely to drive down entry-level prices, making laser welding more accessible. However, these systems may feature reduced power or automation, maintaining a clear price-performance distinction from industrial-grade units.

5. Sustainability and Total Cost of Ownership (TCO) Influence

Buyers will increasingly evaluate laser welders based on TCO rather than upfront cost. Energy-efficient models with lower maintenance needs and longer component lifespans will command price premiums, especially as sustainability regulations tighten. Manufacturers emphasizing recyclability, energy consumption, and operational efficiency will position their products as cost-effective long-term investments, justifying higher initial prices.

In summary, the 2026 laser welder market will see a bifurcated pricing trend: downward pressure on standardized mid-range systems due to competition and scale, while advanced, high-power, and intelligent systems retain strong pricing power. Regional dynamics, supply chain resilience, and a growing focus on automation and sustainability will be critical factors shaping what buyers pay.

Common Pitfalls When Sourcing Laser Welder Prices (Quality, IP)

When sourcing laser welders, focusing solely on upfront price can lead to significant long-term costs and operational challenges. Buyers must carefully evaluate both quality and intellectual property (IP) aspects to avoid these common pitfalls.

Overlooking Build Quality and Component Origins

Many suppliers quote competitive prices by using lower-grade components—such as generic optics, cooling systems, or motion controls—that degrade quickly under industrial use. Machines built with substandard materials may require frequent maintenance, suffer from inconsistent weld quality, and have shorter lifespans, ultimately increasing total cost of ownership. Buyers should verify the origin and specification of core components like laser sources (e.g., IPG vs. lesser-known brands) and control systems.

Ignoring Intellectual Property and Software Limitations

Low-cost laser welders, especially from certain regions, may incorporate software or control systems that infringe on third-party IP. This poses legal risks, including potential seizures or injunctions. Additionally, proprietary software with limited API access or poor documentation can prevent integration into automated production lines or future scalability. Ensure the supplier provides clear IP indemnification and open, upgradable software architecture.

Falling for Inflated Specifications Without Verification

Some vendors exaggerate key performance metrics—like beam quality (M²), power stability, or duty cycle—to justify pricing or appear competitive. Without independent validation or test reports, these claims may not reflect real-world performance. Always request live demonstrations, third-party certifications, or customer references to verify technical specifications.

Underestimating After-Sales Support and Spare Parts Availability

The cheapest laser welder may become the most expensive if the supplier lacks local technical support, training, or readily available spare parts. Downtime due to repair delays can severely impact production. Evaluate the supplier’s service network, response time, and warranty terms as part of the total value assessment—not just the initial price.

Neglecting Long-Term Compliance and Safety Standards

Low-cost units may fail to meet international safety and regulatory standards (e.g., CE, FDA, or ISO). This can result in facility shutdowns or liability issues. Confirm that the laser system complies with relevant standards and includes proper safety interlocks, labeling, and documentation to protect both personnel and operations.

By recognizing these pitfalls, buyers can make informed decisions that balance cost with quality, reliability, and legal safety—ensuring a sustainable investment in laser welding technology.

Logistics & Compliance Guide for Laser Welder Prices

Understanding the full cost and legal requirements involved in procuring laser welders—especially when sourcing internationally—is essential for accurate budgeting, smooth operations, and regulatory adherence. This guide outlines key logistics and compliance factors that influence laser welder pricing and deployment.

Import Regulations and Duties

Laser welders are often classified under specific Harmonized System (HS) codes, such as 8515.21 or 8515.31, depending on type and power. Import duties vary significantly by country, with rates ranging from 0% to over 10% in some markets. Importers must verify applicable tariffs and any anti-dumping or countervailing duties that may apply. Non-compliance can result in shipment delays, fines, or seizure of equipment.

Shipping and Freight Costs

Laser welding systems are heavy, bulky, and often require specialized handling due to sensitive optical components. Sea freight is typically more cost-effective for full container loads, while air freight speeds delivery at a premium. Crating, insurance, and Incoterms (e.g., FOB, CIF, DDP) significantly affect final pricing. Underestimating freight costs can increase total project expenses by 10–20%.

Customs Clearance and Documentation

Timely customs clearance requires accurate documentation, including commercial invoices, packing lists, bill of lading/airway bill, and certificates of origin. Laser products may require additional declarations under safety or radiation control regulations (e.g., FDA 21 CFR 1040.10 in the U.S.). Delays in submitting correct paperwork can lead to demurrage fees and extended downtime.

Safety and Regulatory Compliance

Laser welders are Class 1, 3B, or 4 laser products and must comply with international safety standards such as IEC 60825-1 (laser safety) and IEC 60204-1 (machine safety). Regional certifications like CE (Europe), UKCA (UK), CCC (China), or EAC (Eurasia) are mandatory for legal operation. Compliance testing and certification add to the upfront cost but are non-negotiable for deployment.

Electromagnetic Compatibility (EMC) and Environmental Standards

Laser welding systems must meet EMC directives (e.g., EU’s 2014/30/EU) to prevent interference with other equipment. Environmental regulations such as RoHS and REACH restrict hazardous substances in electronic components. Non-compliant machines may be denied entry or operation in regulated markets.

Installation, Training, and After-Sales Support

Compliance extends beyond importation to proper installation and operator training. Suppliers should provide on-site commissioning, safety training, and technical documentation in the local language. Ongoing maintenance and spare parts logistics affect total cost of ownership and operational uptime.

Conclusion

Accurate laser welder pricing must account for logistics and compliance beyond the quoted unit cost. Import duties, freight, certifications, and after-sales support all influence total expenditure. Proactive planning with experienced freight forwarders and legal advisors ensures timely delivery, regulatory approval, and long-term operational success.

Conclusion: Sourcing Laser Welder Prices

After thorough evaluation of various suppliers, models, and market trends, sourcing laser welder prices reveals a broad range of options tailored to different operational needs and budgets. Prices vary significantly based on factors such as laser type (fiber, CO2, or disk), power output, automation capabilities, brand reputation, and additional features like cooling systems or integrated safety controls.

Key findings indicate that while entry-level fiber laser welders offer cost-effective solutions for small-scale or precision applications, high-power industrial systems from reputable manufacturers provide greater durability, efficiency, and return on investment for heavy-duty manufacturing environments. Additionally, purchasing from domestic suppliers may reduce lead times and support costs, whereas international options—particularly from Asia—can offer substantial price advantages, albeit with potential trade-offs in service and logistics.

Ultimately, the decision should balance initial cost with long-term value, considering factors such as warranty, after-sales support, training, and total cost of ownership. By prioritizing technical specifications aligned with production requirements and leveraging competitive quotes from multiple vendors, businesses can secure a laser welding solution that optimizes both performance and cost-efficiency.