The global laser welding market is experiencing robust growth, driven by increasing demand for high-precision joining solutions in aerospace, medical devices, and high-performance automotive applications. According to Grand View Research, the global laser welding market size was valued at USD 4.8 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2024 to 2030. A key contributor to this expansion is the rising use of laser welding for challenging materials like titanium—valued for its strength-to-weight ratio and corrosion resistance—particularly in critical applications where weld integrity is non-negotiable. Mordor Intelligence highlights that advancements in fiber laser technology and the growing adoption of automation in manufacturing are further accelerating the penetration of laser-based processes in metal fabrication. As industries push for cleaner, more efficient, and repeatable welds, the demand for specialized titanium welding capabilities has surged. This has spurred innovation among manufacturers, resulting in a competitive landscape where precision, reliability, and technical expertise differentiate market leaders. The following list identifies the top 10 manufacturers excelling in laser titanium welding, selected based on technological capability, industry certifications, application track record, and market presence.

Top 10 Laser Titanium Welding Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Maximizing Strength and Precision with Laser Welding Titanium

Website: lxslaser.com

Key Highlights: Introducing the laser welding titanium machine from Jinan Lingxiu Laser Equipment Co., Ltd., a leading manufacturer, supplier, and factory based in China….

#2 TITANIUM LASER WELDING

Website: photonautomation.com

Key Highlights: Titanium laser welding is widely used for implants and surgical tools. It requires extremely precise process control to create strong, defect-free joints ……

#3 Titanium Laser Welding Machines

Website: acctekgroup.com

Key Highlights: Titanium laser welding machines deliver precise, clean, and high-strength welds with minimal heat input—perfect for aerospace, medical, and industrial-grade ……

#4 Laser Welding Titanium

Website: ebindustries.com

Key Highlights: Titanium is laser weldable. Certified ISO 13485:2016 laser welding services. Fast quote and and turn-around. Automated, semi-automated, CAD/CAM design, ……

#5 Laser Welding

Website: ipgphotonics.com

Key Highlights: Laser welding is the process of transferring a laser beam’s energy in the form of heat to fuse or join parts. This transferred heat melts the materials to ……

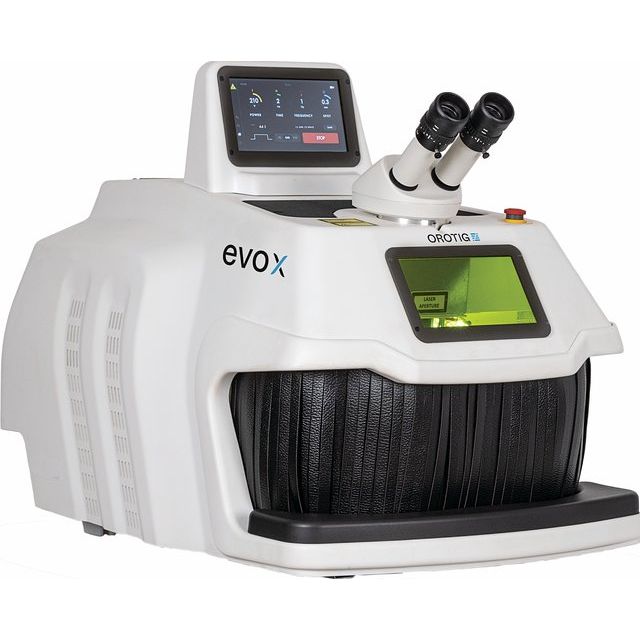

#6 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals….

#7 Laser Processing Solutions

Website: titanovalaser.com

Key Highlights: Discover Titanova’s advanced laser processing services like cladding and heat treating to enhance surface properties and extend component lifespan.…

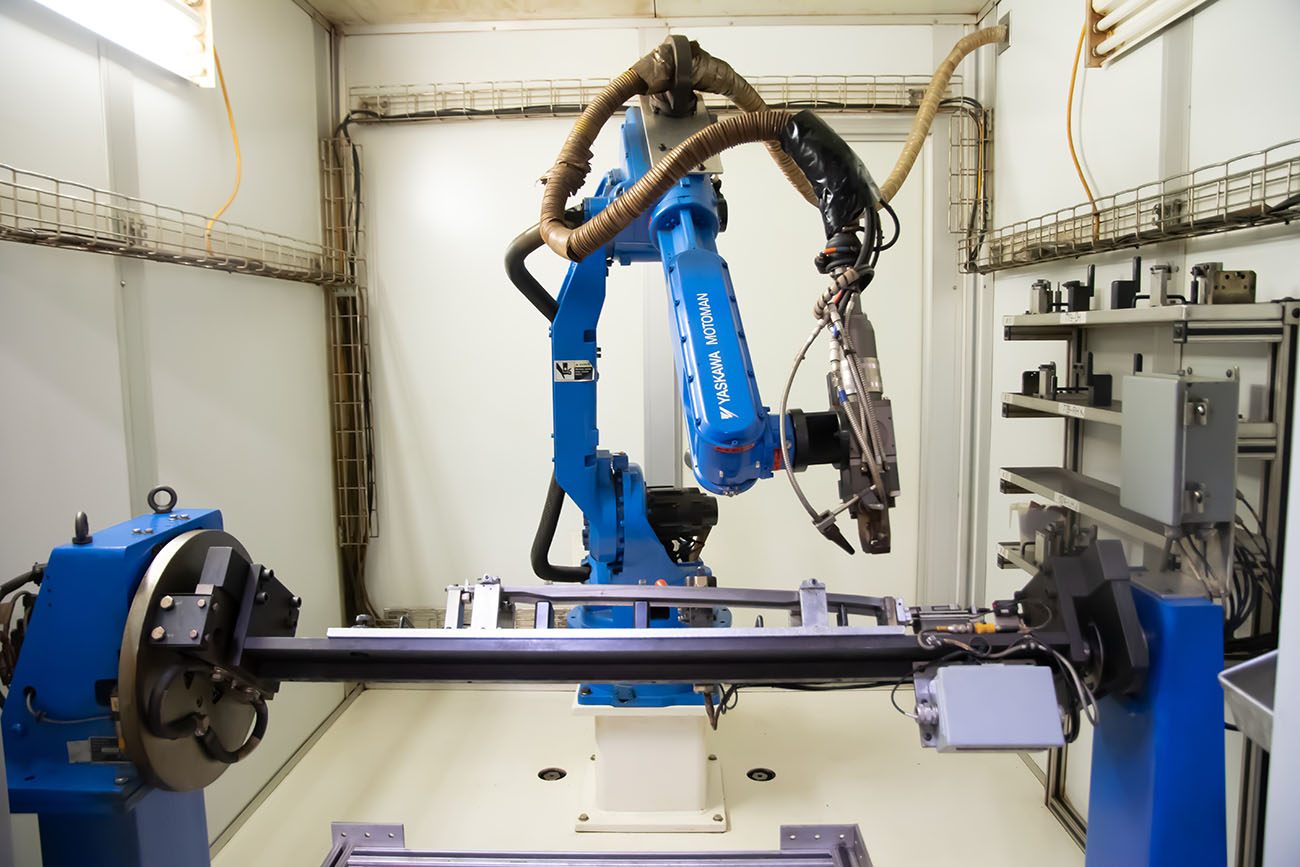

#8 Titanium Welding

Website: rfcorp.com

Key Highlights: Laser welding of titanium allows us to create durable lightweight components that exceeds aviation standards for performance and safety….

#9 Inside the Structural Design of Laser Welding Machines

Website: strlaser-en.com

Key Highlights: Laser welding machines are the backbone of modern high-precision manufacturing, offering unmatched efficiency, minimal thermal distortion, ……

#10 Laser Welding Process

Website: titanium.net

Key Highlights: Laser welding is a new type of welding, laser welding is mainly for thin-wall materials, precision parts welding, spot welding, butt welding, overlap welding, ……

Expert Sourcing Insights for Laser Titanium Welding

H2: Projected 2026 Market Trends for Laser Titanium Welding

The global market for laser titanium welding is poised for significant transformation by 2026, driven by technological advancements, expanding industrial applications, and increasing demand for high-precision and high-strength joining solutions. Key trends shaping the 2026 landscape include:

-

Growth in Aerospace and Defense Applications

The aerospace and defense sectors remain the primary drivers of laser titanium welding demand. With titanium’s exceptional strength-to-weight ratio and corrosion resistance, it is a preferred material for aircraft engines, airframes, and military equipment. By 2026, continued production of next-generation commercial and military aircraft—such as Boeing, Airbus, and emerging hypersonic platforms—will fuel demand for high-efficiency laser welding systems capable of handling complex titanium alloys (e.g., Ti-6Al-4V). Automation and integration with digital twin technologies are expected to enhance process consistency and reduce manufacturing lead times. -

Adoption of High-Power and Ultrafast Lasers

Technological evolution in laser sources, including fiber and disk lasers with power outputs exceeding 10 kW, will enable deeper penetration and faster welding speeds in titanium. Additionally, ultrafast (pulsed) lasers are gaining traction for micro-welding applications in medical devices and electronics. By 2026, these advanced laser systems will offer improved control over heat input, reducing distortion and the need for post-weld treatments—critical for maintaining titanium’s material integrity. -

Rise of Hybrid and Intelligent Welding Systems

Integration of artificial intelligence (AI), machine learning, and real-time monitoring systems will redefine laser welding processes. Smart welding platforms with adaptive control features—such as closed-loop feedback using sensors for seam tracking and defect detection—will enhance reliability in titanium welding. Hybrid systems combining laser-arc welding are also expected to gain adoption, offering deeper weld penetration and greater tolerance to joint misalignment, especially in heavy industrial applications. -

Expansion in Medical and Automotive Sectors

The medical device industry is increasingly utilizing laser welding for titanium implants (e.g., hip joints, dental fixtures) due to its precision and biocompatibility. By 2026, rising global demand for minimally invasive surgeries and personalized implants will boost market growth. In the automotive sector, although titanium use remains limited due to cost, its application in high-performance and electric vehicles (EVs) for lightweight components will gradually increase, supported by advancements in cost-efficient laser welding techniques. -

Sustainability and Process Efficiency Focus

Manufacturers are prioritizing energy-efficient and environmentally sustainable production methods. Laser welding offers advantages over traditional arc welding, including reduced heat-affected zones, lower energy consumption, and minimal material waste. By 2026, regulatory pressures and corporate ESG (Environmental, Social, Governance) goals will accelerate the shift toward laser-based solutions in titanium fabrication. -

Regional Market Dynamics and Supply Chain Shifts

Asia-Pacific—especially China, Japan, and South Korea—is expected to lead market growth due to robust investments in aerospace, electronics, and industrial automation. North America will maintain strong demand driven by defense modernization and advanced manufacturing initiatives. Europe will focus on innovation and sustainability, supported by EU-funded research in laser processing technologies. However, supply chain resilience for high-purity titanium and laser system components will be critical, with potential regionalization of production to mitigate geopolitical and logistical risks.

In conclusion, the 2026 laser titanium welding market will be characterized by technological sophistication, sector diversification, and a strong emphasis on automation and sustainability. Stakeholders who invest in R&D, digital integration, and scalable manufacturing solutions will be best positioned to capitalize on emerging opportunities.

Common Pitfalls in Sourcing Laser Titanium Welding (Quality, IP)

Sourcing laser welding services for titanium components involves navigating significant technical and legal challenges. Overlooking critical aspects can lead to compromised product integrity, project delays, and intellectual property (IP) exposure. Below are key pitfalls related to quality and IP that must be addressed:

Quality-Related Pitfalls

-

Inadequate Process Control and Parameter Validation

Titanium’s reactivity and sensitivity to heat require precise laser parameters (power, speed, pulse frequency, shielding gas flow). Sourcing from vendors without validated and documented procedures risks inconsistent weld quality, porosity, cracking, or embrittlement. Always verify the supplier’s process qualification (e.g., through WPS—Welding Procedure Specifications) and ability to replicate results across batches. -

Insufficient Shielding Gas Management

Contamination from oxygen, nitrogen, or moisture during welding severely degrades titanium’s mechanical properties. A common pitfall is assuming standard shielding practices suffice. Ensure the supplier uses high-purity inert gas (typically argon or helium), maintains proper gas coverage (e.g., trailing shields, glove boxes), and monitors oxygen levels in real time (ideally <50 ppm). -

Lack of Cleanliness and Surface Preparation Control

Titanium is highly susceptible to contamination from oils, chlorides, or particulates. Suppliers who don’t enforce strict cleaning protocols (e.g., solvent degreasing, wire brushing with dedicated tools) risk introducing defects. Verify their cleaning procedures and environmental controls (e.g., cleanroom or dedicated welding areas). -

Inadequate Post-Weld Inspection and Testing

Relying solely on visual inspection is insufficient. Pitfalls arise when suppliers lack capabilities for non-destructive testing (NDT) such as X-ray radiography, dye penetrant, or ultrasonic testing. Ensure the vendor provides comprehensive inspection reports and destructive testing (e.g., tensile, microstructure) when required by your specifications. -

Mismatched Equipment and Expertise

Not all laser welders are suited for titanium. Fiber lasers with precise beam control are often preferred. Sourcing from vendors without specific titanium welding experience or appropriate equipment (e.g., enclosed chambers for reactive materials) increases the risk of substandard welds. Validate their track record with titanium and inspect their facility if possible.

Intellectual Property (IP)-Related Pitfalls

-

Absence of a Robust Non-Disclosure Agreement (NDA)

Sharing design files, material specs, or application details with a supplier without a comprehensive NDA exposes sensitive IP. A weak or unsigned NDA is a major risk. Use a mutual NDA that explicitly covers all shared information and defines usage restrictions. -

Unclear Ownership of Process Development and Tooling

If the supplier develops custom fixturing, welding programs, or process optimizations for your part, IP ownership may be ambiguous. Without a clear contract, the supplier could claim rights or reuse the process for competitors. Specify in the agreement that all work product and IP related to your project belong to you. -

Lack of Control Over Digital Design Files

Sending CAD or CAM files without protection increases the risk of unauthorized duplication or reverse engineering. Use encrypted file transfers, watermark designs where possible, and limit file access to essential personnel. Consider using neutral formats (e.g., STEP) instead of native CAD files. -

Insufficient Audit Rights and Compliance Verification

Assuming a supplier complies with IP and quality standards without verification is risky. Contracts should include audit rights allowing you to inspect their facilities, procedures, and records. This ensures they adhere to agreed-upon protocols and do not misuse your IP. -

Unsecured Supply Chain and Subcontracting

Some suppliers outsource work without consent, exposing your IP to third parties with unknown safeguards. Prohibit subcontracting without prior written approval and ensure any approved subcontractors are bound by equivalent IP protections.

Conclusion

Successfully sourcing laser titanium welding requires due diligence in both technical capability and legal safeguards. Prioritize suppliers with proven titanium expertise, stringent quality systems (e.g., ISO 9001, AS9100), and transparent IP practices. Always formalize agreements with clear terms on quality standards, inspection protocols, and IP ownership to mitigate risks and ensure project success.

H2: Logistics & Compliance Guide for Laser Titanium Welding

Laser titanium welding is a high-precision manufacturing process widely used in aerospace, medical device, and defense industries due to titanium’s exceptional strength-to-weight ratio and corrosion resistance. Ensuring compliance and efficient logistics throughout the welding process is critical to maintaining product integrity, workplace safety, and adherence to regulatory standards. This guide outlines key logistics and compliance considerations for laser titanium welding operations.

H2: Material Handling and Storage Logistics

Proper handling and storage of titanium materials are essential to prevent contamination, which can compromise weld quality and structural integrity.

- Clean Environment: Store titanium stock (plates, rods, tubes) in a dedicated, dry, and contamination-free area. Avoid contact with carbon steel, iron, or other metals to prevent galvanic corrosion.

- Protective Packaging: Maintain original packaging until just before processing. Use clean gloves and non-metallic tools when handling to avoid surface contamination.

- Segregation: Physically separate titanium from other metals during storage and transport to avoid cross-contamination.

H2: Equipment and Facility Requirements

Laser welding systems used for titanium require specialized configurations and environmental controls.

- Controlled Atmosphere: Use inert gas shielding (typically argon or helium) in enclosed chambers or local gas shrouds to prevent oxidation during welding. Ensure oxygen levels are maintained below 50 ppm in welding enclosures.

- Clean Work Environment: Maintain ISO Class 7 or cleaner cleanroom conditions in welding areas to minimize particulate contamination.

- Laser System Calibration: Regularly calibrate laser power, beam alignment, and focus optics. Maintain logs for traceability and compliance audits.

H2: Personnel Training and Safety Compliance

Qualified personnel are crucial for safe and compliant laser titanium welding operations.

- Certification: Ensure welders and operators are certified according to relevant standards (e.g., ASME Section IX, AWS D17.1 for aerospace).

- Laser Safety Training: Operators must be trained in laser safety (per ANSI Z136.1) including proper use of protective eyewear, interlock systems, and emergency shutdown procedures.

- PPE Requirements: Mandate flame-resistant clothing, face shields with appropriate laser filtering, and gloves. Respiratory protection may be required if fumes are generated.

H2: Quality Control and Traceability

Robust quality systems ensure weld integrity and regulatory compliance.

- Weld Procedure Qualification Records (WPQR): Maintain documented and approved welding procedures specific to titanium alloys (e.g., Ti-6Al-4V).

- Non-Destructive Testing (NDT): Perform post-weld inspection using methods such as X-ray radiography, ultrasonic testing, or dye penetrant testing to detect porosity, cracks, or inclusions.

- Material Traceability: Implement full traceability from raw material lot numbers through final product, including weld logs, operator IDs, and process parameters.

H2: Regulatory and Industry Standards

Compliance with international and industry-specific standards is mandatory.

- Aerospace: Adhere to Nadcap (National Aerospace and Defense Contractors Accreditation Program) requirements for welding.

- Medical Devices: Follow FDA 21 CFR Part 820 (Quality System Regulation) and ISO 13485 for implantable devices.

- Environmental and Safety: Comply with OSHA regulations for workplace safety and EPA guidelines for hazardous waste (e.g., spent shielding gas, metal fumes).

- Export Controls: Titanium and laser welding technologies may be subject to ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations) if used in defense applications.

H2: Waste Management and Environmental Compliance

Proper disposal of byproducts ensures environmental responsibility and regulatory adherence.

- Titanium Swarf and Dust: Classify as combustible metal waste; store in non-reactive, sealed containers and dispose of via certified hazardous waste handlers.

- Gas Cylinders: Return or recycle inert gas cylinders through authorized vendors. Monitor for leaks and ensure proper ventilation.

- Fume Extraction: Install HEPA-filtered fume extraction systems to capture titanium oxide particulates generated during welding.

H2: Documentation and Audit Preparedness

Maintaining accurate records supports compliance and continuous improvement.

- Process Logs: Document laser parameters (power, speed, pulse frequency), gas flow rates, and environmental conditions for each weld.

- Calibration and Maintenance Records: Keep up-to-date logs for laser equipment, gas delivery systems, and monitoring instruments.

- Internal Audits: Conduct regular audits to verify compliance with internal procedures and external standards.

Following this logistics and compliance guide ensures safe, repeatable, and high-quality laser titanium welding operations while meeting stringent industry requirements. Regular review and updates to procedures are recommended to align with evolving standards and technological advancements.

Conclusion for Sourcing Laser Titanium Welding

Sourcing laser titanium welding services requires a strategic approach that balances technical expertise, equipment capabilities, quality assurance, and cost-efficiency. Titanium’s unique properties—high strength-to-weight ratio, excellent corrosion resistance, and performance at elevated temperatures—make it ideal for demanding applications in aerospace, medical, defense, and automotive industries. However, these same properties also make titanium challenging to weld, necessitating the precision and control offered by laser welding technology.

When sourcing this specialized capability, it is critical to partner with suppliers possessing proven experience in laser welding titanium alloys, access to high-precision laser systems (such as fiber or disk lasers), and stringent process controls including inert gas shielding (typically argon or helium) to prevent oxidation and ensure weld integrity. Certifications (e.g., AS9100, ISO 13485) and adherence to industry-specific standards are key indicators of a reliable vendor.

Additionally, factors such as design for manufacturability, post-weld inspection (e.g., X-ray, dye penetrant, or mechanical testing), and traceability should be integrated into the sourcing decision. While initial costs may be higher compared to conventional welding methods, the superior quality, repeatability, and minimal distortion achieved through laser welding often result in long-term savings and enhanced product performance.

In conclusion, successful sourcing of laser titanium welding involves thorough due diligence, technical evaluation of suppliers, and a focus on quality and compliance. Choosing the right partner ensures robust, high-integrity welds that meet the demanding requirements of advanced engineering applications.