The global laser stripping tools market is experiencing robust growth, driven by rising demand for precision, non-contact material processing in aerospace, defense, automotive, and electronics industries. According to a 2023 report by Mordor Intelligence, the global laser processing equipment market—encompassing laser cutting, welding, and stripping—is projected to grow at a CAGR of over 7.5% through 2028. Laser stripping, in particular, is gaining traction as manufacturers seek repeatable, environmentally friendly alternatives to mechanical and chemical insulation removal methods. Grand View Research further underscores this trend, noting that advancements in fiber laser technology and automation integration are accelerating adoption across high-reliability sectors. As the need for precision wire and cable preparation intensifies, especially in electric vehicles and avionics, a select group of manufacturers has emerged at the forefront of innovation and performance. Below are the top 9 laser stripping tool manufacturers shaping the future of this rapidly evolving niche.

Top 9 Laser Stripping Tool Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#2 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#3 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#4 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, fiber laser…

#6 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

#7 Laser Stripping

Website: komaxgroup.com

Key Highlights: Semi-automatic laser stripping machines deliver high-quality, completely nick-free stripping of wires and cables….

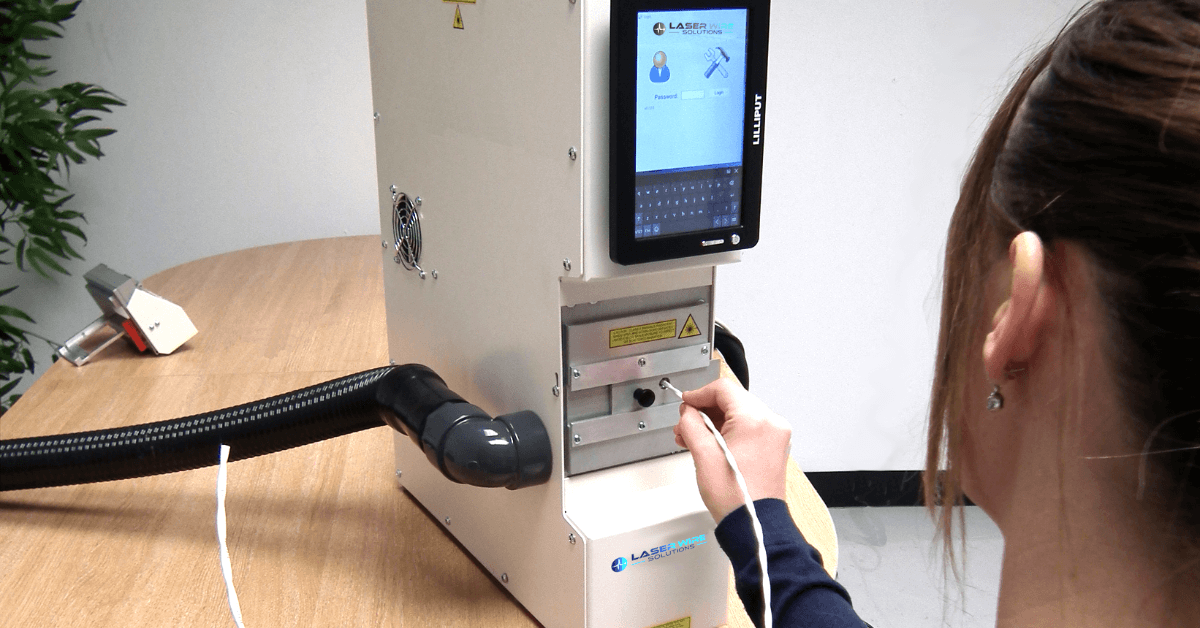

#8 Laser Wire Solutions

Website: laserwiresolutions.com

Key Highlights: Providing cutting-edge laser processing solutions that deliver unparalleled precision and speed….

#9 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

Expert Sourcing Insights for Laser Stripping Tool

2026 Market Trends for Laser Stripping Tools

The global laser stripping tool market is poised for significant transformation by 2026, driven by technological advancements, growing industrial automation, and increasing demand for precision in manufacturing and repair processes. This analysis examines the key trends expected to shape the market landscape in the coming years.

Rising Demand in Aerospace and Defense

The aerospace and defense sectors are major adopters of laser stripping tools due to stringent requirements for non-damaging surface preparation. By 2026, increased aircraft production, maintenance cycles (MRO), and modernization of military assets will drive demand for high-precision, chemical-free stripping solutions. Laser tools offer advantages in removing paint, coatings, and corrosion from sensitive composite and aluminum structures without substrate damage, aligning with environmental and safety regulations.

Growth in Electric Vehicle (EV) Manufacturing

The rapid expansion of the electric vehicle market is creating new applications for laser stripping tools, particularly in battery production and wire harness processing. Precision stripping of insulated wires and connectors is critical for ensuring electrical safety and performance. Laser systems provide clean, burr-free stripping of fine-gauge wires used in EV power electronics, contributing to improved manufacturing yields. As EV production scales globally, demand for automated laser stripping solutions will rise significantly by 2026.

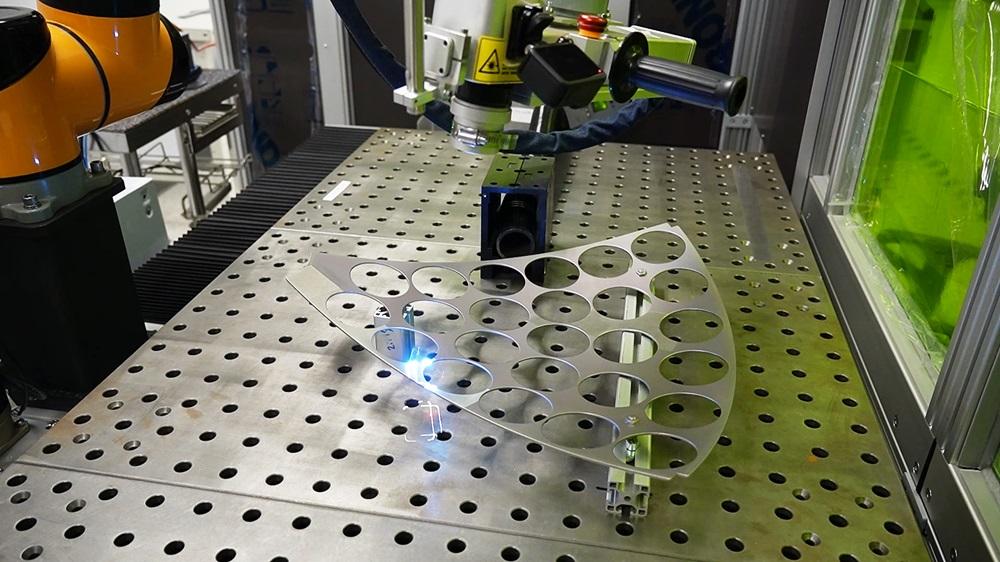

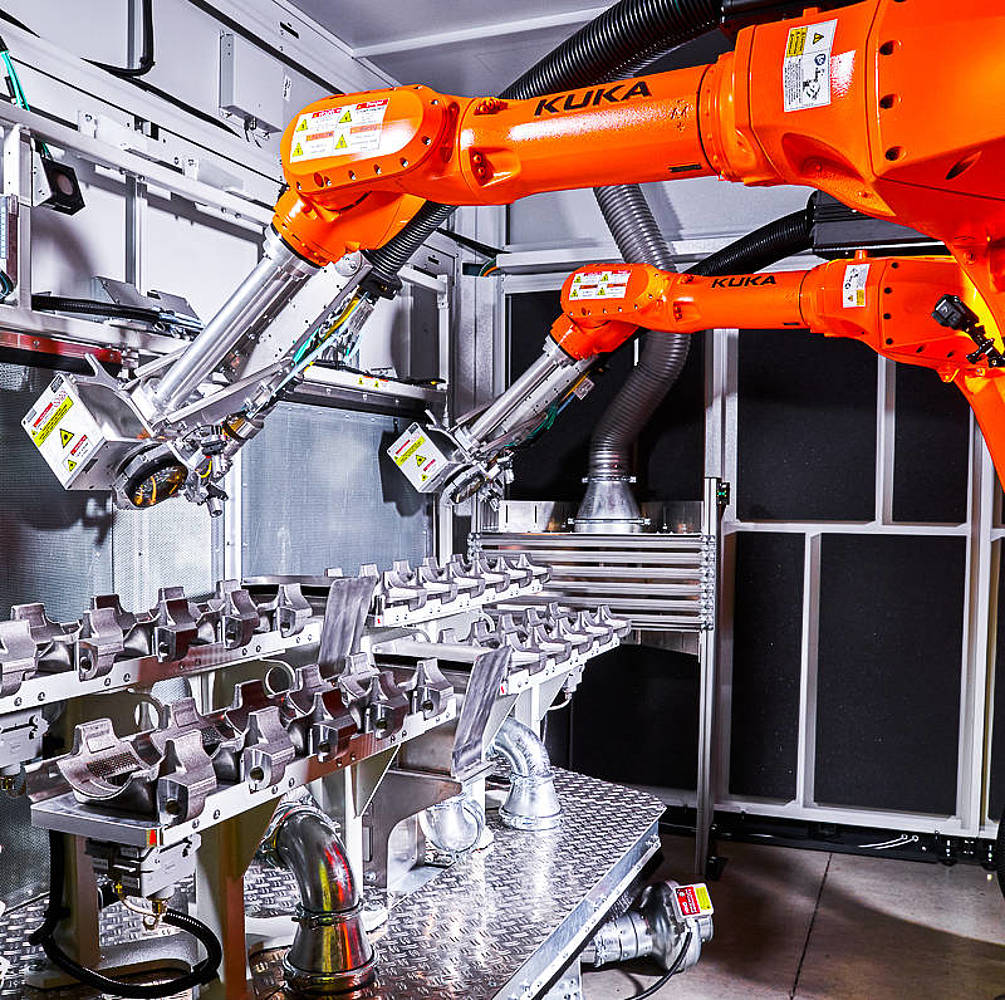

Advancements in Automation and Integration

By 2026, laser stripping tools will increasingly be integrated into fully automated production lines, especially in industries like automotive and consumer electronics. Advances in robotics, machine vision, and AI-driven process control will enhance the accuracy and adaptability of laser systems. Smart laser strippers with real-time monitoring and closed-loop feedback will become standard, reducing operator dependency and enabling consistent quality in high-volume manufacturing environments.

Shift Toward Eco-Friendly and Sustainable Processes

Environmental regulations are pushing industries to replace chemical and abrasive stripping methods with cleaner alternatives. Laser stripping produces no hazardous waste, reduces VOC emissions, and eliminates the need for solvents, making it a sustainable choice. As global sustainability goals intensify, companies across sectors—including automotive, rail, and energy—will adopt laser technology to meet compliance standards and enhance their ESG profiles by 2026.

Technological Innovations Driving Performance

Ongoing R&D is leading to more compact, energy-efficient, and user-friendly laser stripping tools. Fiber and ultrafast (picosecond and femtosecond) lasers are gaining traction due to their precision, minimal heat-affected zones, and ability to handle diverse materials. By 2026, expect broader adoption of handheld laser strippers for field maintenance and repair, as well as modular systems that can be easily reconfigured for different applications, lowering total cost of ownership.

Regional Market Expansion

While North America and Europe remain strong markets due to advanced manufacturing infrastructure, the Asia-Pacific region—particularly China, Japan, and South Korea—is expected to witness the fastest growth. This is fueled by rising investments in high-tech manufacturing, electronics production, and government support for automation. By 2026, localized production and distribution networks will emerge, making laser stripping tools more accessible and affordable in developing economies.

In conclusion, the 2026 market for laser stripping tools will be defined by innovation, sustainability, and deeper integration into industrial automation. Companies that invest in smart, flexible, and environmentally responsible solutions will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing a Laser Stripping Tool (Quality, IP)

When sourcing a laser stripping tool—especially for precision applications like wire or cable processing—several critical pitfalls can compromise both product quality and intellectual property (IP) protection. Awareness of these risks is essential for ensuring reliability, compliance, and long-term operational success.

Poor Build Quality and Inconsistent Performance

One of the most frequent issues is procuring tools with substandard construction or inconsistent laser performance. Low-quality components—such as unstable laser diodes, imprecise optics, or inadequate cooling systems—can lead to incomplete stripping, wire damage, or frequent maintenance needs. This not only reduces throughput but also increases total cost of ownership due to downtime and part replacements.

Lack of Calibration and Repeatability

Inaccurate or non-reproducible stripping results are a major red flag. Tools that lack proper calibration mechanisms or closed-loop feedback systems may strip too aggressively or incompletely, especially when processing different wire gauges or insulation types. Without consistent repeatability, manufacturers risk product defects and non-compliance with industry standards (e.g., aerospace or medical device regulations).

Insufficient IP Protection and Risk of Counterfeiting

Sourcing from vendors without robust IP safeguards exposes companies to counterfeit or cloned equipment. This not only risks performance and safety but may also lead to legal liabilities, especially if the tool incorporates patented technology. Always verify that suppliers hold legitimate licenses or have developed their own proprietary technology to avoid IP infringement.

Inadequate Documentation and Software Lock-In

Some suppliers provide poor technical documentation or proprietary software with restrictive licensing. This can hinder integration into existing production lines and create long-term dependency on the vendor for updates, repairs, or training. Additionally, undocumented firmware may harbor security vulnerabilities or prevent necessary customization.

Non-Compliance with Safety and Regulatory Standards

Laser tools must comply with international safety standards (e.g., IEC 60825 for laser safety). Sourcing from manufacturers who do not certify their equipment can result in workplace hazards, regulatory penalties, or import restrictions. Always confirm compliance documentation and proper laser classification.

Hidden Costs from Limited Support or Warranty

Low upfront pricing may be misleading if the supplier offers minimal technical support, short warranty periods, or charges exorbitant fees for service. Ensure the vendor provides accessible support, spare parts availability, and clear service level agreements to avoid unexpected operational disruptions.

By carefully evaluating potential suppliers for these pitfalls—prioritizing quality, transparency, IP legitimacy, and regulatory compliance—companies can mitigate risk and ensure a reliable, sustainable investment in laser stripping technology.

Logistics & Compliance Guide for Laser Stripping Tool

Product Classification & Regulatory Overview

Laser stripping tools are classified as industrial laser systems, typically falling under Class 4 laser products according to the IEC 60825-1 standard due to their high-power output capable of removing coatings, paint, or surface materials. These tools are subject to international and regional regulations covering laser safety, electromagnetic compatibility (EMC), and environmental compliance. Key regulatory bodies include the U.S. FDA/CDRH (Center for Devices and Radiological Health), the European Union’s CE marking directives (such as the Machinery Directive 2006/42/EC and the EMC Directive 2014/30/EU), and other national standards in target markets.

Packaging & Shipping Requirements

Laser stripping tools must be securely packaged to prevent damage during transit. Use shock-absorbent materials, rigid outer containers, and moisture barriers where necessary. Clearly label packages with “Fragile,” “This Side Up,” and “Laser Radiation” warning labels compliant with IEC 60825. Include a packing slip, safety data sheet (if applicable), and user manual. For air transport, ensure compliance with IATA Dangerous Goods Regulations—while most laser tools are not classified as hazardous, battery-powered units may require UN38.3 certification for lithium batteries. Confirm carrier-specific requirements for industrial equipment shipping.

Import/Export Compliance

Verify export control classifications under the Export Administration Regulations (EAR) or equivalent frameworks (e.g., EU Dual-Use Regulation). Laser systems with specific power outputs or pulsed capabilities may require export licenses. For international shipments, prepare accurate commercial invoices, packing lists, and a certificate of origin. Ensure the product has proper Harmonized System (HS) code classification—for laser tools, this is typically 8515.21 or 8465.99, depending on function. Comply with destination country import regulations, including conformity assessment procedures and local representative requirements (e.g., EU Authorized Representative).

Safety & Certification Documentation

Provide comprehensive compliance documentation with each unit, including:

– Declaration of Conformity (DoC) for relevant directives (CE, UKCA, etc.)

– FDA Laser Product Report (for U.S. market)

– IEC 60825-1 compliance test report

– EMC test reports (e.g., EN 55011, EN 61326)

– RoHS and REACH compliance statements

Ensure user manuals include safety instructions, laser classification details, maintenance guidelines, and emergency procedures. Labels on the device must display the laser warning symbol, class designation, wavelength, and maximum output power.

End-of-Life & Environmental Compliance

Laser stripping tools must comply with environmental directives such as the EU WEEE (Waste Electrical and Electronic Equipment) Directive, requiring proper end-of-life take-back and recycling. Mark products with the crossed-out wheeled bin symbol. Adhere to RoHS (Restriction of Hazardous Substances) limits on lead, cadmium, mercury, and other substances. Provide disassembly and recycling instructions to authorized service or disposal centers. For global operations, follow local e-waste regulations in markets such as the U.S. (state-level recycling rules), Canada (OESO), and China (China RoHS).

Field Use & On-Site Compliance

Operators must be trained in laser safety per ANSI Z136.1 (U.S.) or IEC 60825 standards. Use in controlled environments with appropriate interlocks, beam enclosures, and personal protective equipment (PPE) such as laser safety goggles. Conduct regular maintenance and safety audits. Employers must comply with OSHA (U.S.) or equivalent workplace safety regulations, including hazard assessments and control measures for laser radiation, fumes, and electrical hazards. Maintain logs of usage, maintenance, and safety inspections for audit and compliance purposes.

Conclusion for Sourcing a Laser Stripping Tool

After a comprehensive evaluation of technical requirements, supplier capabilities, cost considerations, and long-term operational needs, sourcing a laser stripping tool represents a strategic investment in precision, efficiency, and quality for wire and cable processing applications. Laser stripping technology offers significant advantages over mechanical and thermal methods, including clean, burr-free cuts, minimal damage to conductive and insulation layers, and the ability to handle complex, high-density wiring found in aerospace, medical, and electronics manufacturing.

Key factors such as compatibility with a range of wire types and diameters, automation integration potential, safety features, and supplier support services have been assessed to ensure optimal performance and return on investment. Leading suppliers have demonstrated reliable track records in delivering robust systems with scalable power outputs and customizable software controls.

By selecting a laser stripping solution from a reputable vendor with strong technical support and service warranties, the organization can enhance production accuracy, reduce waste, and improve throughput in high-mix, low-volume or high-reliability manufacturing environments. In conclusion, the implementation of a laser stripping tool aligns with advanced manufacturing standards and supports ongoing efforts to improve quality, consistency, and operational efficiency across critical production processes.