The global laser stripping machine market is experiencing robust growth, driven by increasing demand for precision, automation, and non-contact material processing across industries such as aerospace, electronics, medical devices, and automotive. According to a report by Mordor Intelligence, the global laser processing equipment market—of which laser stripping is a critical subset—is projected to grow at a CAGR of over 7.5% from 2023 to 2028. Similarly, Grand View Research estimates that the industrial laser system market size was valued at USD 7.3 billion in 2022 and is expected to expand at a CAGR of 7.2% through 2030, fueled by technological advancements and the rising adoption of laser solutions in high-precision manufacturing. As industries shift away from mechanical and chemical stripping methods toward cleaner, more accurate alternatives, laser-based systems have emerged as the preferred choice. This surge in demand has catalyzed innovation and competition among equipment manufacturers worldwide, leading to a diverse range of advanced laser stripping solutions. In this landscape, identifying leading manufacturers becomes crucial for buyers seeking reliability, performance, and technological edge. Based on market presence, product range, innovation, and customer feedback, here are the top 9 laser stripping machine manufacturers offering high-performance systems for industrial applications.

Top 9 Laser Stripping Machine For Sale Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

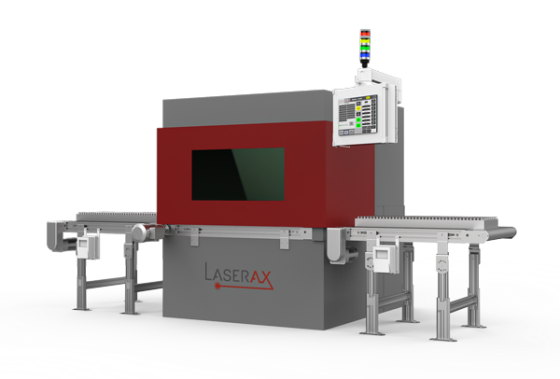

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#3 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

#4 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, fiber laser…

#5 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#6 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Utilize this laser cleaning machine for rust removal and coating removal, decontamination, degreasing, pre- and post-weld surface preparation, and texturing….

#7 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser ……

#8 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#9 Full List of Laser Machines

Website: hantencnc.com

Key Highlights: Manufacturer Direct Sale: SEAL2™ 1000W Pulse Laser Cleaning Machines, Save 30% Off! 20W All-in-one Laser Marking Machine for Sale | Special Offer!…

Expert Sourcing Insights for Laser Stripping Machine For Sale

2026 Market Trends for Laser Stripping Machines for Sale

The global market for laser stripping machines is poised for significant transformation by 2026, driven by advancements in automation, increased demand for precision manufacturing, and the growing need for eco-friendly industrial processes. As industries shift toward high-efficiency, non-contact solutions, laser stripping machines are emerging as a preferred alternative to traditional mechanical and chemical wire insulation removal methods.

One of the primary drivers shaping the 2026 market landscape is the rising adoption in the aerospace, automotive, and electronics sectors. These industries require micron-level precision and minimal material damage—qualities inherent to laser stripping technology. With the proliferation of electric vehicles (EVs) and advanced avionics systems, demand for reliable, high-throughput wire processing equipment continues to grow, boosting the market for laser stripping machines for sale.

Technological innovation is another key trend. By 2026, manufacturers are expected to introduce smarter, AI-integrated laser systems capable of real-time monitoring and adaptive control. These intelligent machines can automatically detect insulation types and adjust laser parameters, reducing operator error and improving yield. Integration with Industry 4.0 platforms enables predictive maintenance, remote diagnostics, and seamless production line connectivity, making laser strippers more attractive to large-scale manufacturers.

Sustainability is also influencing market dynamics. Laser stripping eliminates the need for chemical solvents and reduces mechanical waste, aligning with global green manufacturing initiatives. As environmental regulations tighten, especially in Europe and North America, companies are more inclined to invest in clean technologies—further expanding the customer base for laser stripping machines.

Additionally, the competitive landscape is evolving. A growing number of suppliers are entering the market, offering cost-effective models tailored for small and medium enterprises (SMEs). This increased accessibility is driving down prices and expanding market reach, particularly in emerging economies across Asia-Pacific and Latin America.

Finally, customization is becoming a major selling point. By 2026, buyers increasingly seek modular laser stripping systems that can handle diverse wire gauges, insulation materials (including PTFE, polyimide, and silicone), and production volumes. Vendors that offer scalable, user-friendly platforms with strong technical support are likely to gain a competitive edge.

In summary, the 2026 market for laser stripping machines for sale is characterized by technological sophistication, sustainability, and broadening industrial adoption. As demand for precision, efficiency, and environmental compliance grows, the laser stripping machine sector is set for sustained expansion and innovation.

Common Pitfalls When Sourcing a Laser Stripping Machine for Sale (Quality and IP Concerns)

Sourcing a laser stripping machine for sale can be a complex process, especially when balancing cost, performance, and long-term reliability. Buyers often encounter several pitfalls related to quality assurance and intellectual property (IP) risks. Being aware of these challenges is crucial to making a sound investment.

Poor Quality Control and Inconsistent Performance

One of the most frequent issues when sourcing laser stripping machines—especially from lesser-known or low-cost suppliers—is inconsistent build quality. Machines may use substandard optical components, unreliable motion systems, or inadequate cooling mechanisms. These shortcomings can lead to frequent breakdowns, inaccurate stripping, or safety hazards. Buyers should verify certifications (such as CE, FDA, or ISO), request third-party inspection reports, and perform due diligence on the manufacturer’s quality management systems.

Lack of Technical Support and Spare Parts Availability

Many low-cost suppliers, particularly those based overseas, may offer limited after-sales support. This includes difficulty accessing technical assistance, firmware updates, or replacement parts. Without reliable support, machine downtime can severely impact production. Ensure the supplier has a local service network or clear support policies before purchasing.

Inadequate Power and Precision for Specific Applications

Laser stripping machines vary widely in power, wavelength, and control software. Some machines advertised as “universal” may not meet the precision requirements for delicate wire gauges or specialized insulation materials (e.g., polyimide, PTFE). Buyers must validate machine specifications against their actual use cases and request sample processing tests.

Intellectual Property (IP) Infringement Risks

Purchasing a machine that incorporates cloned or reverse-engineered technology can expose buyers to legal liability. Some suppliers may copy patented laser control systems, software algorithms, or mechanical designs. Using such machines can lead to IP disputes, customs seizures, or forced decommissioning. Always verify that the supplier owns or licenses the core technologies used in the machine.

Hidden Costs from Non-Compliant Equipment

Machines that do not comply with regional safety or electromagnetic compatibility (EMC) standards may require costly retrofits or fail regulatory inspections. Additionally, imported machines lacking proper documentation may face delays or duties at customs. Ensure the machine complies with local regulations (e.g., FCC, RoHS, REACH) before finalizing the purchase.

Insufficient Documentation and Training

Poorly documented machines—missing user manuals, software SDKs, or maintenance guides—can hinder integration and operation. Lack of proper training increases the risk of operator error and reduces efficiency. Confirm that the supplier provides comprehensive documentation and training programs.

Conclusion

Avoiding these pitfalls requires thorough supplier vetting, technical validation, and legal diligence. Prioritize vendors with proven track records, transparent IP ownership, and strong support infrastructure to ensure a reliable and compliant laser stripping solution.

Logistics & Compliance Guide for Laser Stripping Machine For Sale

Overview

When purchasing or selling a laser stripping machine, both buyers and sellers must navigate complex logistics and compliance requirements to ensure safe, legal, and timely delivery. This guide outlines key considerations related to international and domestic shipping, regulatory compliance, documentation, and safety standards.

Export and Import Regulations

Laser stripping machines are subject to export controls due to their classification under dual-use technologies (items that can have both civilian and military applications). Key regulations include:

– International Traffic in Arms Regulations (ITAR) – Not typically applicable unless the machine has defense-related capabilities.

– Export Administration Regulations (EAR) – Most laser systems fall under the Commerce Control List (CCL), specifically ECCN 2B001 or similar, depending on laser power, wavelength, and application.

– Destination Country Restrictions – Certain countries may restrict or ban the import of high-powered laser equipment. Always verify import eligibility with local authorities.

Sellers must obtain an export license if required and file Electronic Export Information (EEI) via the Automated Export System (AES) in the U.S. or equivalent in other countries.

Laser Safety and Regulatory Compliance

Laser stripping machines are classified as Class 1, 3B, or Class 4 laser products under IEC 60825-1 and FDA 21 CFR Part 1040.10 (U.S.). Compliance requirements include:

– FDA Registration and Listing – Required for U.S. market access; sellers must register the device and submit product reports.

– CE Marking (EU) – Must comply with the Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive, and Laser Product Safety standards.

– Laser Safety Labels and Documentation – Machines must have proper warning labels, interlocks, and an accessible user manual detailing safety procedures.

– Performance Testing and Certification – Third-party testing by notified bodies may be required in certain regions (e.g., EU, UKCA).

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit:

– Use custom-built, shock-absorbent crates with internal bracing to secure the machine.

– Include desiccants to control moisture, especially for ocean freight.

– Clearly label packages with “Fragile,” “This Side Up,” and laser warning symbols.

– Secure all movable parts and disconnect sensitive components if required.

Shipping methods:

– Air Freight – Faster but more expensive; suitable for urgent deliveries.

– Sea Freight – Cost-effective for heavy machinery; requires longer lead times and customs coordination.

– Ground Transport – Used for domestic or regional delivery; ensure vehicle has appropriate lifting and securing equipment.

Customs Documentation

Accurate documentation is critical to avoid delays:

– Commercial Invoice (detailing value, terms of sale, and HS code)

– Packing List

– Bill of Lading or Air Waybill

– Export License (if applicable)

– Certificate of Conformity (CE, FCC, etc.)

– Technical Specifications and User Manual (for customs inspection)

– Insurance Certificate

Ensure Harmonized System (HS) code is correctly classified (e.g., 8479.89 for specialized industrial machinery).

Insurance and Liability

- Purchase comprehensive cargo insurance covering damage, loss, and delays.

- Clarify Incoterms® (e.g., FOB, CIF, DDP) to define responsibility for shipping, insurance, and risk transfer.

- Retain proof of compliance and safe packaging to mitigate liability in case of incidents.

Installation and On-Site Compliance

Upon delivery:

– Verify machine integrity and document any damage before signing delivery receipts.

– Ensure the end-user complies with local occupational safety regulations (e.g., OSHA in the U.S.) for laser operation.

– Provide training on safe operation, maintenance, and emergency procedures.

– Confirm proper grounding, ventilation, and protective enclosures are in place.

Environmental and Disposal Regulations

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU for end-of-life disposal.

- Do not ship machines containing restricted substances (e.g., lead, mercury) without proper documentation under RoHS.

Final Recommendations

- Consult a customs broker or freight forwarder experienced in high-tech industrial equipment.

- Verify all compliance requirements with local authorities in the destination country.

- Maintain detailed records of all transactions, certifications, and communications for audit purposes.

Compliance with logistics and regulatory standards ensures smooth delivery and legal operation of laser stripping machines worldwide.

Conclusion: Sourcing a Laser Stripping Machine for Sale

Sourcing a laser stripping machine for sale requires careful evaluation of technical capabilities, application requirements, supplier reputation, and total cost of ownership. Laser wire stripping offers significant advantages over traditional mechanical methods, including precision, cleanliness, reduced wire damage, and compatibility with delicate or high-reliability applications in industries such as aerospace, medical devices, and electronics.

When selecting a laser stripping machine, it is essential to consider factors such as laser type (e.g., UV, fiber, or CO₂), stripping speed, wire diameter range, material compatibility, safety features, and ease of integration into existing production lines. Additionally, supplier support, training, maintenance services, and warranty terms play a crucial role in ensuring long-term performance and reliability.

While the initial investment in a laser stripping system may be higher than conventional alternatives, the long-term benefits—such as improved yield, reduced rework, and increased automation—often justify the cost. Purchasing from a reputable manufacturer or distributor with proven expertise in laser processing technology ensures access to reliable equipment and technical support.

In conclusion, sourcing the right laser stripping machine involves aligning machine specifications with specific production needs, conducting thorough due diligence on potential suppliers, and considering both immediate and long-term operational impacts. With the proper selection and integration, a laser stripping machine can significantly enhance manufacturing efficiency, product quality, and competitiveness in precision-driven markets.