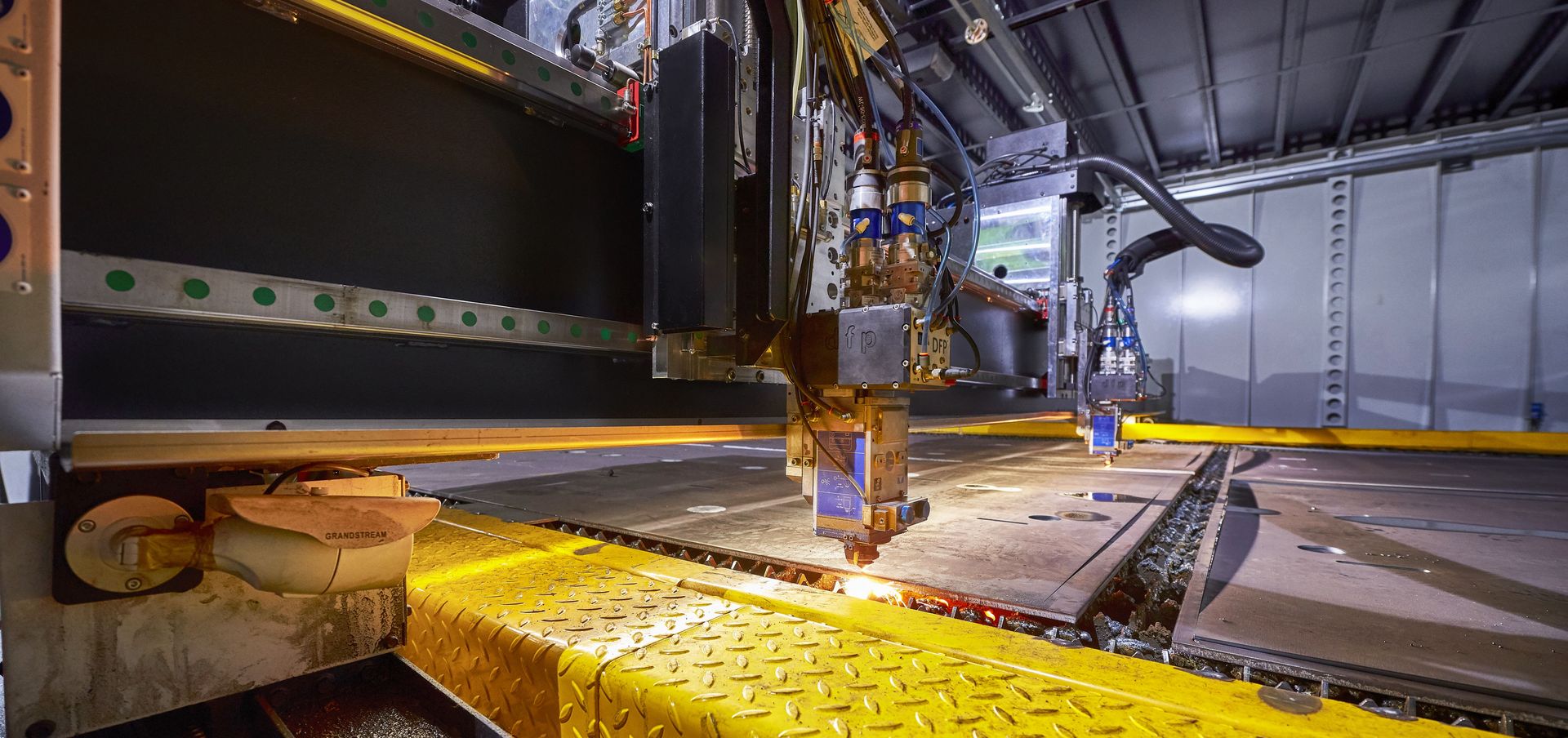

The global laser cutting machine market is experiencing robust expansion, driven by increasing demand for precision manufacturing across industries such as automotive, aerospace, electronics, and metal fabrication. According to Grand View Research, the market was valued at USD 3.34 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by technological advancements in fiber laser systems, rising adoption of automation, and the need for energy-efficient cutting solutions. As industries prioritize accuracy, speed, and operational efficiency, manufacturers are investing heavily in advanced laser cutting technologies. In this competitive landscape, nine companies have emerged as leaders, combining innovation, global reach, and strong R&D capabilities to dominate the sector. These top manufacturers are shaping the future of laser cutting through intelligent systems, improved beam delivery, and integration with Industry 4.0 standards.

Top 9 Laser Snijden Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser machine

Website: balliu.be

Key Highlights: Balliu is the expert in industrial machines for laser cutting, laser welding, laser cladding, laser marking and every other laser application….

#2 – Eight Arms

Website: eightarms.nl

Key Highlights: A wide choice of laser design for anyone with a love of good products. Our webshop is overflowing with original and unique items.Missing: snijden manufacturer…

#3 Yart Factory

Website: yartfactory.nl

Key Highlights: Yart Factory is uw productiepartner voor innovatieve oplossingen in papier, kunststof en houtbewerking met moderne laser- en CNC frees machines….

#4 High Power Laser Cutting Machine

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading provider of laser cutting machine, laser marking mahcine and laser cleaning machine.Email:[email protected]….

#5 Belgian Laser Company

Website: blc.be

Key Highlights: BLC biedt professionele metaalbewerkingsdiensten aan, van lasersnijden tot lassen. Onze expertise gerandeerd hoogwaardige resultaten….

#6 Lasersnijmachines

Website: lvdgroup.com

Key Highlights: Bekijk ons volledige aanbod veelzijdige fiberlasersnijmachines voor het snijden van platen en buizen. Contacteer ons voor meer info!…

#7 Laser Cut Supply

Website: lasercutsupply.nl

Key Highlights: Laser-ready materialen voor makers. Meer dan 160 zorgvuldig geteste materialen, direct klaar voor lasersnijden. Ons assortiment. Voor het perfecte resultaat….

#8 Hollandsteel

Website: hollandsteel.nl

Key Highlights: Wij bieden services zoals lasersnijden, plasmasnijden, kanten (zetten) en afbramen van metalen (staal, rvs, koper, messing en aluminium) platen, kokers, buizen ……

#9 Blog

Website: snijlab.nl

Key Highlights: Start here if you want to know how to create a design for laser cutting. We give you tips and an overview of our tutorials. Jan 22, 2025….

Expert Sourcing Insights for Laser Snijden

H2: Market Trends for Laser Cutting (Laser Snijden) in 2026

As the manufacturing and industrial sectors continue to evolve, laser cutting—known in Dutch as laser snijden—is poised for significant transformation by 2026. Driven by technological innovation, sustainability demands, and shifting industrial needs, several key trends are expected to define the laser cutting market in the coming years.

1. Increased Adoption of Fiber Laser Technology

By 2026, fiber lasers are projected to dominate the laser cutting market, especially in Europe and industrial hubs like the Netherlands. Fiber lasers offer higher efficiency, lower maintenance, and superior cutting speeds compared to traditional CO₂ lasers. Their ability to cut reflective metals such as copper and aluminum with precision makes them ideal for the automotive, aerospace, and renewable energy sectors—industries that are expanding their use of advanced materials.

2. Integration with Industry 4.0 and Smart Manufacturing

The convergence of laser cutting with Industry 4.0 principles is accelerating. By 2026, smart factories will increasingly rely on interconnected laser cutting systems equipped with IoT sensors, real-time monitoring, and AI-driven predictive maintenance. This integration enhances operational efficiency, reduces downtime, and enables remote control of cutting processes—critical for just-in-time manufacturing and customized production runs.

3. Growth in Demand for Customization and Precision

As consumer and industrial demands shift toward personalized and high-precision components, laser cutting’s ability to deliver intricate designs with tight tolerances becomes a competitive advantage. Sectors such as medical device manufacturing, electronics, and architectural metalwork are expected to drive demand for high-accuracy laser cutting solutions, particularly in low-volume, high-mix production environments.

4. Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt greener technologies. Laser cutting, especially with newer fiber systems, offers lower energy consumption and reduced material waste through optimized nesting software and minimal heat-affected zones. By 2026, eco-friendly laser solutions and recyclable material processing will be key selling points in the European market.

5. Expansion in Renewable Energy and Electric Mobility

The booming electric vehicle (EV) and renewable energy sectors—particularly solar and wind—are creating new applications for laser cutting. From cutting battery components to fabricating lightweight chassis parts and wind turbine elements, laser technology enables the high-speed, precise manufacturing required at scale. This trend will fuel investment in laser cutting equipment across supply chains in Western Europe.

6. Rise of Automation and Robotic Integration

Fully automated laser cutting cells, including robotic loading/unloading and integrated conveyors, are becoming standard in high-throughput environments. By 2026, automation will not only improve productivity but also address labor shortages in skilled manufacturing roles. Dutch and German manufacturers, in particular, are expected to lead in deploying autonomous laser cutting workstations.

7. Regional Market Dynamics in Europe

In Benelux countries, demand for laser snijden services is being driven by a dense network of SMEs in metal fabrication, high-tech engineering, and prototyping. The Netherlands, with its strong logistics and innovation infrastructure, is well-positioned to serve as a regional hub for advanced laser cutting services. Increased cross-border industrial collaboration will likely boost the market further.

Conclusion

By 2026, the laser cutting market will be defined by smarter, faster, and more sustainable technologies. Companies investing in fiber laser systems, digital integration, and automation will gain a competitive edge. For Dutch manufacturers and service providers (laser snijden bedrijven), aligning with these trends will be essential to meet evolving customer expectations and maintain relevance in a global, high-precision manufacturing landscape.

Algemene Valkuilen bij het Sourcing van Lasersnijden (Kwaliteit, IP)

Bij het outsourcen van lasersnijdwerkzaamheden zijn er diverse risico’s die invloed kunnen hebben op zowel de kwaliteit van het eindproduct als op intellectuele eigendom (IP). Hieronder staan de meest voorkomende valkuilen:

Kwaliteitsgerelateerde Valkuilen

Onvoldoende controle op maatnauwkeurigheid en snijkwaliteit

Lasersnijden vereist hoge precisie, maar niet alle leveranciers werken met dezelfde toleranties of onderhoudsniveaus. Verzanding, onregelmatige sneden of verkeerde afmetingen kunnen ontstaan als machines niet goed worden onderhouden of gecalibreerd. Zonder duidelijke kwaliteitsnormen en inspectieprotocollen loopt u het risico op productieafkeuring of kostbare herwerkzaamheden.

Geen duidelijke kwaliteitsdocumentatie of traceerbaarheid

Veel leveranciers missen gedetailleerde rapportages over gebruikte machine-instellingen, materiaalherkomst of inspectieresultaten. Dit maakt het lastig om afwijkingen terug te volgen of kwaliteitsproblemen systematisch aan te pakken, vooral in geval van batchafwijkingen.

Verschillen in materiaalverwerking

Niet alle lasersnijmachines zijn geschikt voor elk materiaaltype (bv. roestvrij staal, aluminium, kunststof). Een leverancier die sterk is in zacht staal kan problemen ondervinden bij het verwerken van harder materiaal, wat resulteert in slechtere snijkwaliteit of beschadiging van onderdelen.

IP-gerelateerde Valkuilen

Ontbrekende of onduidelijke IP-overeenkomsten

Veel sourcingpartners werken zonder vaste IP-protectieovereenkomsten (zoals NDA’s of IP-clausules in contracten). Hierdoor kan uw ontwerp- of productinformatie zonder juridische gevolgen worden gedeeld met derden of zelfs worden gekopieerd door concurrenten.

Onbeveiligde data-uitwisseling

CAD-bestanden en technische tekeningen worden vaak onbeveiligd gedeeld (via e-mail of onbeveiligde portaaloplossingen). Dit verhoogt het risico op datalekken of ongeautoriseerde toegang, met name bij leveranciers zonder robuuste IT-beveiliging.

Geen controle over productiegegevens en tooling

Als u specifieke snijprogramma’s of tooling ontwikkelt voor uw onderdelen, is het essentieel dat u de eigendom behoudt. Sommige leveranciers bewaren deze gegevens en kunnen ze hergebruiken of aanbieden aan andere klanten, wat een direct IP-risico vormt.

Aanbevolen Maatregelen

- Sluit altijd een NDA en IP-overeenkomst voorafgaand aan het delen van gevoelige gegevens.

- Vraag om kwaliteitscertificeringen (zoals ISO 9001) en inspecteer de kwaliteitsprocedures van de leverancier.

- Gebruik beveiligde data-uitwisselingsplatforms en beperk toegang tot alleen noodzakelijke personen.

- Document duidelijk eigendom van CAD-bestanden, snijprogramma’s en productie-instrumenten.

- Voer regelmatig audits uit, inclusief kwaliteitscontroles en beoordeling van IP-beveiliging.

Logistics & Compliance Guide for Laser Snijden

Laser Snijden, as a precision manufacturing service provider, must adhere to strict logistics and compliance standards to ensure operational efficiency, safety, and regulatory conformity. This guide outlines key procedures, responsibilities, and regulations relevant to logistics management and compliance.

Order Processing & Documentation

All customer orders must be processed through the central ERP system to ensure traceability and accuracy. Required documentation includes:

– Purchase order (PO) confirmation

– Technical drawings with material specifications

– Delivery instructions (address, timeline, handling requirements)

– Certificate of Conformity (if applicable)

Ensure that all documents are stored digitally with version control and accessible for audit purposes.

Material Handling & Storage

Proper handling and storage of raw materials (e.g., steel, aluminum, plastics) are critical to maintaining quality and safety:

– Store materials in designated, labeled areas away from moisture and contaminants.

– Segregate materials by type, grade, and thickness.

– Use appropriate lifting equipment (e.g., cranes, forklifts) with certified operators.

– Conduct monthly inventory audits to prevent stock discrepancies.

Follow internal Material Safety Data Sheets (MSDS) for handling hazardous materials, if applicable.

Production & Quality Compliance

Laser cutting operations must comply with ISO 9001 quality management standards:

– Perform machine calibration and preventive maintenance according to the schedule.

– Conduct in-process inspections using calibrated measuring tools.

– Maintain non-conformance reports (NCRs) for any deviations and initiate corrective actions.

– Issue inspection reports upon job completion, including dimensional accuracy and edge quality.

Ensure operators are trained and certified in laser safety (e.g., IEC 60825-1 standard).

Packaging & Shipping

Products must be packaged to prevent damage during transit:

– Use edge protectors, anti-corrosion paper, and wooden crates where needed.

– Label each package with customer name, PO number, item description, and handling symbols (e.g., “Fragile,” “This Side Up”).

– Verify shipping labels match the delivery note and customs documentation (for international shipments).

Partner with certified logistics providers and track all shipments in real time.

Export Compliance

For international deliveries, comply with applicable export regulations:

– Verify end-use and end-user information to prevent unauthorized transfers.

– Classify products using the correct HS codes.

– Prepare export documentation: commercial invoice, packing list, certificate of origin, and export declaration.

– Adhere to sanctions lists (e.g., EU, U.S. OFAC) and obtain necessary export licenses if required.

Stay updated on changes in trade regulations, especially concerning EU and non-EU countries.

Environmental & Safety Regulations

Laser Snijden is committed to environmental sustainability and workplace safety:

– Comply with local environmental laws (e.g., emissions, waste disposal).

– Recycle metal offcuts and packaging materials through certified partners.

– Operate under the Arbo-wet (Dutch Working Conditions Act) and conduct regular risk assessments.

– Provide employees with proper PPE (personal protective equipment) and safety training.

Maintain valid environmental permits and conduct annual compliance audits.

Record Retention & Audits

Retain all logistics and compliance records for a minimum of seven years:

– Delivery confirmations

– Quality inspection reports

– Maintenance logs

– Training records

– Export documentation

Be prepared for internal, customer, or regulatory audits by keeping records organized and accessible.

By following this guide, Laser Snijden ensures reliable, compliant, and efficient operations across its logistics and manufacturing processes.

Conclusion voor sourcing van laser snijden

Het insourcen van laser snijden kan een strategische keuze zijn, afhankelijk van de productiebehoeften, volume, kwaliteitseisen en budgettaire randvoorwaarden van het bedrijf. Laser snijden biedt hoge precisie, flexibiliteit in materiaalkeuze en snelle productietijden, wat het geschikt maakt voor zowel prototyping als seriesproductie.

Bij het overwegen van het insourcen dient aandacht te worden besteed aan de initiële investering in apparatuur, onderhoudskosten, expertise van personeel en ruimte-eisen. Voor bedrijven met hoge en constante vraag naar gesneden onderdelen kan insourcen op lange termijn kostenbesparend en efficiënter zijn, met meer controle over kwaliteit en levertijden.

Daarentegen kan outsourcing een betere oplossing zijn voor bedrijven met wisselende volumes of beperkte interne capaciteit, omdat dit flexibiliteit biedt zonder grote kapitaalinvesteringen.

Conclusie: Insourcen van laser snijden is voordelig bij regelmatige, grootschalige productie waarbij controle, snelheid en kwaliteit centraal staan. Voor kleinere volumes of variabele vraag blijft outsourcing vaak de economischere en praktischere optie. Een zorgvuldige afweging van kosten, capaciteit en strategische doelstellingen is essentieel bij het nemen van een weloverwogen beslissing.