The global laser cutting machine market is undergoing robust expansion, driven by increasing demand for high-precision fabrication across industries such as automotive, aerospace, electronics, and heavy manufacturing. According to a 2023 report by Grand View Research, the market was valued at USD 4.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by advancements in fiber laser technology, rising automation in production processes, and the need for energy-efficient and contactless cutting solutions. Additionally, Mordor Intelligence forecasts similar momentum, citing Asia-Pacific’s rapid industrialization and the expanding adoption of laser systems in micro-manufacturing as key market drivers. As competition intensifies and innovation accelerates, identifying the leading manufacturers becomes essential for businesses seeking reliable, high-performance laser cutting solutions. Below is a data-informed overview of the top 10 laser cutting machine manufacturers shaping the industry’s future.

Top 10 Laser Schneiden Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Company for Industrial Laser Solutions

Website: laserline.com

Key Highlights: The leading laser company for integrated & customized diode laser manufacturing solutions for various industries & applications….

#2 Laser, Plasma and Oxy Fuel Cutting Technology

Website: thermacut.com

Key Highlights: For more than 30 years THERMACUT® is successfully designing, producing and distributing HQ products for laser, plasma, and oxy fuel cutting….

#3 iKier

Website: ikier.com

Key Highlights: iKier is a high-end brand of laser cutting and engraving machine. Our products achieved laser auto-focus, automatic sinking-cutting technology, ……

#4 Laser Machines

Website: lclasers.com

Key Highlights: Distribution and manufacture of laser machinery. Sales of laser marking, laser cleaning, laser engraving and welding machines….

#5 Illumination Lasers

Website: cavitar.com

Key Highlights: Cavitar Ltd is an expert in illumination lasers based on diode laser technology. Our laser lighting is used in many demanding high-speed imaging and machine ……

#6 Precision in laser processing & metrology

Website: precitec.com

Key Highlights: Precitec offers solutions for laser cutting, welding, metrology and additive manufacturing – leading in precision, quality and process reliability….

#7 Laser

Website: reiner.de

Key Highlights: Laser cutting means cutting material panels with a laser. At REINER®, these panels are metal sheets, stainless steel or aluminium at thicknesses of 0.5 mm to 4 ……

#8 Cutting

Website: acsyslaser.com

Key Highlights: Our laser cutting systems are used, for example, to produce inlays and templates as well as precisely cut components. Our systems are also capable of high- ……

#9 Laser cutting

Website: bbw-lasertechnik.de

Key Highlights: We offer 3D laser cutting services that can process complex geometries with pieces up to 4 metres long, from individual units to large-scale production….

#10 Creality Falcon Laser

Website: crealityfalcon.com

Key Highlights: Creality Falcon Laser is the laser engraving sub-brand of Creality, built for creators of all levels. From beginner-friendly models to advanced laser ……

Expert Sourcing Insights for Laser Schneiden

H2 2026 Market Trends for Laser Cutting

The global laser cutting market is poised for continued evolution and expansion in H2 2026, driven by technological advancements, shifting industrial demands, and increasing adoption across diverse sectors. Key trends shaping the market during this period include:

1. Accelerated Adoption of High-Power and Ultrafast Lasers:

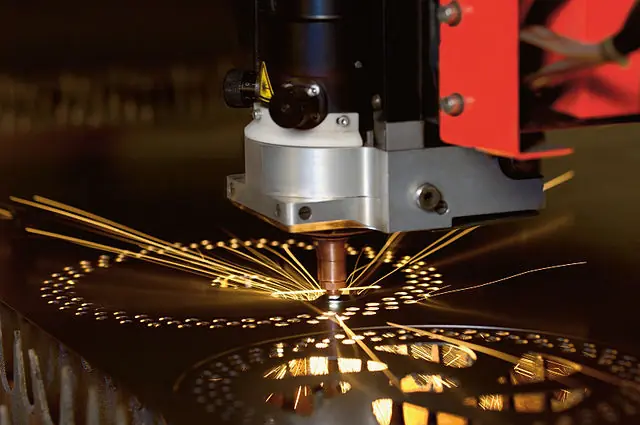

H2 2026 will see broader deployment of multi-kilowatt fiber lasers (10kW–30kW+) and ultrafast (picosecond and femtosecond) lasers in industrial settings. High-power lasers enable faster processing of thick metals (especially in heavy industry and shipbuilding), while ultrafast lasers gain traction in precision applications within electronics, medical devices, and aerospace, where minimal heat-affected zones are critical.

2. Integration of AI and Machine Learning for Smart Manufacturing:

Laser cutting systems will increasingly incorporate AI-driven optimization for predictive maintenance, real-time process monitoring, and adaptive cutting parameters. This intelligence reduces material waste, improves cut quality, and enhances overall equipment effectiveness (OEE), aligning with Industry 4.0 initiatives.

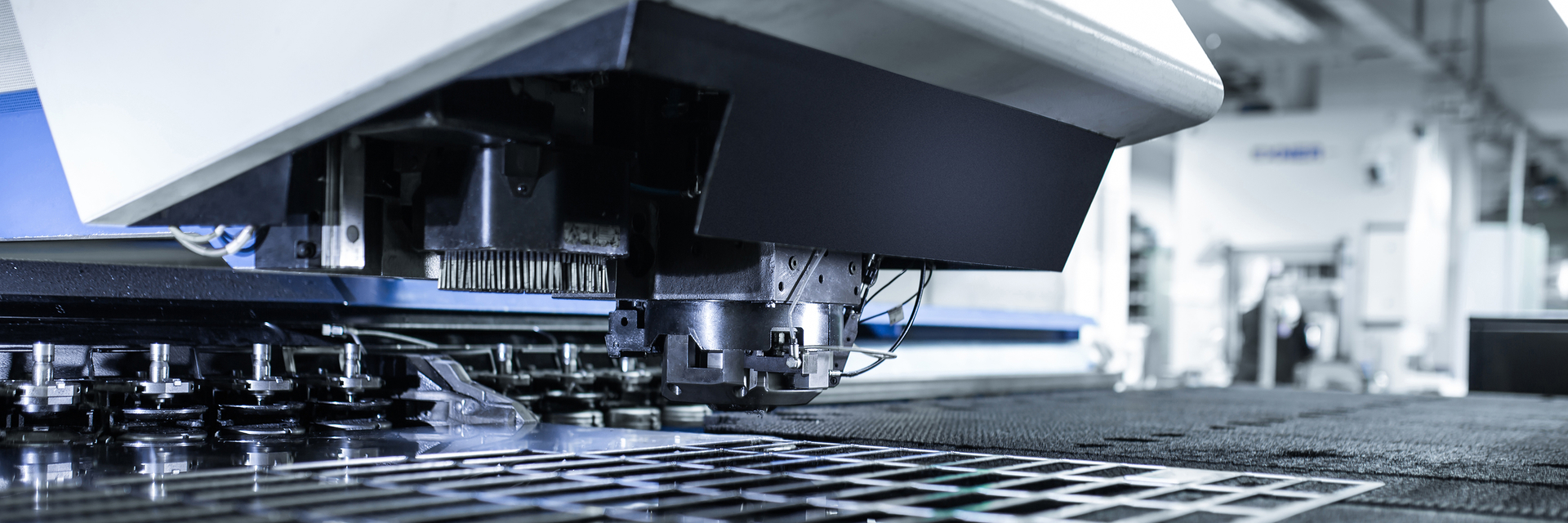

3. Growth in Automation and Robotic Integration:

Demand for fully automated laser cutting cells—featuring robotic material handling, pallet changers, and inline inspection—will surge, particularly in high-volume production environments. This trend is fueled by labor shortages and the need for 24/7 operation in automotive, EV, and metal fabrication industries.

4. Expansion in Electric Vehicle (EV) and Renewable Energy Sectors:

The EV boom will drive significant demand for laser cutting in battery component manufacturing (e.g., copper and aluminum foils, battery casings) and lightweight chassis structures. Similarly, solar panel and wind turbine component fabrication will boost laser use in renewable energy infrastructure.

5. Sustainability and Energy Efficiency as Key Differentiators:

Manufacturers will place greater emphasis on the energy efficiency of laser systems and the recyclability of cut materials. Fiber lasers, known for their lower power consumption compared to CO₂ lasers, will dominate new installations, supported by corporate sustainability goals.

6. Regional Market Shifts and Supply Chain Localization:

Asia-Pacific (especially China, India, and Southeast Asia) will remain the fastest-growing region due to industrial modernization. Meanwhile, North America and Europe will focus on reshoring and nearshoring, increasing demand for advanced laser cutting solutions in localized manufacturing hubs.

7. Rise of Cloud-Based Monitoring and Remote Services:

Original equipment manufacturers (OEMs) will expand cloud platforms for remote diagnostics, software updates, and performance analytics. This enables proactive service, reduces downtime, and supports decentralized manufacturing operations.

Conclusion:

In H2 2026, the laser cutting market will be defined by smarter, faster, and more sustainable solutions. Companies investing in AI integration, automation, and high-performance laser technologies will lead the market, capitalizing on growth in advanced manufacturing, green energy, and high-tech industries.

Häufige Fallstricke beim Sourcing von Laser-Schneiden: Qualität und geistiges Eigentum

Beim Sourcing von Laser-Schneid-Dienstleistungen können Unternehmen schnell auf kritische Probleme stoßen, insbesondere im Bereich Qualitätssicherung und Schutz geistigen Eigentums. Die folgenden Abschnitte beleuchten die häufigsten Fallstricke und zeigen, wie sie vermieden werden können.

Unzureichende Qualitätskontrolle und Prozessstabilität

Ein zentraler Risikofaktor ist die mangelnde oder inkonsistente Qualitätskontrolle beim Lieferanten. Unterschiedliche Lasersysteme, ungeeignete Parameter (z. B. falsche Leistung, Fokuslage oder Schneidgas) oder fehlende Wartung führen zu variabler Schnittqualität – etwa Graten, verfärbten Kanten (Oxidation) oder ungenauen Maßen. Ohne dokumentierte Qualitätsprüfungen und Prozessüberwachung (SPC) ist die Reproduzierbarkeit gefährdet, was besonders bei Serienfertigung problematisch ist.

Gegenmaßnahme: Klare Qualitätsvorgaben im Lastenheft definieren (z. B. nach ISO 9013), Erstbemusterung verlangen und regelmäßige Audits durchführen. Langfristig lohnt sich die Zertifizierung des Lieferanten nach ISO 9001.

Fehlende Material- und Werkstoffkenntnis

Nicht alle Laser-Schneider verfügen über die nötige Expertise für spezielle Werkstoffe wie rostfreie Stähle, Aluminiumlegierungen oder legierte Stähle. Fehlerhafte Parameterwahl kann zu Rissbildung, vermindertem Korrosionswiderstand oder veränderten mechanischen Eigenschaften führen – besonders kritisch in sicherheitsrelevanten Anwendungen.

Gegenmaßnahme: Vorab prüfen, ob der Dienstleister Erfahrung mit dem zu schneidenden Material hat. Materialdatenblätter und gegebenenfalls Werkstoffprüfungen einfordern.

Unklare IP-Rechte und mangelnder Schutz vertraulicher Daten

Ein oft unterschätztes Risiko ist der Umgang mit geistigem Eigentum (IP). CAD-Daten, Konstruktionszeichnungen und technische Spezifikationen werden beim Sourcing zwangsläufig an den Lieferanten weitergegeben. Fehlt ein verbindlicher Geheimhaltungsvertrag (NDA) oder sind die IP-Rechte im Vertrag nicht eindeutig geregelt, kann es zu unbefugter Nutzung, Nachahmung oder Weitergabe an Wettbewerber kommen.

Gegenmaßnahme: Im Vertrag festlegen, dass alle übermittelten Daten Eigentum des Auftraggebers bleiben. Verwendung ausschließlich für den vereinbarten Auftrag regeln. Verpflichtung zur Datenlöschung nach Auftragsende vereinbaren. NDA vor Datenaustausch unterzeichnen.

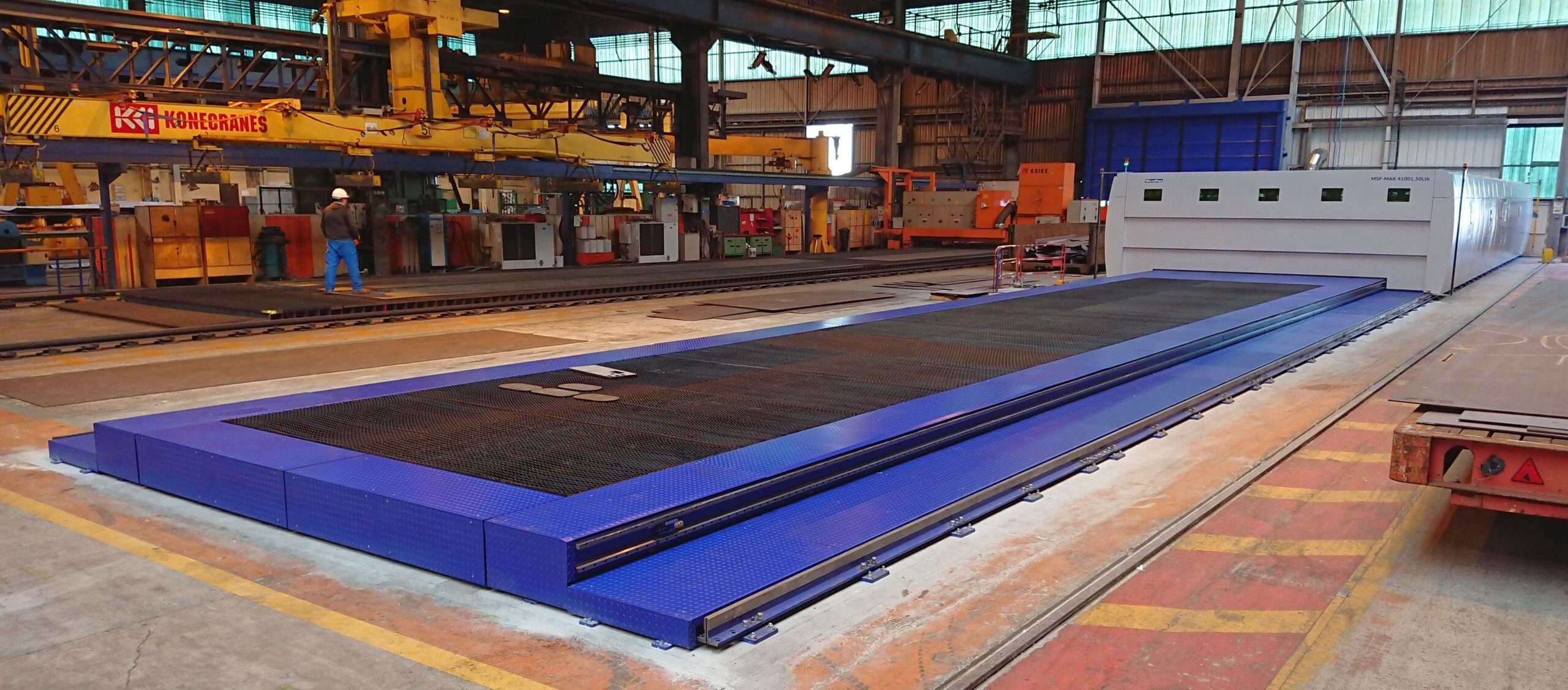

Unzureichende Maschinenausstattung und Kapazitätsengpässe

Einige Anbieter werben mit „Laser-Schneiden“, verfügen aber nur über veraltete oder unterdimensionierte Anlagen. Dies führt zu längeren Durchlaufzeiten, eingeschränkten Materialdicken oder unzureichender Präzision. Bei steigendem Auftragsvolumen kann es zudem zu Kapazitätsproblemen kommen, was Liefertermine gefährdet.

Gegenmaßnahme: Vorab den Maschinenpark prüfen (Laserleistung, maximale Tischgröße, Automatisierung). Kapazitätsreserven und Notfallpläne abfragen. Referenzen einholen.

Mangelnde Dokumentation und Rückverfolgbarkeit

Ohne lückenlose Dokumentation (z. B. Chargennummern, Schneidparameter, Prüfberichte) ist eine Rückverfolgbarkeit bei Qualitätsproblemen nicht möglich. Dies verstößt oft gegen Anforderungen in Branchen wie Medizintechnik oder Automotive.

Gegenmaßnahme: Dokumentationspflicht im Vertrag festlegen. Anforderungen an Prüfprotokolle und Materialrückverfolgung definieren.

Durch proaktive Prüfung dieser Fallstricke und vertragliche Absicherung können Unternehmen Risiken beim Sourcing von Laser-Schneiden wirksam minimieren und langfristig zuverlässige, qualitativ hochwertige Lieferbeziehungen aufbauen.

Logistics & Compliance Guide for Laser Schneiden

This guide outlines essential logistics considerations and compliance requirements for laser cutting (Laser Schneiden) operations in industrial and manufacturing environments.

Regulatory Compliance

Ensure all laser cutting operations adhere to applicable national and international regulations. Key standards include:

- Laser Safety (IEC 60825-1): Classify lasers according to emission levels and implement protective measures such as interlocks, warning signs, and protective enclosures.

- Machine Safety (ISO 13849 / EN 60204-1): Guarantee proper guarding, emergency stops, and risk assessments are conducted for all laser cutting machines.

- Occupational Health & Safety (OSHA / DGUV): Provide appropriate personal protective equipment (PPE), including laser safety goggles, flame-resistant clothing, and respiratory protection where fumes are generated.

- Environmental Regulations (EPA / TA-Luft): Manage exhaust emissions and particulate matter using certified fume extraction systems. Dispose of metal residues and filters in accordance with hazardous waste guidelines.

Equipment Certification & Documentation

Maintain up-to-date documentation for all laser cutting systems:

- Machine CE or UL certification

- Laser safety classification labels

- Risk assessment reports

- Maintenance logs and calibration records

- Operator training certifications

Ensure traceability and audit readiness through digital documentation systems.

Material Handling & Storage

Implement safe procedures for receiving, storing, and preparing materials for laser cutting:

- Store raw materials (e.g., sheet metal) in designated, dry, and organized areas.

- Label materials clearly with grade, thickness, and compliance status (e.g., RoHS, REACH).

- Use appropriate lifting equipment (e.g., vacuum lifters) to prevent damage and injury during handling.

- Segregate cut parts and scrap metal to avoid contamination and ensure recycling compliance.

Transportation & Shipping

Adhere to logistics standards when shipping laser-cut components:

- Package parts securely using anti-corrosion materials and protective coatings if required.

- Use standardized containers or pallets to prevent shifting during transit.

- Label shipments with handling instructions (e.g., “Fragile,” “This Side Up”) and include compliance documentation (e.g., material certificates, safety data sheets).

- Follow dangerous goods regulations (e.g., ADR) if transporting coated or treated metals with residual chemicals.

Waste Management & Environmental Compliance

Establish protocols for waste generated during laser cutting:

- Collect and segregate metal offcuts, filters, and sludge.

- Partner with certified waste disposal providers for recycling or hazardous waste treatment.

- Monitor air quality and maintain filtration systems to meet local emission limits.

- Keep records of waste disposal for regulatory audits.

Operator Training & Safety Protocols

Ensure all personnel are trained and certified:

- Conduct regular training on laser safety, machine operation, and emergency procedures.

- Display safety instructions near workstations in relevant languages.

- Enforce lockout/tagout (LOTO) procedures during maintenance.

- Perform routine safety drills and equipment inspections.

By following this guide, companies can ensure safe, efficient, and legally compliant laser cutting operations across the supply chain.

Conclusion for Sourcing Laser Cutting Services

In conclusion, sourcing laser cutting services requires a strategic approach that balances precision, cost-efficiency, material compatibility, and supplier reliability. Laser cutting offers significant advantages, including high accuracy, clean edges, minimal material waste, and the ability to handle complex geometries across a wide range of materials such as metal, plastic, and composites. When selecting a supplier, it is essential to evaluate their technological capabilities (e.g., CO₂ vs. fiber lasers), capacity, quality control processes, turnaround times, and certifications—especially for industries with strict regulatory standards.

Additionally, total cost should be assessed beyond the initial quote, factoring in logistics, lead times, and potential scalability. Building strong relationships with reputable, technologically advanced partners can enhance supply chain resilience and support innovation in product development. Ultimately, a well-informed sourcing decision in laser cutting contributes to improved manufacturing efficiency, product quality, and competitive advantage in the market.