The global surface treatment equipment market, driven by rising demand for precision finishing in automotive, aerospace, and industrial manufacturing, is witnessing a significant shift toward advanced technologies like laser ablation. According to Grand View Research, the global laser cleaning equipment market size was valued at USD 618.7 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 17.8% from 2023 to 2030. This surge is fueled by the increasing adoption of eco-friendly, chemical-free cleaning methods and stringent environmental regulations phasing out traditional sandblasting techniques. As laser sandblasting—also known as laser ablation or laser surface cleaning—emerges as a sustainable and highly efficient alternative, manufacturers are investing heavily in R&D to enhance power output, portability, and application versatility. Against this backdrop, we spotlight the top 9 laser sandblaster manufacturers leading innovation, scalability, and global market penetration in this rapidly evolving sector.

Top 9 Laser Sandblaster Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: PULSAR Laser is a manufacturer of professional laser cleaning machines, developed and engineered for industrial maintenance, manufacturing, restoration and ……

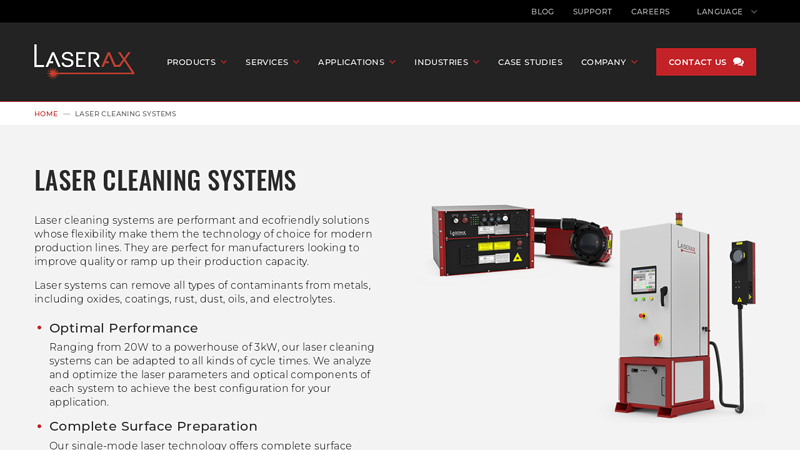

#2 Laser Cleaning Systems

Website: laserax.com

Key Highlights: Oem Laser Cleaning Systems. From low-power to high-power lasers, our range of products allow manufacturers to efficiently solve their surface cleaning needs….

#3 CL1000 Laser

Website: nortonsandblasting.com

Key Highlights: Norton Sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal ……

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#6 Argento Lux

Website: argentolux.com

Key Highlights: Argento Lux, experts in laser cleaning, utilizing high-powered lasers to remove contamination from various surfaces. Similar to sandblasting without the ……

#7 Clean Laser Technologies

Website: cleanlasertechnologies.com

Key Highlights: Clean Laser Technologies is a Mississippi-based company specializing in laser cleaning technology, providing state-of-the-art laser cleaning machines, training ……

#8 Laser Cleaning Machine – LaserBlast Systems

Website: alliedscientificpro.com

Key Highlights: Our fiber laser cleaning system requires no blast media, consuming only electricity and utilizing a highly efficient power input. Digitally controlled, ……

#9 Laser Cleaning vs. Dustless Blasting

Website: dustlessblasting.com

Key Highlights: While laser cleaning excels in precision for delicate surfaces, Dustless Blasting is superior for tough jobs like removing coatings and profiling surfaces….

Expert Sourcing Insights for Laser Sandblaster

H2: 2026 Market Trends for Laser Sandblasters

The global market for laser sandblasters is poised for significant transformation by 2026, driven by advancements in automation, environmental regulations, and growing demand for precision surface treatment across key industries. As traditional abrasive blasting methods face increasing scrutiny due to environmental and health concerns, laser sandblasting—also known as laser ablation or laser cleaning—is emerging as a sustainable and highly efficient alternative.

One of the most notable trends shaping the 2026 outlook is the integration of artificial intelligence (AI) and robotics into laser sandblasting systems. Industrial automation is accelerating adoption in sectors such as automotive, aerospace, and shipbuilding, where precision, repeatability, and reduced downtime are critical. Smart laser systems with real-time monitoring and adaptive control capabilities are expected to dominate new installations, improving cleaning efficiency and reducing operational costs.

Environmental sustainability is another major driver. With stricter global regulations on dust emissions, waste disposal, and worker safety (e.g., EU’s REACH and OSHA standards), industries are shifting toward chemical-free and non-abrasive cleaning methods. Laser sandblasters produce no secondary waste, require no consumables, and are fully compliant with eco-friendly manufacturing standards, making them ideal for green production lines.

Additionally, the decreasing cost of high-power fiber lasers and improved portability of laser systems are expanding their use beyond large industrial facilities into mid-sized workshops and field service applications. Handheld and mobile laser units are gaining traction in maintenance, restoration (e.g., historical monuments), and offshore operations.

By 2026, the Asia-Pacific region—particularly China, Japan, and South Korea—is expected to lead market growth, fueled by rapid industrial modernization and government incentives for clean technology. North America and Europe will maintain strong demand, especially in defense and nuclear decommissioning projects where contamination control is paramount.

In summary, the 2026 laser sandblaster market will be defined by technological innovation, regulatory support, and a shift toward sustainable industrial practices. As the technology becomes more accessible and versatile, its adoption is projected to grow at a compound annual growth rate (CAGR) of approximately 12–15% through 2026, solidifying its role in the future of industrial surface preparation.

Common Pitfalls When Sourcing a Laser Sandblaster (Quality, IP)

Sourcing a laser sandblaster—particularly for industrial applications like surface preparation, rust removal, or coating stripping—requires careful consideration to avoid significant issues related to both product quality and intellectual property (IP). Here are key pitfalls to watch for:

Poor Build Quality and Performance Inconsistencies

Many suppliers, especially those from less-regulated markets, offer laser sandblasters with substandard components. These units may use low-quality lasers, inadequate cooling systems, or flimsy housings that lead to rapid degradation, inconsistent performance, and frequent downtime. Buyers often discover too late that the advertised power output (e.g., 1000W) does not match real-world results, resulting in inefficient processing and increased operational costs.

Lack of Safety and Compliance Certification

A major quality concern is the absence of international safety certifications (e.g., CE, FDA, IEC). Non-compliant laser systems can pose serious risks, including eye and skin hazards, fire, or electrical issues. Sourcing from vendors who cannot provide valid compliance documentation exposes your operation to liability and may prevent the equipment from being legally used in regulated environments.

Misrepresentation of Technical Specifications

Some suppliers exaggerate key metrics such as laser power, pulse frequency, or cleaning speed. For example, a device marketed as “500W” might only deliver 300W of actual output due to inefficient energy conversion. This misrepresentation leads to inaccurate expectations and underperformance on the job site, undermining return on investment.

Inadequate After-Sales Support and Spare Parts Availability

Low-cost laser sandblasters are often sold by vendors with limited technical support, poor documentation, and no local service network. When maintenance is needed or components fail, sourcing spare parts can take weeks or months, causing extended downtime. This lack of support is particularly problematic for mission-critical operations.

Intellectual Property (IP) Infringement Risks

Purchasing laser sandblasters from manufacturers that copy patented designs or use proprietary technology without licensing exposes your company to legal risk. If the equipment incorporates stolen IP—such as control software, optical configurations, or mechanical designs—you could face legal action, import seizures, or reputational damage, especially in markets with strict IP enforcement.

Use of Counterfeit or Reverse-Engineered Components

Some suppliers integrate counterfeit laser diodes or controllers that mimic reputable brands but fail prematurely. These components may not only degrade performance but also violate IP laws. Using such systems can void warranties on other equipment and increase long-term costs due to frequent replacements.

Insufficient IP Due Diligence by Buyers

Buyers often focus solely on price and specs, neglecting to verify whether the supplier owns or legally licenses the technology. Failing to conduct IP due diligence—such as checking patents, trademarks, or software licenses—can result in unknowingly supporting infringement and jeopardizing your own business operations.

Avoiding these pitfalls requires vetting suppliers thoroughly, requesting third-party test reports, reviewing IP documentation, and prioritizing long-term reliability over initial cost savings.

Logistics & Compliance Guide for Laser Sandblaster

Product Classification and Documentation

Ensure accurate classification of the laser sandblaster under the Harmonized System (HS) Code. Typically, industrial laser equipment falls under HS Code 8515. This classification is essential for import/export declarations, customs clearance, and determining applicable tariffs. Maintain comprehensive documentation, including technical specifications, user manuals, safety data sheets (if applicable), and CE or other regional conformity markings (e.g., FCC, RoHS).

Regulatory Compliance

The laser sandblaster must comply with international and local safety and environmental regulations. Key compliance standards include:

- IEC 60825-1: Safety of laser products – Equipment classification and requirements. Ensure the device is properly labeled with laser class, output power, and warning symbols.

- CE Marking (EU): Confirm compliance with the Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and Low Voltage Directive (2014/35/EU).

- FDA/CDRH (USA): Register the product with the U.S. Food and Drug Administration Center for Devices and Radiological Health. Submit a laser product report and comply with 21 CFR 1040.10 and 1040.11 requirements.

- RoHS and REACH (EU): Confirm that the device is free from restricted hazardous substances.

- FCC Compliance (USA): If the equipment generates radio frequency emissions, verify compliance with Part 18 of the FCC rules.

Packaging and Handling

Package the laser sandblaster to withstand international shipping conditions. Use shock-absorbent materials, moisture barriers, and secure crating for heavy components. Clearly label packages with:

- Fragile and heavy item indicators

- Orientation arrows

- Laser warning symbols

- Proper shipping name and UN number (if applicable, e.g., for lithium batteries in control units)

Ensure compliance with IATA, IMDG, or other transport regulations if hazardous components are present.

Import/Export Licensing and Restrictions

Verify whether export controls apply under regulations such as:

- EAR (Export Administration Regulations, USA): Check if the laser system falls under ECCN 6A003 or similar categories due to power output or precision capabilities.

- Dual-Use Goods: Some laser systems may be subject to dual-use export controls (e.g., EU Dual-Use Regulation). Obtain necessary export licenses if required.

- Destination-Specific Restrictions: Certain countries may have import bans or require special permits for laser equipment. Consult with local customs authorities prior to shipment.

Transportation and Carrier Requirements

Coordinate with freight forwarders experienced in handling industrial machinery and regulated equipment. Provide accurate:

- Weight and dimensions for freight classification

- Power requirements and disassembly instructions (if applicable)

- Insurance valuation based on replacement cost

Use carriers compliant with hazardous materials regulations if batteries or compressed gases are included. Air, sea, or ground transport must align with equipment sensitivity and delivery timelines.

Customs Clearance

Prepare a complete set of shipping documents, including:

- Commercial Invoice (with detailed description, value, and HS code)

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Conformity (CE, FCC, etc.)

- Export License (if applicable)

- Statement of Non-Proprietary Parts (to avoid delays)

Ensure Harmonized Tariff Schedule (HTS) codes are correctly applied to avoid overpayment of duties or customs holds.

End-User Verification and Recordkeeping

Implement an end-user verification process, especially for exports subject to dual-use or strategic trade controls. Maintain records of:

- Sales contracts

- Export licenses

- Compliance certifications

- Customer declarations (e.g., non-military use)

Retain records for a minimum of five years as required by most export control regimes.

Post-Shipment Support and Compliance Monitoring

Provide customers with compliance documentation and safety training materials. Monitor regulatory updates in target markets and issue product compliance bulletins when standards change. Establish a process to recall or retrofit units if new safety or environmental regulations render the product non-compliant.

Environmental and Disposal Compliance

Inform end-users of proper end-of-life disposal procedures in accordance with WEEE (Waste Electrical and Electronic Equipment) directives or local e-waste regulations. Provide take-back or recycling options where required.

Conclusion: Sourcing a Laser Sandblaster

After a thorough evaluation of available technologies, market suppliers, cost structures, and operational requirements, sourcing a laser sandblaster presents a strategic opportunity to enhance precision, efficiency, and environmental sustainability in surface treatment processes. Unlike traditional abrasive blasting methods, laser sandblasting offers non-contact cleaning, minimal substrate damage, reduced waste generation, and lower long-term operational costs due to decreased media and disposal expenses.

Key factors in finalizing the sourcing decision include the compatibility of the laser system with existing production workflows, required power specifications, maintenance demands, and supplier support services. Leading manufacturers offer varying capabilities in terms of power output, automation integration, and application versatility—making it essential to align technical specifications with specific industrial needs, such as corrosion removal, paint stripping, or surface preparation in aerospace, automotive, or marine sectors.

Additionally, while the initial investment in laser sandblasting technology is higher than conventional methods, the long-term return on investment through improved quality, compliance with environmental regulations, and reduced labor and consumable costs justifies the expenditure for high-volume or precision-critical operations.

In conclusion, sourcing a laser sandblaster is a forward-looking decision that supports operational advancement, sustainability goals, and long-term cost efficiency. By partnering with reputable suppliers and ensuring proper training and integration, organizations can leverage this innovative technology to gain a competitive edge in quality and productivity.