The global laser surface treatment market has experienced robust growth, driven by increasing demand for precision cleaning and eco-friendly alternatives to traditional sandblasting methods. According to a report by Mordor Intelligence, the industrial lasers market—which includes laser-based surface cleaning and texturing technologies—is projected to grow at a CAGR of over 7.5% from 2023 to 2028. This upward trend is further supported by Grand View Research, which highlights a rising adoption of laser cleaning systems in automotive, aerospace, and heavy manufacturing sectors due to their ability to reduce waste, lower operational costs, and meet stringent environmental regulations. As industries shift toward automation and sustainable practices, laser sand blasting has emerged as a high-accuracy, non-abrasive solution for surface preparation. In this evolving landscape, a select group of manufacturers are leading innovation in power efficiency, scalability, and integration capabilities. Below, we examine the top 10 laser sand blaster manufacturers shaping this transformative segment.

Top 10 Laser Sand Blaster Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Robotic Abrasive Blast Systems

Website: empire-airblast.com

Key Highlights: We provide integrated robotic air-blast solutions for aerospace, transport, energy, gas & Oil, high technology, military, medical and industrial / consumer ……

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 JH Norton Company Inc.

#4 Equipment

Website: ikonicsimaging.com

Key Highlights: The IKONICS Imaging CrystalBlast line of sandcarving equipment, designed and engineered in partnership with Media Blast & Abrasive, Inc….

#5 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#6 Laser Cleaning vs. Dustless Blasting

Website: dustlessblasting.com

Key Highlights: While laser cleaning excels in precision for delicate surfaces, Dustless Blasting is superior for tough jobs like removing coatings and profiling surfaces….

#7 IKONICS

Website: ikonics.com

Key Highlights: IKONICS Imaging is the Total Solution Supplier for all sandcarving needs with high-quality equipment and products. IKONICS Imaging provides everything needed to ……

#8 Laser Cleaning Machine – LaserBlast Systems

Website: alliedscientificpro.com

Key Highlights: Our fiber laser cleaning system requires no blast media, consuming only electricity and utilizing a highly efficient power input. Digitally controlled, ……

#9 Clemco Industries

Website: clemcoindustries.com

Key Highlights: Clemco is a global leader in abrasive blasting, cleaning, shot peening, and surface preparation solutions, serving industries from aerospace and energy to ……

#10 Laser Rust Removal Guide

Website: pulsar-laser.com

Key Highlights: A practical guide for professionals and entrepreneurs using PULSAR Laser systems to remove rust safely, efficiently and without abrasives….

Expert Sourcing Insights for Laser Sand Blaster

H2: 2026 Market Trends for Laser Sand Blasters

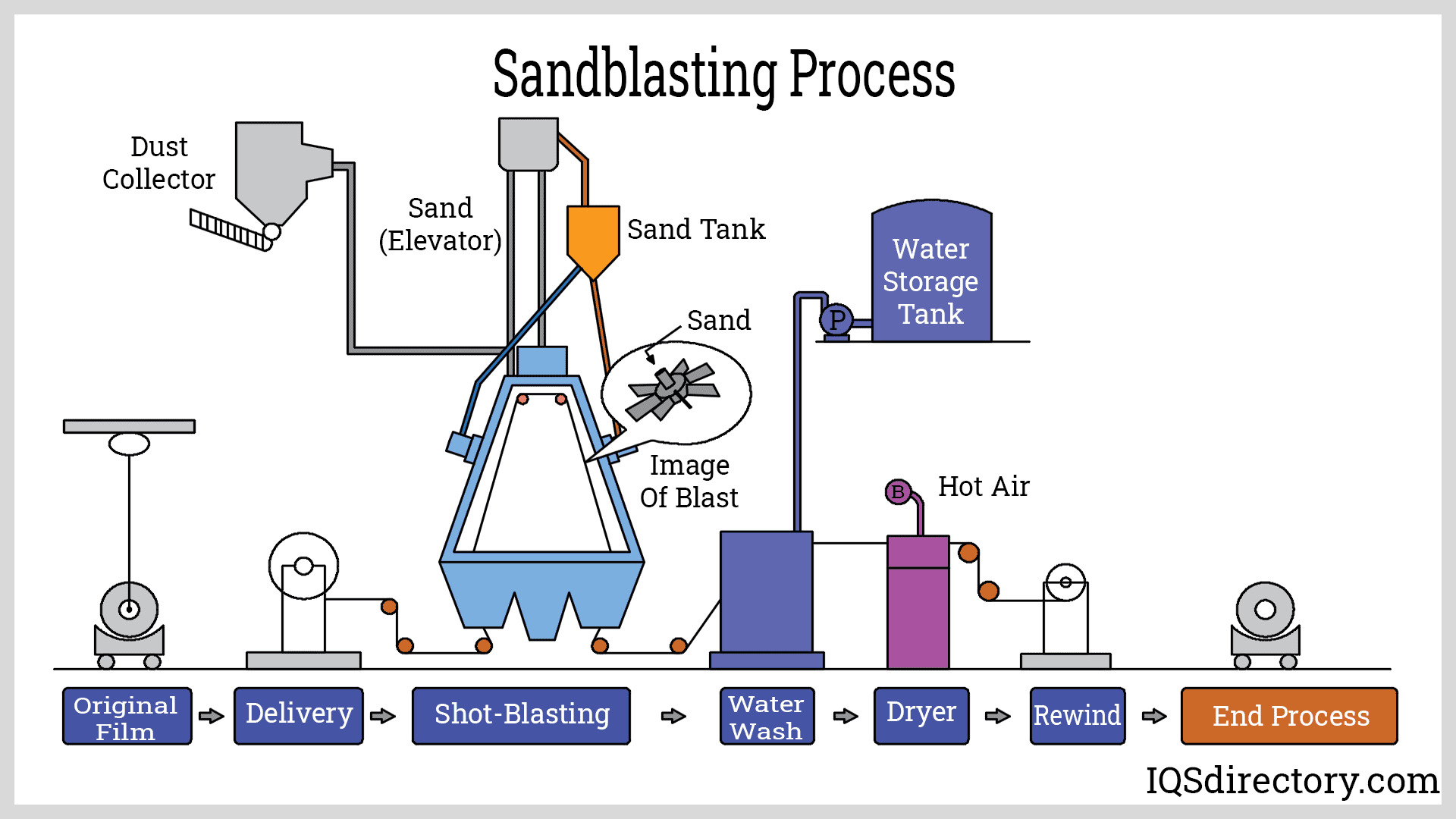

The global market for laser sand blasters is poised for significant transformation by 2026, driven by technological innovation, growing environmental regulations, and increased demand for precision surface treatment across key industries. Unlike traditional abrasive blasting methods, laser sand blasters utilize high-intensity laser beams to remove coatings, rust, and contaminants without media or significant substrate damage—offering a cleaner, more sustainable alternative. This analysis explores the key trends expected to shape the laser sand blaster market in 2026.

1. Rising Adoption in Industrial Manufacturing and Shipbuilding

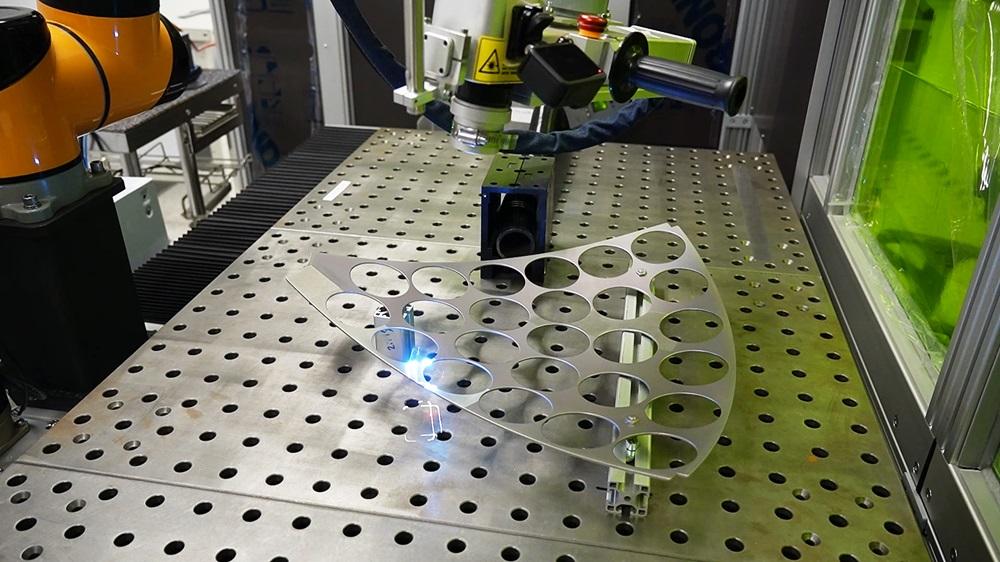

By 2026, laser sand blasters are projected to gain substantial traction in heavy industries such as shipbuilding, automotive manufacturing, and aerospace. These sectors are increasingly prioritizing non-contact, precise surface preparation techniques to improve product quality and reduce downtime. In shipyards, laser cleaning is replacing sandblasting for rust and paint removal due to its ability to minimize secondary waste and reduce worker exposure to hazardous dust. The integration of robotics with laser systems will further enhance automation and efficiency in large-scale applications.

2. Environmental and Regulatory Drivers

Stringent environmental regulations—particularly those targeting hazardous waste and silica dust emissions from traditional sandblasting—are accelerating the shift toward eco-friendly alternatives. Regions such as the European Union and North America are enforcing tighter industrial emission standards, making laser-based surface treatment a compliant and future-proof solution. The absence of consumable abrasives and chemical agents positions laser sand blasters as a sustainable technology aligned with circular economy principles, further boosting market demand.

3. Advancements in Laser Technology and Cost Efficiency

By 2026, continued improvements in fiber laser efficiency, portability, and power output are expected to reduce operational costs and expand accessibility. Innovations such as handheld laser cleaners and modular systems will enable small and medium enterprises (SMEs) to adopt the technology without heavy capital investment. Additionally, falling prices of key components like diode lasers and improved cooling systems will contribute to lower total cost of ownership, making laser sand blasters more competitive with traditional methods.

4. Growth in Renewable Energy and Infrastructure Maintenance

The renewable energy sector—especially wind and solar—is emerging as a new growth vector for laser sand blasters. Maintenance of wind turbine blades and photovoltaic structures requires delicate cleaning to avoid surface degradation. Laser systems offer a non-abrasive solution ideal for these sensitive applications. Similarly, aging infrastructure in developed markets will drive demand for efficient, non-destructive maintenance tools, further expanding the addressable market.

5. Regional Market Expansion and Competitive Landscape

Asia-Pacific is anticipated to be the fastest-growing region by 2026, fueled by rapid industrialization in China, India, and South Korea, along with government initiatives promoting smart manufacturing and green technologies. North America and Europe will remain key markets due to high R&D investment and early adoption of advanced surface treatment systems. The competitive landscape is expected to consolidate, with major players focusing on strategic partnerships, product diversification, and integration with Industry 4.0 platforms.

In conclusion, the 2026 market for laser sand blasters will be defined by technological maturity, regulatory support, and cross-industry adoption. As companies prioritize sustainability, safety, and precision, laser-based surface cleaning is set to transition from a niche alternative to a mainstream industrial solution.

Common Pitfalls When Sourcing a Laser Sand Blaster: Quality and Intellectual Property Risks

Sourcing a Laser Sand Blaster—especially from international suppliers or lesser-known manufacturers—can present significant challenges related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls is essential to avoid costly mistakes, legal disputes, or substandard equipment performance.

1. Compromised Build Quality and Performance

One of the most frequent issues when sourcing Laser Sand Blasters is receiving equipment that does not meet advertised specifications. Many suppliers, particularly in regions with lax manufacturing oversight, may cut corners on materials, laser components, or safety mechanisms. This can lead to:

- Inconsistent blasting results due to underpowered or poorly calibrated lasers

- Rapid wear and tear of critical parts such as nozzles and optical lenses

- Safety hazards from inadequate shielding or cooling systems

To mitigate this, always request third-party inspection reports, conduct factory audits, and test units before full-scale procurement.

2. Lack of Certification and Compliance

Laser equipment is subject to strict international safety and emissions standards (e.g., FDA/CDRH in the U.S., CE in Europe, IEC 60825). Some suppliers may provide units that lack proper certification or offer falsified documentation. Non-compliant devices can result in:

- Equipment seizure at customs

- Legal liability in case of operator injury

- Inability to use the machine in regulated industries

Ensure all documentation is verifiable and matches the actual product configuration.

3. Intellectual Property Infringement

Many low-cost Laser Sand Blasters on the market are reverse-engineered copies of patented designs. Purchasing such equipment—even unknowingly—can expose your company to:

- Legal action from original equipment manufacturers (OEMs)

- Seizure of infringing equipment by customs or regulatory bodies

- Damage to your brand’s reputation for ethical sourcing

To avoid IP risks, perform due diligence by:

– Requesting proof of IP ownership or licensing from the supplier

– Conducting patent landscape searches

– Working with legal counsel to assess supplier legitimacy

4. Inadequate Technical Support and Spare Parts Availability

Even if a Laser Sand Blaster initially meets quality standards, long-term operation can be undermined by poor after-sales support. Common issues include:

- Delayed or nonexistent technical assistance

- Unavailability of replacement parts, especially for proprietary components

- Obsolete software or firmware with no update path

Choose suppliers with a proven service network and clear spare parts policies.

5. Misrepresentation of Capabilities

Some suppliers exaggerate the performance metrics of their Laser Sand Blasters—such as power output, processing speed, or material compatibility. This misrepresentation can lead to poor integration with existing production lines and unmet operational goals.

Always verify claims through independent testing or pilot trials before committing to bulk orders.

By proactively addressing these quality and IP-related pitfalls, businesses can ensure they source reliable, compliant, and legally sound Laser Sand Blasting equipment that supports long-term operational success.

Logistics & Compliance Guide for Laser Sand Blaster

Product Classification and Documentation

Ensure the Laser Sand Blaster is accurately classified under the appropriate Harmonized System (HS) code for international shipping and customs clearance. Common classifications may fall under machinery for surface preparation (e.g., HS 8479.89 or 8515.80, depending on primary function). Maintain complete technical documentation including user manuals, safety data sheets (SDS) for consumables, electrical specifications, and CE or other regional conformity certificates.

Export Controls and Regulations

Verify whether the Laser Sand Blaster is subject to export control regulations such as the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR). Most industrial laser systems fall under EAR Category 2 or 6. Check the Commerce Control List (CCL) for the specific Export Control Classification Number (ECCN). If the laser exceeds power thresholds (e.g., over Class 4 lasers), additional licensing may be required for shipment to certain countries.

Safety and Certification Compliance

The Laser Sand Blaster must comply with relevant safety standards prior to distribution. In the European Union, adherence to the Machinery Directive (2006/42/EC) and the Laser Product Safety standard (IEC 60825-1) is mandatory. In the U.S., compliance with FDA/CDRH laser product regulations (21 CFR 1040.10) is required. Ensure all equipment bears required warning labels, interlocks, and protective enclosures.

Packaging and Handling Requirements

Package the Laser Sand Blaster to prevent damage during transit. Use shock-absorbent materials and secure all components, especially optical and laser elements. Clearly label packages with “Fragile,” “This Side Up,” and “Laser Equipment – Do Not Expose to Light or Heat.” Include handling instructions and ensure the packaging meets ISTA or ASTM standards for industrial machinery.

Transportation and Shipping

Use freight carriers experienced in handling industrial laser equipment. For air freight, comply with IATA Dangerous Goods Regulations if applicable—note that high-powered lasers or associated batteries may be classified as hazardous. For sea freight, follow IMDG Code guidelines. Declare the shipment accurately, including power output, voltage, and any embedded batteries.

Import Requirements by Region

Research import regulations in the destination country. Some regions require pre-shipment inspections, local representation, or conformity assessment (e.g., KC Mark for South Korea, CCC for China). Import duties, VAT, and customs brokerage fees should be accounted for. Provide a detailed commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

On-Site Installation and Training Compliance

Ensure that installation and operator training are conducted by qualified personnel in accordance with local occupational safety regulations (e.g., OSHA in the U.S., HSE in the UK). Provide training documentation confirming personnel have been instructed on laser safety (ANSI Z136.1 or equivalent), emergency shutdown procedures, and proper use of personal protective equipment (PPE).

Environmental and Disposal Regulations

Address end-of-life disposal in compliance with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU or equivalent local laws. Laser components and electronic boards may contain hazardous materials requiring special recycling procedures. Maintain records of equipment disposal or recycling through authorized facilities.

Regulatory Updates and Recordkeeping

Monitor changes in international laser safety, transportation, and environmental regulations. Maintain a compliance file for each unit shipped, including certificates, shipping documents, and customer training records. Retain records for a minimum of five years or as required by local law to support audits or incident investigations.

Conclusion for Sourcing a Laser Sand Blaster

After thorough evaluation of available technologies, market offerings, and operational requirements, sourcing a laser sand blaster presents a forward-thinking solution for precision surface preparation and coating removal. Unlike traditional abrasive blasting methods, laser blasting offers superior accuracy, minimal substrate damage, reduced waste, and enhanced environmental and operator safety by eliminating media consumption and minimizing hazardous byproducts.

The initial investment in laser sand blasting equipment may be higher than conventional methods; however, the long-term benefits—including lower operating costs, reduced cleanup time, compliance with environmental regulations, and the ability to automate processes—justify the cost for many industrial applications, particularly in aerospace, automotive, maritime, and cultural heritage restoration sectors.

When sourcing a laser sand blaster, key considerations should include laser power output, wavelength suitability for target materials, system portability, safety certifications, ease of integration with existing workflows, and availability of technical support and training.

In conclusion, sourcing a laser sand blaster is a strategic investment in sustainable, efficient, and high-precision surface treatment technology. Organizations seeking to improve quality, reduce environmental impact, and future-proof their operations should strongly consider adopting laser-based solutions as part of their advanced manufacturing or maintenance processes.