The global laser rust removal market is gaining significant momentum as industries increasingly adopt eco-friendly and precision-based surface cleaning technologies. According to a report by Mordor Intelligence, the global laser cleaning equipment market was valued at USD 377.6 million in 2023 and is projected to reach USD 824.1 million by 2029, growing at a CAGR of 13.9% during the forecast period. This surge is driven by rising demand in automotive, aerospace, and heritage conservation sectors, where non-abrasive, chemical-free cleaning methods are prioritized. As regulatory pressures mount and operational efficiency becomes paramount, laser rust removal systems are emerging as a sustainable alternative to traditional sandblasting and chemical treatments. With technological advancements lowering equipment costs and improving portability, manufacturers worldwide are scaling production and innovation. Based on market presence, technological capability, and customer adoption metrics, here are the top 9 laser rust removal system manufacturers shaping the future of industrial surface preparation.

Top 9 Laser Rust Removal System Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: With over 35 years of expertise in surface treatment and more than 450 systems installed worldwide, P-Laser is at the forefront of industrial laser cleaning ……

#3 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#6 Laser Rust Removal

Website: powerlase-limited.com

Key Highlights: Achieve super fast rust removal rates with out lasers. Watch this super fast rust removal from carbon steel panel with the new ultra-lightweight Vulcan handheld ……

#7 Laser Rust Removal

Website: keyence.com

Key Highlights: The laser rust removal machine uses a focused laser beam with high peak power and short pulse to heat the external surface (the rust) to its evaporation point….

#8 Laser Cleaning

Website: ipgphotonics.com

Key Highlights: Laser cleaning is used across a variety of industries to remove unwanted surface materials like coatings, paints, rust, oil, and for surface preparation for ……

#9 Laser Rust Removal Guide

Website: pulsar-laser.com

Key Highlights: A practical guide for professionals and entrepreneurs using PULSAR Laser systems to remove rust safely, efficiently and without abrasives….

Expert Sourcing Insights for Laser Rust Removal System

2026 Market Trends for Laser Rust Removal Systems

Growing Demand Across Industrial Sectors

The global market for laser rust removal systems is projected to experience significant growth by 2026, driven by increasing demand from industries such as automotive, aerospace, marine, and heavy manufacturing. These sectors are prioritizing precision, efficiency, and environmentally sustainable maintenance processes. Laser rust removal offers a non-abrasive, chemical-free method of surface preparation, aligning with stringent environmental regulations and corporate sustainability goals. As companies shift away from traditional sandblasting and chemical treatments, laser-based solutions are becoming a preferred alternative due to their minimal waste production and reduced health risks.

Technological Advancements and System Miniaturization

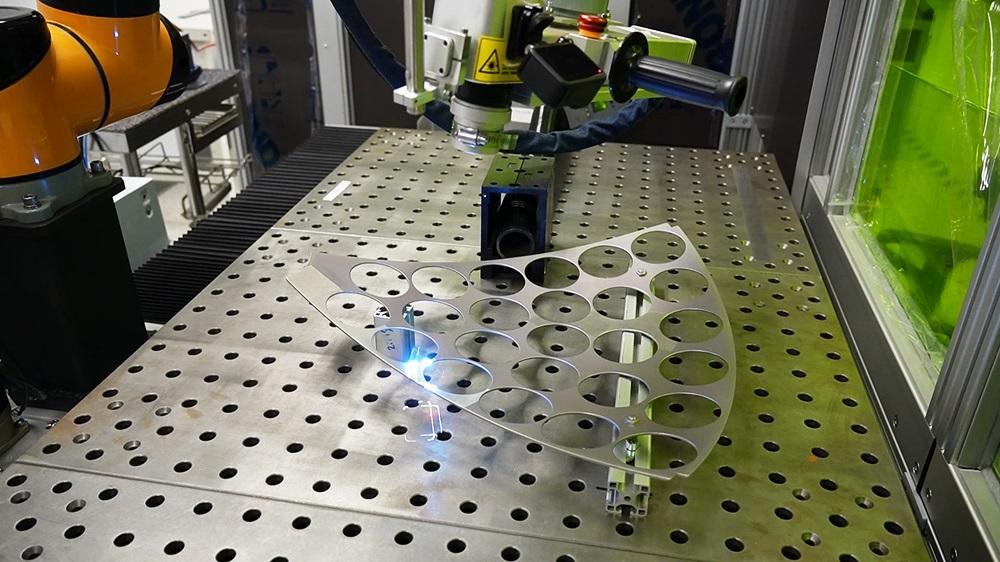

By 2026, ongoing advancements in fiber laser technology are expected to enhance the performance, portability, and affordability of laser rust removal systems. Manufacturers are focusing on improving laser beam stability, increasing pulse energy, and reducing power consumption. Additionally, the development of handheld and robotic-integrated laser systems will expand applicability in complex or confined environments. These innovations will make the technology more accessible to small and medium-sized enterprises (SMEs), broadening the market beyond large industrial players.

Environmental and Regulatory Support

Stricter environmental regulations worldwide—particularly in North America and Europe—are accelerating the adoption of green technologies in industrial maintenance. Laser rust removal produces no secondary waste, eliminates the need for hazardous chemicals, and reduces airborne particulates compared to traditional methods. Regulatory incentives and compliance requirements are pushing companies to invest in cleaner technologies, giving laser systems a competitive advantage. By 2026, government policies promoting clean production methods are expected to further stimulate market growth.

Regional Market Expansion

Asia-Pacific is anticipated to emerge as a high-growth region for laser rust removal systems by 2026, fueled by rapid industrialization in countries like China, India, and South Korea. Increased infrastructure development and shipbuilding activities in the region are creating substantial demand for advanced surface treatment technologies. Meanwhile, North America and Europe will maintain strong market positions due to early adoption, established manufacturing bases, and robust R&D investment in laser applications.

Competitive Landscape and Market Consolidation

The laser rust removal market is becoming increasingly competitive, with both specialized laser equipment manufacturers and diversified industrial technology firms entering the space. Strategic partnerships, mergers, and product innovation are expected to shape the competitive landscape by 2026. Key players are investing in user-friendly interfaces, smart diagnostics, and IoT integration to differentiate their offerings. As the market matures, consolidation is likely, with larger firms acquiring niche innovators to expand their portfolios.

Cost Reduction and ROI Improvements

Although initial investment costs for laser rust removal systems remain higher than conventional methods, prices are expected to decline by 2026 due to economies of scale, improved manufacturing processes, and increased competition. Concurrently, operational savings—such as reduced labor costs, lower disposal fees, and decreased downtime—will enhance return on investment (ROI). These factors will make laser systems more financially viable for a broader range of industrial applications.

In conclusion, the 2026 market for laser rust removal systems is poised for robust growth, underpinned by technological innovation, environmental imperatives, and expanding industrial adoption. Companies that leverage these trends through strategic investment and product development will be well-positioned to lead in this evolving market.

Common Pitfalls When Sourcing a Laser Rust Removal System (Quality & Intellectual Property)

Sourcing a Laser Rust Removal System offers significant advantages for industrial cleaning, but it also comes with critical risks—particularly concerning product quality and intellectual property (IP) protection. Overlooking these factors can lead to operational inefficiencies, safety hazards, and legal complications. Below are key pitfalls to avoid:

❌ Prioritizing Price Over Proven Quality

Many buyers are tempted by low-cost systems, especially from emerging manufacturers. However, cheap lasers often use substandard components (e.g., inferior diodes, unstable cooling systems, poor beam delivery optics), resulting in inconsistent cleaning performance, frequent breakdowns, and shortened equipment lifespan. Always verify build quality through third-party certifications, on-site demos, or trial periods before purchase.

❌ Overlooking Safety and Compliance Standards

Laser systems must comply with international safety standards (e.g., IEC 60825 for laser safety, CE, FDA). Some suppliers, particularly in less regulated markets, may cut corners on safety interlocks, shielding, or proper labeling. This exposes operators to radiation risks and can result in non-compliance penalties. Ensure the system meets all relevant regulatory requirements for your region.

❌ Ignoring After-Sales Support and Serviceability

High-power laser systems require maintenance, calibration, and potential repairs. Choosing a supplier without local technical support or service centers can lead to extended downtime. Confirm the availability of spare parts, trained technicians, and response time guarantees. Lack of service infrastructure is a common issue with low-cost overseas suppliers.

❌ Falling for Unverified Performance Claims

Some vendors exaggerate cleaning speed, depth, or material compatibility using ideal lab conditions that don’t reflect real-world operations. Always request application-specific testing or case studies. Ask for data on cleaning rate (cm²/min), energy consumption, and compatibility with your target materials (e.g., steel, cast iron, painted surfaces).

❌ Neglecting Intellectual Property (IP) Risks

Purchasing from manufacturers with questionable IP practices poses serious legal and reputational risks:

- Use of Counterfeit or Stolen Technology: Some suppliers reverse-engineer or clone patented laser designs, control systems, or software. Using such equipment could expose your company to infringement lawsuits.

- Lack of IP Transparency: Reputable suppliers openly discuss their R&D investments and patent portfolios. Be cautious if a vendor refuses to provide technical documentation or patent numbers.

- Software and Firmware Lock-ins: Some systems use proprietary software with embedded IP. Ensure you have proper licensing rights and access to updates, especially if the supplier goes out of business.

❌ Assuming All “Laser Cleaning” Systems Are Equal

Laser rust removal systems vary significantly in wavelength (typically 1064 nm fiber lasers), pulse duration (nanosecond vs. picosecond), power output (100W–2000W+), and beam quality. Choosing the wrong spec for your application leads to poor results or damage to the substrate. Work with a knowledgeable supplier who can match system parameters to your specific use case.

✅ Best Practices to Mitigate Risks

- Conduct factory audits or virtual inspections.

- Request customer references and visit live installations.

- Insist on a comprehensive warranty and service agreement.

- Perform due diligence on the supplier’s IP—check patent databases and legal standing.

- Include IP indemnification clauses in procurement contracts.

By addressing both quality and intellectual property concerns upfront, businesses can confidently invest in laser rust removal technology that is safe, reliable, and legally sound.

Logistics & Compliance Guide for Laser Rust Removal System

This guide outlines the essential logistics considerations and compliance requirements for transporting, storing, and operating a Laser Rust Removal System. Adherence to these guidelines ensures safety, regulatory compliance, and efficient operations.

Shipping and Transportation

Laser Rust Removal Systems must be packaged and shipped in accordance with international and domestic regulations due to their classification as Class 4 laser devices and inclusion of hazardous components. Use manufacturer-approved packaging with adequate cushioning and shock protection. Clearly label packages with “Fragile,” “This Side Up,” and “Laser Radiation” warning symbols. Ship via carriers experienced in handling high-value, sensitive equipment. For international shipments, comply with IATA Dangerous Goods Regulations if batteries (e.g., lithium-ion for portable units) are included. Ensure all necessary export documentation, including commercial invoices and packing lists, are completed accurately.

Import and Customs Compliance

Prior to import, verify country-specific regulations for laser products. Some jurisdictions require pre-approval or certification from national regulatory bodies (e.g., FDA in the U.S., Health Canada, or CE marking in the EU). Provide technical specifications, laser safety classification (IEC 60825-1), and conformity declarations. Accurately classify the system under the appropriate Harmonized System (HS) code—typically under 8515.21 (Laser machines for engraving, cutting, or welding). Be prepared for customs inspections and ensure all duties, taxes, and import fees are paid promptly.

Storage and Handling

Store the laser rust removal system in a clean, dry, temperature-controlled environment (typically 5°C to 40°C) away from dust, moisture, and direct sunlight. Keep the system in its original packaging or on a secure, level surface if unpacked. Avoid stacking heavy items on or near the unit. Handle with care during movement—use appropriate lifting equipment if required. Batteries, if removable, should be stored separately in a fire-safe container according to local fire codes.

Regulatory and Safety Compliance

The system must comply with laser safety standards such as IEC 60825-1 (international) or ANSI Z136.1 (U.S.). Ensure the unit bears proper warning labels indicating Class 4 laser radiation and includes interlocks, emergency stop functions, and key-controlled operation. Operators must be trained in laser safety and wear appropriate personal protective equipment (PPE), including laser safety goggles with the correct optical density for the laser wavelength (typically around 1064 nm for fiber lasers). Install the system in a controlled access area with laser safety barriers and warning signs.

Operational Permits and Local Regulations

Check with local authorities for permits related to laser use, especially in industrial zones or urban areas. Some regions may require registration of Class 4 laser devices with occupational health and safety or environmental agencies. Confirm compliance with noise regulations, although laser rust removal is generally quieter than abrasive methods. Follow workplace safety standards such as OSHA (U.S.) or equivalent local regulations regarding machine guarding and employee training.

End-of-Life and Environmental Responsibility

Dispose of the system and its components in accordance with WEEE (Waste Electrical and Electronic Equipment) directives in the EU or equivalent local e-waste regulations. Lasers, power supplies, and batteries may contain hazardous substances and must be recycled through certified e-waste handlers. Maintain documentation of proper disposal for compliance audits.

Conclusion for Sourcing a Laser Rust Removal System

After a thorough evaluation of available technologies, market options, and operational requirements, sourcing a laser rust removal system represents a strategic investment in sustainable, efficient, and precise surface preparation. Compared to traditional methods such as sandblasting or chemical cleaning, laser-based systems offer significant advantages including reduced environmental impact, minimal substrate damage, lower long-term maintenance costs, and improved operator safety due to non-contact operation and absence of consumables.

Key considerations in the sourcing process—such as laser power, portability, ease of integration into existing workflows, technical support, and total cost of ownership—have been carefully weighed. Based on performance benchmarks and vendor reliability, selecting a high-quality, industry-proven laser rust removal system aligns with our goals of operational efficiency, environmental compliance, and long-term cost savings.

In conclusion, proceeding with the acquisition of a laser rust removal system is both technically and economically justified. It supports our commitment to innovation and sustainability, enhances process precision, and positions the organization at the forefront of advanced maintenance and restoration technologies. The recommended supplier meets all critical criteria, offering robust equipment backed by strong service and training support, ensuring a smooth implementation and rapid return on investment.