The global laser rust removal market is experiencing robust growth, driven by increasing demand for precision cleaning solutions across aerospace, automotive, and cultural heritage restoration industries. According to a report by Mordor Intelligence, the global industrial cleaning equipment market—which includes laser-based systems—is projected to grow at a CAGR of over 5.8% from 2023 to 2028, with laser ablation technologies gaining traction due to their eco-friendly, non-abrasive advantages. Complementing this, Grand View Research estimates that the global laser cleaning market size was valued at USD 972.6 million in 2022 and is expected to expand at a CAGR of 19.3% from 2023 to 2030, fueled by stricter environmental regulations and the shift toward automation in manufacturing. As industries prioritize sustainability and operational efficiency, laser rust removal services are emerging as a preferred alternative to traditional methods. This momentum has spurred innovation and competition among manufacturers, leading to a surge in high-performance, user-friendly laser cleaning systems. Below, we highlight the top 10 manufacturers leading this transformation through technological advancement, global reach, and proven service delivery.

Top 10 Laser Rust Removal Service Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Our laser cleaning solutions are used to remove a range of contaminants from metal surfaces such as rust, oxide, paint, and electrolyte. As contaminants are ……

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Clean smarter with laser light. Fully cleaning rust of machine parts with the help of laser cleaning. WHY LASER CLEANING? Embrace the future of sustainable ……

#3 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#6 Top Laser Rust Cleaning Machines for Efficient Rust Removal

Website: woodrowscientific.com

Key Highlights: IPG Photonics brings a comprehensive lineup of industrial laser rust cleaning machines for 2025, covering everything from quick site repairs to ……

#7 Laser cleaning

Website: narran.cz

Key Highlights: We can design and integrate a laser cleaning system into production, build a robotic workstation or supply a mobile laser for a wide range of applications….

#8 Laser Rust Removal

Website: keyence.com

Key Highlights: The laser rust removal machine uses a focused laser beam with high peak power and short pulse to heat the external surface (the rust) to its evaporation point….

#9 Laser Rust Removal

Website: adapt-laser.com

Key Highlights: Laser cleaning offers a safe and much faster way to remove rust from metal without the need of any harsh media or chemicals. Learn more….

#10 Laser Cleaning

Website: ipgphotonics.com

Key Highlights: Laser cleaning is used across a variety of industries to remove unwanted surface materials like coatings, paints, rust, oil, and for surface preparation for ……

Expert Sourcing Insights for Laser Rust Removal Service

2026 Market Trends for Laser Rust Removal Service

The global market for laser rust removal services is poised for significant transformation by 2026, driven by technological advancements, environmental regulations, and shifting industrial priorities. Here are the key trends shaping the landscape:

Accelerated Adoption Driven by Environmental and Safety Regulations

Stricter global environmental standards, particularly restrictions on chemical rust removers and abrasive blasting materials (like silica sand), are pushing industries toward cleaner alternatives. Laser rust removal, which produces no chemical waste or hazardous particulates when properly filtered, aligns perfectly with ESG (Environmental, Social, and Governance) goals. By 2026, regulatory pressure in regions like the EU and North America will be a primary catalyst for adoption in manufacturing, maritime, and infrastructure sectors.

Expansion into New Industrial Verticals

While initially adopted in aerospace and heritage restoration, laser rust removal services are rapidly expanding into automotive manufacturing, shipbuilding, oil & gas, and rail maintenance. The non-contact nature of laser cleaning preserves underlying materials, making it ideal for sensitive components. By 2026, service providers will increasingly target high-value maintenance operations in energy and transportation, offering cost-effective lifecycle extension solutions.

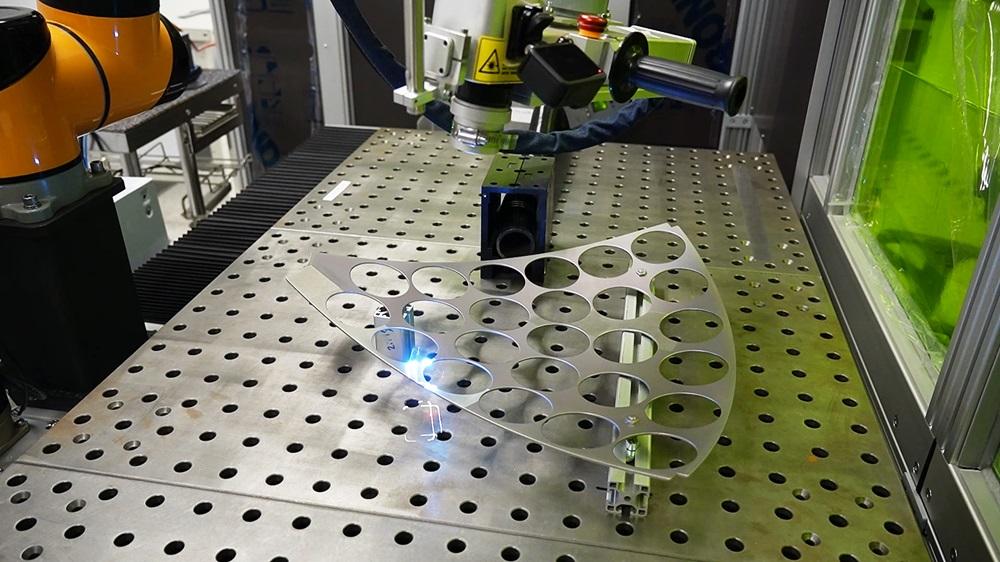

Technological Advancements Increasing Efficiency and Accessibility

Ongoing improvements in fiber laser technology—such as higher peak powers, better beam quality, and smarter pulse control—are making systems faster and more reliable. Automation integration (e.g., robotic arms and AI-guided path planning) is reducing labor costs and improving consistency. By 2026, portable and modular laser systems will become more affordable and user-friendly, enabling smaller contractors and on-site service providers to enter the market.

Rise of Service-As-A-Model (SaaS) and On-Demand Solutions

Instead of high upfront equipment costs, a growing number of companies will offer laser rust removal as a service. This pay-per-use or contract-based model lowers the barrier to entry for end-users and allows specialized providers to deploy advanced equipment efficiently. By 2026, on-demand mobile laser cleaning units—similar to pressure washing services—will become more common, especially for infrastructure and emergency maintenance projects.

Integration with Predictive Maintenance and Industry 4.0

Laser cleaning systems are increasingly being integrated into smart factory ecosystems. Paired with sensors and IoT platforms, they can be scheduled as part of predictive maintenance routines. For example, automated inspection drones can identify corrosion hotspots, triggering laser cleaning robots. By 2026, data collected during cleaning operations will inform asset health analytics, optimizing maintenance cycles and reducing downtime.

Cost Competitiveness and ROI Focus

Although initial costs remain higher than traditional methods, total cost of ownership (TCO) is improving due to longer equipment lifespans, lower consumable costs, and reduced waste disposal. Service providers will emphasize measurable ROI—such as extended equipment life, reduced rework, and compliance savings—to justify adoption. By 2026, competitive pricing models and proven case studies will make laser rust removal a standard option in maintenance budgets.

In summary, the 2026 laser rust removal service market will be characterized by broader industrial adoption, smarter and more portable technology, and a growing service-oriented business model—all driven by sustainability, efficiency, and digital integration demands.

Common Pitfalls When Sourcing Laser Rust Removal Services (Quality and Intellectual Property)

Inadequate Assessment of Service Provider Expertise

Many businesses assume all laser rust removal providers deliver the same results, but expertise varies significantly. Choosing a vendor without verifying their experience with your specific materials (e.g., steel alloys, vintage parts) can lead to inconsistent cleaning, surface damage, or incomplete rust removal. Always request case studies, certifications, and on-site demonstrations.

Lack of Quality Control Standards

Not all providers adhere to recognized quality benchmarks. Without defined inspection protocols or post-treatment validation (e.g., surface profilometry, adhesion testing), you risk receiving subpar results that compromise downstream processes like coating or welding. Ensure the service follows ISO or industry-specific quality standards.

Poor Documentation and Traceability

Inadequate record-keeping of treatment parameters (laser power, pulse duration, coverage pass) makes it difficult to reproduce results or troubleshoot issues. This lack of traceability can undermine process validation, especially in regulated industries like aerospace or automotive.

Overlooking Intellectual Property (IP) Risks

When outsourcing laser cleaning, especially for proprietary components, there’s a risk of exposing sensitive design information. Providers may not have robust data protection policies or non-disclosure agreements (NDAs) in place, potentially leading to IP leakage or unauthorized replication of parts.

Failure to Secure IP Rights in Process Development

If you collaborate with a provider to develop a custom cleaning protocol for your components, ownership of that process may not be clearly defined. Without explicit contractual terms, the service provider could claim partial IP rights or reuse the developed method for competitors.

Inconsistent Equipment Calibration and Maintenance

Laser systems require regular calibration to maintain performance. Providers using poorly maintained equipment may deliver inconsistent results, affecting surface quality and potentially damaging parts. Ask about their maintenance schedules and equipment specifications.

Insufficient Data Security Measures

Digital models, CAD files, or treatment logs shared with the provider may contain confidential information. If the provider lacks cybersecurity safeguards (e.g., encrypted data transfer, access controls), your sensitive data could be vulnerable to breaches.

Absence of Clear Service Level Agreements (SLAs)

Without SLAs defining turnaround times, quality metrics, and liability for errors, disputes over deliverables become more likely. Ensure contracts specify performance expectations and remedies for non-compliance to protect your operational timelines and quality requirements.

Logistics & Compliance Guide for Laser Rust Removal Service

Service Overview and Scope

Laser rust removal is a non-abrasive, environmentally friendly method of surface preparation that uses pulsed laser beams to remove rust, paint, and contaminants from metal surfaces. This guide outlines the logistical considerations and compliance requirements for safely and effectively delivering laser rust removal services.

Equipment Transportation and Setup

Ensure all laser equipment, including the laser generator, handheld or robotic scanner, cooling unit, and power supply, is securely transported using padded, shock-resistant containers. Conduct pre-deployment inspections to verify system integrity. Set up in a stable, well-ventilated area with access to adequate power (typically 208–480V, 3-phase). Confirm that grounding and circuit protection meet local electrical codes.

Site Assessment and Preparation

Perform a site evaluation prior to service initiation. Identify substrate types, rust severity, and access constraints. Confirm client approval for work zones and implement barriers to restrict unauthorized access. Remove flammable materials within a 10-meter radius and ensure emergency exits remain unobstructed. Document site conditions with photos and condition reports.

Operator Safety and Training

Only trained and certified personnel may operate laser equipment. All operators must complete laser safety training compliant with ANSI Z136.1 and wear appropriate personal protective equipment (PPE), including laser safety goggles with correct optical density (OD) ratings for the laser wavelength (typically 1064 nm). Conduct daily safety briefings and maintain training records on file.

Laser Safety and Controlled Access

Establish a designated laser-controlled area marked with warning signs indicating laser operation. Use safety interlocks and beam shutters to prevent accidental exposure. Implement a lockout/tagout (LOTO) procedure during maintenance. Nominate a Laser Safety Officer (LSO) to oversee compliance and respond to incidents. Adhere to Class 4 laser safety protocols, including controlled beam paths and remote operation where feasible.

Environmental and Waste Management

Laser ablation generates particulate matter (metal oxide dust). Use a HEPA-filtered fume extraction system positioned close to the work area to capture airborne particles. Dispose of collected waste as hazardous material if testing confirms heavy metal content (e.g., lead, chromium). Maintain manifests and recycling/disposal records in accordance with local environmental regulations (e.g., EPA, EU Waste Framework Directive).

Regulatory Compliance

Ensure full compliance with applicable standards and regulations, including:

– OSHA 29 CFR 1910 (General Industry Standards)

– ANSI Z136.1 (Safe Use of Lasers)

– NFPA 70 (National Electrical Code)

– Local fire and building codes

– EU Machinery Directive (for operations in Europe)

Conduct annual audits and maintain compliance documentation for client and regulatory review.

Documentation and Reporting

Provide clients with a post-service report including scope of work, areas treated, equipment used, safety measures, and waste disposal certification. Maintain internal logs of service dates, operator certifications, equipment maintenance, and incident reports for a minimum of five years.

Emergency Procedures

Establish and communicate emergency protocols for laser exposure, fire, electrical faults, or equipment malfunction. Equip the worksite with first aid kits, fire extinguishers (Class C for electrical fires), and emergency shutoff switches. Train all personnel in emergency response and ensure local emergency services are aware of laser operations on-site.

Client Communication and Coordination

Coordinate access schedules, site restrictions, and safety expectations with the client prior to mobilization. Provide a safety data sheet (SDS) for generated particulates upon request. Obtain written confirmation of work completion and client satisfaction following service delivery.

In conclusion, sourcing a laser rust removal service offers a highly efficient, eco-friendly, and precision-driven alternative to traditional rust removal methods. With benefits such as non-abrasive cleaning, minimal substrate damage, reduced waste, and compliance with environmental and safety regulations, laser technology proves to be a sustainable and cost-effective solution in the long run. When selecting a service provider, it is essential to evaluate their technical expertise, equipment capabilities, industry experience, and safety standards to ensure optimal results. As industries continue to adopt advanced technologies, investing in professional laser rust removal services not only enhances maintenance efficiency but also supports operational sustainability and asset longevity.